In Mold Decorating of Injection Molded Parts - Esterline

In Mold Decorating of Injection Molded Parts - Esterline

In Mold Decorating of Injection Molded Parts - Esterline

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

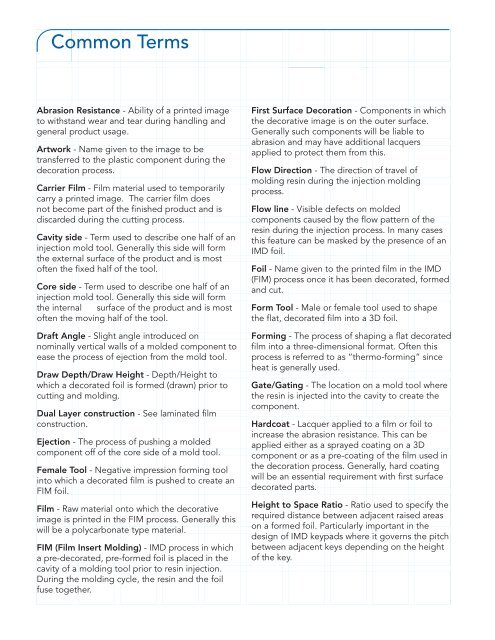

Common TermsAbrasion Resistance - Ability <strong>of</strong> a printed imageto withstand wear and tear during handling andgeneral product usage.Artwork - Name given to the image to betransferred to the plastic component during thedecoration process.Carrier Film - Film material used to temporarilycarry a printed image. The carrier film doesnot become part <strong>of</strong> the finished product and isdiscarded during the cutting process.Cavity side - Term used to describe one half <strong>of</strong> aninjection mold tool. Generally this side will formthe external surface <strong>of</strong> the product and is most<strong>of</strong>ten the fixed half <strong>of</strong> the tool.Core side - Term used to describe one half <strong>of</strong> aninjection mold tool. Generally this side will formthe internal surface <strong>of</strong> the product and is most<strong>of</strong>ten the moving half <strong>of</strong> the tool.Draft Angle - Slight angle introduced onnominally vertical walls <strong>of</strong> a molded component toease the process <strong>of</strong> ejection from the mold tool.Draw Depth/Draw Height - Depth/Height towhich a decorated foil is formed (drawn) prior tocutting and molding.Dual Layer construction - See laminated filmconstruction.Ejection - The process <strong>of</strong> pushing a moldedcomponent <strong>of</strong>f <strong>of</strong> the core side <strong>of</strong> a mold tool.Female Tool - Negative impression forming toolinto which a decorated film is pushed to create anFIM foil.Film - Raw material onto which the decorativeimage is printed in the FIM process. Generally thiswill be a polycarbonate type material.FIM (Film <strong>In</strong>sert <strong>Mold</strong>ing) - IMD process in whicha pre-decorated, pre-formed foil is placed in thecavity <strong>of</strong> a molding tool prior to resin injection.During the molding cycle, the resin and the foilfuse together.First Surface Decoration - Components in whichthe decorative image is on the outer surface.Generally such components will be liable toabrasion and may have additional lacquersapplied to protect them from this.Flow Direction - The direction <strong>of</strong> travel <strong>of</strong>molding resin during the injection moldingprocess.Flow line - Visible defects on moldedcomponents caused by the flow pattern <strong>of</strong> theresin during the injection process. <strong>In</strong> many casesthis feature can be masked by the presence <strong>of</strong> anIMD foil.Foil - Name given to the printed film in the IMD(FIM) process once it has been decorated, formedand cut.Form Tool - Male or female tool used to shapethe flat, decorated film into a 3D foil.Forming - The process <strong>of</strong> shaping a flat decoratedfilm into a three-dimensional format. Often thisprocess is referred to as “thermo-forming” sinceheat is generally used.Gate/Gating - The location on a mold tool wherethe resin is injected into the cavity to create thecomponent.Hardcoat - Lacquer applied to a film or foil toincrease the abrasion resistance. This can beapplied either as a sprayed coating on a 3Dcomponent or as a pre-coating <strong>of</strong> the film used inthe decoration process. Generally, hard coatingwill be an essential requirement with first surfacedecorated parts.Height to Space Ratio - Ratio used to specify therequired distance between adjacent raised areason a formed foil. Particularly important in thedesign <strong>of</strong> IMD keypads where it governs the pitchbetween adjacent keys depending on the height<strong>of</strong> the key.