You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

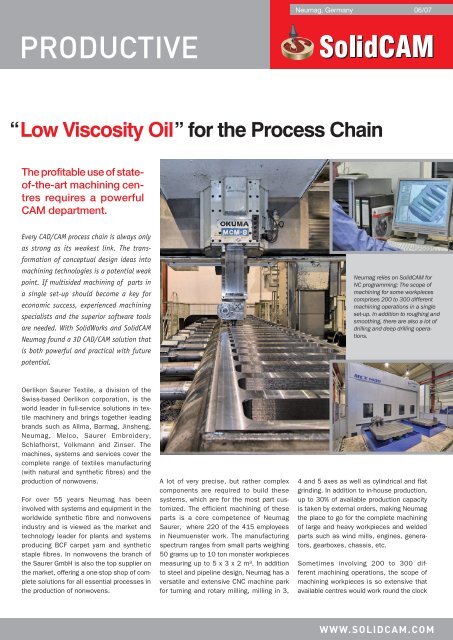

Neumag, Germany 06/07PRODUCTIVE“ Low Viscosity Oil ” for <strong>the</strong> Process ChainThe profitable use of stateof-<strong>the</strong>-artmachining centresrequires a powerfulCAM department.Every CAD/CAM process chain is always onlyas strong as its weakest link. The transformationof conceptual design ideas intomachining technologies is a potential weakpoint. If multisided machining of parts ina single set-up should become a key foreconomic success, experienced machiningspecialists and <strong>the</strong> superior software toolsare needed. With SolidWorks and <strong>SolidCAM</strong>Neumag found a 3D CAD/CAM solution thatis both powerful and practical with futurepotential.Neumag relies on <strong>SolidCAM</strong> forNC programming: The scope ofmachining for some workpiecescomprises 200 to 300 differentmachining operations in a singleset-up. In addition to roughing andsmoothing, <strong>the</strong>re are also a lot ofdrilling and deep drilling operations.Oerlikon Saurer Textile, a division of <strong>the</strong>Swiss-based Oerlikon corporation, is <strong>the</strong>world leader in <strong>full</strong>-service solutions in textilemachinery and brings toge<strong>the</strong>r leadingbrands such as Allma, Barmag, Jinsheng,Neumag, Melco, Saurer Embroidery,Schlafhorst, Volkmann and Zinser. Themachines, systems and services cover <strong>the</strong>complete range of textiles manufacturing(with natural and syn<strong>the</strong>tic fibres) and <strong>the</strong>production of nonwovens.For over 55 years Neumag has beeninvolved with systems and equipment in <strong>the</strong>worldwide syn<strong>the</strong>tic fibre and nonwovensindustry and is viewed as <strong>the</strong> market andtechnology leader for plants and systemsproducing BCF carpet yarn and syn<strong>the</strong>ticstaple fibres. In nonwovens <strong>the</strong> branch of<strong>the</strong> Saurer GmbH is also <strong>the</strong> top supplier on<strong>the</strong> market, offering a one-stop shop of completesolutions for all essential processes in<strong>the</strong> production of nonwovens.A lot of very precise, but ra<strong>the</strong>r complexcomponents are required to build <strong>the</strong>sesystems, which are for <strong>the</strong> most part customized.The efficient machining of <strong>the</strong>separts is a core competence of NeumagSaurer, where 220 of <strong>the</strong> 415 employeesin Neumuenster work. The manufacturingspectrum ranges from small parts weighing50 grams up to 10 ton monster workpiecesmeasuring up to 5 x 3 x 2 m³. In additionto steel and pipeline design, Neumag has aversatile and extensive CNC machine parkfor turning and rotary milling, milling in 3,4 and 5 axes as well as cylindrical and flatgrinding. In addition to in-house production,up to 30% of available production capacityis taken by external orders, making Neumag<strong>the</strong> place to go for <strong>the</strong> complete machiningof large and heavy workpieces and weldedparts such as wind mills, engines, generators,gearboxes, chassis, etc.Sometimes involving 200 to 300 differentmachining operations, <strong>the</strong> scope ofmachining workpieces is so extensive thatavailable centres would work round <strong>the</strong> clockWWW.SOLIDCAM.COM

For <strong>the</strong> automatic machining in one set-up<strong>the</strong> CNC machining centres require a varietyof precisely preset tools that are immediatelyaccessible.for a week with one clamping. In addition to<strong>the</strong> complexity of machining, <strong>the</strong> ambitiousrange of parts keeps Production SpecialistThorsten Nebbe on <strong>the</strong> go. “The NC programsbasically contain our historicallydeveloped machining know-how. This is afundamental component for <strong>the</strong> market successof every company. We now have nearly40,000 tested and optimized NC programsin our archive.” An impressive number!And <strong>the</strong> question comes up, which CAD/CAM system can master this “diversity” inquantity, quality, time/schedule and is alsoflexible?Neumag Saurer has relied on <strong>the</strong> SolidWorks3D CAD system for about 5 years. ThorstenNebbe began at Neumag just as <strong>the</strong> systemwas introduced. Armed with 15 years ofexperience in different NC programmingsystems it became his task to evaluateand introduce a suitable 3D CAM system,which he now supervises as a <strong>full</strong>-timejob. “We looked at a variety of solutions. Apress release <strong>the</strong>n brought my attention to<strong>SolidCAM</strong>. The Nortec trade fair in Hamburgtook place shortly after that. And <strong>the</strong>re I had<strong>the</strong> first opportunity for a presentation.”It was so convincing that three <strong>SolidCAM</strong>licenses were ordered after a test installationin May 2002.Seven SolidWorks+<strong>SolidCAM</strong> seats arenow installed at Neumag. Thorsten Nebbe:“A striking argument in favour of <strong>SolidCAM</strong>was of course <strong>the</strong> complete integration inSolidWorks. However, more important tous were <strong>the</strong> CAM features, <strong>the</strong> programmingapproach and, above all, <strong>the</strong> issue ofpostprocessors.”Neumag has currently installed 24 differentCNC centres, e.g. OKUMA, Hermle, Burkhardt+ Weber, Mazak, Deckel Maho, SHW, beingsupplied with NC programs via a DNC network.The range of control units varies fromdiverse OKUMA OSPs and different generationsof Heidenhain and Siemens to <strong>the</strong> controlunits of Mazak. Thorsten Nebbe: “Wheninvesting in CAD/CAM <strong>the</strong> postprocessorsare mostly <strong>the</strong> smallest items. However,<strong>the</strong>y tip <strong>the</strong> scales for <strong>the</strong> success of millingand are somewhat like <strong>the</strong> lubricant forevery process chain.”<strong>SolidCAM</strong> provides <strong>the</strong>ability to tune <strong>the</strong> postprocessors perfectlyto <strong>the</strong> CNC machine controllers. This is whystep by step Nebbe wrote perfectly customizedpostprocessors for each machine andeach control unit. “The individual modificationof <strong>the</strong> <strong>SolidCAM</strong> postprocessors is easyto learn. We are thus flexible and independentfrom external support.”Functionally, <strong>SolidCAM</strong> today meets allrequirements that have practical relevanceat Neumag – and that’s mostly 2.5D jobsin all variations. After 5 years of systemmaturation Nebbe in particular praised <strong>the</strong>“successful integration in SolidWorks and<strong>the</strong> practical approach towards NC programming.A CAM system should support programmersin <strong>the</strong>ir method of working and not<strong>the</strong> o<strong>the</strong>r way around. Our NC programmersare experienced machinists.” To quickly tap<strong>the</strong> performance potential of <strong>the</strong> software,management treated each of <strong>the</strong> would-beCAM specialists to a solid <strong>SolidCAM</strong> trainingcourse. Nebbe can “strongly recommend toeveryone” this investment, not for example,because <strong>the</strong> software is complicated, butbecause “<strong>the</strong> structured introduction conveyed<strong>the</strong> philosophy of <strong>the</strong> software and alot of tips and tricks.”At Neumag every part and every order is different.In order to have <strong>the</strong> optimal drillingor milling strategy, it’s not infrequent thatup to 10 different home positions have toNeumag has are currently 24 different CNC centres, like OKUMA, Hermle, Burkhardt + Weber, Mazak,Deckel Maho, SHW, all being supplied with NC programs via a DNC network. The range of control unitsincludes diverse OKUMA OSPs, different generations of Heidenhain and Siemens control units and alsocontrol units from Mazak.

Thorsten Nebbe, CAD/CAM specialist atNeumag in Neumünster: “With respect to<strong>the</strong> scope of work and <strong>the</strong> quality of <strong>the</strong> NCprograms, <strong>SolidCAM</strong> can hold its own againstsignificantly more expensive systems.”Age is no barrier to CAD/CAM: Erwin Eipel has been building devices for 39 years. The Neumag veteranhas been using SolidWorks+<strong>SolidCAM</strong> for more than 5 years.be defined in one part, especially whenmachining on 4 and 5-axis centres. Thisis why for Nebbe <strong>the</strong> “complete automationfor generating” recommended by someCAM vendors “is more of an impediment.Especially for <strong>the</strong> numerous 2.5D jobs, settinga machining strategy requires a lot oftechnological know-how and practical experience.No matter if we have to machine aluminium,cast iron or high-temperature stainlesssteels on 3, 4 or 5 axes, with <strong>SolidCAM</strong>we can incorporate our know-how and turn itinto process-optimized NC programs.”Nebbe appreciates <strong>the</strong> extensive simulationfeatures of <strong>SolidCAM</strong>. “The possibilitiesare fantastic, but we try to simulate aslittle as possible and as often as needed.As I said before, <strong>the</strong> NC programmers hereare well-trained machining experts.” And <strong>the</strong>machine operators have to follow <strong>the</strong> directionsof <strong>the</strong> NC program when clamping aworkpiece.Things naturally look different for true 3Dmachining. Here, <strong>the</strong> faith in <strong>the</strong> ma<strong>the</strong>maticalgorithms and <strong>the</strong> reliablity of <strong>the</strong> CAM softwareis indispensable. According to Nebbe,<strong>SolidCAM</strong> is also a very good choice for 3Djobs, but such machining tasks are not <strong>the</strong>main issue at Neumag. Ne<strong>the</strong>r<strong>the</strong>less <strong>the</strong>people in Neumünster appreciate to workin 3D. Options like zooming, rotating, colorizing,shading, showing and hiding details,etc. enable <strong>the</strong> NC programmer to work continuouslyin a comfortable “What-you-see-iswhat-you-get”environment. 3D helps <strong>the</strong>NC programmer to “understand” a complexworkpiece in minutes ra<strong>the</strong>r than in days.“The integrated 3D CAD/CAM environmentsaves us a lot of time. You can, for example,create any cross-section and <strong>the</strong> dimensionsare right <strong>the</strong>re.”Modern times: Neumag has a Flexible Manufacturing System which supplies <strong>the</strong> jobs to three modelMA 800 and MS 600 OKUMA machining centres round <strong>the</strong> clock from a <strong>full</strong>y automated Fastemspallet warehousing system.Ano<strong>the</strong>r advantage of <strong>the</strong> complete, Gold-certifiedintegration of <strong>SolidCAM</strong> in SolidWorks:CAD and CAM use <strong>the</strong> same 3D model withmodifications to <strong>the</strong> part being automaticallyavailable for NC programming. Nebbe: “TheCAD/CAM integration inside <strong>the</strong> program

![Download [PDF] - SolidCAM](https://img.yumpu.com/41122364/1/190x245/download-pdf-solidcam.jpg?quality=85)

![Download [PDF] - SolidCAM](https://img.yumpu.com/39561632/1/167x260/download-pdf-solidcam.jpg?quality=85)