sonic start® streamline - Smith & Loveless Inc.

sonic start® streamline - Smith & Loveless Inc.

sonic start® streamline - Smith & Loveless Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

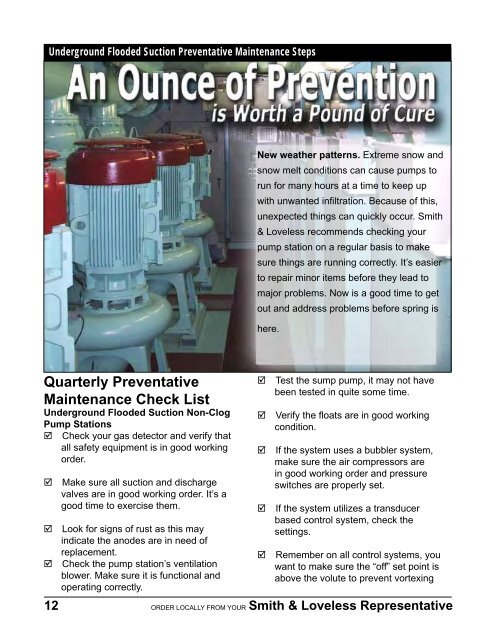

Underground Flooded Suction Preventative Maintenance StepsNew weather patterns. Extreme snow andsnow melt conditions can cause pumps torun for many hours at a time to keep upwith unwanted infiltration. Because of this,unexpected things can quickly occur. <strong>Smith</strong>& <strong>Loveless</strong> recommends checking yourpump station on a regular basis to makesure things are running correctly. It’s easierto repair minor items before they lead tomajor problems. Now is a good time to getout and address problems before spring ishere.Quarterly PreventativeMaintenance Check ListUnderground Flooded Suction Non-ClogPump Stations Check your gas detector and verify thatall safety equipment is in good workingorder. Make sure all suction and dischargevalves are in good working order. It’s agood time to exercise them. Look for signs of rust as this mayindicate the anodes are in need ofreplacement. Check the pump station’s ventilationblower. Make sure it is functional andoperating correctly. Test the sump pump, it may not havebeen tested in quite some time. Verify the floats are in good workingcondition. If the system uses a bubbler system,make sure the air compressors arein good working order and pressureswitches are properly set. If the system utilizes a transducerbased control system, check thesettings. Remember on all control systems, youwant to make sure the “off” set point isabove the volute to prevent vortexing12 Order Locally From Your <strong>Smith</strong> & <strong>Loveless</strong> Representative