DLC 2100 Flying Paster/Splicer - Megtec Systems

DLC 2100 Flying Paster/Splicer - Megtec Systems

DLC 2100 Flying Paster/Splicer - Megtec Systems

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

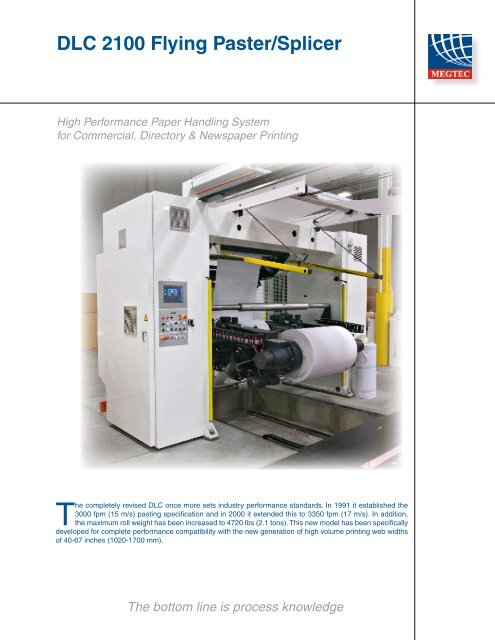

<strong>DLC</strong> <strong>2100</strong> <strong>Flying</strong> <strong>Paster</strong>/<strong>Splicer</strong>High Performance Paper Handling Systemfor Commercial, Directory & Newspaper PrintingThe completely revised <strong>DLC</strong> once more sets industry performance standards. In 1991 it established the3000 fpm (15 m/s) pasting specification and in 2000 it extended this to 3350 fpm (17 m/s). In addition,the maximum roll weight has been increased to 4720 lbs (2.1 tons). This new model has been specificallydeveloped for complete performance compatibility with the new generation of high volume printing web widthsof 40-67 inches (1020-1700 mm).The bottom line is process knowledge

The touch screen control provides theoperator with easy control and rapid access toinformationOptional ROLLOAD automated handlingsystem allows up to 100% no operatorpresence during roll loading and changingOperator displaySplit Arm DesignErgonomic correctness and userfriendliness have been two of the mostimportant considerations in the designof the <strong>2100</strong>. The machine roll width isadjusted to the printing width of thepress and variations of up to 2000 mmare possible. Two motorized roll holdersare placed on each side of the roll arm.These can be moved sideways by linearcontrol independently of the other rollposition. This permits the loading of tworolls of different widths in the machine. Inturn, this facilitates very simple and rapidsplicing to other roll widths without firsthaving to take out both rolls and then readjustingthe position of the roll arm.PastingThe gapless splice pattern is simple toprepare. It can be either straight, V or W.The detection system uses a photo cellwith black biodegradable tabs. Pasteand cut are made simultaneously undertension with a constant short tail length tominimize potential folder jams.PLC Control SystemThe pasting cycle, tension and runningoperations are automatically managedby a PLC. Operating status and faultfinding diagnosis are displayed on thesupervision screen. Like all MEGTECWebline products the paster can beintegrated with the press control system.A paper management data system is alsoavailable.Easy Roll LoadingThe <strong>DLC</strong> <strong>2100</strong> paster works with manydifferent configurations of roll loadsystems, from manual to fully automatic.Fully automatic chucks improve operatingefficiency and safety. Loading is controlledby a push button for chuck engagementwith automatic tightening at the endof insertion. The chucks are positivelylocked into the core and do not have to bere-tightened during running - even afteran emergency stop. As an added safetyfeature, the lock will not release even ifelectricity and compressed air supply isinterrupted.Illustration HereThe optional ROLLOAD® automatedhandling system allows up to “100% nooperator presence” roll changing. Thebenefits of operation include reducedpaper waste, higher efficiency andenhanced safety.Web GuidesWeb guides are available (option withconnected and independent infeeds)and can be connected with the paster’ssidelay to provide web pre-alignment. Thisalso eliminates any counter correctionbetween sidelay and the web guide.Newspaper coldset printers can alsospecify Chuck Web Steering to continuallycontrol lateral web position to ± 0.7 mm.This option helps improve color printingquality and reduce waste.Optional Infeed VersionsTension control begins at the paster.MEGTEC’s pasters and DSA infeedscan be controlled in tandem foroptimum performance. This allowsthe paster to operate at a low tensionto limit tension variations to beprocessed by the infeed. The DSA’sextremely stable tension of ± 1.1 lbs(0.5 daN) is made possible by the use ofhigh dynamic servo regulation with lowinertia mechanical elements, twin dancerrollers and a nipping roller.Connected or independent DSA shaftlessinfeeds provide fast and accurate tensioncontrol from 11 lbs (5 daN) up to 400lbs(180 daN) with optional web guides.A separate model (<strong>DLC</strong> 3200) is availablefor high volume offset requiring rollweights up to 7,046 lbs (3.2 Tons) andwidths up to 80 inches (2040 mm).

<strong>DLC</strong> <strong>2100</strong> <strong>Flying</strong> <strong>Paster</strong>/<strong>Splicer</strong>AMERICASUnited StatesMEGTEC <strong>Systems</strong>, Inc.Telephone: +1-920-336-5715Toll-free: +1-800-558-2884Solvent Recovery DivisionMEGTEC <strong>Systems</strong>, Inc.Telephone: +1-772-567-1320BrazilMEGTEC <strong>Systems</strong>, Inc.Telephone: +55-19-3885-6116EUROPEFranceMEGTEC <strong>Systems</strong> SASTelephone: +33-1-69-89-4793United KingdomMEGTEC <strong>Systems</strong>, Ltd.Telephone: +44-1628-59-1700MEGTEC Environmental Ltd.Telephone: +44-1257-42-7070GermanySequa GmbH & Co.MEGTEC <strong>Systems</strong> KGTelephone: +49-6181-94040SwedenMEGTEC <strong>Systems</strong> ABTelephone: +46-31-65-7800MEGTEC <strong>Systems</strong> Amal ABTelephone: +46-532-62900ASIA-PACIFICSingaporeSingapore Sales Branch -MEGTEC <strong>Systems</strong> SASTelephone: +65-6298-4666ChinaMEGTEC <strong>Systems</strong> (Shanghai) Ltd.Telephone: +86-21-6769-7878IndiaMEGTEC <strong>Systems</strong> India Pvt. LtdTelephone: +91-20-662033-70 (71, 72)JapanMEGTEC <strong>Systems</strong>, Inc.Telephone: +81-78-783-0161AustraliaMEGTEC <strong>Systems</strong> Australia, Inc.Telephone: +61-3-9574-7450www.megtec.comAugust 2007Standard Equipment & FeaturesStdAuto Roll<strong>Flying</strong> paster with 2 arms • •Split arms • •Core acceleration and braking by 4 quadrant AC motors • •Control and regulation by PLC • •Splice pattern straight, V or W • •Black pasting tabs with photo cell detection • •Simultaneous cut & paste under tension • •Local push-button panel and WEBVIEW • •Motorized chuck insertion with torque assisted expansion•Arm motorized positioning•Arm automatic positioning•Automatic roll alignment before splicing•Normal and symmetric arrangement • •Manual cocking roller adjustment to assist running deformed rolls • •Independent frames • •Fully assembled, pre-wired, pre-piped and tested for easy installation • •Versions at Additional Cost3 arms (with auto loading pre-positioning only) •100 tons load bearing frames • •Remote control panel for sidelay, web tension and brakes • •MEGTEC motorized web-up device option • •WEBCOM (WEBVIEW + interface for press communication) • •Integrated DSA Infeed • •Automatic roll alignment before splicing•Automatic roll alignment before splicing and chuck web steering • •ROLLOAD paper handling system • •QUALIROLL paper management system • •Operating SpecificationsMaximum roll weight 4720 lbs <strong>2100</strong> daNMaximum running & splicingspeed3350 fpm 17 m/sMinimum splicing speed 165 fpm 0.83 m/sSidelay adjustment ± 7/8 inches ± 20 mmMaximum roll Ø 51 inches 1300 mmMinimum roll Ø for splicing 20 inches 500 mmMinimum roll width for splice 10 inches 250 mmRoll core inner Ø 3 inches 76 mmStandard tension range 11-66 lbs 5-30 daNOption web tension range:307 lbs/in 120 daN/mIntegrated infeedE-stop rate 330 fpm/s 100 m/mn/sPaper weight range 25-100 lbs 37-150 gsmWeb widths 40, 54, 60, and 67 inches 1020, 1370,1530, 1700 mmThis document is not contractual. © MEGTEC®