Humid Air Motor - MAN Diesel & Turbo Canada

Humid Air Motor - MAN Diesel & Turbo Canada

Humid Air Motor - MAN Diesel & Turbo Canada

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

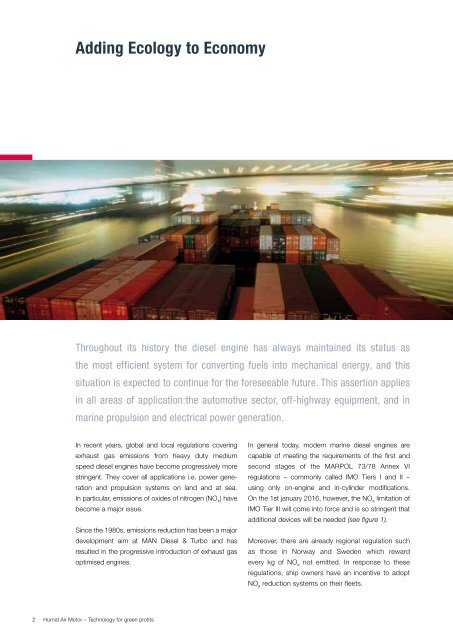

Adding Ecology to EconomyHAMA widely acclaimed technology for reducing NO xpollution from diesel engines is the “<strong>Humid</strong> <strong>Air</strong> <strong>Motor</strong>”(HAM). This technology is able to reduce NO x formationby up to 65%. In the HAM system the turbochargedcombustion air is saturated with water vapour producedaboard the ship using sea water and engine heat.This lowers the temperature peaks in the combustionchamber, which are normally the main reason for NO xformation. HAM is characterised by extremely lowCutting NO x with humid airoperating costs due to sea water usage, decreasedlube oil consumption, very low maintenance costs anda very high availability factor.Consequently, following its philosophy of environmentallyfriendly engine development, <strong>MAN</strong> <strong>Diesel</strong> & <strong>Turbo</strong>now offers the HAM system. The company’s decisionto offer this technology is based, in particular, on theeconomics of the HAM system, which create favourableconditions for profitable engine operation.1816Throughout its history the diesel engine has always maintained its status asthe most efficient system for converting fuels into mechanical energy, and thissituation is expected to continue for the foreseeable future. This assertion appliesin all areas of application:the automotive sector, off-highway equipment, and inmarine propulsion and electrical power generation.In recent years, global and local regulations covering In general today, modern marine diesel engines areexhaust gas emissions from heavy duty medium capable of meeting the requirements of the first andspeed diesel engines have become progressively more second stages of the MARPOL 73/78 Annex VIstringent. They cover all applications i.e. power generationand propulsion systems on land and at sea. using only on-engine and in-cylinder modifications.regulations – commonly called IMO Tiers I and II –In particular, emissions of oxides of nitrogen (NO x ) have On the 1st january 2016, however, the NO x limitation ofbecome a major issue.IMO Tier III will come into force and is so stringent thatadditional devices will be needed (see figure 1).Since the 1980s, emissions reduction has been a majordevelopment aim at <strong>MAN</strong> <strong>Diesel</strong> & <strong>Turbo</strong> and has Moreover, there are already regional regulation suchresulted in the progressive introduction of exhaust gas as those in Norway and Sweden which rewardoptimised engines.every kg of NO x not emitted. In response to theseregulations, ship owners have an incentive to adoptNO x reduction systems on their fleets.NO x [g/kWh]141210864200 200 400 600 800 1000 1200 1400 1600 1800 2000 2200rpm [1/min]IMO Tier 1 IMO Tier 2 IMO Tier 3Figure 1: NO x limit curve of IMOTemperatureincreaseinside thecylinderwithout HAMNo HAMHAMNO x generating peakFigure 2: Cutting NO x with humid air – schematic heat release diagramTemperature increaseinside the cylinderwith HAMNO x forms exponentionallyover thistemperatureCrank angle2 <strong>Humid</strong> <strong>Air</strong> <strong>Motor</strong> – Technology for green profits <strong>Humid</strong> <strong>Air</strong> <strong>Motor</strong> – Technology for green profits 3