Handling of Microsilica Slurry - Elkem

Handling of Microsilica Slurry - Elkem

Handling of Microsilica Slurry - Elkem

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

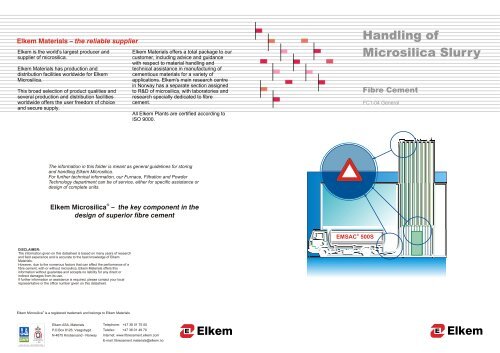

<strong>Elkem</strong> Materials – the reliable supplier<strong>Elkem</strong> is the world's largest producer andsupplier <strong>of</strong> microsilica.<strong>Elkem</strong> Materials has production anddistribution facilities worldwide for <strong>Elkem</strong><strong>Microsilica</strong>.This broad selection <strong>of</strong> product qualities andseveral production and distribution facilitiesworldwide <strong>of</strong>fers the user freedom <strong>of</strong> choiceand secure supply.<strong>Elkem</strong> Materials <strong>of</strong>fers a total package to ourcustomer, including advice and guidancewith respect to material handling andtechnical assistance in manufacturing <strong>of</strong>cementious materials for a variety <strong>of</strong>applications. <strong>Elkem</strong>'s main research centrein Norway has a separate section assignedto R&D <strong>of</strong> microsilica, with laboratories andresearch specially dedicated to fibrecement.All <strong>Elkem</strong> Plants are certified according toISO 9000.<strong>Handling</strong> <strong>of</strong><strong>Microsilica</strong> <strong>Slurry</strong>Fibre CementFC1-04 GeneralThe information in this folder is meant as general guidelines for storingand handling <strong>Elkem</strong> <strong>Microsilica</strong>.For further technical information, our Furnace, Filtration and PowderTechnology department can be <strong>of</strong> service, either for specific assistance ordesign <strong>of</strong> complete units.®<strong>Elkem</strong> <strong>Microsilica</strong> – the key component in thedesign <strong>of</strong> superior fibre cement®EMSAC 500SDISCLAIMER:The information given on this datasheet is based on many years <strong>of</strong> researchand field experience and is accurate to the best knowledge <strong>of</strong> <strong>Elkem</strong>Materials.However, due to the numerous factors that can affect the performance <strong>of</strong> afibre cement, with or without microsilica, <strong>Elkem</strong> Materials <strong>of</strong>fers thisinformation without guarantee and accepts no liability for any direct orindirect damages from its use.If further information or assistance is required, please contact your localrepresentative or the <strong>of</strong>fice number given on this datasheet.®<strong>Elkem</strong> <strong>Microsilica</strong> is a registered trademark and belongs to <strong>Elkem</strong> Materials<strong>Elkem</strong> ASA, MaterialsP.O.Box 8126, VaagsbygdN-4675 Kristiansand - NorwayTelephone: +47 38 01 75 00Telefax: +47 38 01 49 70Internet: www.fibrecement.elkem.comE-mail: fibrecement.materials@elkem.no<strong>Elkem</strong><strong>Elkem</strong>

® ®<strong>Elkem</strong> <strong>Microsilica</strong> slurry: EMSAC 500SEMSAC 500S is a multi-benefit, superpozzolanic mineral additive for fibre cement basedmaterials.<strong>Elkem</strong> <strong>Microsilica</strong> originates from the production <strong>of</strong> silicon metal and ferro-silicon alloys.The material consists <strong>of</strong> amorphous, sub-micron, spherical particles and, in the original3state, has a ”fluffy” appearance with bulk density below 300 kg/m .To facilitate handling and dosing, the powder is further processed with water to produce astable slurry. The process is continuously monitored and controlled before shipment tostorage and distribution depots or customers.3EMSAC 500S, has a density <strong>of</strong> approx. 1400kg/m and 50% solids content by weight.Gooseneck for ventilation on silo top,min. ND 100.Arrangement for inspection and maintenance<strong>of</strong> silo interior.Steel, plastic or rubber pipe, min. ND 100(plastic or rubber preferred due to corrosion).Filling pipe; easy to dismount for cleaning.Minimum pipe diameter100 mm (ND 100).JCirculationLevel switches formax./min. level.Max. size for this type <strong>of</strong> installation3(w/ pump circulation) is 60m , dia. max. 3.0m.With other arrangements, mechanicalagitation should be considered.Normal discharge by compressed air (2 bar).Alt. local compressor or pump.Connection hose min. ND 100.Storage tank temperature shouldo obe within the range 5 - 40 C.Connection system truck/tank to fit.Alarm when storage tankis full (light/sound).AirDrainageManually operatedservice valveTo MixerPossibility for injection <strong>of</strong> compressed airupstream from pump.Different pump types can be used. Purging <strong>of</strong>sealing should be considered.Circulation system to silo preferably viaweigh bin, alt. from pump to filling pipe.®EMSAC 500SPumpAlternativecirculationSystem to be cleaned regularly.Drainage system for circulationpipes.DrainageAlarm