Mine water as a Renewable Energy Resource - Promoscene

Mine water as a Renewable Energy Resource - Promoscene

Mine water as a Renewable Energy Resource - Promoscene

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The size of the Shawfair development after three full<br />

ph<strong>as</strong>es w<strong>as</strong> estimated to require a heating demand of<br />

25MW t, although this estimate would since have decre<strong>as</strong>ed<br />

because of incre<strong>as</strong>ingly stringent requirements for new<br />

buildings.<br />

However, the detailed analysis progressed by considering<br />

just the first ph<strong>as</strong>e, since the data were better known, and<br />

the available grant finding could in any c<strong>as</strong>e only extend<br />

this far. Such a scheme would require a much smaller flow<br />

rate; indeed the integrated system that w<strong>as</strong> then examined<br />

involved a flow rate of 30kg/s.<br />

3.2.4<br />

System design<br />

The planned first ph<strong>as</strong>e of Shawfair includes 555 dwellings,<br />

12000 m 2 of office development and a 15000 m 2 school.<br />

The estimated aggregate heating load to service this<br />

development is approximately 3000 kW t.<br />

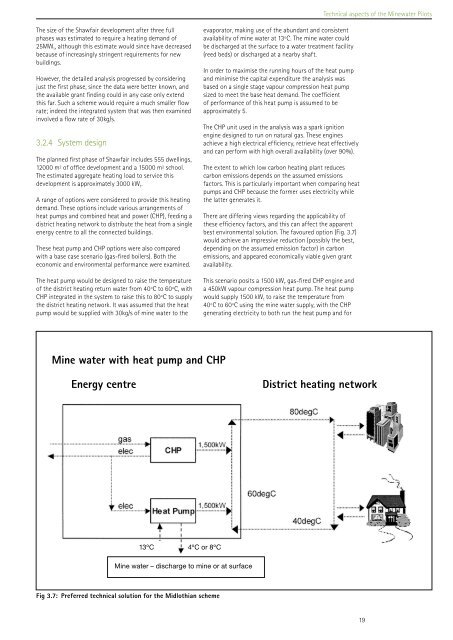

A range of options were considered to provide this heating<br />

demand. These options include various arrangements of<br />

heat pumps and combined heat and power (CHP), feeding a<br />

district heating network to distribute the heat from a single<br />

energy centre to all the connected buildings.<br />

These heat pump and CHP options were also compared<br />

with a b<strong>as</strong>e c<strong>as</strong>e scenario (g<strong>as</strong>-fired boilers). Both the<br />

economic and environmental performance were examined.<br />

The heat pump would be designed to raise the temperature<br />

of the district heating return <strong>water</strong> from 40ºC to 60ºC, with<br />

CHP integrated in the system to raise this to 80ºC to supply<br />

the district heating network. It w<strong>as</strong> <strong>as</strong>sumed that the heat<br />

pump would be supplied with 30kg/s of mine <strong>water</strong> to the<br />

<strong>Mine</strong> <strong>water</strong> with heat pump and CHP<br />

13ºC 4ºC or 8ºC<br />

<strong>Mine</strong> <strong>water</strong> – discharge to mine or at surface<br />

Fig 3.7: Preferred technical solution for the Midlothian scheme<br />

evaporator, making use of the abundant and consistent<br />

availability of mine <strong>water</strong> at 13ºC. The mine <strong>water</strong> could<br />

be discharged at the surface to a <strong>water</strong> treatment facility<br />

(reed beds) or discharged at a nearby shaft.<br />

In order to maximise the running hours of the heat pump<br />

and minimise the capital expenditure the analysis w<strong>as</strong><br />

b<strong>as</strong>ed on a single stage vapour compression heat pump<br />

sized to meet the b<strong>as</strong>e heat demand. The coefficient<br />

of performance of this heat pump is <strong>as</strong>sumed to be<br />

approximately 5.<br />

The CHP unit used in the analysis w<strong>as</strong> a spark ignition<br />

engine designed to run on natural g<strong>as</strong>. These engines<br />

achieve a high electrical efficiency, retrieve heat effectively<br />

and can perform with high overall availability (over 90%).<br />

The extent to which low carbon heating plant reduces<br />

carbon emissions depends on the <strong>as</strong>sumed emissions<br />

factors. This is particularly important when comparing heat<br />

pumps and CHP because the former uses electricity while<br />

the latter generates it.<br />

There are differing views regarding the applicability of<br />

these efficiency factors, and this can affect the apparent<br />

best environmental solution. The favoured option (Fig. 3.7)<br />

would achieve an impressive reduction (possibly the best,<br />

depending on the <strong>as</strong>sumed emission factor) in carbon<br />

emissions, and appeared economically viable given grant<br />

availability.<br />

This scenario posits a 1500 kW e g<strong>as</strong>-fired CHP engine and<br />

a 450kW vapour compression heat pump. The heat pump<br />

would supply 1500 kW t to raise the temperature from<br />

40ºC to 60ºC using the mine <strong>water</strong> supply, with the CHP<br />

generating electricity to both run the heat pump and for<br />

<strong>Energy</strong> centre District heating network<br />

Technical <strong>as</strong>pects of the <strong>Mine</strong><strong>water</strong> Pilots<br />

19