For Cutting and Machining Pipe, Tube and Boiler Panels - ESCO Tool

For Cutting and Machining Pipe, Tube and Boiler Panels - ESCO Tool

For Cutting and Machining Pipe, Tube and Boiler Panels - ESCO Tool

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

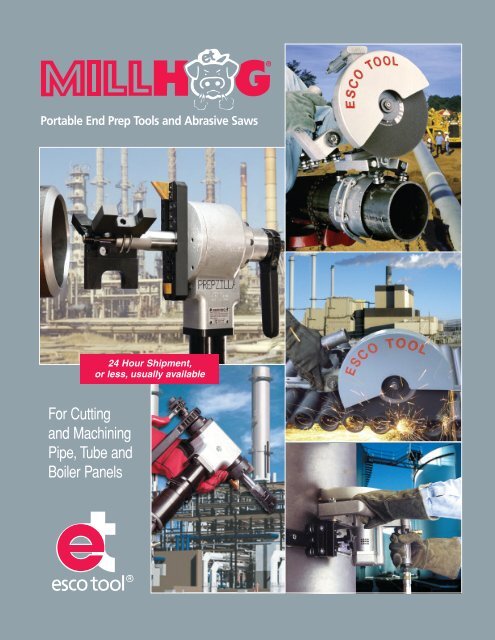

Portable End Prep <strong>Tool</strong>s <strong>and</strong> Abrasive Saws<br />

<strong>For</strong> <strong>Cutting</strong><br />

<strong>and</strong> <strong>Machining</strong><br />

<strong>Pipe</strong>, <strong>Tube</strong> <strong>and</strong><br />

<strong>Boiler</strong> <strong>Panels</strong><br />

24 Hour Shipment,<br />

or less, usually available

Esco<strong>Tool</strong><br />

<strong>For</strong> over 50 years,<br />

Esco <strong>Tool</strong> has worked<br />

closely with end-users<br />

on the toughest tube<br />

<strong>and</strong> pipe cutting <strong>and</strong><br />

end prep applications<br />

in the power generation<br />

<strong>and</strong> metalworking<br />

industries. Our knowledge<br />

<strong>and</strong> experience<br />

has allowed us to invent<br />

<strong>and</strong> manufacture high<br />

quality tools that work<br />

efficiently <strong>and</strong> require<br />

no special operator<br />

training.<br />

This catalog describes<br />

our rugged MILLHOG ®<br />

<strong>and</strong> PANELHOG ® tools,<br />

High-Speed Bevelers<br />

<strong>and</strong> accessories. These<br />

tools are built tough<br />

<strong>and</strong> precision machined<br />

from the finest materials<br />

to make sure that<br />

you get your job done<br />

properly, on time,<br />

<strong>and</strong> under budget.<br />

The World Leader in <strong>Boiler</strong> Maintenance <strong>Tool</strong>s<br />

The Esco Quality Commitment…<br />

Esco MILLHOG ® End Prep <strong>Tool</strong>s are built tough <strong>and</strong> precision machined<br />

from the finest materials.<br />

• Sturdy Gear Drive—We select the best components available today. <strong>For</strong> example, the<br />

“Wart” MILLHOG ® features dual opposed tapered roller bearings, two ball bearings that<br />

support the link between the drive shaft <strong>and</strong> right angle gear assembly <strong>and</strong> a bearing<br />

supported cutterhead, providing optimum rigidity <strong>and</strong> stability.<br />

• Rigid I.D. Clamping—All MILLHOGS provide torque-free operation <strong>and</strong> incorporate<br />

self-centering draw rod assemblies that rigidly mount to the tube or pipe I.D.<br />

• EscoLock Blade Lock System—This wedge lock design creates a superior blade<br />

holding force which minimizes vibration, a primary cause of premature blade failure.<br />

• Superior Bevel Blade Design—Providing more end preps per bevel blade, Esco’s unique<br />

chip breaker helps produce a continuous chip which minimizes heat buildup on the blade.<br />

All MILLHOG ® blades are made of T-15 tool steel which is TiN (titanium nitride) coated. They<br />

work on all boiler tube materials, including stainless steel, <strong>and</strong> are designed to run cooler <strong>and</strong><br />

produce 2 to 5 times more bevels per blade than competitive blades, without cutting oil.<br />

Esco PANELHOG ® Universal Air-Powered Saws provide accurate cuts with no “HAZ”<br />

(Heat Affected Zone).<br />

• <strong>Boiler</strong>maker Tough <strong>and</strong> Field Proven—The PANELHOG ® saw glides along the EscoTrack<br />

System <strong>and</strong> produces a straight, clean horizontal cut that requires no further rework for boiler<br />

tube panel removal.<br />

• <strong>Pipe</strong> <strong>Cutting</strong> Made Easy—The EscoWrap Track System is ideal for cutting pipe from 6” to 60”<br />

O.D. by 4” wall thickness. This innovative universal pipe trolley <strong>and</strong> clamp assembly mounts<br />

to the pipe <strong>and</strong> lets the saw glide around the circumference making a perfectly square cut<br />

with no heat affected zone.<br />

• Esco <strong>Tool</strong>, The World Leader In <strong>Boiler</strong> Maintenance <strong>Tool</strong>s—<strong>For</strong> over 50 years we have<br />

worked closely with end-users to solve the toughest maintenance <strong>and</strong> construction problems in<br />

the power generation <strong>and</strong> metalworking industries.<br />

• No Special Training Required—All Esco <strong>Tool</strong>s are rugged, reliable, versatile, <strong>and</strong> easy<br />

to operate so you can get your job done properly, on-time, <strong>and</strong> under budget.<br />

We pledge to provide you with the finest <strong>and</strong> most innovative tools <strong>and</strong> accessories available<br />

today <strong>and</strong> to support them with fair, prompt, <strong>and</strong> courteous service.<br />

Matthew Brennan<br />

Matthew Brennan, President<br />

esco tool • 75 October Hill Road, Holliston, MA 01746 • 800.343.6926 • 508.429.4441 • Fax 508.429.2811 • e-mail: millhog@escotool.com<br />

Available <strong>For</strong> Sale or Rent<br />

How to Order<br />

You may contact your local Esco representative<br />

or contact Esco <strong>Tool</strong> directly by telephone at<br />

508.429.4441 (worldwide)<br />

800.343.6926 (U.S. & Canada)<br />

FAX: 508.429.2811 • e-mail: millhog@escotool.com • www.escotool.com

Typical Applications Index<br />

• End prepping super duplex<br />

pipe<br />

• End prepping high chrome<br />

tubes<br />

• Membrane <strong>and</strong> weld overlay<br />

removal from tube O.D.<br />

• Flat facing tube or pipe<br />

• 37 1/2° bevel tube or pipe<br />

• 30° bevel tube or pipe<br />

• Peel back on stainless clad<br />

tubes<br />

• <strong>Tube</strong> sheet seal weld removal<br />

• <strong>Tube</strong> sheet strength weld<br />

removal<br />

• <strong>Tube</strong> stub removal<br />

• <strong>Tube</strong> seal weld removal<br />

• Facing fin fan tubes<br />

• Compound bevel for heavy<br />

wall pipe step bevel for<br />

composite tubes<br />

Capabilities Chart<br />

Millhog End Prep <strong>Tool</strong>s<br />

“Ground” MILLHOG ®<br />

“Mongoose” MILLHOG ®<br />

“<strong>Tube</strong> Weasel” MILLHOG ®<br />

“Wart” MILLHOG ®<br />

“Fin” MILLHOG ®<br />

“Mini” MILLHOG ®<br />

“C-Hog” MILLHOG ®<br />

“PrepZilla” MILLHOG ®<br />

“Comm<strong>and</strong>er” model C-314 MILLHOG ®<br />

“Dictator” model D-418 MILLHOG ®<br />

High Speed End Prep <strong>Tool</strong>s<br />

HHB-5,000<br />

HHB-5,000RA<br />

HHB-10,000<br />

HHB-10,000RA<br />

Saws for <strong>Boiler</strong> <strong>Tube</strong> <strong>Panels</strong>/<strong>Pipe</strong>/Tanks<br />

APS-438 (<strong>Boiler</strong> <strong>Tube</strong> Panel <strong>Cutting</strong>)<br />

APS-438LP (<strong>Boiler</strong> <strong>Tube</strong> Panel <strong>Cutting</strong>)<br />

APS-438 w/Trolley (<strong>Pipe</strong> <strong>Cutting</strong>)<br />

APS-438 (Built in Trolley for <strong>Pipe</strong> <strong>Cutting</strong>)<br />

• Counterboring<br />

• J-preps<br />

• Sawing of waterwall panels<br />

• Notching of membrane<br />

• Slotting of membrane<br />

• Sawing pendant tubes<br />

• Sawing single tubes<br />

• Sawing pipe 6” to 60” dia.<br />

• Sawing concrete lined pipe<br />

• Sawing tanks of any diameter<br />

• Flex Track for custom sawing<br />

curved surfaces<br />

• Cut-off of pipe ends<br />

• Flange facing<br />

• Grooving of pipe O.D.<br />

• H<strong>and</strong> hole cap removal<br />

• Beveling for window welds<br />

• High speed beveling<br />

• Track mounted beveling<br />

1/2”<br />

12.7mm<br />

1”<br />

25.4mm<br />

2-1/4”<br />

57.15mm<br />

3”<br />

76.2mm<br />

<strong>Tool</strong> Page<br />

“Ground” MILLHOG ®<br />

2<br />

“Mongoose” MILLHOG ®<br />

3<br />

“<strong>Tube</strong> Weasel” MILLHOG ®<br />

4<br />

“Wart” MILLHOG ®<br />

5-6<br />

“Fin” MILLHOG ®<br />

7<br />

“Air Clamp” Series 8-9<br />

“Mini” MILLHOG ®<br />

10<br />

HHB High Speed H<strong>and</strong>-Held Bevelers 11<br />

“Prepzilla” MILLHOG ®<br />

12-13<br />

“Comm<strong>and</strong>er” MILLHOG ® Model C-314 14<br />

“Dictator” MILLHOG ® Model D-418 15<br />

MILLHOG ® Cutterblades (bits) 16-17<br />

PANELHOG ® APS-438 Universal Air-Powered Saw 18<br />

Wrap Track ® APS-438LRC Saw with <strong>Pipe</strong> Trolley 19<br />

PANELHOG ® APS-438 Accessories, Tracks <strong>and</strong> Brackets 20-21<br />

“C-HOG” MILLHOG 22<br />

MILLHOG ® Membrane <strong>and</strong> Overlay Removal Heads 23<br />

MILLHOG ® Rolling Motors <strong>and</strong> <strong>Tube</strong> Exp<strong>and</strong>ers 24<br />

Action Request <strong>For</strong>m 25<br />

<strong>Pipe</strong> Chart Back Cover<br />

4-1/2”<br />

114.3mm<br />

6-5/8”<br />

168.3mm<br />

8-5/8”<br />

219.1mm<br />

12-3/4”<br />

323.9mm<br />

14”<br />

355.6mm<br />

16-1/4”<br />

412.8mm<br />

esco tool • 75 October Hill Road, Holliston, MA 01746 • 800.343.6926 • 508.429.4441 • Fax 508.429.2811 • e-mail: millhog@escotool.com<br />

Available <strong>For</strong> Sale or Rent<br />

<strong>and</strong> larger<br />

<strong>and</strong> larger<br />

18”<br />

460mm<br />

1

2<br />

“Ground”<br />

Self-contained I.D. clamping tool easily<br />

fits between small diameter water wall<br />

boiler tubes...<br />

Key Features<br />

• Patented push-pull clamping <strong>and</strong><br />

release system<br />

• Self-centering torque-free operation<br />

• Permanently attached clamps <strong>and</strong> wrenches<br />

• Rigidly mounts to tube I.D., easy to release<br />

• Sealed construction allows use in any orientation<br />

• Produces a smooth, continuous chip<br />

• Compact, low-maintenance end prep tool<br />

• Performs any angle of bevel<br />

• Steel housing with integral radial-thrust<br />

ball bearing<br />

• Chatter-free cutter blade locking design<br />

• Uses TiN coated cutter blades<br />

High Performance End-Prep <strong>Tool</strong><br />

Features Easy Clamp <strong>and</strong> Release Operation<br />

The Esco “Ground” MILLHOG ® is a right angle, I.D.<br />

clamping end prep tool for small diameter boiler tubes<br />

<strong>and</strong> pipes. Featuring a push-pull clamp <strong>and</strong> release<br />

mechanism with permanently attached clamps <strong>and</strong><br />

wrenches, thisself-centering tool performs any angle<br />

of bevel <strong>and</strong> produces a smooth continuous chip.<br />

Eliminating the possibility of loose parts falling down the<br />

tubes, this high performance tool utilizes the EscoLock<br />

wedge-style blade lock system <strong>and</strong> TiN coated blades<br />

for chatter-free beveling.<br />

The “Air Clamp” Ground<br />

MILLHOG ® is ideal for production<br />

applications <strong>and</strong> takes only minutes<br />

to convert from a manual clamping<br />

end prep tool to one of the fastest<br />

clamping tools on the market.<br />

(for more information see pages 8-9)<br />

© U.S. Patent 5,531,550<br />

“Ground” MILLHOG ® clamp rib selector<br />

Rugged right angle<br />

gear drive<br />

Stop nut<br />

prevents<br />

draw rod<br />

from<br />

coming<br />

out of<br />

tool<br />

Draw rod clamping<br />

mechanism with<br />

permanently<br />

attached ratchet<br />

feed & clamping<br />

wrenches<br />

Item<br />

No.<br />

Description<br />

I.D. Range<br />

(in.)<br />

I.D. Range<br />

(mm)<br />

M<strong>and</strong>rel<br />

Size<br />

G-01 Clamp rib set .500 – .655 12.7 – 16.6 1/2" (12.7 mm)<br />

G-02 Clamp rib set .625 – .780 15.9 – 19.8 5/8" (15.9 mm)<br />

G-03 Clamp rib set .750 – .905 19.1 – 22.9 5/8" (15.9 mm)<br />

G-04 Clamp rib set .875 – 1.030 22.3 – 26.1 5/8" (15.9 mm)<br />

G-05 Clamp rib set 1.00 – 1.155 25.4 – 29.3 5/8" (15.9 mm)<br />

G-06 Clamp rib set 1.125 – 1.280 28.6 – 32.5 5/8" (15.9 mm)<br />

G-07 Clamp rib set 1.250 – 1.405 31.8 – 35.6 5/8" (15.9 mm)<br />

G-08 Clamp rib set 1.375 – 1.530 35.0 – 38.8 5/8" (15.9 mm)<br />

G-09 Clamp rib set 1.500 – 1.655 38.1 – 42.0 5/8" (15.9 mm)<br />

G-10 Clamp rib set 1.625 – 1.780 41.3 – 45.2 5/8" (15.9 mm)<br />

G-11 Clamp rib set 1.750 – 1.905 44.5 – 48.3 5/8" (15.9 mm)<br />

G-12 Clamp rib set 1.875 – 2.030 47.7 – 51.5 5/8" (15.9 mm)<br />

G-13 Clamp rib set 2.000 – 2.155 51.0 – 54.7 5/8" (15.9 mm)<br />

®<br />

Steel housing<br />

with integral<br />

radial-thrust<br />

ball bearing<br />

Low maintenance,<br />

efficient air motor<br />

Easy to<br />

change<br />

cutterhead<br />

Compact right angle drive design fits low<br />

radial clearance areas.<br />

Totally sealed construction<br />

allows use in any orientation<br />

<strong>and</strong> the “Ground” MILLHOG ®<br />

only requires a 1.5” clearance,<br />

making it ideal for prepping<br />

tubes ranging from 0.5” I.D. to<br />

2.25” O.D. with walls up to<br />

0.5” thick.<br />

Right Angle I,D, Clamping End Prep <strong>Tool</strong><br />

0.5” I.D. to 2.25” O.D.<br />

12.7 mm I. D. to 57.15 mm O. D.<br />

Uses st<strong>and</strong>ard<br />

MILLHOG ® TiN<br />

coated cutting<br />

blades securely<br />

mounted in the<br />

EscoLock blade<br />

lock system<br />

Safety lever throttle<br />

Safety air disconnect<br />

High strength m<strong>and</strong>rel<br />

Clamp<br />

ribs<br />

cover<br />

wide<br />

range<br />

Rugged<br />

clamp<br />

actuator<br />

keeps<br />

clamps<br />

securely<br />

on m<strong>and</strong>rel<br />

Specifications<br />

“Ground” MILLHOG ®<br />

Working Range: 1/2” (12.7 mm) I.D.to 2-1/4” (57.15 mm) O.D.<br />

Motor, pneumatic 2/3 h.p. (.497 kw)<br />

Air Pressure 90 psi.(6.2 bar)<br />

Air Volume 25 cfm (708 It/min.)<br />

Speed 200 RPM<br />

Minimum Clearance 1-1/2” (38.1 mm)<br />

Head Length 14” (355.6 mm)<br />

Working Weight 9 lbs. (4.1 kg)<br />

Shipping Weight 40 lbs. (18.2 kg)<br />

Shipping Dimensions 20” x18” x 5” (508 mm x 457 mm x 127 mm)<br />

Manufacturer reserves the right to change specifications without notice.<br />

The “GROUND” MILLHOG ® is shipped complete with<br />

everything including cutterhead, clamping ribs, air hose<br />

with quick-connect couplings, lubricator, filter, operating<br />

instructions, <strong>and</strong> a rugged metal carrying case.<br />

Ordering Information<br />

Kit No. Description<br />

G-200 “Ground” Millhog tool kit<br />

for 5/8” I.D. to 2-1/4” O.D.<br />

Kit Includes:<br />

Motor, gear drive assembly<br />

Draw rod<br />

M<strong>and</strong>rel .625”<br />

1) cutterhead, specify size<br />

1) clamp rib set, specify size<br />

Hose, 1/2” w/filter, oiler & 3/8”<br />

coupler<br />

Carrying case<br />

Allen wrench set<br />

Operating instructions<br />

G-300 “Ground” Millhog tool kit<br />

for 5/8” I.D. to 2-1/4” O.D.<br />

Kit Includes:<br />

Motor, gear drive assembly<br />

Draw rod<br />

M<strong>and</strong>rel .625”<br />

Cutterhead, 2-1/4”<br />

Hose, 1/2” w/filter, oiler &<br />

3/8” coupler<br />

Clamp ribs (G-02 through G-13)<br />

Cutterhead, 1-1/2”<br />

Carrying case<br />

Allen wrench set<br />

Operating instructions<br />

G-175 M<strong>and</strong>rel kit, 1/2” for<br />

1/2” I.D. to .655” I. D.<br />

Part No. Spares<br />

The patented push-pull<br />

I.D. clamping system<br />

makes disengaging the<br />

tool from the tube as<br />

easy as clamping it <strong>and</strong><br />

the blades are securely<br />

held in place by the<br />

EscoLock blade lock<br />

system to provide<br />

smooth, chatter-free<br />

operation.<br />

Kit Includes:<br />

Clamp rib set .500” to .655”<br />

1/2” push pull rod & actuator<br />

M<strong>and</strong>rel, 1/2”<br />

Cutterhead, 1-1/2” for 1/2” m<strong>and</strong>rel<br />

G-14 Spring for G-04 through G-11 ribs<br />

G-14C B<strong>and</strong> for G3 clamp ribs<br />

G-14D B<strong>and</strong> for G1 & G2 clamp ribs<br />

G-15 Actuator roll pin .625” & .750”<br />

G-15A Actuator roll pin .500”<br />

G16 Actuator for G-02, .625” I.D.<br />

G-17 Actuator for G-03 & up, .750” I.D.<br />

G-17A Actuator for G-01, .500” I.D.<br />

G-206 Cutterhead, 1-1/2” for 1/2” m<strong>and</strong>rel<br />

G-23 Cutterhead, 1-1/2” for 5/8” m<strong>and</strong>rel<br />

G-24 Cutterhead, 2” for 5/8” m<strong>and</strong>rel<br />

G-25 Cutterhead, 2-1/4” for 5/8” m<strong>and</strong>rel<br />

esco tool • 75 October Hill Road, Holliston, MA 01746 • 800.343.6926 • 508.429.4441 • Fax 508.429.2811 • e-mail: millhog@escotool.com<br />

Available <strong>For</strong> Sale or Rent

“Mongoose”<br />

Powerful, lightweight end prep tool that<br />

fits into very small spaces for beveling<br />

any angle of prep, tube sheet seal weld<br />

removal <strong>and</strong> facing…<br />

Key Features<br />

• Bevels, faces <strong>and</strong> bores stainless steel<br />

<strong>and</strong> other highly alloyed tubing<br />

• Patented, self-centering, push-pull clamp<br />

<strong>and</strong> release mechanism has permanently<br />

attached wrenches<br />

• Only 2-1/4” wide<br />

• Rugged with torque-free operation<br />

• Powerful pneumatic motor needs only<br />

25 CFM air flow<br />

• Produces a thick chip without cutting oils<br />

• Easy-to-change m<strong>and</strong>rels<br />

• EscoLock blade locking system<br />

I.D. clamp<br />

ribs G-2 – G13<br />

& H1 – H5<br />

Cutterhead – 3 sizes<br />

2-1/4”, 2-1/2” & 3”<br />

Rugged, fast, <strong>and</strong> field-proven<br />

The <strong>ESCO</strong> “Mongoose” MILLHOG ® ‚<br />

is a lightweight, small diameter end prep<br />

tool for beveling tubes from 5/8” I.D. to<br />

3” O.D. Featuring a patented push-pull clamp <strong>and</strong> release<br />

mechanism <strong>and</strong> permanently attached wrenches, it allows the<br />

clamps to release from a tube as easily as they tighten. Ideal<br />

for performing bevel facing <strong>and</strong> boring on a wide range of tube<br />

<strong>and</strong> pipe alloys, the Mongoose has dual opposed tapered roller<br />

bearings <strong>and</strong> employs the rigid EscoLock blade locking system<br />

to provide chatter-free performance <strong>and</strong> produce a thick chip<br />

without cutting fluids.<br />

Available with 5/8” <strong>and</strong> 3/4” m<strong>and</strong>rels <strong>and</strong> a 1-1/4” wedge,<br />

every Mongoose includes attached heavy-duty m<strong>and</strong>rel<br />

wrenches for centering <strong>and</strong> securing the tool to the I.D.<br />

The 1-1/4” wedge attaches to the 3/4” m<strong>and</strong>rel <strong>and</strong> uses the<br />

H series Wart MILLHOG ® clamp ribs with nearly 1/2” expansion,<br />

making it easy to clamp-up <strong>and</strong> release while requiring a<br />

minimum of ribs to cover a wide range of tube sizes.<br />

Specifications<br />

Working Range: .625" (15.9 mm) I.D. to 3”<br />

(76.2 mm) O.D.<br />

Motor, pneumatic 2/3 h.p. (.497 kw)<br />

Air Pressure 90 psi.(6.2 bar)<br />

Air Volume 25 cfm (708 It/min.)<br />

Speed 200 RPM<br />

Minimum Clearance 2-1/4” (57.2 mm)<br />

Head Length 15” (381 mm)<br />

Working Weight 13 lbs. (5.9 kg)<br />

Shipping Weight 30 lbs. (14 kg)<br />

Shipping Dimensions 20” x 18” x 5”<br />

(508 mm x 457 mm x 127 mm)<br />

Manufacturer reserves the right to change specifications<br />

without notice.<br />

© U.S. Patent 5,531,550<br />

®<br />

<strong>Cutting</strong> bits<br />

for any angle<br />

of end prep<br />

Precision m<strong>and</strong>rel is<br />

gun drilled, hardened<br />

<strong>and</strong> ground<br />

Efficient 2/3 h.p. motor<br />

Lever throttle<br />

3/8” air inlet<br />

Clamp rib selector chart<br />

EscoLock blade locking<br />

system firmly holds blades<br />

Right Angle I.D. Clamping End Prep <strong>Tool</strong><br />

Operating Range<br />

5/8” I.D. to 3” O.D.<br />

15.9 mm to 76.2 mm<br />

Precision<br />

machined<br />

aircraft<br />

quality<br />

aluminum<br />

gear<br />

housing<br />

Heavy duty<br />

feed wrench<br />

Patented push<br />

pull clamping<br />

<strong>and</strong> release<br />

system<br />

Draw rod<br />

wrench is<br />

attached<br />

to tool<br />

An optional<br />

air-clamp<br />

cylinder<br />

decreases<br />

the cycle time<br />

between end<br />

preps by up<br />

to 400% <strong>and</strong><br />

is ideal for<br />

fabricating<br />

shops.<br />

Item<br />

No.<br />

Description<br />

I.D. Range<br />

(in.)<br />

I.D. Range<br />

(mm)<br />

M<strong>and</strong>rel<br />

Size<br />

G-02 Clamp rib set .625 – .780 15.9 – 19.8 5/8” (15.9 mm)<br />

G-03 Clamp rib set .750 – .905 19.1 – 22.9 3/4” (19.1 mm)<br />

G-04 Clamp rib set .875 – 1.030 22.3 – 26.1 3/4” (19.1 mm)<br />

G-05 Clamp rib set 1.00 – 1.155 25.4 – 29.3 3/4” (19.1 mm)<br />

G-06 Clamp rib set 1.125 – 1.280 28.6 – 32.5 3/4” (19.1 mm)<br />

G-07 Clamp rib set 1.250 – 1.405 31.8 – 35.6 3/4” (19.1 mm)<br />

G-08 Clamp rib set 1.375 – 1.530 35.0 – 38.8 3/4” (19.1 mm)<br />

G-09 Clamp rib set 1.500 – 1.655 38.1 – 42.0 3/4” (19.1 mm)<br />

G-10 Clamp rib set 1.625 – 1.780 41.3 – 45.2 3/4” (19.1 mm)<br />

G-11 Clamp rib set 1.750 – 1.905 44.5 – 48.3 3/4” (19.1 mm)<br />

G-12 Clamp rib set 1.875 – 2.030 47.7 – 51.5 3/4” (19.1 mm)<br />

G-13 Clamp rib set 2.000 – 2.155 51.0 – 54.7 3/4” (19.1 mm)<br />

H-01 Clamp rib set 1.375 – 1.600 34.9 – 40.6 3/4” & 1.25” wedge<br />

H-02 Clamp rib set 1.525 – 1.925 38.8 – 48.9 3/4” & 1.25” wedge<br />

H-03 Clamp rib set 1.850 – 2.250 47.0 – 57.2 3/4” & 1.25” wedge<br />

H-04 Clamp rib set 2.175 – 2.575 55.3 – 65.4 3/4” & 1.25” wedge<br />

H-02 & H-05 Clamp rib set & pad set 2.500 – 2.900 63.5 – 73.7 3/4” & 1.25” wedge<br />

The “Mongoose” is a nimble<br />

tool that is only 2-1/4” wide<br />

<strong>and</strong> weighs just 13 lbs. for<br />

easy h<strong>and</strong>ling.<br />

Ordering Information<br />

Kit No. Description<br />

MG-100 Mongoose Millhog Kit, Backup<br />

Kit includes:<br />

Motor & gear drive<br />

Feed mechanism<br />

Carrying Case<br />

Operating & maintenance instructions<br />

MG-200 Mongoose Millhog kit, Basic<br />

Kit includes:<br />

Motor & gear drive<br />

Feed mechanism<br />

(1) M<strong>and</strong>rel (3/4” or 5/8”)<br />

Drawrod assembly<br />

Cutterhead (1) State size 2-1/4”, 2-1/2”, or 3”<br />

Clamp rib set (1) (specify G3-G13)<br />

1/2” Hose w/filter, oiler & 3/8” coupler<br />

Carrying Case<br />

Operating & maintenance instructions<br />

MG-300 Mongoose Millhog kit, Deluxe<br />

Kit includes:<br />

Motor & gear drive<br />

Feed mechanism<br />

(1) M<strong>and</strong>rel (3/4” or 5/8”)<br />

Drawrod assembly<br />

Cutterhead (1) specify 2-1/4”, 2-1/2”, or 3”<br />

Clamp rib sets (include G3-G13)<br />

1/2” Hose w/filter, oiler & 3/8” coupler<br />

Carrying Case<br />

Operating & maintenance instructions<br />

MG-400 Wedge Kit for Mongoose Millhog<br />

1.375” I.D. to 2.900” I.D.<br />

Kit includes:<br />

Actuator<br />

Roll pin<br />

Wedge<br />

Screw<br />

Torque key<br />

Clamp rib set 1.375” – 1.600”<br />

Clamp rib set 1.525” – 1.925”<br />

Clamp rib set 1.850” – 2.250”<br />

Clamp rib set 2.175” – 2.575”<br />

Clamp pad set 2.500” – 2.900” (with H-02)<br />

MG-175 M<strong>and</strong>rel kit, .625” I.D. to .780” I.D.<br />

Part No. Spares<br />

Kit includes:<br />

M<strong>and</strong>rel, 5/8” Mongoose<br />

Actuator, 5/8”<br />

Draw rod<br />

Cutterhead, 2-1/4” for 5/8” m<strong>and</strong>rel<br />

Clamp rib set, .625:” – .780”<br />

MG-01 Actuator, 3/4”<br />

MG-01A Actuator, 5/8”<br />

G-02 Clamp rib set, G-2 .625” – .780”<br />

G-03–13 Clamp rib set, G3 – G13<br />

MG-14 Roll Pin<br />

MG-15 Clamp rib spring for G-04 through G-13 ribs<br />

MG-15A Clamp rib b<strong>and</strong> for G3<br />

MG-15B Clamp rib b<strong>and</strong> for G2<br />

MG-16 Draw rod for 5/8” <strong>and</strong> 3/4” m<strong>and</strong>rel<br />

MG-28 Cutterhead, 2-1/4” for 3/4” m<strong>and</strong>rel<br />

MG-28A Cutterhead, 2-1/2” for 3/4” m<strong>and</strong>rel<br />

MG-28B Cutterhead, 3” for 3/4” m<strong>and</strong>rel<br />

MG-28C Cutterhead, 2-1/4” for 5/8” m<strong>and</strong>rel<br />

esco tool • 75 October Hill Road, Holliston, MA 01746 • 800.343.6926 • 508.429.4441 • Fax 508.429.2811 • e-mail: millhog@escotool.com<br />

Available <strong>For</strong> Sale or Rent<br />

3

4<br />

“TUBE WEASEL”<br />

Agile enough to fit between small diameter boiler tubes, this<br />

rugged high-tech tool performs end preps on all types of hard<br />

alloys quickly <strong>and</strong> efficiently…<br />

Key Features<br />

• Right angle tool rigidly mounts to tube I.D.<br />

• Sealed construction allow use in any orientation<br />

• Fits a “Dutchman” <strong>and</strong> h<strong>and</strong>les hard alloys<br />

• Clamping system is self-centering <strong>and</strong> easy to use<br />

• EscoLock blade lock system securely holds cutting blades<br />

• Chatter-free end preps produce thick continuous chip<br />

• Torque-free operation with TiN coated cutting bits<br />

• Requires only (25 cfm), 708 lt./min air flow<br />

• Gear head design has performed millions of end preps<br />

• Field proven <strong>and</strong> simple to operate <strong>and</strong> maintain<br />

Provides Superior Value <strong>and</strong> Performance<br />

The <strong>ESCO</strong> “<strong>Tube</strong> Weasel” MILLHOG ® is a lean, extremely durable tool that performs<br />

end preps on all boiler tube alloys quickly <strong>and</strong> efficiently. Featuring a right angle<br />

gear head drive system which incorporates dual opposed tapered roller bearings,<br />

this compact tool provides a big bite with a small appetite because it requires only<br />

(25 cfm), 708 It./min of air to pull a heavy continuous chip.<br />

The “Air Clamp” <strong>Tube</strong> Weasel<br />

MILLHOG ® is ideal for production applications<br />

<strong>and</strong> takes only minutes to convert from<br />

a manual clamping end prep tool to one of the<br />

fastest clamping tools on the market.<br />

(for more information see pages 6-7)<br />

The “<strong>Tube</strong> Weasel” fits a Dutchman window for single tube end prep work <strong>and</strong> totally sealed construction<br />

allows it to be used in any orientation. Most importantly, the holding clamps are designed to stay on the<br />

m<strong>and</strong>rel <strong>and</strong> not fall down the tubes.<br />

“<strong>Tube</strong> Weasel” MILLHOG ® clamp rib <strong>and</strong> pad selector<br />

Item<br />

Description<br />

I.D. Range I.D. Range M<strong>and</strong>rel<br />

No. (in.) (mm) Size<br />

G-03 Clamp rib set. .750 – .905 19.1 – 22.9 3/4" (19.1 mm)<br />

G-04 Clamp rib set .875 – 1.030 22.3 – 26.1 3/4" (19.1 mm)<br />

G-05 Clamp rib set 1.00 – 1.155 25.4 – 29.3 3/4" (19.1 mm)<br />

G-06 Clamp rib set 1.125 – 1.280 28.6 – 32.5 3/4" (19.1 mm)<br />

H-00 Clamp rib set 1.000 – 1.300 25.4 – 33.0 1" (25.5 mm)<br />

H-01 Clamp rib set 1.250 – 1.600 31.8 – 40.6 1-1/4" (31.8 mm)<br />

H-02 Clamp rib set 1.525 – 1.925 38.8 – 48.9 1-1/4" (31.8 mm)<br />

H-03 Clamp rib set 1.850 – 2.250 47.0 – 57.2 1-1/4" (31.8 mm)<br />

H-04 Clamp rib set 2.175 – 2.575 55.2 – 65.4 1-1/4" (31.8 mm)<br />

H-02 & H-05 Clamp rib & pad set 2.500 – 2.900 63.5 – 73.7 1-1/4" (31.8 mm)<br />

®<br />

Specifications<br />

Right Angle I.D. Clamping End Prep <strong>Tool</strong><br />

3/4” I.D. to 3” O.D.<br />

19.1 mm I.D. to 76.2 mm O.D.<br />

St<strong>and</strong>ard clamping range<br />

1-1/4” I.D. to 3” O.D.<br />

3/4” optional<br />

Clamps stay on the<br />

m<strong>and</strong>rel <strong>and</strong> will not<br />

fall down the tube<br />

Features EscoLock<br />

blade lock system <strong>and</strong><br />

TiN coated blades to<br />

bevel, face <strong>and</strong> bore<br />

simultaneously<br />

Field proven,<br />

highly reliable<br />

pneumatic motor<br />

Safety lever throttle<br />

helps prevent<br />

unwanted motor<br />

start-up<br />

The “<strong>Tube</strong> Weasel” MILLHOG ® is<br />

shipped complete with<br />

cutterhead, st<strong>and</strong>ard m<strong>and</strong>rel kit,<br />

operating instructions, tools, <strong>and</strong><br />

a rugged metal carrying case.<br />

“<strong>Tube</strong> Weasel” features the rigid EscoLock blade lock system <strong>and</strong><br />

titanium nitride coated cutter blades which combine to pull a thick<br />

continuous chip on all types of tube <strong>and</strong> pipe without cutting oils.<br />

“<strong>Tube</strong> Weasel” MILLHOG ®<br />

Working Range: 3/4” (19.1 mm) I.D.to 3” (76.2 mm) O.D.<br />

Motor, pneumatic 2/3 h.p. (.497 kw)<br />

Air Pressure 90 psi.(6.2 bar)<br />

Air Volume 25 cfm (708 It/min.)<br />

Speed 200 RPM<br />

Minimum Clearance 3” (76.2 mm)<br />

Head Length 14-1/2” (368.3 mm)<br />

Working Weight 18 lbs. (8.2 kg)<br />

Shipping Weight 40 lbs. (19 kg)<br />

Shipping Dimensions 20” x 18” x 5” (508 mm x 457 mm x 127 mm)<br />

Manufacturer reserves the right to change specifications without notice.<br />

Dual opposed tapered<br />

roller bearings<br />

Ordering Information<br />

Kit No. Description<br />

Adjusting<br />

wrenches are<br />

permanently<br />

attached.<br />

TW-200 “<strong>Tube</strong> Weasel” Millhog tool kit<br />

for 1-1/4” I.D. to 3” O.D.<br />

Kit Includes:<br />

Motor <strong>and</strong> gear drive<br />

Feed mechanism<br />

Clamp rib <strong>and</strong> pad sets (H-01–H-05)<br />

Cutterhead, 3”<br />

Draw rod & wrench assembly<br />

Carrying case<br />

Allen wrench set<br />

Operating instructions<br />

TW-240 M<strong>and</strong>rel kit, 3/4”<br />

Kit Includes:<br />

M<strong>and</strong>rel, 3/4”<br />

Drawrod assembly<br />

Cutterhead, for 3/4” m<strong>and</strong>rel<br />

Clamp rib set (.750” I.D.–.905”)<br />

Clamp rib set (.875”–1.030”)<br />

Clamp rib set (1.000”–1.155”)<br />

Clamp rib set (1.125”–1.280”)<br />

Part No. Spares for clamp ribs<br />

Draw rod<br />

retaining<br />

nut secures<br />

clamps<br />

G-14 Spring for G-04 through G-13 ribs<br />

G-14C B<strong>and</strong> for G3 clamp ribs<br />

G-14D B<strong>and</strong> for G1 & G2 clamp ribs<br />

G-15 Actuator roll pin .625” & .750”<br />

G-15A Actuator roll pin .500”<br />

G16 Actuator for .625” I.D.<br />

G-17 Actuator for .750” I.D.& up<br />

G-17A Actuator for .500” I.D.<br />

H-11 Actuator roll pin<br />

H-12 Actuator 1.250” I.D. <strong>and</strong> larger<br />

H-14B Spring for H1–H4 ribs<br />

esco tool • 75 October Hill Road, Holliston, MA 01746 • 800.343.6926 • 508.429.4441 • Fax 508.429.2811 • e-mail: millhog@escotool.com<br />

Available <strong>For</strong> Sale or Rent

“Wart”<br />

Built for boilermakers, h<strong>and</strong>les hard alloys, <strong>and</strong> fits<br />

between tubes for single tube removal<br />

Key Features<br />

• A heavy duty ratchet wrench <strong>and</strong> knurled knob<br />

allows easy clamping <strong>and</strong> is perfect for limited<br />

access areas<br />

• Mounts rigidly to produce a clean, continuous chip<br />

• Requires no cutting lubricant<br />

• Simultaneously bevels, faces, <strong>and</strong> bores<br />

• Lightweight <strong>and</strong> requires no special training<br />

• Efficient chatter-free cutter blade locking design<br />

• Torque-free operation prevents operator fatigue<br />

• Low maintenance, compact, air-powered tool<br />

Engineered for High Volume Use<br />

The Esco “Wart” MILLHOG ® is a right angle, I.D.<br />

clamping end prep tool that features an efficient,<br />

low-maintenance design incorporating dual opposed<br />

tapered roller bearings. This makes the “Wart” rigid,<br />

stable <strong>and</strong> extremely durable. Built for boilermakers,<br />

there are no bushings to wear out <strong>and</strong> the sealed<br />

m<strong>and</strong>rel prevents debris from getting inside the tool,<br />

allowing it to be used in any orientation. What's<br />

more, the compact design requires a minimum of<br />

2-5/8” to fit between tubes.<br />

One m<strong>and</strong>rel covers 1.250” I.D. to 4.500” O.D. <strong>and</strong> titanium<br />

nitride coated cutter blades fit securely into the multi-angular<br />

EscoLock blade locking system.<br />

Ideal for peeling<br />

back clad tubes, or<br />

tubes with weld<br />

overlay while<br />

beveling the core<br />

tube. Ask for the<br />

new “Hard Lube”<br />

coated blades.<br />

“Wart” <strong>and</strong> “Electric Wart” MILLHOG ® clamp rib <strong>and</strong><br />

pad selector<br />

Item<br />

No.<br />

Description<br />

I.D. Range<br />

(in.)<br />

I.D. Range<br />

(mm)<br />

M<strong>and</strong>rel<br />

Size<br />

G-03 Clamp rib set .750 – .905 19.1 – 22.9 3/4" (19.1mm)<br />

G-04 Clamp rib set .875 – 1.030 22.2 – 26.1 3/4" (19.1mm)<br />

G-05 Clamp rib set 1.00 – 1.155 25.4 – 29.3 3/4" (19.1mm)<br />

G-06 Clamp rib set 1.125 – 1.280 28.6 – 32.5 3/4" (19.1mm)<br />

H-00 Clamp rib set 1.000 – 1.300 25.4 – 33.0 1" (25.5mm)<br />

H-01 Clamp rib set 1.250 – 1.600 31.8 – 40.6 1-1/4" (31.8mm)<br />

H-02 Clamp rib set 1.525 – 1.925 38.8 – 48.9 1-1/4" (31.8mm)<br />

H-03 Clamp rib set 1.850 – 2.250 47.0 – 57.2 1-1/4" (31.8mm)<br />

H-04 Clamp rib set 2.175 – 2.575 55.3 – 65.4 1-1/4" (31.8mm)<br />

H-02 & H-05 Clamp rib & pad set 2.500 – 2.900 63.5 – 73.7 1-1/4" (31.8mm)<br />

H-03 & H-05 Clamp rib & pad set 2.825 – 3.225 71.8 – 81.9 1-1/4" (31.8mm)<br />

H-04 & H-05 Clamp rib & pad set 3.150 – 3.550 80.0 – 90.2 1-1/4" (31.8mm)<br />

H-02 & H-08 Clamp rib & pad set 3.475 – 3.875 88.3 – 98.4 1-1/4" (31.8mm)<br />

H-03 & H-08 Clamp rib & pad set 3.800 – 4.200 96.6 – 106.6 1-1/4" (31.8mm)<br />

H-04 & H-08 Clamp rib & pad set 4.125 – 4.525 104.8 – 114.9 1-1/4" (31.8mm)<br />

®<br />

Clamp ribs <strong>and</strong> pads<br />

secure tool to tube<br />

I.D. for stable,<br />

smooth operation<br />

One m<strong>and</strong>rel<br />

to cover<br />

1.250" I.D. –<br />

41/2” O.D.<br />

Bevel, face<br />

<strong>and</strong> bore<br />

simultaneously.<br />

Sealed construction keeps<br />

out debris,permits use in any<br />

orientation<br />

Rugged pneumatic<br />

motor provides optimum<br />

performance in a<br />

lightweight package<br />

Safety lever throttle<br />

helps prevent unwanted<br />

motor start-up<br />

Interchangeable Clamp <strong>and</strong> Rib Pads<br />

Simple to operate, the “Wart” MILLHOG ® uses one<br />

m<strong>and</strong>rel for the vast majority of jobs (see clamp rib<br />

<strong>and</strong> clamp pad selector chart). All you have to do<br />

is measure the tube I.D., select the correct ribs<br />

<strong>and</strong>/or pads <strong>and</strong> install them on the m<strong>and</strong>rel.<br />

Because they self-align, that’s all there is to it.<br />

Now insert the m<strong>and</strong>rel into the tube I.D., exp<strong>and</strong><br />

the clamp ribs <strong>and</strong>/or pads <strong>and</strong> perform your end<br />

preps in seconds.<br />

Specifications<br />

Cutterheads are easily<br />

changed <strong>and</strong> use the<br />

multi-angular EscoLock<br />

blade locking system<br />

“Wart”<strong>and</strong> “Electric Wart” MILLHOG ®<br />

Working Range: 3/4” (19.1 mm) I.D.to 4-1/2” (114.3 mm) O.D.<br />

Motor, pneumatic/electric 1-1/4 h.p. (.932 kw)<br />

Power Requirements 120 volt 12 amp 60 cycle or 220 volt 6.5 amp<br />

50 cycle<br />

Air Pressure 90 psi.(6.2 bar)<br />

Air Volume 40 cfm (1133 It/min.)<br />

Speed 180 RPM (electric speed variable up to 180 RPM)<br />

Minimum Clearance 2-5/8” (66.68 mm)<br />

Head Length 14-1/2” (368.3 mm)<br />

Working Weight 19 lbs. (8.7 kg)<br />

Shipping Weight Basic: 55 lbs. (25 kg)<br />

Deluxe: 63 lbs. (28.6 kg)<br />

Shipping Dimensions 24” x 20” x 7” (610 mm x 508 mm x 178 mm)<br />

Manufacturer reserves the right to change specifications without notice<br />

Right Angle I.D. Clamping End Prep <strong>Tool</strong><br />

.75” I.D. to 4.5” O.D.<br />

19.1 mm I.D. to 114.3 mm O.D.<br />

Right angle gear drive<br />

features opposing<br />

tapered roller bearings to<br />

ensure long, trouble-free,<br />

continuous operation<br />

Ratchet feed is<br />

easy to use <strong>and</strong><br />

maintain<br />

Quick connect<br />

air coupling<br />

Wrenches are<br />

securely<br />

attached<br />

Ideal for limited access areas, the “Wart” MILLHOG ® requires a minimum<br />

width of 2-5/8” clearance to fit between tubes, <strong>and</strong> easily clamps into place<br />

with the Knurled Knob <strong>and</strong> Heavy Duty Ratchet.<br />

The “Wart” MILLHOG ® is also available with<br />

a number of accessories to accommodate more<br />

specific end prep application needs.<br />

(see page 6 for details)<br />

Ordering Information<br />

Kit No. Description<br />

H-200/ “Wart”/Electric “Wart” Millhog<br />

H-200E basic kit for 1-1/4” I.D. to 4-1/2” O.D.<br />

Kit Includes:<br />

Pneumatic motor <strong>and</strong> gear drive<br />

OR<br />

Electric motor <strong>and</strong> speed<br />

reduction gear drive<br />

Feed mechanism<br />

Hose, 1/2” w/filter, oiler &<br />

3/8” coupler<br />

Draw rod wrench assembly<br />

(1) clamp rib set, specify size<br />

(1) clamp pad set, specify size<br />

Allen wrench set<br />

Carrying case (WMH)<br />

(1) cutterhead, specify size<br />

Operating & maintenance<br />

instructions<br />

H-300/ “Wart” / Electric “Wart” Millhog,<br />

H-300E deluxe kit for 1-1/4” I.D. to<br />

4-1/2” O.D.<br />

Kit Includes:<br />

Pneumatic motor <strong>and</strong> gear drive<br />

OR<br />

Electric motor <strong>and</strong> speed<br />

reduction gear drive<br />

Feed mechanism<br />

Hose, 1/2” w/filter, oiler &<br />

3/8” coupler<br />

Draw rod wrench assembly<br />

Clamp rib & pad sets<br />

(H1–H5 & H8)<br />

(2) Cutterheads, choice of<br />

2-5/8”, 3”, 3-1/2”, 4” & 4-1/2”<br />

Carrying case (WMH)<br />

Allen wrench set<br />

Operating & maintenance<br />

instructions<br />

H-240 M<strong>and</strong>rel kit, 3/4” for<br />

3/4” I.D. to 1-1/4” I. D.<br />

Kit Includes:<br />

M<strong>and</strong>rel, 3/4”<br />

Drawrod w/clamp release,<br />

wrench & actuator<br />

Cutterhead, 3/4” – 2-5/8”<br />

Clamp rib set (.750” – .905”)<br />

Clamp rib set (.875” – 1.030”)<br />

Clamp rib set (1.000 – 1.155”)<br />

Clamp rib set (1.125 – 1.280”)<br />

H-221 M<strong>and</strong>rel kit, 1” for<br />

1” I.D. to 1-1/4” I. D.<br />

Kit Includes:<br />

M<strong>and</strong>rel, 1” w/feed stop<br />

Clamp rib set, H-O (1.000” – 1.250”)<br />

Actuator, 1”<br />

Draw rod & stop collar<br />

Part No. Cutterheads<br />

CH-20 Cutterhead, 2-5/8”<br />

CH-21 Cutterhead, 3”<br />

CH-22 Cutterhead, 3-1/2”<br />

CH-23 Cutterhead, 4”<br />

CH-24 Cutterhead, 4-1/2”<br />

Spares for clamp ribs<br />

H-11 Actuator, roll pin<br />

H-12 Actuator, 1.250”<br />

H-12A Actuator, 1”<br />

H-14A Spring, clamp rib H-00<br />

H-14B Spring, clamp rib H1–H4<br />

Just want the electric motor?<br />

H-201E Electric motor <strong>and</strong> speed<br />

reduction gear drive<br />

esco tool • 75 October Hill Road, Holliston, MA 01746 • 800.343.6926 • 508.429.4441 • Fax 508.429.2811 • e-mail: millhog@escotool.com<br />

Available <strong>For</strong> Sale or Rent<br />

5

6<br />

“Wart” ®<br />

Electrically or pneumatically powered for st<strong>and</strong>ard or specialty<br />

applications including tube stub removal, pipe fitting end<br />

prepping <strong>and</strong> tube end profiling...<br />

“Electric Wart” MILLHOG ®<br />

Interchangeable with the pneumatic motor, the “Wart” gear head<br />

can easily convert from Air Driven to Electrically Powered in a<br />

matter of minutes, <strong>and</strong> requires no special tools or training.<br />

Easily turned “on” <strong>and</strong> “off”, the powerful variable speed, 1400<br />

watt double insulated motor <strong>and</strong> the <strong>ESCO</strong> proprietary speed<br />

reduction spider combine to develop maximum cutting force at<br />

the blade, that produces a thick chip, <strong>and</strong> prevents work<br />

hardening without using a cutting lubricant.<br />

“Z Wart” MILLHOG ® End Prep <strong>Tool</strong><br />

The “Z Wart” MILLHOG ® is a powerful narrow body specialty end<br />

prep tool for applications when tool width is critical <strong>and</strong> torque<br />

needs to be maximized. A slender 2-5/8” wide, the “Z Wart”<br />

MILLHOG ® adds an additional right angle drive into the<br />

conventional “Wart” MILLHOG ® drive train that reduces the RPM by<br />

half, <strong>and</strong> doubles the torque at the cutting blade.<br />

The low RPM <strong>and</strong> high torque of the “Z Wart” MILLHOG ® make it<br />

well suited for end prep applications that include tube stub removal<br />

<strong>and</strong> weld overlay. Please consult factory for application<br />

specifications, <strong>and</strong> ordering information.<br />

“Contour Wart” MILLHOG ®<br />

The “Contour Wart” MILLHOG ® , or “fishmouth”, is a specialty end<br />

prep tool for profiling tube ends so they sit evenly on the radius<br />

of a header <strong>and</strong> allows for full penetration welds. The profile<br />

shape of the end prep is specific to the application, <strong>and</strong> is ideal<br />

when a large number of end preps, of consistent size need to be<br />

profiled. <strong>For</strong> ordering information, <strong>and</strong> application specifications,<br />

please consult the factory.<br />

The “Z Wart’s” low RPM <strong>and</strong> high torque<br />

make it well suited for applications that<br />

include tube stub removal.<br />

Specialty End Prep <strong>Tool</strong>s<br />

Already own a “Wart”, no<br />

problem, the electric motor<br />

is interchangeable, takes<br />

only minutes to switch, <strong>and</strong><br />

requires no special tools.<br />

Fast, perfectly<br />

contoured end<br />

preps are easily<br />

accomplished<br />

<strong>and</strong> requires no<br />

further rework<br />

prior to end<br />

prepping...<br />

every time.<br />

The Contour<br />

“Wart” MILLHOG ®<br />

produces flawless<br />

end preps on<br />

tube ends when<br />

accurate fit-up is<br />

needed to weld<br />

tubes to a header.<br />

esco tool • 75 October Hill Road, Holliston, MA 01746 • 800.343.6926 • 508.429.4441 • Fax 508.429.2811 • e-mail: millhog@escotool.com<br />

Available <strong>For</strong> Sale or Rent<br />

Like the Air<br />

Powered<br />

“Wart”, the<br />

“Electric Wart”<br />

is ideal for<br />

close quarters.<br />

The “Z Wart” features a<br />

cutterhead that holds<br />

the cutting blades 180<br />

degrees apart, <strong>and</strong><br />

distributes the cutting<br />

force evenly on the<br />

cutting surface. This<br />

significantly reduces<br />

chatter, which helps to<br />

prolong blade life.

“Fin”<br />

®<br />

<strong>Tube</strong> Fin Removal <strong>Tool</strong><br />

Removes fin from tube O.D <strong>and</strong> bevels<br />

tube end in one-step<br />

This innovative, time-saving tool eliminates the need for<br />

chipping hammers <strong>and</strong> grinders<br />

Key Features<br />

• Removes 4” (101mm) of fin from the tube O.D. in under<br />

two minutes.<br />

• Bevels the tube end after removing the fin, all in one-step.<br />

• Pneumatically powered with no reaction torque to the operator.<br />

• High grade tool steel cutter blade can be resharpened.<br />

• Heavy-duty rack <strong>and</strong> pinion feed mechanism assures smooth<br />

operation for greater fin removal control.<br />

• Rigidly clamps to the tube I.D.<br />

• Works in any position to separate the fin from tube.<br />

• Easy to operate <strong>and</strong> no cutting lubricants are necessary.<br />

• Saves a lot of time by eliminating chipping <strong>and</strong> grinding.<br />

Proprietary Blade Produces Exceptional Results<br />

The Fin MILLHOG ® tube fin removal tool is air-powered, clamps<br />

to the tube I.D., <strong>and</strong> features a patent pending fin removal head<br />

that peels the fin from a tube <strong>and</strong> then bevels the tube end,<br />

all in one-step. <strong>For</strong>get about chipping hammers <strong>and</strong> grinders.<br />

A true time saver, this tool can remove a 4” (101mm) fin from a<br />

tube O.D. in under two minutes!<br />

Easy to operate, the Fin MILLHOG ® does it all. Once it is clamped<br />

into the tube I.D. <strong>and</strong> you engage the throttle, the fin removal head<br />

rotates, is fed into the fin, <strong>and</strong> efficiently cuts the bond between the<br />

fin <strong>and</strong> tube O.D. Then a bevel blade end preps the tube, all in onestep.<br />

Built tough, the cutter blade is made from a high grade tool<br />

steel that can be resharpened, while a heavy-duty rack <strong>and</strong> pinion<br />

feed mechanism assures smooth operation, without requiring any<br />

cutting fluids.<br />

Left h<strong>and</strong> wound fin<br />

Bevels the tube end<br />

after separating the fin,<br />

all in one step<br />

The Fin MILLHOG can remove<br />

a 4” fin from a tube O.D. in<br />

under two minutes <strong>and</strong> can<br />

be used in any orientation.<br />

Specifications<br />

This h<strong>and</strong>-held fin removal tool features a cutter head that efficiently cuts<br />

the bond between the fin <strong>and</strong> the tube O.D.<br />

“Fin” MILLHOG ®<br />

Working Range 1-1/4” (31.8 mm) I.D. to 3” (76.2 mm) O.D.<br />

Motor, pneumatic 1-1/4” h.p. (.932 kW)<br />

Air Pressure 90 psi (6.2 bar)<br />

Air Volume 40 cfm (1133 lpm)<br />

Speed 180 rpm<br />

Minimum Clearance 2-5/8” (66.68 mm)<br />

Head Length 19” (483 mm)<br />

Working Weight 24 lbs (10.9 kg)<br />

Shipping Weight 63 lbs (28.6 kg)<br />

Shipping Dimensions 24” x 20” x 7” (610 mm x 508 mm x 178 mm)<br />

Manufacturer reserves the right to change specifications without notice.<br />

Sealed construction keeps<br />

Clamp ribs<br />

out debris <strong>and</strong> permits use<br />

exp<strong>and</strong> nearly<br />

in any orientation<br />

1/2” (12mm)<br />

Bevel blade<br />

Fin removal head<br />

(Specify right or<br />

left h<strong>and</strong> rotation)<br />

Powerful pneumatic<br />

motor provides optimum<br />

power in a light weight<br />

package<br />

© U.S. Patent 7,305,746 other patents pending<br />

Ordering Information<br />

Kit No. Description<br />

FH-200 “Fin” Millhog for 1-1/4” I.D. to 3” O.D.<br />

Kit Includes:<br />

Rack <strong>and</strong> pinion<br />

feed mechanism rapidly<br />

feeds tool<br />

into tube fin<br />

Stop collar<br />

prevents<br />

clamps from<br />

falling down<br />

the tube<br />

Ratchet feed<br />

wrench is securely<br />

attached to tool<br />

Safety lever throttle<br />

helps prevent<br />

unwanted start-ups<br />

Quick connect air coupling<br />

Pneumatic motor <strong>and</strong> gear drive<br />

Fin Hog m<strong>and</strong>rel<br />

(1) Fin removal head, specify size <strong>and</strong> fin<br />

direction of tube<br />

Draw rod wrench assembly<br />

(1) Clamp rib set (choose from H-1–H-4)<br />

Hose with filter, oiler <strong>and</strong> 3/8” couplers<br />

Allen wrench set<br />

Carrying case<br />

Operating instructions<br />

esco tool • 75 October Hill Road, Holliston, MA 01746 • 800.343.6926 • 508.429.4441 • Fax 508.429.2811 • e-mail: millhog@escotool.com<br />

Available <strong>For</strong> Sale or Rent<br />

7

8<br />

““““ AAAA iiii rrrr CCCC llll aaaa mmmm pppp ””””<br />

Ideal for <strong>Tube</strong> Fabrication Facilities, the<br />

MILLHOG ® Production End Prep <strong>Tool</strong>s<br />

equipped with the “Air Clamp” have<br />

increased production by more than 300%!!!<br />

Key features<br />

• Locks tool instantly to tube I.D.<br />

• Disengages immediately with the flip of a<br />

switch<br />

• Significantly decreases cycle time<br />

between end preps<br />

• Ideal for boiler tube component<br />

fabrication<br />

• Bevel face <strong>and</strong> bore in one operation<br />

• Rugged braided hose to control air flow<br />

• Simple to operate<br />

• Retrofits to existing MILLHOG ® end prep tools<br />

• Esco lock blade locking system delivers<br />

superior blade performance<br />

<strong>Tool</strong> Applications<br />

• <strong>Boiler</strong> tube panel fabrication<br />

• <strong>Tube</strong> sheet seal weld removal<br />

• <strong>Tube</strong> sheet end facing<br />

• End prep large numbers of consistent size<br />

tube <strong>and</strong> pipe<br />

Air Clamp Series<br />

• Ground Millhog<br />

• Mongoose Millhog<br />

• <strong>Tube</strong> Weasel Millhog<br />

Production Increases Over 300%<br />

The MILLHOG ® “Air Clamp” is designed for<br />

shop use when cycle time between end preps<br />

needs to be minimized. A side by side<br />

comparison shows, end prep production can<br />

increase by more than 300% using the<br />

“Air Clamp” when compared to a manually<br />

actuated clamping system.<br />

The “Air Clamp” instantly locks the tool to the<br />

pipe or tube i.d <strong>and</strong> holds it securely in place<br />

while performing the end prep. When done,<br />

removing the tool from the work is simple,<br />

reverse the valve <strong>and</strong> the clamps disengage<br />

automatically releasing the tool from the tube<br />

I.D. immediately.<br />

Easy to install, the “Air Clamp” can be fitted to<br />

an existing “Mongoose”, “Ground”, <strong>and</strong> “<strong>Tube</strong><br />

Weasel” MILLHOG ® in minutes, <strong>and</strong> requires<br />

no special tools of training.<br />

®<br />

Ideal for <strong>Tube</strong> Fabrication Facilities...<br />

Automatic I.D. Clamping End Prep <strong>Tool</strong><br />

Built for production, the “Air Clamp” series MILLHOGS are ideal for tube<br />

fabrication shops that do large numbers of end preps on tube <strong>and</strong> pipe of<br />

consistent size.<br />

Operators will like the quick action of the “Air Clamp”. This simple innovation is<br />

easy to use, increases production, <strong>and</strong> minimizes operator fatigue by<br />

eliminating the tedious <strong>and</strong> time consuming task of manual clamping.<br />

Designed to last, “Air Clamp” MILLHOGS are built on the reliable MILLHOG ®<br />

dual opposed, bearing supported gear drive system that has performed<br />

millions of end preps on all types of tube <strong>and</strong> pipe alloys proving itself to be<br />

second to none for durability <strong>and</strong> performance.<br />

“Air Clamp” MILLHOGS also feature the “EscoLock” blade locking system that<br />

holds the cutting blade so rigid that MILLHOGS are capable of<br />

producing 2-3 more end preps per blade, <strong>and</strong> in less time than competitive<br />

tools. This helps make the “Air Clamp” MILLHOGS the fastest <strong>and</strong> most cost<br />

efficient end prep tools you can use in a production application.<br />

To operate, simply acuate the valve,<br />

<strong>and</strong> the clamps instantly lock the tool<br />

into position. Reverse the valve, <strong>and</strong><br />

the clamps disengage from the I.D<br />

immediately.<br />

“Air Clamps” are available for<br />

the “Ground”, “<strong>Tube</strong> Weasel”<br />

<strong>and</strong> “Mongoose” Millhog ® ,<br />

<strong>and</strong> can be installed by simply<br />

removing the manual draw rod<br />

assembly <strong>and</strong> attaching the<br />

“Air Clamp”.<br />

esco tool • 75 October Hill Road, Holliston, MA 01746 • 800.343.6926 • 508.429.4441 • Fax 508.429.2811 • e-mail: millhog@escotool.com<br />

Available <strong>For</strong> Sale or Rent

““““ AAAA iiii rrrr CCCC llll aaaa mmmm pppp ””””<br />

Specifications<br />

Built for production, the “Air Clamp” series MILLHOGS are ideal<br />

for tube fabrication shops that do large numbers of end preps<br />

on tube <strong>and</strong> pipe of consistent size.<br />

“Ground” MILLHOG ® “Mongoose” MILLHOG ® “<strong>Tube</strong> Weasel” MILLHOG ®<br />

Working Range: 1/2” (12.7 mm) I.D. to 2-1/4” (57.2 mm) O.D. 5/8” (15.9 mm) I.D. to 3” (76.2 mm) O.D. 3/4” (19.1 mm) I.D. to 3” (76.2 mm) O.D.<br />

Motor 2/3 h.p. (.497 kw) 2/3 h.p. (.497 kw) 2/3 h.p. (.497 kw)<br />

Air Pressure 90 psi.(6.2 bar) 90 psi.(6.2 bar) 90 psi.(6.2 bar)<br />

Air Volume 25 cfm (708 It/min.) 25 cfm (708 It/min.) 25 cfm (708 It/min.)<br />

Speed<br />

Minimum Clearance:<br />

200 RPM 200 RPM 200 RPM<br />

At cutterhead 1-1/2” (38.1 mm) 2-1/4” (57.2 mm) 3” (76.2 mm)<br />

At “Air Clamp” cylinder 3-5/8” (92.1 mm) 3-5/8” (92.1 mm) 4-3/8” (111.1 mm)<br />

Head Length 16” (406 mm) 17” (431.1 mm) 17” (431.1 mm)<br />

Working Weight 11 lbs. (5.0 kg) 15 lbs. (6.8 kg) 20 lbs. (9.1 kg)<br />

Shipping Weight 55 lbs. (25 kg) 55 lbs. (25 kg) 55 lbs. (25 kg)<br />

Shipping Dimensions 24” x 20” x 7” (610 mm x 508 mm x 178 mm) 24” x 20” x 7” (610 mm x 508 mm x 178 mm) 24” x 20” x 7” (610 mm x 508 mm x 178 mm)<br />

Manufacturer reserves the right to change specifications without notice.<br />

®<br />

Automatic I.D. Clamping End Prep <strong>Tool</strong><br />

Ordering Information<br />

Kit No. Description<br />

ACG- Air Clamp “Ground” Millhog tool kit<br />

200 for 5/8” I.D. to 2-1/4” O.D.<br />

Kit Includes:<br />

“Air Clamp” System<br />

Motor, gear, drive assembly<br />

M<strong>and</strong>rel .625”<br />

Hose, 1/2” w/filter, oiler & 3/8” coupler<br />

(1) clamp rib set; specify size<br />

(1) cutterhead; specify size<br />

Carrying case<br />

Allen wrench set<br />

Operating instructions<br />

ACG- Air Clamp “Ground” Millhog tool kit<br />

300 for 1.575” I.D. to 2-1/4” O.D.<br />

Kit Includes:<br />

“Air Clamp” System<br />

Motor, gear drive assembly<br />

M<strong>and</strong>rel .625”<br />

Hose 1/2” w/ filter, oiler & 3/8” coupler<br />

(12) Clamp rib sets, (G2 — G13)<br />

Cutterhead, 1-1/2”<br />

Cutterhead, 2-1/4”<br />

ball valve & 3/8” coupler<br />

Carrying case<br />

Allen wrench set<br />

Operating instructions<br />

ACMG- Air Clamp “Mongoose” Millhog tool kit<br />

200 for 3/4” i.d. to 3” o.d.<br />

Kit Includes:<br />

“Air Clamp” System<br />

motor & gear drive<br />

(1) M<strong>and</strong>rel 3/4” (5/8” optional consult factory)<br />

Draw rod assembly<br />

Cutterhead (1) state size 2-1/4”,<br />

2-1/2” & 3”<br />

Clamp rib set (1) specify size (G2 — G13)<br />

1/2” Hose w/filter, oiler & 3/8” coupler<br />

Carrying case<br />

Allen wrench set<br />

Operating instructions<br />

ACMG- Air Clamp “Mongoose” Millhog tool kit<br />

300 for 3/4” i.d. to 3” o.d.<br />

Kit Includes:<br />

“Air Clamp” System<br />

motor & gear drive<br />

(1) M<strong>and</strong>rel 3/4” (5/8” optional consult factory)<br />

Draw rod assembly<br />

Cutterhead (1) state size 2-1/4”,<br />

2-1/2” & 3”<br />

Clamp rib sets (Includes G2 - G13)<br />

1/2” Hose w/filter, oiler & 3/8” coupler<br />

Carrying case<br />

Allen wrench set<br />

Operating instructions<br />

ACTW- Air Clamp “<strong>Tube</strong> Weasel” Millhog<br />

200 tool kit for 1-1/4” i.d. to 3” o.d.<br />

Kit Includes:<br />

“Air Clamp” System<br />

Motor, gear drive assembly<br />

Clamp rib <strong>and</strong> pad sets (H-01 to H-05)<br />

Cutterhead, 3”<br />

Carrying case<br />

Allen wrench set<br />

Operating instructions<br />

Conversion “Air Clamp” kits<br />

G-270 “Air Clamp” for Ground & Mongoose”<br />

Millhog (m<strong>and</strong>rel size required)<br />

H-270 “Air Clamp” for “<strong>Tube</strong>weasel” Millhog<br />

(m<strong>and</strong>rel size required)<br />

Conversion kits include everything to<br />

convert your Millhog to an “Air Clamp”<br />

Millhog. State the m<strong>and</strong>rel size your<br />

Millhog is set up with when ordering.<br />

esco tool • 75 October Hill Road, Holliston, MA 01746 • 800.343.6926 • 508.429.4441 • Fax 508.429.2811 • e-mail: millhog@escotool.com<br />

Available <strong>For</strong> Sale or Rent<br />

9

10<br />

“Mini”<br />

Cuts heavy wall pipe or tube!<br />

Fast, chatter-free <strong>and</strong> easy to use...<br />

Key Features<br />

• <strong>Tool</strong> rigidly mounts to pipe or tube l. D.<br />

• Self-centering draw rod assembly<br />

• Single gear drive system for optimum performance<br />

• One m<strong>and</strong>rel covers majority of the cutting range<br />

• Cutter blade locking design eliminates chatter<br />

• Cutter blades index easily for proper set up<br />

• Pneumatically powered with torque-free operation<br />

• Removes tube stub welds <strong>and</strong> prepares the header<br />

• Automatically squares off the end of pipe or tube<br />

• Produces clean, continuous chip without cutting oils<br />

• Lightweight <strong>and</strong> simple to operate without special training<br />

Rugged, Fast <strong>and</strong> Reliable<br />

Esco MILLHOG ® “Mini” Series end prep tools are the<br />

most ruggedly built <strong>and</strong> efficiently designed tools<br />

available today for milling heavy wall pipe <strong>and</strong> tube from<br />

1.25" I.D. to 6.625" O.D. Rigidly mounting to the l.D. by<br />

a draw rod clamping assembly which centers the tool<br />

automatically, they utilize a ratchet mechanism for<br />

feeding the cutter head. Featuring titanium nitride coated<br />

cutter blades for smooth milling, without requiring cutting<br />

oils, they produce a clean, continuous chip <strong>and</strong> square<br />

off the end of the pipe or tube.<br />

The MILLHOG ® “Mini” Series comes complete<br />

with motor gear drive feed mechanism,<br />

manual draw rod wrench <strong>and</strong> actuator,<br />

cutterhead, clamp ribs <strong>and</strong> pads, air hose with<br />

quick connected couplings, lubricator, ball<br />

valve throttle, filter, operating instructions <strong>and</strong><br />

metal carrying case.<br />

“Mini” MILLHOG ® clamp rib <strong>and</strong> pad selector<br />

Esco MILLHOG ®<br />

“Mini” Series end prep<br />

tools rigidly mount to<br />

the pipe or tube l.D.<br />

by a draw rod<br />

clamping assembly<br />

which centers the tool<br />

automatically to<br />

produce a clean<br />

bevel with a<br />

square end.<br />

Item<br />

No.<br />

Description<br />

I.D. Range<br />

(in.)<br />

I.D. Range<br />

(mm)<br />

M<strong>and</strong>rel<br />

Size<br />

H-01 Clamp rib set 1.250–1.600 31.8–40.6 1-1/4" (31.8mm)<br />

H-02 Clamp rib set 1.525–1.925 38.8–48.9 1-1/4" (31.8mm)<br />

M-01 Clamp rib set 1.800–2.270 45.8–57.6 1.800" (45.8mm)<br />

M-02 Clamp rib set 2.240–2.695 56.9–68.4 1.800" (45.8mm)<br />

M-03 Clamp rib set 2.665–3.120 67.7–79.2 1.800" (45.8mm)<br />

M-04 Clamp rib set 3.050–3.500 77.4–88.9 1.800" (45.8mm)<br />

M-02 & M-05 Clamp rib & pad set 3.415–3.865 86.7–98.1 1.800" (45.8mm)<br />

M-03 & M-05 Clamp rib & pad set 3.780–4.230 96.0–107.4 1.800" (45.8mm)<br />

M-04 & M-05 Clamp rib & pad set 4.145–4.595 105.3–116.7 1.800" (45.8mm)<br />

M-02 & M-08 Clamp rib & pad set 4.510–4.960 114.5–126.0 1.800" (45.8mm)<br />

M-03 & M-08 Clamp rib & pad set 4.875–5.325 123.8–135.2 1.800" (45.8mm)<br />

M-04 & M-08 Clamp rib & pad set 5.240–5.690 133.1–144.5 1.800" (45.8mm)<br />

M-02 & M-11 Clamp rib & pad set 5.605–6.055 142.3–153.8 1.800" (45.8mm)<br />

M-03 & M-11 Clamp rib & pad set 5.970–6.420 151.6–163.0 1.800" (45.8mm)<br />

®<br />

<strong>Tool</strong> rigidly<br />

clamps to the<br />

pipe or tube I.D.<br />

Clamps<br />

are easy<br />

to change<br />

Specifications<br />

Multi-angular<br />

EscoLock Blade<br />

lock system<br />

Blade<br />

squares off<br />

end of pipe<br />

or tube<br />

I.D. Clamping End Prep <strong>Tool</strong><br />

1.25" I.D. to 6.625" O.D.<br />

31.8 mm I.D. to 168.3 mm O.D.<br />

Single gear drive system<br />

with 1 1/4 h.p. air motor<br />

Self-centering draw rod<br />

mounting assembly<br />

Few moving parts for<br />

optimum performance<br />

<strong>and</strong> low maintenance<br />

Ratchet feed is<br />

cutting control<br />

Low RPM <strong>and</strong> extraordinary torque at the cutting bit make MILLHOG ® end prep<br />

tools a good match for many tube stub removal applications.<br />

“Mini” MILLHOG ®<br />

Working Range: 1-1/4” (31.8 mm) I.D.to 6-5/8” (168.3 mm) O.D.<br />

Motor, pneumatic 1-1/4 h.p. (.9325 kw)<br />

Air Pressure 90 psi. (6.2 bar)<br />

Air Volume 40 cfm (1133 It/min.)<br />

Speed 34 RPM<br />

Minimum Clearance 5-1/4” (133.3 mm)<br />

Head Length 13” (330.2 mm)<br />

Working Weight 25 lbs. (11.33 kg)<br />

Shipping Weight 65 lbs. (29.5 kg)<br />

Shipping Dimensions 21” x 18” x 7” (533 mm x 457 mm x 178 mm)<br />

Manufacturer reserves the right to change specifications without notice.<br />

Safety lever<br />

throttle<br />

Titanium nitride coated cutter<br />

blades provide smooth milling,<br />

without cutting oils, <strong>and</strong> produce<br />

a clean continuous chip.<br />

Ordering Information<br />

Kit No. Description<br />

M-200 “Mini” Millhog tool kit<br />

for 1.8” I.D. to 6.625” O.D.<br />

Kit Includes:<br />

Motor assembly<br />

Feed mechanism<br />

Blade block, 6.625” w/wedges<br />

Draw rod & wrench<br />

Clamp ribs <strong>and</strong>/or pads,<br />

choice of (2)<br />

Hose, 1/2” w/filter, oiler,<br />

ball valve & 3/8” coupler<br />

Carrying case<br />

Allen wrench set<br />

Operating <strong>and</strong> maintenance<br />

instructions<br />

M-300 “Mini” Millhog, tool kit<br />

for 1.8” I.D. to 6.625” O.D.<br />

Kit Includes:<br />

Motor assembly<br />

Feed mechanism<br />

Blade block, 6.625” w/wedges<br />

Draw rod & wrench<br />

Clamp rib sets M1–M5, M8 & M11<br />

Hose, 1/2” w/filter, oiler,<br />

ball valve & 3/8” coupler<br />

Carrying case<br />

Allen wrench set<br />

Operating <strong>and</strong> maintenance<br />

instructions<br />

M-240 M<strong>and</strong>rel kit, 1-1/4”<br />

for 1.25” I.D. to 1.925” I.D.<br />

Kit Includes:<br />

M<strong>and</strong>rel, 1.250” w/feed stop<br />

Clamp rib set, 1.25”–1.6”<br />

Clamp rib set, 1.525”–1.925”<br />

Draw rod, 1-1/4”<br />

Actuator<br />

Part No. Spares for clamp ribs<br />

Because of our unique<br />

EscoLock blade locking<br />

system, it is easy to pull<br />

a heavy chip on the<br />

toughest alloys.<br />

H-11 Actuator, roll pin<br />

H-12 Actuator, 1.250”<br />

H-14B Spring, clamp rib H1–H4<br />

M-46 Actuator, 1.8”<br />

M-47 Actuator, roll pin 1.8”<br />

M-52 Spring, clamp rib M1–M4.<br />

esco tool • 75 October Hill Road, Holliston, MA 01746 • 800.343.6926 • 508.429.4441 • Fax 508.429.2811 • e-mail: millhog@escotool.com<br />

Available <strong>For</strong> Sale or Rent

High Speed<br />

H<strong>and</strong> Held Bevelers<br />

Straight-Thru, Track-Mountable, <strong>and</strong><br />

Right Angle Models available<br />

Key Features<br />

• Capable of prepping tubes<br />

in seconds<br />

• Air-powered beveling with<br />

no torque reaction<br />

• Pilot automatically locates<br />

on tube or pipe I.D.<br />

• No clamping or loose parts<br />

that can fall down tubes<br />

• H<strong>and</strong>les variety of tubes,<br />

materials <strong>and</strong> applications<br />

• Field changeable pilot <strong>and</strong><br />

cutterhead saves time<br />

• Carbide blade inserts have<br />

multiple cutting edges<br />

• High speed cutterhead<br />

spins faster than 5,000 RPM<br />

• Precise end preps without<br />

cutting oils<br />

• Field proven tools require<br />

very little maintenance<br />

These high speed straight-thru h<strong>and</strong> held<br />

bevelers provide torque-free operation<br />

<strong>and</strong> feature quick-change tooling. Right<br />

angle models are available for<br />

getting into tight spaces.<br />

Straight-Thru <strong>and</strong> Right Angle Models<br />

The straight-thru models can machine any degree of bevel on heavy <strong>and</strong> thin wall<br />

tubes, as well as tangent tubes. The most powerful pneumatic high speed end prep<br />

tools available anywhere, they can be used by h<strong>and</strong> or with the EscoTrack mount panel<br />

replacement system by using the optional Track Chassis <strong>and</strong> Post Assembly. With this<br />

option, these tools make fast work out of repetitive end preps <strong>and</strong> cut hours <strong>and</strong> even<br />

days off of boiler tube panel replacement outages.<br />

When you need to get into a “Dutchman” of less than six inches, our right angle<br />

models do the job better than ever. The HHB-5000 RA or HHB-10000 RA end prep<br />

tools are every bit as rugged as our straight-thru models, <strong>and</strong> are ideal for single boiler<br />

tube repairs. All of these h<strong>and</strong> held bevelers feature quick-change tooling <strong>and</strong> the<br />

automatic pilot system that locates itself on the tube I.D.<br />

Fast, Accurate <strong>and</strong> Easy to Use<br />

These high speed bevelers feature the EscoPilot locating system which eliminates the<br />

need for clamping <strong>and</strong> special operator training. Unlike conventional end prep tools<br />

that require clamping to the tube or pipe I.D., these tools locate themselves<br />

automatically <strong>and</strong> there are no loose parts that can fall down the tube <strong>and</strong> waste your<br />

time. Simple to operate, just insert the pilot into the tube I.D., squeeze the throttle <strong>and</strong><br />

finish your end prep completely in as fast as 3 seconds!<br />

Specifications<br />

HHB-5000 HHB-5000 RA HHB-10000 HHB-10000 RA<br />

Working range .450” (11.43 mm) .450” (11.43 mm) .450” (11.43 mm) .450” (11.43 mm)<br />

to 2.250” (57.15 mm) 2.250” (57.16 mm) 4.00” (101.6 mm) 4.00” (101.6 mm)<br />

Motor, pneumatic 1.5 h.p. (1.122 kw) 1.5 h.p. (1.122 kw) 3 h.p. (2.244 kw) 3 h.p. (2.244 kw)<br />

Air pressure 90 psi (6.2 bar) 90 psi (6.2 bar) 90 psi (6.2 bar) 90 psi (6.2 bar)<br />

Air Volume 50 cfm (1416 It/min.) 50 cfm (1416 It/min.) 80 cfm (2265 It/min.) 80 cfm (2265 It/min.)<br />

Speed 5000 5000 10000 10000<br />

Radial 1.5” (38.1 mm) 1.9” (48.3 mm) 2.125” (54 mm) 2.5” (63.5 mm)<br />

Working weight 9 lbs.(4.1 kg) 8 lbs.(3.7 kg) 14 lbs.(6.4 kg) 13 lbs.(5.9 kg)<br />

Shipping weight 40 lbs.(18.2 kg) 40 lbs.(18.2 kg) 45 lbs.(20.4 kg) 45 lbs.(20.4 kg)<br />

Track mountable yes no yes no<br />

Shipping dimensions 27”x18”x7” (686 mm x 457 mm x 177 mm)<br />

Manufacturer reserves the right to change specifications without notice.<br />

Model HHB-5000<br />

Model HHB-10000<br />

Model HHB-5000 RA<br />

Model HHB-10000 RA<br />

Ordering Information<br />

Kit No. Description<br />

50-200 HHB-5,000 High Speed H<strong>and</strong> Held Beveler kit<br />

Kit includes:<br />

High speed air motor w/oiler<br />

Gear drive, off set<br />

Chip shield<br />

Chip guard bracket<br />

Wrench set (17 mm x 17 mm)<br />

Carrying case<br />

Hose, 1/2” w/ filter, oiler & 3/8” coupler<br />

Operating <strong>and</strong> maintenance instructions<br />

Allen wrench set<br />

50-200RA HHB-5,000RA Right Angle High Speed<br />

H<strong>and</strong> Held Beveler kit<br />

Kit includes:<br />

High speed air motor<br />

Right angle drive<br />

Chip shield<br />

Chip guard bracket<br />

Wrench set (17 mm x 17 mm)<br />

Carrying case<br />

Hose, 1/2” w/filter, oiler & 3/8” coupler<br />

Operating <strong>and</strong> maintenance instructions<br />

Allen wrench set<br />

10-200 HHB-10,000 High Speed H<strong>and</strong> Held Beveler kit<br />

Kit includes:<br />

High speed air motor<br />

Offset gear drive<br />

Chip shield<br />

Chip guard bracket<br />

Hose, 1/2” w/filter, oiler & 1/2” coupler<br />

Carrying case<br />

Wrench set (17 mm x 9/16”)<br />

Allen wrench set<br />

Operating <strong>and</strong> maintenance instructions<br />

10-200RA HHB-10,000RA Right Angle High Speed<br />

H<strong>and</strong> Held Beveler kit<br />

Kit includes:<br />

High speed air motor<br />

Right angle drive<br />

Chip shield<br />

Chip guard bracket<br />

Hose, 1/2” w/ filter, oiler & 1/2” coupler<br />

Carrying case<br />

Wrench set (17 mm x 17 mm)<br />

Allen wrench set<br />

Operating <strong>and</strong> maintenance instructions<br />

Part No. Cutterheads, 37-1/2 deg.<br />

1050-01 Cutterhead, 1-1/4” (.450” I.D. – 1.250” O.D.) use 1/2” inserts<br />

1050-02 Cutterhead, 1-1/2” (.700” I.D. – 1.500” O.D.) use 1/2” inserts<br />

1050-03 Cutterhead, 1-3/4” (.700” I.D. – 1.750” O.D.) use 5/8” inserts<br />

1050-04 Cutterhead, 2” (.950” I.D. – 2.000” O.D.) use 5/8” inserts<br />

1050-05 Cutterhead, 2-1/4” (1.200” I.D. – 2.250” O.D.) use 5/8” inserts<br />

1050-06 Cutterhead, 2-1/2” (1.450” I.D. – 2.500” O.D.) use 5/8” inserts<br />

1050-07 Cutterhead, 2-3/4” (1.700” I.D. – 2.750” O.D.) use 5/8” inserts<br />

1050-08 Cutterhead, 3” (1.950” I.D. – 3.000” O.D.) use 5/8” inserts<br />

1050-09 Cutterhead, 3-1/4” (2.200” I.D. – 3.250” O.D.) use 5/8” inserts<br />

1050-10 Cutterhead, 3-1/2” (2.450” I.D. – 3.850” O.D.) use 5/8” inserts<br />

1050-11 Cutterhead, 3-3/4” (2.700” I.D. – 3.750” O.D.) use 5/8” inserts<br />

1050-12 Cutterhead, 4” (2.950” I.D. – 4.000” O.D.) use 5/8” inserts<br />

Other angles available<br />

St<strong>and</strong>ard inserts<br />

1050-14 Insert 1/2” double edge for 37-1/2 deg. cutterheads<br />

1050-15 Insert 5/8” double edge for 37-1/2 deg. cutterheads<br />

1050-16 Insert 1/2” 4 edge for 37-1/2 deg. cutterheads<br />

1050-17 Insert 5/8” 4 edge for 37-1/2 deg. cutterheads<br />

1050-18 Screw, for 1/2” insert blade for 37-1/2 deg. cutterheads<br />

1050-19 Screw, for 5/8” insert blade for 37-1/2 deg. cutterheads<br />

Other inserts available, consult factory<br />

Pilots<br />

1050-140 Pilot blank (.400-1.500) available in 1/4” (6.35mm) increments<br />

1050-141 Pilot blank (1.501-2.500) available in 1/4” (6.35mm) increments<br />

1050-142 Pilot blank (2.501-3.500) available in 1/4” (6.35mm) increments<br />

1050-143 Pilot blank (3.501-3.900) available in 1/4” (6.35mm) increments<br />

1050-40 I.D. pilot (range .400-1.500) O.D. & m.w.t., or pipe size & sch. needed<br />

1050-41 I.D. pilot (range 1.501-2.500) O.D. & m.w.t., or pipe size & sch. needed<br />

1050-42 I.D. pilot (range 2.501-3.500) O.D. & m.w.t., or pipe size & sch. needed<br />