Mine water as a Renewable Energy Resource - Promoscene

Mine water as a Renewable Energy Resource - Promoscene

Mine water as a Renewable Energy Resource - Promoscene

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Mine</strong><strong>water</strong> <strong>as</strong> a <strong>Renewable</strong> <strong>Energy</strong> <strong>Resource</strong><br />

Hydrothermal modelling revealed results are very site<br />

dependent. The Freyming-Merlebach mine w<strong>as</strong> selected<br />

for further analysis. Of the 8 shafts two (Vouters2 and<br />

Cuvelette-Nord) reach the lowest gallery at 1250m depth.<br />

The modelling for a single shaft suggests that the <strong>water</strong><br />

temperature is strongly dependent on the ratio between<br />

the shaft diameter and the height of the <strong>water</strong> column. For<br />

a 7.5 m diameter shaft (Vouters2) a steady temperature is<br />

established along the <strong>water</strong> column, while for a diameter<br />

1m is used<br />

Due to variable hydraulic losses in the network, the<br />

use of 3 separate types of pump, for production,<br />

circulation and re-injection.<br />

For heat exchangers and pumps, titanium components<br />

instead of stainless steel (notably 316L type) due to the<br />

presence of NaCl and other chloride brine.<br />

PVC and high density polyethylene coated pipes for<br />

mine <strong>water</strong> transportation.<br />

Ongoing monitoring of <strong>water</strong> level and the installation<br />

of a stand-by pump in order to prevent accidental<br />

contamination of the sandstone aquifer<br />

Chemical monitoring of the mine <strong>water</strong> (at le<strong>as</strong>t every<br />

3 months).<br />

Cost benefit analysis<br />

In order for the capital investment and likely return for<br />

initiating a mine <strong>water</strong> project to stand a chance of being<br />

viable the following elements are necessary:<br />

•<br />

Close proximity of the mine to the heat production<br />

plant (within 1 km)<br />

• Heat demand ≥ 40 GWht<br />

per year<br />

•<br />

The use of existing shafts (no new well drilling)<br />

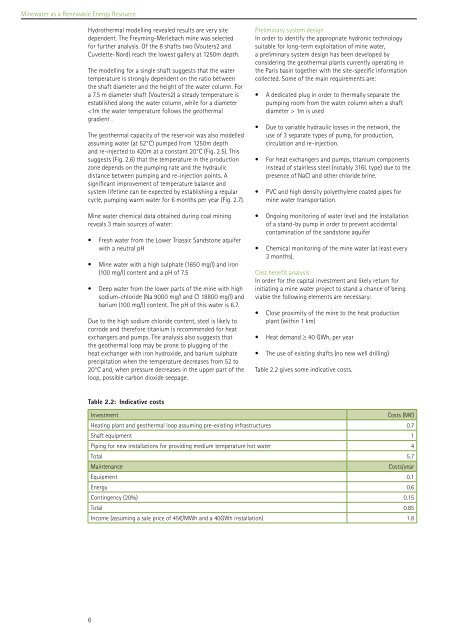

Table 2.2 gives some indicative costs.<br />

Investment Costs (M€)<br />

Heating plant and geothermal loop <strong>as</strong>suming pre-existing infr<strong>as</strong>tructures 0.7<br />

Shaft equipment 1<br />

Piping for new installations for providing medium temperature hot <strong>water</strong> 4<br />

Total 5.7<br />

Maintenance Costs/year<br />

Equipment 0.1<br />

<strong>Energy</strong> 0.6<br />

Contingency (20%) 0.15<br />

Total 0.85<br />

Income (<strong>as</strong>suming a sale price of 45€/MWh and a 40GWh installation) 1.8