Safe Work Procedures - Manitoba Heavy Construction Association

Safe Work Procedures - Manitoba Heavy Construction Association

Safe Work Procedures - Manitoba Heavy Construction Association

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

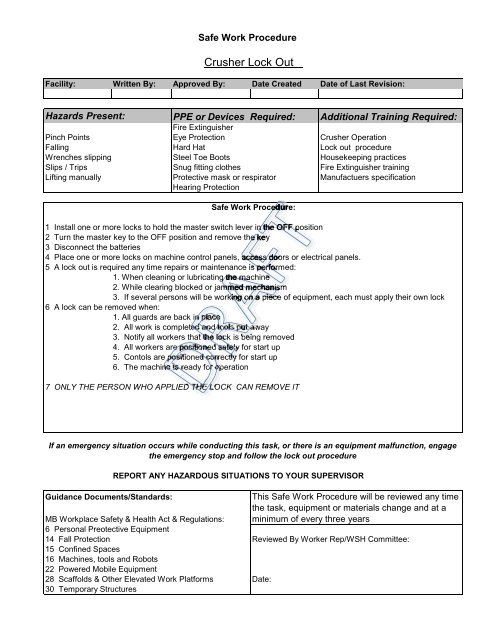

<strong>Safe</strong> <strong>Work</strong> ProcedureCrusher Lock OutFacility: Written By: Approved By: Date Created Date of Last Revision:Hazards Present: PPE or Devices Required: Additional Training Required:Fire ExtinguisherPinch Points Eye Protection Crusher OperationFalling Hard Hat Lock out procedureWrenches slipping Steel Toe Boots Housekeeping practicesSlips / Trips Snug fitting clothes Fire Extinguisher trainingLifting manually Protective mask or respirator Manufactuers specificationHearing Protection<strong>Safe</strong> <strong>Work</strong> Procedure:1 Install one or more locks to hold the master switch lever in the OFF position2 Turn the master key to the OFF position and remove the key3 Disconnect the batteries4 Place one or more locks on machine control panels, access doors or electrical panels.5 A lock out is required any time repairs or maintenance is performed:1. When cleaning or lubricating the machine2. While clearing blocked or jammed mechanism3. If several persons will be working on a piece of equipment, each must apply their own lock6 A lock can be removed when:1. All guards are back in place2. All work is completed and tools put away3. Notify all workers that the lock is being removed4. All workers are positioned safely for start up5. Contols are positioned correctly for start up6. The machine is ready for operation7 ONLY THE PERSON WHO APPLIED THE LOCK CAN REMOVE ITIf an emergency situation occurs while conducting this task, or there is an equipment malfunction, engagethe emergency stop and follow the lock out procedureREPORT ANY HAZARDOUS SITUATIONS TO YOUR SUPERVISORGuidance Documents/Standards:This <strong>Safe</strong> <strong>Work</strong> Procedure will be reviewed any timethe task, equipment or materials change and at aMB <strong>Work</strong>place <strong>Safe</strong>ty & Health Act & Regulations: minimum of every three years6 Personal Preotective Equipment14 Fall Protection Reviewed By <strong>Work</strong>er Rep/WSH Committee:15 Confined Spaces16 Machines, tools and Robots22 Powered Mobile Equipment28 Scaffolds & Other Elevated <strong>Work</strong> Platforms Date:30 Temporary Structures