AE94.2 Gas Turbine

AE94.2 Gas Turbine

AE94.2 Gas Turbine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

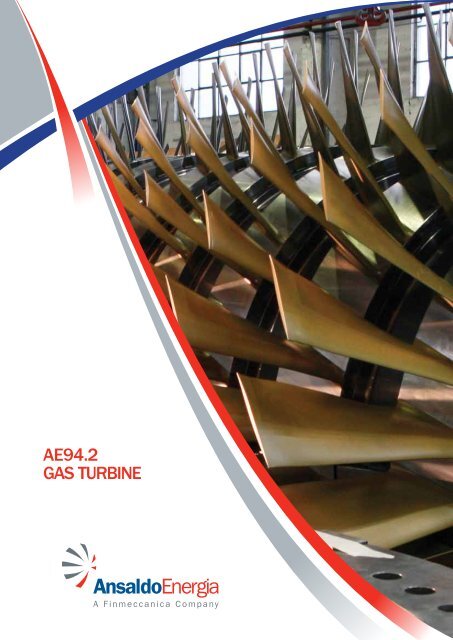

<strong>AE94.2</strong><br />

GAs TuRBINE

<strong>AE94.2</strong> - The <strong>Gas</strong> <strong>Turbine</strong> for<br />

a Flexible Approach<br />

The <strong>AE94.2</strong> <strong>Gas</strong> <strong>Turbine</strong> meets customer needs<br />

in terms of performance, emissions and operational/fuel<br />

flexibility for intermediate-class gas turbines,<br />

by delivering a competitive and cost-effective<br />

package based on established technology.<br />

The latest continuous improvements have been<br />

made available for previous releases through a<br />

retrofittable package.<br />

With the special <strong>AE94.2</strong>K version, this gas turbine<br />

can also burn low-BTU fuels and high H 2 content<br />

gas.<br />

<strong>AE94.2</strong> <strong>Gas</strong> <strong>Turbine</strong> and Generator view<br />

A proven layout for a reliable engine<br />

• Compressor cold-end drive<br />

• Compressor with variable inlet guide vanes<br />

• Disk-type rotor with two bearings<br />

• Improved compressor exhaust diffuser<br />

• 2 vertical silo type combustion chambers<br />

• 16 hybrid burners (diffusion or premix<br />

operation) for natural gas and light oil<br />

• Axial exhaust<br />

<strong>AE94.2</strong> <strong>Gas</strong> <strong>Turbine</strong> and Generator package<br />

• <strong>Turbine</strong> blades/vanes, hot casing and mixing<br />

chamber with advanced coating and Thermal<br />

Barrier Coating (TBC)<br />

• Easy maintenance features (all blades and<br />

vanes are replaceable with rotor in place, and<br />

the hot gas path can be inspected with no need<br />

to open the turbine)<br />

• Fuel system designed to manage non conventional<br />

fuels (naphtha, crude and heavy fuel oil, low<br />

BTU gases, hydrogen rich fuels, coal gases,<br />

dwell gases, etc.)<br />

Performance (natural gas, ISO conditions, base load)<br />

Power output at generator terminals [MW]<br />

Efficiency at generator terminals [%]<br />

Exhaust gas mass flow [kg/s]<br />

Exhaust gas temperature [°C]<br />

1 GT + 1 ST Combined cycle power output [MW]<br />

1 GT + 1 ST Combined cycle efficiency [%]<br />

2 GT + 1 ST Combined cycle power output [MW]<br />

2 GT + 1 ST Combined cycle efficiency [%]<br />

<strong>AE94.2</strong><br />

170<br />

34.7<br />

535<br />

552<br />

258.4<br />

53.1<br />

518<br />

53.3<br />

A benchmark in flexibility<br />

The <strong>AE94.2</strong> gas turbine is a benchmark for both<br />

operational and fuel flexibility. The ability to adapt<br />

rapidly to provide the requested grid power is becoming<br />

more and more important:<br />

• start up and loading time: full speed no load reached<br />

in less than 5 minutes and baseload conditions<br />

about 15 minutes later. Fast loading gradient<br />

procedures can reduce this time to about 6 minutes

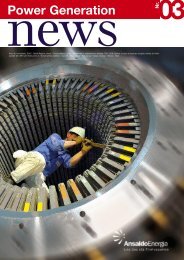

<strong>AE94.2</strong> <strong>Gas</strong> <strong>Turbine</strong> compressor<br />

• best dynamic performance during grid support:<br />

40 MW in few seconds is a well proven result on<br />

several units.<br />

The <strong>AE94.2</strong> is the best solution to satisfy increasing<br />

market demand of greater fuel flexibility:<br />

• optimum operation with a broad variety of fuel<br />

compositions and characteristics (from naphtha<br />

to heavy oil, fuel gas from different sources:<br />

refinery, blast furnaces, dwells, etc.).<br />

• gas/oil fuel change-over: can be performed across<br />

almost the entire load range and carried out in as<br />

little as a few minutes in certain conditions<br />

• mixed operation (concurrent combustion of gas<br />

and oil): this mode is particularly useful when<br />

neither fuel gas nor fuel oil can be supplied in<br />

sufficient quantities to achieve the base load.<br />

Low emissions for challenging targets<br />

<strong>AE94.2</strong><br />

NOx [mg/Nm 3 ] *<br />

CO [mg/Nm 3 ] *<br />

FUEL GAS<br />

PREMIX<br />

DRY<br />

50 **<br />

30<br />

PREMIX<br />

FUEL OIL<br />

DIFFUSION<br />

DRY 140% water/fuel<br />

150 85<br />

30 30<br />

* Dry gases, 15% O2 ** 30 mg/Nm 3 option available<br />

The VeLoNOx burner, designed by Ansaldo<br />

Energia to reduce NOx emissions in fuel gas<br />

mode, achieves NOx emissions levels lower than<br />

30 mg/Nm 3 .<br />

Recognised excellence in commissioning<br />

and after sales services<br />

Ansaldo Energia offers a full range of services and<br />

qualified personnel for erection and/or supervision,<br />

start-up and testing of your <strong>AE94.2</strong> gas turbine.<br />

The availability of standard arrangements and in<br />

some cases packaged solutions ensures rapid, problem-free<br />

erection, start-up and commissioning.<br />

The Ansaldo Energia Service Organisation provides<br />

technical assistance services worldwide, available 24<br />

hours a day, 7 days a week, in the fields of maintenance,<br />

spare parts supply and preventive maintenance<br />

programs, so ensuring that customers are in the<br />

best position to achieve optimum operation.<br />

Continuous process improvements guarantee the<br />

best assistance for our customers: for example,<br />

the latest maintenance procedures include extended<br />

spare parts stocks and streamlined logistics.<br />

<strong>AE94.2</strong>K - Matching customer fuel flexibility<br />

needs with a tailored solution<br />

Ansaldo Energia has been working on the use of<br />

low caloric value gas in heavy duty gas turbines<br />

since 1997. The special <strong>AE94.2</strong>K version,<br />

specifically designed for low BTU fuels (syngas,<br />

steel mill, blast furnace gases, biomass, etc.),<br />

can burn fuels with LHV in the range 8-13 MJ/kg<br />

and lower. The combustion system, including the<br />

modification to allow it to burn a wide range of<br />

fuels, has been patented.<br />

Power Plant<br />

Feedstock<br />

Natural <strong>Gas</strong><br />

Integration<br />

Net power<br />

(GT/CC)<br />

First firing date<br />

GT EOH (2011)<br />

Isab Energy Priolo G.<br />

<strong>Gas</strong>ification of Asphalt<br />

0 %<br />

2x162 MW/520 MW<br />

Nov 1998/Apr 1999<br />

Unit 1: 137,000<br />

Unit 2: 110,000<br />

Elettra GLT Servola<br />

Feed Mill <strong>Gas</strong><br />

45 - 49%<br />

1x110 MW/180 MW<br />

Jul 2000<br />

96,000<br />

Enipower Ferrera E.<br />

<strong>Gas</strong>ification of Asphalt<br />

0 - 30%<br />

1x166 MW/255 MW<br />

Mar 2004<br />

62,000<br />

Proud of our worldwide references - decades of<br />

experience:<br />

Our <strong>AE94.2</strong> fleet is installed worldwide, and has<br />

an excellent track record of robustness, operational<br />

flexibility and durability.<br />

5,000,000<br />

4,500,000<br />

4,000,000<br />

3,500,000<br />

3,000,000<br />

2,500,000<br />

2,000,000<br />

1,500,000<br />

1,000,000<br />

500,000<br />

1996<br />

<strong>AE94.2</strong> Cumulative<br />

Equivalent Operating Hours<br />

Dec. 2011: 4 300 000 EOH<br />

1998<br />

2000<br />

2002<br />

2004<br />

Years<br />

2006<br />

2008<br />

2010

Ansaldo Energia <strong>AE94.2</strong><br />

<strong>Gas</strong> <strong>Turbine</strong> References in the World<br />

UK (3)<br />

Barry (1)<br />

Ballylumford (2)<br />

ITALY (7)<br />

Rosignano (1)<br />

Priolo Gargallo (3)<br />

Servola (1)<br />

Cassano d’Adda (1)<br />

Ferrera Erbognone (1)<br />

ALGERIA (6)<br />

Larbaa (4)<br />

Batna (2)<br />

Ajn Djasser (2)<br />

Labreg (2)<br />

CHILE (1)<br />

Mejillones (1)<br />

POLAND (1)<br />

Lublin (1)<br />

EGYPT (4)<br />

6 th October<br />

OTHER MIDDLE<br />

EAST (44)<br />

16152 Genova - Via N. Lorenzi, 8 - Italy<br />

Tel: +39 010 6551 - Fax: +39 010 655 3411<br />

E-mail: ansaldoenergia@aen.ansaldo.it<br />

ansaldoenergia.com<br />

FINLAND (3)<br />

Espoo (1)<br />

Forssa (2)<br />

LEBANON (2)<br />

Zaharani (1)<br />

Beddawi (1)<br />

JORDAN (2)<br />

Amman East (2)<br />

DUBAI (3)<br />

Jabel Ali (3)<br />

CONGO REP. (2)<br />

Pointe-Noire (2)<br />

OMAN (5)<br />

Barka (5)<br />

PAKISTAN (1)<br />

Liberty (1)<br />

INDIA (1)<br />

Samalkot (1)<br />

BANGLADESH (3)<br />

Meghnaghat (2)<br />

Sylhet (1)<br />

Stampa: Microart Recco - Genova 05/2012 Petergraf