31 July 2011 C1 CIVIL AVIATION DEPARTMENT HONG KONG ...

31 July 2011 C1 CIVIL AVIATION DEPARTMENT HONG KONG ...

31 July 2011 C1 CIVIL AVIATION DEPARTMENT HONG KONG ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

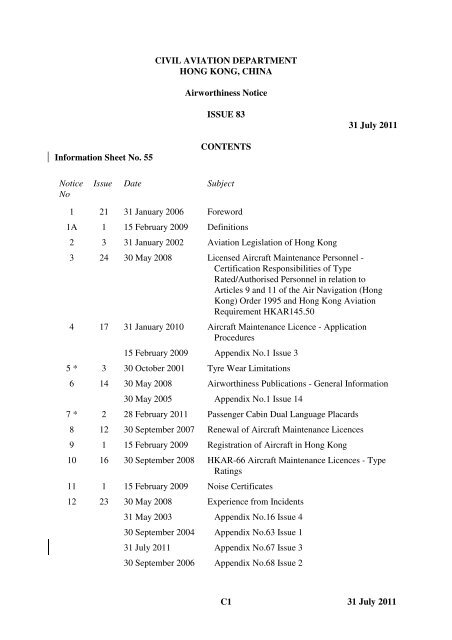

<strong>CIVIL</strong> <strong>AVIATION</strong> <strong>DEPARTMENT</strong><strong>HONG</strong> <strong>KONG</strong>, CHINAAirworthiness NoticeISSUE 83<strong>31</strong> <strong>July</strong> <strong>2011</strong>Information Sheet No. 55CONTENTSNoticeNoIssue Date Subject1 21 <strong>31</strong> January 2006 Foreword1A 1 15 February 2009 Definitions2 3 <strong>31</strong> January 2002 Aviation Legislation of Hong Kong3 24 30 May 2008 Licensed Aircraft Maintenance Personnel -Certification Responsibilities of TypeRated/Authorised Personnel in relation toArticles 9 and 11 of the Air Navigation (HongKong) Order 1995 and Hong Kong AviationRequirement HKAR145.504 17 <strong>31</strong> January 2010 Aircraft Maintenance Licence - ApplicationProcedures15 February 2009 Appendix No.1 Issue 35 * 3 30 October 2001 Tyre Wear Limitations6 14 30 May 2008 Airworthiness Publications - General Information30 May 2005 Appendix No.1 Issue 147 * 2 28 February <strong>2011</strong> Passenger Cabin Dual Language Placards8 12 30 September 2007 Renewal of Aircraft Maintenance Licences9 1 15 February 2009 Registration of Aircraft in Hong Kong10 16 30 September 2008 HKAR-66 Aircraft Maintenance Licences - TypeRatings11 1 15 February 2009 Noise Certificates12 23 30 May 2008 Experience from Incidents<strong>31</strong> May 2003 Appendix No.16 Issue 430 September 2004 Appendix No.63 Issue 1<strong>31</strong> <strong>July</strong> <strong>2011</strong> Appendix No.67 Issue 330 September 2006 Appendix No.68 Issue 2<strong>C1</strong><strong>31</strong> <strong>July</strong> <strong>2011</strong>

NoticeNoIssue Date Subject30 May 2006 Appendix No.69 Issue 114 9 15 November 2010 Approval of Organisations for Maintenance ofAircraft and Components<strong>31</strong> January 2002 Appendix No.1 Issue 530 May 2008 Appendix No.2 Issue 4<strong>31</strong> January 2002 Appendix No.5 Issue 215 7 23 February 2009 Accident and Mandatory Occurrence Reporting16 10 <strong>31</strong> January 2010 The Process for Acceptance of Used Engines,Engine Modules, Auxiliary Power Units(APUs) and Propellers for Use on AircraftRequiring A Hong Kong Certificate ofAirworthiness17 8 <strong>31</strong> January 2010 The Acceptance of Aircraft Components15 November 2010 Appendix No.1 Issue 14<strong>31</strong> January 2002 Appendix No.2 Issue <strong>31</strong>7A 2 <strong>31</strong> January 2010 Acceptance of Aeronautical Products18 2 <strong>31</strong> <strong>July</strong> <strong>2011</strong> Implementation of HKAR-2119 7 15 February 2009 The Problem of Bogus Parts20 * 6 30 May 2006 Cotton, Linen and Synthetic Fabric-coveredAircraft21 1 1 June 1990 Microbiological Contamination of Fuel Tanks ofTurbine Engined Aircraft23 * 1 15 February 2009 Reduced Vertical Separation Minima (RVSM)Operations – Airworthiness Requirement24 * 6 <strong>31</strong> <strong>July</strong> <strong>2011</strong> Airborne Collision Avoidance System (ACAS)and ATC Mode S Transponder26 * 2 30 September 2002 Ground Proximity Warning System27 * 5 <strong>31</strong> January 2007 Emergency Locator Transmitter (ELT)* 30 May 2007 Appendix No.1 Issue 327A 1 <strong>31</strong> January 2005 Guidance on Testing 406 MHz EmergencyLocator Transmitters (ELT)28 11 30 September 2008 Approval of Organisations<strong>31</strong> January 2010 Appendix No.2 Issue 229 8 15 February 2009 Civil Aviation Department Airworthiness Officeand Personnel Licensing Office<strong>31</strong> <strong>July</strong> <strong>2011</strong> C2

NoticeNoIssue Date Subject30 5 30 September 2008 Cooperation Arrangement on Mutual Acceptanceof Approval of Aircraft MaintenanceOrganisations between General Administrationof Civil Aviation of China, Civil AviationDepartment, Hong Kong, China and CivilAviation Authority – Macao, China30A 3 30 September 2008 Technical Arrangement on Aviation Maintenancebetween the Hong Kong Civil AviationDepartment and the Civil Aviation Authority ofSingapore30B 1 30 September 2006 Technical Arrangement on Aircraft Maintenancebetween the Civil Aviation Department ofHong Kong and the Transport Canada CivilAviation Directorate<strong>31</strong> 5 <strong>31</strong> January 2002 Approval of Aircraft Radio Stations35 6 30 May 2005 Light Aircraft Piston Engine Overhaul Periods30 May 2005 Appendix No.1 Issue 430 May 2005 Appendix No.2 Issue 430 May 2005 Appendix No.3 Issue 136 * 16 28 February <strong>2011</strong> Mandatory Modifications, Inspections andChanges to Approved Documentation<strong>31</strong> January 2002 Appendix No.1 Issue 536A * 3 28 February <strong>2011</strong> Least-risk Bomb Location36B * 2 30 September 2003 Cargo Compartment Class Change36C 2 <strong>31</strong> January 2003 Foreign Airspace Authorisation to Fly forDamaged Aircraft36E * 1 30 September 2002 Cockpit Security36F * 6 15 November 2010 Serviceability Checks of Flight Recorders36G * 1 23 February 2009 Operations of Single-engine Turbine-poweredAeroplanes at Night and/or in InstrumentMeteorological Conditions (IMC) andHelicopters in Performance Class 3 in IMCExcept Special Visual Flight Rules (VFR)Flights38 7 <strong>31</strong> January 2005 Painting of Aircraft39 5 <strong>31</strong> January 2002 The Selection and Procurement of ElectronicComponents40 CancelledC3<strong>31</strong> <strong>July</strong> <strong>2011</strong>

NoticeNoIssue Date Subject41 * 5 30 September 2005 Maintenance of Cockpit and Cabin CombustionHeaters and Their Associated Exhaust Systems43 3 30 September 2005 Aircraft Field Loadable Software (FLS) andDatabase Field Loadable Data (DFLD)30 September 2005 Appendix No.1 Issue 144 * 4 <strong>31</strong> January 2002 Gas Turbine Engine Parts Subject to Retirementor Ultimate (Scrap) Lives45 * 4 <strong>31</strong> January 2002 Software Management1 June 1987 Appendix No.1 Issue 145A * 5 <strong>31</strong> January 2003 Software Management and CertificationGuidelines<strong>31</strong> January 2003 Appendix No.1 Issue 4<strong>31</strong> January 2003 Appendix No.2 Issue 347 6 30 September 2006 Licensed Aircraft Maintenance Engineers -Personal Responsibility When Medically Unfitor under the Influence of Drink or Drugs<strong>31</strong> January 2003 Appendix No.1 Issue 249 2 <strong>31</strong> January 2003 Eligibility of Organisations for Design andProduction Approval50 * 5 30 September 2005 Deterioration of Wooden Aircraft Structures52 6 <strong>31</strong> January 2002 Concession Control and Related Certifications53 * 5 <strong>31</strong> January 2004 Vertical Speed Indicators on Imported Aircraft54 4 <strong>31</strong> January 2002 Aircraft, Engine & Variable-Pitch Propeller LogBooks for Aircraft Not Exceeding 2730 KgMTWA55 * 2 30 September 2003 Fuel Tank Safety Review56 * 4 <strong>31</strong> January 2002 Emergency Floor Path Lighting System57 * 4 <strong>31</strong> January 2002 Toilet Flush Motor58 * 5 30 September 2006 Flame Resistant Furnishing Materials59 * 3 <strong>31</strong> January 2002 Aircraft Seats and Berths – Resistance to Fire60 * 4 <strong>31</strong> January 2002 Cabin and Toilet Fire Protection61 * 4 30 May 2006 Improved Flammability Test Standards for CabinInterior Materials62 4 <strong>31</strong> January 2002 Fatigue Lives64 * 4 30 May 2006 Minimum Space for Seated Passengers<strong>31</strong> <strong>July</strong> <strong>2011</strong> C4

NoticeNoIssue Date Subject65 * 1 <strong>31</strong> January 2006 Continuing Airworthiness and Safety Standardsof Passenger Service and In-flightEntertainment Systems* <strong>31</strong> January 2006 Appendix No. 1 Issue 167 * 3 <strong>31</strong> January 2002 Portable Oxygen Equipment Pressure Relief69 4 <strong>31</strong> January 2002 Approval of Test Houses Holding UKASAccreditation70 * 4 30 May 2006 Tyre Bursts in Flight - Inflation Media71 3 30 September 2006 Maintenance Error Management Systems72 2 <strong>31</strong> January 2002 Safety Critical Maintenance Tasks74 5 30 May 2005 Airworthiness Concessions in respect of Aircraftwithout a Hong Kong Type Certificate1 June 1994 Appendix No.1 Issue 230 May 2005 Appendix No.2 Issue 575 * 5 30 May 2004 Maintenance Requirements for Variable PitchPropellers Installed on Aircraft Holding a HongKong Certificate of Airworthiness* 30 May 2004 Appendix No.1 Issue 576 * 3 30 September 2006 Electrical Power Supplies for Aircraft RadioSystems77 * 4 <strong>31</strong> January 2007 Counter/Pointer Altimeters78 1 <strong>31</strong> January 2007 Safety Management Systems79 * 5 30 May 2006 Access to and Opening of Type III and Type IVEmergency Exits80 * 4 <strong>31</strong> January 2002 Class C and D Cargo or Baggage Compartment -Fire Containment Capability81 * 5 30 May 2006 Emergency Power Supply for ElectricallyOperated Gyroscopic Bank and Pitch Indicators(Artificial Horizons)82 * 4 30 May 2006 Electrical Generation Systems - Aircraft NotExceeding 5700 Kg Maximum Total WeightAuthorised83 * 8 <strong>31</strong> <strong>July</strong> <strong>2011</strong> Fire Precautions – Aircraft Toilets84 * 5 15 February 2009 Airborne ILS (Localiser) VOR and VHFCommunication Receivers – Improved FMBroadcast Interference Immunity Standards85 * 2 <strong>31</strong> <strong>July</strong> 2009 HF Communication SystemC5<strong>31</strong> <strong>July</strong> <strong>2011</strong>

NoticeNoIssue Date Subject86 * 1 15 February 2009 Aircraft Equipment87 * 1 15 February 2009 Time-Piece and Rate of Climb and DescentIndicator88 * 4 30 May 2006 Electrical Generation Systems – Bus-bar LowVoltage Warning Single-engined Aircraft witha Hong Kong Certificate of Airworthiness92 * 5 30 May 2006 Cargo Containment94 7 <strong>31</strong> January 2004 Personnel Certification for Non-destructiveTesting of Aircraft, Engines, Components andMaterials30 May 2006 Appendix No.1 Issue 295 5 <strong>31</strong> January 2002 Use of High Intensity Ultra-violet Lamps inFluorescent Penetrant and Magnetic ParticleInspections96 2 <strong>31</strong> January 2002 Disposition of Scrap Aircraft Parts & Materials97 5 15 February 2009 Return to Service of Aircraft Items* Recoveredfrom Aircraft Involved in Accidents/Incidentsand Unserviceable Aircraft99 * 9 30 May 2007 Galley Equipment101 * 1 30 September 2008 Equipment Approval101A* 2 28 February <strong>2011</strong> Safety Belts101B* 1 30 September 2008 Life Jacket101C* 1 30 September 2008 Public Address System101D* 3 <strong>31</strong> <strong>July</strong> <strong>2011</strong> Flight Recorders101E* 2 <strong>31</strong> <strong>July</strong> 2009 First-Aid Kits and Medical Supplies101F* 1 15 February 2009 Helicopters Cabin Crew Seats101G* 1 15 February 2009 Safety Harness102* 1 28 February <strong>2011</strong> Equipment Certification Requirements forOperational Approval102E* 1 28 February <strong>2011</strong> Performance Based Navigation (PBN)102F* 3 <strong>31</strong> <strong>July</strong> <strong>2011</strong> Automatic Dependent Surveillance Broadcast(ADS-B) Out103* 1 <strong>31</strong> <strong>July</strong> <strong>2011</strong> Fuel Tank Flammability Reduction104* 1 <strong>31</strong> <strong>July</strong> <strong>2011</strong> Carriage of Supernumeraries in Cargo Aeroplane<strong>31</strong> <strong>July</strong> <strong>2011</strong> C6

[ * ] : Airworthiness Notices and/or Appendices marked with * constitute the DefinitiveList the compliance status of which are required to be declared for the purpose of issue orrenewal of Certificate of Airworthiness.C7<strong>31</strong> <strong>July</strong> <strong>2011</strong>

<strong>CIVIL</strong> <strong>AVIATION</strong> <strong>DEPARTMENT</strong><strong>HONG</strong> <strong>KONG</strong>, CHINAAirworthiness NoticeNo. 1Issue 21<strong>31</strong> January 2006FOREWORD1 GeneralCAD 455 Airworthiness Notices are issued by the Director-General of Civil Aviationto circulate information to all concerned with the airworthiness of civil aircraft.2 ICAO Compliance Statement to CAD 455 Airworthiness Notices2.1 It is the policy of the Chief Executive to exercise his various discretionarypowers by reference to certain documents with a view to ensuring effectiveimplementation of International Civil Aviation Organisation (ICAO) standards.In order to ensure that all these ICAO standards are reflected in Hong Kongaviation legislation, this ICAO compliance statement to Civil AviationDocument (CAD) CAD 455 is issued.2.2 This document CAD 455 is published in support of the powers of the ChiefExecutive contained in Article 8(3) of the Air Navigation (Hong Kong) Order1995, as amended. The document includes international standards containedin Annexes to the Chicago Convention.2.3 It is the policy of the Chief Executive to have reference to this document whenexercising the discretionary powers referred to above and in particular he willnormally exercise those powers so as to ensure effective implementation ofany such international standards.3 Definition3.1 "Director-General" or "Director" means the Director-General of Civil Aviationwho is authorised for the purpose under the Air Navigation (Hong Kong)Order 1995, as amended by the Chief Executive of Hong Kong SpecialAdministrative Region and includes any person who is delegated for thatpurpose.3.2 "Chief Executive" means the Officer for the time being administering theGovernment of Hong Kong Special Administrative Region.4 Contents List and CancellationsAN-1 P.1<strong>31</strong> January 2006

4.1 The contents list is re-issued with each batch of Notices and gives particularsof all current Notices.4.2 Cancellation of a Notice will be indicated in the contents list by the deletion ofall details except for the number. The word "Cancelled" and the customarymarginal line will be added. At the next issue of the contents list the numberof the cancelled Notice will be removed.5 Arrangement5.1 Each Notice is identified by a number, followed by an issue number and anissue date. This information is listed in sequence in the contents list.5.2 When a procedure, which has already been the subject of a Notice, is changed,the particular Notice is re-issued under the same number, but bearing a newissue number and issue date.5.3 Material differences between issues are marked by marginal lines.5.4 All Notices are concerned with matters affecting the airworthiness of civilaircraft. Notices issued or amended prior to Airworthiness Notice Issue No.62 were printed on colour papers. The colour of paper on which they areprinted indicates the type of information contained therein.(a)Pink paper: Notices covering matters which have a direct effect onairworthiness.(b) Yellow paper: Notices covering administrative and technicalprocedures.(c)White paper: Notices which contain general information onadministrative matters.As of Airworthiness Notice Issue No. 62 dated 30 May 2004, all newly issuedor amended Notices (including Appendices) are to be printed on white papersonly and the colour coding of Notices (and Appendices) as prescribed abovewill cease effect at the same time. All Notices (and Appendices) aredemarcated into two kinds: mandatory or non-mandatory. For Notices (andAppendices) carrying mandatory requirements, the statement "This NoticeGives Details of a Mandatory Action" will appear on the title of the Notice.Notices (and Appendices) previously printed on colour papers will be replacedby white paper Notices at the time they are amended.6 Publication and Distribution6.1 Airworthiness Notices are published on the Hong Kong Civil Aviation<strong>31</strong> January 2006 AN-1 P.2

Department website atwww.cad.gov.hk/english/publications_press_release.html.6.2 As of Airworthiness Notice Amendment Issue No. 68, hardcopy amendmentsto the Hong Kong Airworthiness Notices will no longer be available.Holders of hardcopy Hong Kong Airworthiness Notices should visit the HongKong Civil Aviation Department website, shown in paragraph 6.1 above, forup-to-date Airworthiness Notices.7 EnquiriesAny enquiries regarding supply or technical content of Airworthiness Notices shouldbe made to the Civil Aviation Department, Airworthiness Office, 10/F CommercialBuilding, Airport Freight Forwarding Centre, 2 Chun Wan Road, Chek Lap Kok,Hong Kong.8 CancellationThis Notice cancels Notice No. 1, Issue 20, dated <strong>31</strong> January 2005, which should bedestroyed.Norman LODirector-General of Civil AviationAN-1 P.3<strong>31</strong> January 2006

INTENTIONALLY LEFT BLANK<strong>31</strong> January 2006 AN-1 P.4

<strong>CIVIL</strong> <strong>AVIATION</strong> <strong>DEPARTMENT</strong><strong>HONG</strong> <strong>KONG</strong>, CHINAAirworthiness NoticeNo. 1AIssue 115 February 2009DEFINITIONS1. IntroductionThis Airworthiness Notice is intended to supplement the definitions of terms thatare not included in various airworthiness publications published by CAD.2. DefinitionsThe following terms are defined in current ICAO Standards and RecommendedPractices:Air Operator Certificate. A certificate authorizing an operator to carry outspecified commercial air transport operations.Aircraft Operating Manual. A manual, acceptable to the State of the Operator,containing normal, abnormal and emergency procedures, checklists, limitations,performance information, details of the aircraft systems and other materialrelevant to the operation of the aircraft.Note: The Aircraft Operating Manual is part of the Operations Manual whichcontaining procedures, instructions and guidance for use by operationalpersonnel in the execution of their duties..Altimetry System Error (ASE). The difference between the altitude indicatedby the altimetry display, assuming a correct altimeter barometric setting, and thepressure altitude corresponding to the undisturbed ambient pressure.Auxiliary-Power-Unit (APU). A self-contained power-unit on an aircraftproviding electrical/pneumatic power to aircraft systems during groundoperations.Category A Helicopter. A multi-engine helicopter designed with engine andsystem isolation features specified in Part IVB of ICAO Annex 8 and capable ofoperations using take-off and landing data scheduled under a critical enginefailure concept which assures adequate designated surface area and adequateperformance capability for continued safe flight or safe rejected take-off.AN-1A P.115 February 2009

Category B Helicopter. A single-engine or multi-engine helicopter which doesnot meet Category A standards. Category B helicopters have no guaranteedcapability to continue safe flight in the event of an engine failure, and a forcedlanding is assumed.Critical Power-Unit(s). The power-unit(s) failure of which gives the mostadverse effect on the aircraft characteristics relative to the case underconsideration.Note: On some aircraft there may be more than one equally critical power-unit.In this case, the expression “the critical power-unit” means one of those criticalpower-units.Engine. A unit used or intended to be used for aircraft propulsion. It consists ofat least those components and equipment necessary for functioning and control,but excludes the propeller (if applicable).Final Approach and Take-off Area (FATO). A defined area over which thefinal phase of the approach manoeuvre to hover or landing is completed andfrom which the take-off manoevre is commenced. Where the FATO is to be usedby performance Class 1 helicopters, the defined area includes the rejectedtake-off area available.Fire Resistant. The capability to withstand the application of heat by a flame fora period of 5 minutes.Note: The characteristics of an acceptable flame can be found in ISO 2685.Fireproof. The capability to withstand the application of heat by a flame for aperiod of 15 minutes.Note: The characteristics of an acceptable flame can be found in ISO 2685.Fireproof Material. A material capable of withstanding heat as well as or betterthan steel when the dimensions in both cases are appropriate for the specificpurpose.Flight Recorder. Any type of recorder installed in the aircraft for the purpose ofcomplementing accident/incident investigation.Glider. A non-power-driven heavier-than-air aircraft, deriving its lift in flightchiefly from aerodynamic reactions on surfaces which remain fixed under givenconditions of flight.Ground Handling. Services necessary for an aircraft’s arrival at, and departurefrom, an airport, other than air traffic services.Gyroplane. A heavier-than-air aircraft supported in flight by the reactions of the15 February 2009 AN-1A P.2

air on one or more rotors which rotate freely on substantially vertical axes.Heavier-than-air Aircraft. Any aircraft deriving its lift in flight chiefly fromaerodynamic forces.Integrated Survival Suit. A survival suit which meets the combinedrequirements of the survival suit and life jacket.Landing Surface. That part of the surface of an aerodrome which the aerodromeauthority has declared available for the normal ground or water run of aircraftlanding in a particular direction.Lighter-than-air Aircraft. Any aircraft supported chiefly by its buoyancy inthe air.Navigation Specification. A set of aircraft and aircrew requirements needed tosupport performance-based navigation operations within a defined airspace.There are two kinds of navigation specification:RNAV specification – A navigation specification based on area navigation thatdoes not include the requirement for performance monitoring and alerting,designated by the prefix RNAV, e.g. RNAV 5, RNAV 1.RNP specification - A navigation specification based on area navigation thatdoes not include the requirement for performance monitoring and alerting,designated by the prefix RNP, e.g. RNP 4, RNP APCH.Ornithopter. A heavier-than-air aircraft supported in flight chiefly by thereactions of the air on planes to which a flapping motion is imparted.Performance Class 1 Helicopter. A helicopter with performance such that, incase of engine failure, it is able to land on the rejected take-off area or safelycontinue the flight to an appropriate landing area.Performance Class 2 Helicopter. A helicopter with performance such that, incase of engine failure, it is able to safely continue the flight, except when thefailure occurs prior to a defined point after take-off or after a defined pointbefore landing, in which cases a forced landing may be required.Performance Class 3 Helicopter. A helicopter with performance such that, incase of engine failure at any point in the flight profile, a forced landing must beperformed.Powered-lift. A heavier-than-air aircraft capable of vertical take-off, verticallanding, and low-speed flight, which depends principally on engine-driven liftdevices or engine thrust for the lift during these flight regimes and onnon-rotating aerofoil(s) for lift during horizontal flight.Power-Unit. A system of one or more engines and ancillary parts which areAN-1A P.<strong>31</strong>5 February 2009

together necessary to provide thrust, independently of the continued operation ofany other power-unit(s), but not including short period thrust-producing devices.Pressure-altitude. An atmospheric pressure expressed in terms of altitudewhich corresponds to that pressure in the Standard Atmosphere.Required Communication Performance (RCP). A statement of theperformance requirements for operational communication in support of specificATM functions.Required Communication Performance Type (RCP Type). A label (e.g. RCP240) that represents the values assigned to RCP parameters for communicationtransaction time, continuity, availability and integrity.Rotocraft. A power-driven heavier-than-air aircraft supported in flight byreactions of the air on one or more rotors.Self-sustaining Powered Sailplane. A powered aeroplane with available enginepower which allows it to maintain level flight but not to take off under its ownpower.Standard Atmosphere. An atmosphere defined as follows:a) the air is a perfect dry gas;b) the physical constants are:- Sea level mean molar mass: M 0 = 28.964420 x 10 -3 kg mol -1- Sea level atmospheric pressure: P 0 = 1013.250 hPa- Sea level temperature: t 0 = 15 0 C, T 0 = 288.15 K- Sea level atmospheric density: ρ 0 = 1.2250 kg m -3- Temperature of the ice point: T i = 273.15 K- Universal gas constant: R* = 8.<strong>31</strong>432 JK -1 mol -1c) the temperature gradients are:Geopotential altitude(km)Temperature gradientFrom To (Kelvin per standard geopotential kilometer)-5.0 11.0 -6.511.0 20.0 0.020.0 32.0 +1.032.0 47.0 +2.847.0 51.0 0.051.0 71.0 -2.871.0 80.0 -2.015 February 2009 AN-1A P.4

State of Design. The State having jurisdiction over the organization responsiblefor the type design.State of Manufacture. The State having jurisdiction over the organizationresponsible for the final assembly of the aircraft.State of Registry. The State on whose register the aircraft is entered.Note: In the case of the registration of an international operating agency on otherthan a national basis, the States constituting the agency are jointly and severallybound to assume the obligations which, under the Chicago Convention, attach toa State of Registry. See, in this regard, the Council Resolution of 14 December1967 on Nationality and Registration of Aircraft Operated by InternationalOperating Agencies which can be found in Policy and Guidance Material on theEconomic Regulation of International Air Transport (Doc 9587).Subsonic Aircraft. An aeroplane incapable of sustaining level flight at speedexceeding flight Mach number of 1.Total Vertical Error (TVE). The vertical geometric difference between theactual pressure altitude flown by an aircraft and its assigned pressure altitude(flight level).Norman LODirector-General of Civil AviationAN-1A P.515 February 2009

<strong>CIVIL</strong> <strong>AVIATION</strong> <strong>DEPARTMENT</strong><strong>HONG</strong> <strong>KONG</strong>, CHINAAirworthiness NoticeNo. 2Issue 3<strong>31</strong> January 2002<strong>AVIATION</strong> LEGISLATION OF <strong>HONG</strong> <strong>KONG</strong>NOTE:This Airworthiness Notice was previously entitled ‘Air Navigation (HongKong) Order 1995.1 GeneralCivil Aviation Ordinance (CAP. 448) and Civil Aviation (Aircraft Noise) Ordinance(CAP <strong>31</strong>2) are the primary aviation legislation of Hong Kong. The Ordinancesprovide the legal power for the Director-General to carry out Chicago Convention,any Annex thereto relating to international standards and recommended practices andgenerally for regulating air navigation.2 Civil Aviation Ordinance (CAP. 448)Chapter 448 (CAP. 448) of the Laws of Hong Kong, cited as the Civil AviationOrdinance, is the Ordinance to repeal and re-enact with appropriate modificationscertain provisions relating to civil aviation. The following are the subsidiarylegislation (sub.leg.), being regulations or orders, made under the Ordinance.2.1 CAP 448 sub. leg. A − Air Transport (Licensing of Air Services) RegulationsThese regulations are provisions for the licences and operating permits for thecarriage of passengers, mail or cargo by air for hire or reward on scheduledjourneys and upon journeys other than the scheduled journeys.2.2 CAP. 448 sub. leg. B − Hong Kong Civil Aviation (Investigation of Accidents)Regulations2.2.1 These regulations are provisions for the investigations of any accidentarising out of or in the course of air navigation and occurring in or overHong Kong, or occurring elsewhere to aircraft registered in HongKong.2.2.2 The fundamental purpose of investigating accidents under theseregulations shall be to determine the circumstances and causes of theaccident with a view to the preservation of life and the avoidance ofaccidents in the future; it is not the purpose to apportion blame orAN-2 P.1<strong>31</strong> January 2002

liability.2.3 CAP. 448 sub. leg. C − Air Navigation (Hong Kong) Order 1995The Air Navigation (Hong Kong) Order 1995 (AN(HK)O) is the Order withprovisions made for regulating air navigation.2.3.1 The AN(HK)O consists of the following ten parts and sixteenschedules:Part I− Registration and Marking of AircraftPart II − Air Operators' CertificatesPart III − Airworthiness and Equipment of AircraftPart IV − Aircraft Crew and LicensingPart V − Operation of AircraftPart VI − Fatigue of CrewPart VII − Documents and RecordsPart VIII− Control of Air TrafficPart IX − Aerodromes, Aeronautical Lights and Dangerous LightsPart X − GeneralSchedule 1− Part A. Table of General Classification of AircraftPart B. Nationality and Registration Marks ofAircraft Registered in Hong KongPart C. Aircraft Dealer's Certificate – ConditionsSchedule 2Schedule 3Schedule 4Schedule 5Schedule 6− A and B Conditions− Categories of Aircraft− Aerodome Manual− Aircraft Equipment− Radio and Radio Navigation Equipment to be carriedin Aircraft<strong>31</strong> January 2002 AN-2 P.2

Schedule 7Schedule 8Schedule 9− Aircraft, Engine and Propeller Log Books− Areas Specified in connection with the Carriage ofFlight Navigators as Members of the Flight Crews orApproved Navigational Equipment on PublicTransport Aircraft− Flight Crew of Aircraft, Licences and RatingsSchedule 10 − Aircraft Traffic Controllers: RatingsSchedule 11 − Public Transport - Operational RequirementsSchedule 12 − Documents to be carried by Aircraft Registered inHong KongSchedule 13 − PenaltiesSchedule 14 − Rules of the AirSchedule 15 − Air Navigation (General) RegulationsSchedule 16 − The Air Navigation (Dangerous Goods) Regulations2.4 CAP. 448 sub. leg. D − Hong Kong Air Navigation (Fees) RegulationsThese regulations provide the fees payable to the Hong Kong SpecialAdministrative Region Government in connection with matters prescribed byor under the Air Navigation (Overseas Territories)) Order 1977.2.5 CAP. 448 sub. leg. E − Air Navigation (Flight Prohibition) OrderThis Order is made to give provisions on aircraft flying over Prohibition Area.2.6 CAP. 448 sub. leg. F − Civil Aviation (Insurance) OrderThis Order is made to give provisions on aircraft insurance.3 Civil Aviation (Aircraft Noise) Ordinance (CAP. <strong>31</strong>2)The Civil Aviation (Aircraft Noise) Ordinance is made to control the emission ofnoise by aircraft and for matters ancillary thereto or connected therewith. There arethree subsidiary legislation made to the Ordinance:(1) Civil Aviation (Aircraft Noise) (Certification) RegulationsAN-2 P.3<strong>31</strong> January 2002

(2) Civil Aviation (Aircraft Noise) (Limitation on Operation of Engines andAuxiliary Power Units) Regulations(3) Civil Aviation (Aircraft Noise) (Limitation on Landing or Taking Off ofAircraft) Notice4 Publication4.1 The loose-leaf edition of the CAP.448 and CAP.<strong>31</strong>2 may be ordered from theGovernment Publication Centre of the Information Services Department atthe following address: Government Publication Centre, Low Block, GroundFloor, Queensway Government Offices, 66 Queensway, Hong Kong. Theymay also be ordered on line at http://bookstore.esdlife.com.4.2 The CAP. 448 and CAP. <strong>31</strong>2, together with other Chapters of the Laws ofHong Kong are available in the Bilingual Laws Information System (BLIS) onInternet at http//www.justice.gov.hk for easy access by the general public. Theamendments to the Laws of Hong Kong are notified by means of theGovernment of the Hong Kong Special Administrative Region Gazetteavailable on Internet at http//ww.info.gov.hk..5 CancellationThis Notice cancels Airworthiness Notice No. 2 Issue 2, dated 1 November 1996,which should be destroyed.Albert K. Y. LAMDirector-General of Civil Aviation<strong>31</strong> January 2002 AN-2 P.4

<strong>CIVIL</strong> <strong>AVIATION</strong> <strong>DEPARTMENT</strong><strong>HONG</strong> <strong>KONG</strong>, CHINAAirworthiness NoticeNo. 3Issue 2430 May 2008LICENSED AIRCRAFT MAINTENANCE PERSONNEL–CERTIFICATIONRESPONSIBILITIES OF TYPE RATED/AUTHORISED PERSONNEL INRELATION TO ARTICLES 9 AND 11 OF THE AIR NAVIGATION (<strong>HONG</strong> <strong>KONG</strong>)ORDER 1995 AND <strong>HONG</strong> <strong>KONG</strong> <strong>AVIATION</strong> REQUIREMENT HKAR145.501 GeneralThe purpose of this Notice is to describe the certification responsibilities of LicensedAircraft Maintenance Personnel. Such personnel are the holders of an AircraftMaintenance Licence issued under HKAR-66. The responsibilities apply whenissuing certifications either as a Type Rated licence holder or a certifying staffholding a certification authorisation. It also describes the privileges of the variousType Rated licences.It should be noted that where the holder of a licence is performing maintenanceactivities on an aircraft on which he or she is not appropriately licensed, i.e. acting asa non-certifying staff, they are still expected to act responsibly and carry out suchwork in accordance with the procedures and standards identified in the followingparagraphs.A licence issued by the Director-General does not confer any certification privilegeswith respect to aircraft which are not registered in Hong Kong unless the licenceholder is entitled to certify for such activities by way of having the licence validatedby the relevant Airworthiness Authority and/or is authorised by a maintenanceorganisation approved by that Authority.NOTES: (1) A HKAR-66 Aircraft Maintenance Licence does not normally confer anycertification privileges on the holder in their own right (except for that allowed underAirworthiness Notice No. 10). Such licence must be used in conjunction with acertification authorisation. See paragraph 1.10.(2) In the context of this Notice, reference to an authorisation means an authorisationissued by a HKAR-145 approved maintenance organisation approved by theDirector-General to allow the holder to issue certifications within the limitationsshown on the authorisation.1.1 The Certificate referred to under Article 9 of the Air Navigation (Hong Kong)Order 1995 as amended is a Certificate of Maintenance Review to be issuedAN-3 P.130 May 2008

following completion of the review required by the Order. The certificatereferred to under Article 11 of the Air Navigation (Hong Kong) Order 1995 asamended is a Certificate of Release to Service to be issued on completion ofmaintenance of aircraft or components, either required or not required to bemaintained under the provisions of HKAR-145.1.2 In connection with the issue of Certificates of Release to Service, thefollowing definitions apply:(a)(b)(c)(d)(e)(f)Maintenance means any one or combination of overhaul, repair,inspection, replacement, modification or defect rectification of anaircraft/aircraft component.Overhaul means the restoration of an aircraft/aircraft component byinspection and replacement in conformity with an approved standard toextend the operational life.Repair means the restoration of an aircraft/aircraft component to aserviceable condition in conformity with an approved standard.Inspection means the examination of an aircraft/aircraft component toestablish conformity with an approved specification.Replacement is any work operation which involves the removal andreplacement of the same part or the substitution of an approvedalternative part.Modification means the alternation of an aircraft/aircraft componentin conformity with an approved standard.NOTE 1:NOTE 2:Defect rectification normally consists of an element of inspection andtroubleshooting followed by repair and replacement of the defective item.Inspection includes:(i) Mandatory Inspection, an inspection classified as Mandatory by theDirector-General, where the inspection itself is the work. (SeeAirworthiness Notice No.36).(ii) Scheduled Maintenance Inspection, an inspection or maintenanceincluding tests required by the Approved Maintenance Schedule orProgramme.1.3 Although many terms in common usage describe the various aspects ofaircraft engineering, the meanings assigned to such terms are not always thesame. For the purpose of this Notice, in relation to airworthiness, thefollowing definitions apply:(a) Condition – the physical state of an item.30 May 2008 AN-3 P.2

(b) Assembly – that items are fitted, assembled, attached, installed,connected, secured or adjusted in the approvedmanner.(c)Functioning – operation in the approved manner achieving suchperformance, range of movement and freedom ofmovement as may be specified.The certifying staff shall be responsible for the condition, assembly andfunctioning of the aircraft or its components for maintenance that has beencertified under the privileges of a Type Rated licence or an authorisation.1.4 The certifying staff shall be responsible for ensuring that work is performedand recorded in a satisfactory manner taking into account the following:(a)(b)(c)Whenever work is carried out on an aircraft, it is the duty of all personsto whom this Notice applies to ensure that the work, for which they areresponsible, progresses in a managed and controlled manner. Wherethey are supported by additional staff to carry out the work,consideration shall be given by them before starting the work to themanpower resource available and the abilities of the staff concerned.This is to ensure that the certifying staff determines and exercises anadequate degree of supervision over such staff.In relation to work carried out on an aircraft, it is the duty of allpersons to whom this Notice applies to ensure that an adequate recordof the work carried out is maintained. This is particularly importantwhere such work carries on beyond a working period or shift, or ishanded over from one person to another. The work accomplished,particularly if only disassembly or disturbance of components oraircraft systems, should be recorded as the work progresses or prior toundertaking a disassociated task. In any event, records should becompleted no later than the end of the work period or shift of theindividual undertaking the work. Such records should include 'open'entries to reflect the remaining actions necessary to restore the aircraftto a serviceable condition prior to release. In the case of complextasks which are undertaken frequently, consideration should be givento the use of pre-planned stage sheets to assist in the control,management and recording of these tasks. Where such sheets areused, care must be taken to ensure that they accurately reflect thecurrent requirements and recommendations of the manufacturer andthat all key stages, inspections, or replacements are recorded.It is also the duty of all persons to whom this Notice applies toconsider the effect such work may have, directly or indirectly, on itemswhich are the responsibilities of other such persons. In all casesAN-3 P.330 May 2008

where an overlap of responsibility between licence categories occurs,the person primarily responsible for the item must involve all othertrade disciplines affected. Every person to whom this Notice appliesmust therefore be conversant with all other relevant paragraphs of thisNotice. Certificates of Release to Service for each relevant tradecategory must be issued by all persons concerned, each assumingresponsibility of and certifying those aspects of the work for which thelicence/authorisation holder is entitled to assume responsibility.1.5 A Certificate of Release to Service shall only be issued on completion ofmaintenance when the signatory is satisfied that the work has been properlycarried out and accurately recorded, having due regard to the use of:(a)(b)(c)up-to-date instructions and maintenance data (including manuals,drawings, specifications, CAD mandatory modifications/inspections,and, where applicable, company procedures);recommended tooling and test equipment which is currently calibratedwhere applicable; anda working environment appropriate to the work being carried out.When issuing a Certificate of Release to Service for work performed by others,the certifying staff assumes responsibility. The certifying staff must haveinspected a sufficiently representative sample of the work and the associateddocumentation, and be satisfied with the competence of the persons who haveperformed the work. For complex tasks this may require progressiveinspections to be carried out as the work proceeds. In the case of an aircraftor component where welding a metallic part is considered essential toairworthiness, it is the responsibility of the certifying staff to establish that thewelder is approved in accordance with the requirements in HKAR-1Sub-section 1.8-10.NOTE: HKAR-66 Aircraft Maintenance Licence holders certifying under the privileges oftheir licence may not deviate from the manufacturer's maintenance instruction ormaintenance data, nor use alternative parts, components or assemblies unless suchdeviation is supported by the written agreement of the manufacturer, approved as amodification or agreed by the Director-General. The Director-General should beconsulted in cases of difficulty. Certifying staff shall comply with all companyprocedures covering such issues.1.6 (a) When the work involves the assembly or any disturbance of a vitalpoint defined in HKAR-1 Sub-section 1.5-3 or control system, theduplicate inspection required must be completed and certified inaccordance with HKAR-1 Sub-section 1.6-2 before the relevantCertificate of Release to Service is issued.30 May 2008 AN-3 P.4

(b)The holder of a Type Rated HKAR-66 Licence in Category B1 maymake certification on aircraft (or their engines, as appropriate) below5700 kg Maximum Total Weight Authorized for Duplicate Inspectionsof minor adjustments to control systems on other types within theCategory in which the licence is Type Rated.NOTE: A minor adjustment is considered to be a single point adjustment orreassembly of a control.1.7 The holder of an appropriately Type Rated HKAR-66 licence in Category B1may issue a Certificate of Release to Service to cover Non Destructive TestInspections on aircraft or components, within the privileges of the licence orauthorisation held, subject to the work being carried out as follows:(a)(b)Inspection requiring the use of Field Kit for the Colour Contrast DyePenetrant technique may be carried out by persons either Type Ratedas above or persons qualified in accordance with Airworthiness NoticeNo. 94.Non Destructive Test Inspections requiring any other technique,including Fluorescent Penetrant Dye, shall be carried out and signedfor by persons appropriately qualified in accordance withAirworthiness Notice No. 94 prior to the issue of the Certificate ofRelease to Service by a licensed or authorised certifying staff.1.8 Use of either a Type Rated licence or an authorisation to issue a certificationrequires that, in addition to the licence or authorisation being valid at the timeof certification, the holder has been engaged for periods totalling at least 6months during the 24 months preceding the date of the certification on workaffording experience comparable with that required for the grant of thelicence/authorisation.1.9 A Type Rated licensed certifying staff may issue the certificates identifiedbelow in relation to aircraft for which the licence is Type Rated and inaccordance with the privileges detailed in the remaining paragraphs to thisNotice. An authorised certifying staff may only issue these certificates aspermitted within the limitations shown on the authorisation.(a)(b)Certificates of Release to Service for aircraft not required to bemaintained under HKAR-145 — the holder of an appropriately TypeRated licence may issue Certificates of Release to Service subject tocompliance with the requirements of HKAR-1 Sub-section 1.6-2 and1.6-7.Certificate of Maintenance Review — the Director-General willspecify who may issue a Certificate of Maintenance Review. For anorganisation approved in accordance with HKAR-145 the signatoryAN-3 P.530 May 2008

will be a person authorised in accordance with the Appendix No.3 toSub-section 1.8-13. For all other cases the signatory will be anengineer possessing an appropriately type rated HKAR-66 Category Bor C Licence valid in the sub-category of the aircraft reviewed.(c)Certificates of Fitness for Flight — the holder of an appropriatelyType Rated HKAR-66 licence in Category B1 may issue Certificatesof Fitness for Flight subject to compliance with the Appendix No.3 toSub-section 1.8-13.1.10 HKAR-66 Aircraft Maintenance Licences (Aircraft Maintenance Licence withType Ratings, if applicable) may be used to allow the grant of an authorisationwithin a HKAR-145 approved maintenance organisation. In addition to theforegoing paragraphs, when working within such organisations, the licensedcertifying staff should be aware that he/she is part of a comprehensivemaintenance system. It is therefore important to realise that companyprocedures may further define, or require specific actions, as to how certainissues are to be dealt with and these procedures must be adhered to. It is alsoimportant to realise that when working within a HKAR-145 approvedmaintenance organisation and certifying under the privileges of anauthorisation the licensed certifying staff is not certifying under the privilegesof the licence.2 Compass Compensation and AdjustmentThe Paragraph 15 Type Rating of Airworthiness Notice No. 10 permits the issue ofCertificates of Release to Service by the holder in respect of the compensation andadjustment of direct and remote reading compasses on any aircraft not subject to therequirements of HKAR-1 Sub-section 1.8-13.3 HKAR-66 Category A Aircraft Maintenance Licence3.1 A HKAR-66 Category A Aircraft Maintenance Licence may be issued to aperson who has demonstrated a competence to complete minor scheduled linemaintenance and simple defect rectification. The licence does not entitle theholder to exercise any certification privileges in respect of aircraft unless anduntil the holder is issued with a corresponding certification authorisation.Such authorisations will be issued by a HKAR-145 maintenance organisationappropriately approved by the Director-General.NOTE: The holder of a HKAR-66 Category B1 licence is also qualified as a HKAR-66Category A licence holder in the same sub-category, e.g. Aeroplanes Turbine, andmay be issued with HKAR-66 Category A certification authorisation.3.2 These HKAR-66 Category A privileges will be limited to the performance andcertification of specific simple maintenance tasks, either individually or incombination, as defined in HKAR-145 AMC 145.30(g) and will require a30 May 2008 AN-3 P.6

combination of theoretical and practical training to be undertaken on eachaircraft type to qualify for the task authorisation. Such authorisation, issuedby a HKAR-145 approved maintenance organisation will specify thelimitations of the privileges that may be applicable. HKAR-66 licenceholders will therefore be required to act in accordance with the authorisationprocedures of the company concerned.3.3 HKAR-66 Category A licences are issued in licence sub-categories which are:A1A2A3A4Aeroplanes TurbineAeroplanes PistonHelicopters TurbineHelicopters Piston4 HKAR-66 Category B1 Aircraft Maintenance Licence4.1 A HKAR-66 Category B1 Aircraft Maintenance Licence may be issued to aperson who has demonstrated a competence to complete maintenance,including aircraft structure, powerplant and mechanical and electrical systems.Replacement of avionic line replaceable units, requiring simple tests to provetheir serviceability, shall also be included in the privileges. The HKAR-66Category B1 licence is primarily intended to be used for the purposes ofqualification of line maintenance staff for authorisation. The licence, in itsown right, does not entitle the holder to exercise any certification privileges inrespect of aircraft and will be used in conjunction with a HKAR-145certification authorisation.4.2 Such authorisation will be issued by a HKAR-145 maintenance organisationappropriately approved by the Director-General. HKAR 145.30(g) requiresit to be used as a prerequisite for authorisation of staff acting as inspectors orsupervisors within base maintenance (base maintenance technicians).HKAR-66 licence holders will therefore act in accordance with theauthorisation procedures of the company concerned.4.3 HKAR-66 Category B1 licences apply to all aircraft (aeroplanes andhelicopters) and are issued in licence sub-categories which are:B1.1 Aeroplanes TurbineB1.2 Aeroplanes PistonB1.3 Helicopters TurbineB1.4 Helicopters PistonNOTES:(1) An unrestricted Category B1 sub-category entitles the holder to be grantedCategory A certification authorisations in the same sub-category, e.g.Aeroplanes Turbine.(2) An unrestricted Category B1.2 sub-category permits the holder to begranted Category B3 certification authorisations.AN-3 P.730 May 2008

(3) An unrestricted Category B1.2 or B3 sub-category permits the holder toissue Certificates of Release to Service for simple light aeroplanes after abase maintenance check in the case that such aeroplanes are maintained in aHKAR-145 organisation,4.4 HKAR-66 Category B1 certification authorisations allow the holder to issueCertificates of Release to Service under HKAR 145.50 for line maintenanceon aircraft which are endorsed as individual types on the licence and thecorresponding authorisation. HKAR-66 Category B1 licences to the fullHKAR-66 standard include scope to allow the issue of a certificationauthorisation covering work on a combination of the following disciplines:• airframe and their related systems;• engines and their related systems (including Auxiliary Power Units);• electrical power generation and distribution systems (power distribution inrespect of airframe and/or engine systems) including lighting systems (thisincludes all electrical components in mechanical systems such as sensors,motors and control units);• avionic line replaceable units (LRU).In respect of avionic LRUs, the work is limited to cases where theserviceability of the system can be established by a simple self test facility(BITE) or by using simple test equipment and it is expected that, for referencepurposes, a list of such components will be prepared for each aircraft type bythe HKAR-145 approved maintenance organisation. (Defect rectification onavionic systems which requires an element of decision making in itsapplication – other than a simple go/no go decision – cannot be certified).NOTE: The HKAR-66 Category B1 licence holder is not entitled to certify for any overhaulwork.4.5 The certification authorisation can only be issued by a HKAR-145 approvedmaintenance organisation when the HKAR-66 Aircraft Maintenance holderhas the appropriate basic sub-category listed and the aircraft type ratingendorsed on the licence. The type training for a HKAR-66 Category B1 typeendorsement, conducted under a HKAR-147 approval, will represent theappropriate technologies as specified in HKAR-66. The certificationauthorisation will specify the privileges for the individual, giving due regardto the company scope of approval and any associated procedures agreed withthe Director-General, and will specify any limitations to the authorisationaccordingly.NOTE: A HKAR-66 licence issued on the basis of 'protected rights' may contain technicalrestrictions equivalent to the limitations of any HKAR-AMEL licence or companyauthorisations previously held. These 'protected rights' under HKAR-66 are a30 May 2008 AN-3 P.8

continuation of certification privileges under an existing licence or certificationauthorisation which allows current personnel to continue working and certifyingwithout the need to re-qualify. The recognition of these privileges is shown by theinclusion of code 999 against that type rating. Authorisations issued by a HKAR-145approved maintenance organisation should therefore be similarly restricted in scope.It should be noted that conversion to the full HKAR-66 licence standard is optional.4.6 HKAR-66 Category B1 licences may also be issued with an endorsementallowing the certification, under the provisions of Articles 9 and 11 of the AirNavigation (Hong Kong) Order 1995 as amended, for work outside of aHKAR-145 approved maintenance organisation on aircraft which are notoperated for commercial air transport. Such privileges are limited to HongKong registered aircraft only. Certifications may only be made for thoseaircraft types which are endorsed individually or as Group Type Ratings onthe licence. The privileges of the endorsement will reflect the certificationlimitations on the licence.5 HKAR-66 Category B2 Aircraft Maintenance Licence5.1 A HKAR-66 Category B2 Aircraft Maintenance Licence may be issued to aperson who has demonstrated a competence to complete maintenance onavionic and electrical systems. The HKAR-66 Category B2 licence isprimarily intended to be used for the purposes of qualification of avionic linemaintenance staff for authorisation. The licence, in its own right, does notentitle the holder to exercise any certification privileges in respect of aircraftand will be used in conjunction with a HKAR-145 certification authorisation.5.2 Such authorisations will be issued by a HKAR-145 maintenance organisationappropriately approved by the Director-General. HKAR 145.30(g) alsorequires it to be used as a prerequisite for authorisation of staff acting asinspectors or supervisors within base maintenance (base maintenancetechnician). HKAR-66 licence holders will therefore act in accordance withthe authorisation procedures of the company concerned.NOTE: A HKAR-66 Category B2 licence cannot be used for the purposes of a HKAR-66Category A certification authorisation unless the HKAR-66 Category A licence isalso held.5.3 HKAR-66 Category B2 certification authorisations allow the holder to issueCertificates of Release to Service under HKAR 145.50 for the linemaintenance on aircraft which are endorsed as individual types on the licenceand the corresponding authorisation. HKAR-66 Category B2 licences to thefull HKAR-66 standard include scope to allow the issue of a certificationauthorisation covering work on a combination of the following aircraftsystems:• instruments;AN-3 P.930 May 2008

• automatic pilots (aeroplanes, helicopters and autoland systems);• radio communication/navigation;• radio radar;• electrical power generation and distribution systems (powerdistribution in respect of avionic systems) including lightingsystems.Scope is not included for authorisation in respect of work on electrical powerdistribution systems or electrical/avionic components in mechanical systems.(Licences issued on the basis of 'protected rights' may include such scopewhere so endorsed.)NOTE: The HKAR-66 Category B2 licence holder is not entitled to certify for any overhaulwork.5.4 The certification authorisation can only be issued by a HKAR-145 approvedmaintenance organisation when the licence holder has the appropriate basicHKAR-66 Category B2 listed and the aircraft type rating endorsed on theHKAR-66 Aircraft Maintenance Licence. The type training for a HKAR-66Category B2 type endorsement, conducted under a HKAR-147 approval, willrepresent the appropriate technologies as specified in HKAR-66. Thecertification authorisation will specify the privileges for the individual, givingdue regard to the company scope of approval and any associated proceduresagreed with the Director-General, and will specify any limitations to theauthorisation accordingly.NOTE: A HKAR-66 licence issued on the basis of 'protected rights' may contain technicalrestrictions equivalent to the limitations of any HKAR-AMEL licence or companyauthorisations previously held. These 'protected rights' under HKAR-66 are acontinuation of certification privileges under an existing licence or certificationauthorisation which allows current personnel to continue working and certifyingwithout the need to re-qualify. The recognition of these privileges is shown by theinclusion of code 999 against that type rating. Authorisations issued by a HKAR-145approved maintenance organisation should therefore be similarly restricted in scope.It should be noted that conversion to the full HKAR-66 licence standard is optional.5.5 HKAR-66 Category B2 licences may also be issued with an endorsementallowing the certification, under the provisions of Articles 9 and 11 of the AirNavigation (Hong Kong) Order 1995 as amended, for work outside of aHKAR-145 approved maintenance organisation on aircraft which are notoperated for commercial air transport. Such privileges are limited to HongKong registered aircraft only. Certification may only be made for thoseaircraft types which are endorsed individually or as Group Type Ratings onthe licence. The privileges of the endorsement will reflect the certificationlimitations on the licence.30 May 2008 AN-3 P.10

6 HKAR-66 Category B3 Aircraft Maintenance Licence6.1 A HKAR-66 Category B3 Aircraft Maintenance Licence may be issued to aperson who has demonstrated a competence to act in the role of a certifyingengineer for maintenance of simple light aeroplanes. The licence, in its ownright, does not entitle the holder to exercise any certification privileges inrespect of aircraft and will be used in conjunction with a HKAR-145certification authorisation.NOTE: HKAR-145 does not require a HKAR-66 Category C certifying staff for thecertification of simple light aeroplanes as Category B1.2 or B3 covers allmaintenance.6.2 Such authorisations will be issued by a HKAR-145 maintenance organisationappropriately approved by the Director-General.NOTE: A HKAR-66 Category B3 licence cannot be used for the purpose of a HKAR-66Category A certification authorization unless the Category A licence is also held.6.3 HKAR-66 Category B3 certification authorisations allow the holder to issueCertificates of Release to Service under HKAR 145.50 for maintenance onsimple light aeroplanes which are endorsed as individual aeroplane types,aeroplane manufacturers group types, aeroplane group types and/or woodenaeroplane group types on the licence and the corresponding authorisation.HKAR-66 Category B3 licences to the full HKAR-66 standard include scopeto allow the issue of a certification authorisation covering work on acombination of the following disciplines:• airframe and their related systems;• engines and their related systems;• electrical power generation and distribution systems (power distribution inrespect of airframe and/or engine systems) including lighting systems;• avionic line replaceable units (LRU).In respect of avionic LRUs, the work is limited to cases where theserviceability of the system can be established by a simple self test facility(BITE) or by using simple test equipment and it is expected that, for referencepurposes, a list of such components will be prepared for each aircraft type bythe HKAR-145 approved maintenance organisation. (Defect rectification onavionic systems which requires an element of decision making in itsapplication – other than a simple go/no go decision – cannot be certified).NOTE: The HKAR-66 Category B3 licence holder is not entitled to certify for any overhaulwork.AN-3 P.1130 May 2008

6.4 The certification authorisation can only be issued by a HKAR-145 approvedmaintenance organisation when the licence holder has the appropriate basicHKAR-66 Category listed and the aircraft type rating endorsed on theHKAR-66 Aircraft Maintenance Licence. The type training for a HKAR-66Category B3 type endorsement, conducted under a HKAR-147 approval, willrepresent the appropriate technologies as specified in HKAR-66. Thecertification authorisation will specify the privileges for the individual, givingdue regard to the company scope of approval and any associated proceduresagreed with the Director-General, and will specify any limitations to theauthorization accordingly.NOTE: A HKAR-66 licence issued on the basis of 'protected rights' may contain technicalrestrictions equivalent to the limitations of any HKAR-AMEL licence or companyauthorisations previously held. These 'protected rights' under HKAR-66 are acontinuation of certification privileges under an existing licence or certificationauthorisation which allows current personnel to continue working and certifyingwithout the need to re-qualify. Authorisations issued by a HKAR-145 approvedmaintenance organisation should therefore be similarly restricted in scope. Itshould be noted that conversion to the full HKAR-66 licence standard is optional.6.5 HKAR-66 Category B3 licences may also be issued with an endorsementallowing the certification, under the provisions of Articles 9 and 11 of the AirNavigation (Hong Kong) Order 1995 as amended, for work outside of aHKAR-145 approved maintenance organisation on aircraft which are notoperated for commercial air transport. Such privileges are limited to HongKong registered aircraft only. Certifications may only be made for thoseaircraft types which are endorsed individually or as Group Type Ratings onthe licence. The privileges will reflect the limitations for the relevant licencecategories.7 HKAR-66 Category C Aircraft Maintenance Licence7.1 A HKAR-66 Category C Aircraft Maintenance Licence may be issued to aperson who as demonstrated a competence to release an aircraft followingBase Maintenance. The privileges apply to the aircraft in its entirety in aPart-145 organisation. The licence, in its own right, does not entitle theholder to exercise any certification privileges in respect of aircraft and will beused in conjunction with a HKAR-145 certification authorisation.NOTE: HKAR-145 does not require a HKAR-66 Category C certifying staff for thecertification of simple light aeroplanes as Category B1.2 or B3 covers allmaintenance.7.2 Such authorisations will be issued by a HKAR-145 maintenance organisationappropriately approved by the Director-General. HKAR-66 licence holderswill therefore act in accordance with the authorisation procedures of thecompany concerned.7.3 HKAR-66 Category C certification authorisations allow the holder to issue30 May 2008 AN-3 P.12

Certificates of Release to Service under HKAR 145.50 following thecompletion of base maintenance on aircraft which are endorsed on the licenceand the corresponding authorisation as individual types. Such persons are inessence certifying for the completion of the process associated with basemaintenance and are supported by appropriately qualified and experiencedHKAR-66 Categories B1 and B2 staff who will inspect and supervise theactual work. The scope of coverage therefore reflects the whole aircraft andis not limited to certification of solely mechanical or avionic systems.7.4 It should be noted that a HKAR-66 Category C licence holder cannot beauthorised to act as a line maintenance certifying engineer, exercising linemaintenance certification privileges, nor conducting base maintenance, in therole of an inspector or supervisor clearing individual tasks, unless the licenceis also endorsed with the appropriate HKAR-66 Category B1 and/or B2licence with the relevant type rating endorsements.7.5 The certification authorisation can only be issued by a HKAR-145 approvedmaintenance organisation when the HKAR-66 licence holder has the basicCategory C listed and the aircraft type rating endorsed on the HKAR-66Aircraft Maintenance Licence. The type training for a HKAR-66 Category Ctype endorsement, conducted under a HKAR-147 approval, will represent theappropriate mix of systems knowledge as specified in HKAR-66. Thecertification authorisation will specify the privileges for the individual, givingdue regard to the company scope of approval and any associated proceduresagreed with the Director-General.8 HKAR-66 GeneralNOTE: A person qualified to HKAR-66 Category B1 or B2 level with type endorsementswill also be eligible for a Category C type authorisation, providing the basicHKAR-66 Category C licence is held.Holders of HKAR-66 Aircraft Maintenance Licence with type endorsements may berequired to undertake appropriate differences type training where the aircraft type to beauthorised embodies significant variations in the equipment fitted or the aircraft systemsconfiguration. The responsibility for determining the training to be undertaken willremain with the HKAR-145 approved maintenance organisation.9 CancellationThis Notice cancels Airworthiness Notice No. 3 Issue 23, dated <strong>31</strong> January 2006, whichshould be destroyed.Norman LODirector-General of Civil AviationAN-3 P.1330 May 2008

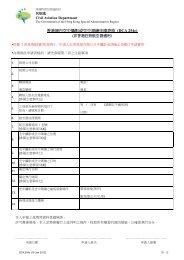

<strong>CIVIL</strong> <strong>AVIATION</strong> <strong>DEPARTMENT</strong><strong>HONG</strong> <strong>KONG</strong>, CHINAAirworthiness NoticeNo. 4Issue 17<strong>31</strong> January 2010AIRCRAFT MAINTENANCE LICENCEAPPLICATION PROCEDURES1 General1.1 No person has a right to obtain a Hong Kong Aircraft Maintenance Licence(AML) without undergoing such examinations as the Director-General mayrequire.1.2 The procedure for the application of an HKAR-66 Aircraft MaintenanceLicence is described in the current issue of HKAR-66 and HKAR-2 Chapter22. The procedure and basis for the licence examination is described in theHKAR-2 Chapter 23. Additional information, such as examination scheduleand application forms, can be downloaded from the CAD website or obtainedfrom the CAD Personnel Licensing Office. Refer Airworthiness Notice No.29 for details. The purpose of this notice is to clarify certain aspects of therequirements for the application and issue/extension of a licence.2 Record of Experience2.1 Record of Experience form DCA35B will be required together with theappropriate application and other supporting documentation for both basiccategories and type rating licences.2.2 The content of the Record of Experience shall be in accordance with theAppendix 4 of HKAR-66, and the sub-headings used for clarification andsubsequent ease of assessment. The Record of Experience should havesufficient depth to reflect the system complexity of different subjects andadequate coverage of relevant ATA chapters.2.3 Applicant has to meet the experience requirements as per HKAR 66.30 beforethe issue/extension of the AML. The Record of Experience can be submittedtogether with the application for examination or application for licenceissue/extension when the applicant has passed the required examinations.AN-4 P.1<strong>31</strong> January 2010

3 Application3.1 The following application forms are used:Form DCA 35EForm DCA 35Application for examinationApplication for issue/extension of licence3.2 The completed form DCA35 or DCA35E, together with the Record ofExperience form or CAD approved log book should be submitted to thePersonnel Licensing Office. Original documents pertaining apprenticeships,completion of aeronautical engineering courses, licences granted by otherAviation Authorities and professional qualifications should be submitted to theDirector-General in support of the application where relevant. Thesedocuments will be returned after assessment. For certain certificates andqualifications, the Director-General may grant partial exemption from thelicence examinations. For general application for examination, theapplication forms must be received by Personnel Licence Office two monthsbefore the intended examination date. For applications for licenceconversion examination, the application forms must be received by PersonnelLicence Office three months before the intended examination date. ThePersonnel Licence Office will notify the applicant about the examination timeand venue arrangement four weeks in advance.3.3 Applicants should have studied the current Air Navigation (Hong Kong) Order1995, HKAR-1, HKAR-2, HKAR-66, and Hong Kong Airworthiness Notices.3.4 The applicant shall pay the fee as prescribed in the Hong Kong Air Navigation(Fees) Regulations.3.5 Where the applicant is not a resident of Hong Kong, the application will onlybe accepted if the Director-General is satisfied that there is a need for suchlicence to maintain Hong Kong registered aircraft.3.6 All examinations will be conducted by the Civil Aviation Department.Examinations will be held at the Civil Aviation Department and CADAuthorised Examination Centre. Refer Appendix No.1 for details. Enquires onthe written examination sittings available should be made to the PersonnelLicensing Office.4 Exemptions from AML Examinations4.1 Exemptions from part of the HKAR-66 written examination may be granted bythe Director-General based on qualifications held and the category for whichapplication has been made.<strong>31</strong> January 2010 AN-4 P.2

4.1.1 Holder of a restricted HKAR-66 licence in one or more Categories,when applying for conversion to a full HKAR-66 licence BasicCategory, will be granted exemptions from those modules which formpart of the examinations for the Categories already held. The applicantshould approach CAD for the details of the examinations required.4.1.2 Holder of a non HKAR-66 licences that have been assessed by theDirector-General, when applying for the issue of a HKAR-66 licence inBasic Category, may be granted exemptions from part of the HKAR-66examinations as are so specified. This will be dependent on theCategories for which application has been made and the candidate willbe advised accordingly once the application has been accepted.Details of non HKAR-66 licences and the required conversionexamination are listed in HKAR-2 Chapter 23 Appendix 2.4.2 Exemptions will only be considered provided the relevant supportingdocuments are submitted with the application form DCA35. Where a licencegranted by other aviation authority is the basis of request for exemption it mustbe valid on the date of application.4.3 Holder of an aircraft maintenance licence issued by an aviation authority otherthan those listed in HKAR-2 Chapter 23 Appendix 2 can apply to thePersonnel Licensing Office of CAD for exemptions. A copy of the relevantaviation requirements detailing the aircraft maintenance licensing system andits syllabus should be submitted with the application form for assessment.CAD will consider whether to proceed with the assessment and advise theapplicant accordingly.5 CancellationThis Notice cancels Notice No. 4 Issue 16, dated 30 May 2008, which should bedestroyed.Norman LODirector-General of Civil AviationAN-4 P.3<strong>31</strong> January 2010

Airworthiness Notice No. 4Appendix No. 1Issue <strong>31</strong>5 February 2009HKAR-66 AIRCRAFT MAINTENANCE LICENCE EXAMINATION CENTRES1 Introduction1.1 The demand for Aircraft Maintenance Licence (AML) holder is very high dueto the rapid expansion in the civil aviation industry in Hong Kong. In orderto provide more examination slots for HKAR-66 AML applicants, in additionto the regular examination at our examination centre in Chek Lap Kok, CADhas opened tenders for a CAD Authorised Examination Centre for HKAR-66AML examination. Hong Kong Aircraft Engineering Company Limited(HAECO) has successfully bid the tender and hence has been authorisedaccordingly.1.2 This CAD Authorised Examination Centre employs computers only or thepaperless multiple choice examinations on all HKAR-66 AML modules.Examination schedules and booking are available at the Centre’s website.1.3 The arrangement for essay examinations on relevant HKAR-66 AML modulesremains unchanged.2 Application procedure2.1 Applicants applying for HKAR-66 AML examinations shall select one of thefollowing examination centres for attending examinations:2.1.1 Civil Aviation Department (CAD), 10 th Floor, Airport FreightForwarding Centre, 2 Chun Wan Road, Lantau, Hong Kong.2.1.2 CAD Authorised Examination Centre - Hong Kong AircraftEngineering Company Limited (HAECO), 3 rd Floor, 80 Chun ChoiStreet, Tseung Kwan O Industrial Estate, Tseung Kwan O, N.T., HongKong.2.2 The application procedures remain essentially the same except that applicanthas to tick the examination venue as printed on the application form.2.3 If applicant chooses to take the examination in the CAD AuthorisedExamination Centre, CAD will provide the login information to the applicant.The applicant can then book the provisional examination date(s) through theCentre’s website.AN-4 A1 P.115 February 2009

2.4 Both examination centres use identical question bank to generate examinationpapers. The CAD Authorised Examination Centre is providing computerisedexaminations on multiple-choice questions for all HKAR-66 Modules.2.5 Examination results issued by either examination centre are equally acceptedby CAD for the granting of HKAR-66 AML.2 CancellationThis Notice Appendix cancels Airworthiness Notice No. 4 Appendix No. 1 Issue 2,dated 30 May 2008, which should be destroyed.15 February 2009 AN-4 A1 P.2

<strong>CIVIL</strong> <strong>AVIATION</strong> <strong>DEPARTMENT</strong><strong>HONG</strong> <strong>KONG</strong>, CHINAAirworthiness NoticeNo. 5Issue 330 October 2001TYRE WEAR LIMITATIONS1 Introduction1.1 Hong Kong Aviation Requirements require that for certification of new types ofaircraft, the depth of tyre tread below which wet braking friction characteristicsare impaired should be specified at the time of certification; it is also requiredthat it should be possible to determine, in operational conditions, when the treaddepth is worn below this limit.1.2 This Notice provides general guidance on the subject of tyre wear limitationsfor operators of all public transport aeroplanes of more than 5700 kg MaximumTotal Weight Authorised on the Hong Kong Register for which a limiting tyretread depth is not otherwise available.2 Discussion2.1 Accidents and incidents, resulting from both loss of braking friction and loss ofdirectional control on wet runways, continue to occur. While the scheduledaccelerate-stop and landing distances provide some allowance for deteriorationin friction, it has been established that this allowance is not sufficient tomaintain the required level of safety if tyres which are more than 80% worn areused in wet runway operations.2.2 As it is not possible fully to allow for this by increasing the scheduled distances(because of the frequency of incidents caused by loss of directional control,even on the most favourable wheel arrangements), the Director-General favoursthe retention of current scheduled distances, together with a recommendedminimum tread depth applicable to all aircraft tyres.3 RecommendationIn the absence of evidence of the safety of a lower limit for a particularaircraft/tyre/operation combination, it is recommended that a tyre be withdrawn fromservice when it is worn to such an extent that its wet runway performance would beseriously impaired. This may be defined as when:-(a)it is worn such that any groove has a depth of less than 2 mm of tread for moreAN-5 P.130 October 2001

than one quarter of the tread circumferenceor(b)at any place on the circumference the tread pattern is worn to a depth of lessthan 2 mm across the whole width of the tread in contact with the runway.NOTE: This is not a rigid definition and equivalence may be provided if, for example, tyre wear issuch that whilst one groove is less than 2 mm all the others are 3 mm or more.4 CancellationThis notice cancels Airworthiness Notice No. 5 Issue 2, dated 1 November 1996,which should be destroyed.Albert K. Y. LAMDirector-General of civil Aviation30 October 2001 AN-5 P.2

<strong>CIVIL</strong> <strong>AVIATION</strong> <strong>DEPARTMENT</strong><strong>HONG</strong> <strong>KONG</strong>, CHINAAirworthiness NoticeAIRWORTHINESS PUBLICATIONS - GENERAL INFORMATIONNo. 6Issue 1430 May 20081 This Notice gives details of the various airworthiness publications which may ingeneral be available on CAD website at http://www.cad.gov.hk under “Publicationsand press release”. Some of them however may still be obtained in hardcopy formatfrom the CAD Airworthiness Office, 10/F Commercial Building, Airport FreightForwarding Centre, 2 Chun Wan Road, Lantau, Hong Kong (Tel. (852)27697641, Fax.(852)23624250). The prices and versions of those hardcopy format airworthinesspublications are available on the aforementioned CAD website under “Publicationsand press release” then ‘Other Publications for Subscription’.General information on airworthiness publications published by UKCAA, JAA andEASA are described in the Appendix No.1 to this Notice.2 Airworthiness Requirements2.1 Hong Kong Aviation Requirements (HKAR)These comprise minimum requirements and constitute the basis for the issueof approvals and certificates required by the Air Navigation (Hong Kong)Order 1995 as amended (hereinafter referred to as AN(HK)O).HKAR-1 Airworthiness Procedures (CAD 554)HKAR-2 Administrative & Guidance Material (CAD 2)HKAR-21 Certification of Aircraft and Related Products, Parts andAppliances, and of Design and ProductionOrganisations (CAD 21)HKAR-66 Licensing of Maintenance Personnel (Certifying Staff –Maintenance) (CAD 66)HKAR-145 Approved Maintenance Organisations (CAD 145)HKAR-147 Approved Maintenance Training/Examination (CAD147)HKAR-MMEL/MEL Master Minimum Equipment List/Minimum EquipmentList (CAD 549)AN-6 P.130 May 2008

3 Airworthiness Notices (CAD 455)3.1 Airworthiness Notices are published on the aforementioned CAD website.3.2 This document CAD 455 is published in support of the powers of theDirector-General contained in Article 8(3) of the AN(HK)O. The documentincludes international standards contained in Annexes to the ChicagoConvention.4 Syllabuses of Examination for Aircraft Maintenance Personnel4.1 Aircraft Maintenance LicenceThe syllabus for Aircraft Maintenance Licence is contained in HKAR-66Licensing of Maintenance Personnel (Certifying Staff – Maintenance) (CAD66).5 Type Certificate Data Sheets (CAD 477)These Data Sheets constitute the documentation associated with Type Certificateswhich are issued by the Director-General to signify approval of the design of certaintypes of aircraft.NOTE: The description 'Type Certificate Data Sheet' is only applicable to Type Certificates foraircraft.6 Log BooksThe following are available:Aircraft Exceeding 2730 kg MTWA:Aircraft Log Book (CAD 408)Engine Log Book (CAD 391)Variable Pitch Propeller Log Book (CAD 388)Modification Record Book (CAD 395)Aircraft Not Exceeding 2730 kg MTWA:Aircraft Log Book (CAD 398)Engine Log Book (CAD 399)Variable Pitch Propeller Log Book (CAD 400)Time Limited Task and Component Change Record (CAD 543)7 Air Navigation (Hong Kong) Order 1995The Statutory Instruments concerned with Air Navigation are published by the30 May 2008 AN-6 P.2