Turbomachinery for the world's largest nitrogen plant - MAN Diesel ...

Turbomachinery for the world's largest nitrogen plant - MAN Diesel ...

Turbomachinery for the world's largest nitrogen plant - MAN Diesel ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

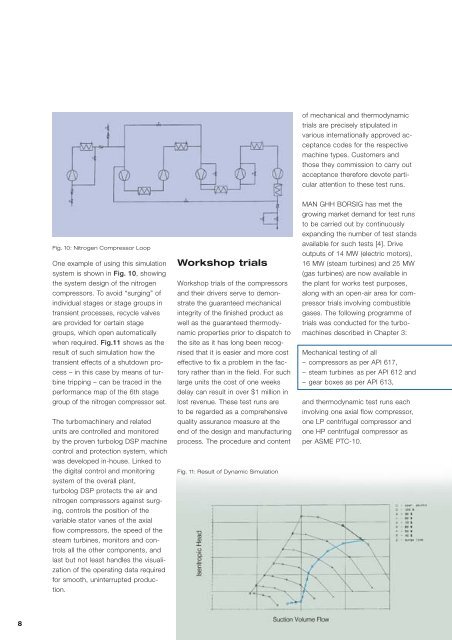

of mechanical and <strong>the</strong>rmodynamictrials are precisely stipulated invarious internationally approved acceptancecodes <strong>for</strong> <strong>the</strong> respectivemachine types. Customers andthose <strong>the</strong>y commission to carry outacceptance <strong>the</strong>re<strong>for</strong>e devote particularattention to <strong>the</strong>se test runs.Fig. 10: Nitrogen Compressor LoopOne example of using this simulationsystem is shown in Fig. 10, showing<strong>the</strong> system design of <strong>the</strong> <strong>nitrogen</strong>compressors. To avoid “surging” ofindividual stages or stage groups intransient processes, recycle valvesare provided <strong>for</strong> certain stagegroups, which open automaticallywhen required. Fig.11 shows as <strong>the</strong>result of such simulation how <strong>the</strong>transient effects of a shutdown process– in this case by means of turbinetripping – can be traced in <strong>the</strong>per<strong>for</strong>mance map of <strong>the</strong> 6th stagegroup of <strong>the</strong> <strong>nitrogen</strong> compressor set.The turbomachinery and relatedunits are controlled and monitoredby <strong>the</strong> proven turbolog DSP machinecontrol and protection system, whichwas developed in-house. Linked to<strong>the</strong> digital control and monitoringsystem of <strong>the</strong> overall <strong>plant</strong>,turbolog DSP protects <strong>the</strong> air and<strong>nitrogen</strong> compressors against surging,controls <strong>the</strong> position of <strong>the</strong>variable stator vanes of <strong>the</strong> axialflow compressors, <strong>the</strong> speed of <strong>the</strong>steam turbines, monitors and controlsall <strong>the</strong> o<strong>the</strong>r components, andlast but not least handles <strong>the</strong> visualizationof <strong>the</strong> operating data required<strong>for</strong> smooth, uninterrupted production.Workshop trialsWorkshop trials of <strong>the</strong> compressorsand <strong>the</strong>ir drivers serve to demonstrate<strong>the</strong> guaranteed mechanicalintegrity of <strong>the</strong> finished product aswell as <strong>the</strong> guaranteed <strong>the</strong>rmodynamicproperties prior to dispatch to<strong>the</strong> site as it has long been recognisedthat it is easier and more costeffective to fix a problem in <strong>the</strong> factoryra<strong>the</strong>r than in <strong>the</strong> field. For suchlarge units <strong>the</strong> cost of one weeksdelay can result in over $1 million inlost revenue. These test runs areto be regarded as a comprehensivequality assurance measure at <strong>the</strong>end of <strong>the</strong> design and manufacturingprocess. The procedure and contentFig. 11: Result of Dynamic Simulation<strong>MAN</strong> GHH BORSIG has met <strong>the</strong>growing market demand <strong>for</strong> test runsto be carried out by continuouslyexpanding <strong>the</strong> number of test standsavailable <strong>for</strong> such tests [4]. Driveoutputs of 14 MW (electric motors),16 MW (steam turbines) and 25 MW(gas turbines) are now available in<strong>the</strong> <strong>plant</strong> <strong>for</strong> works test purposes,along with an open-air area <strong>for</strong> compressortrials involving combustiblegases. The following programme oftrials was conducted <strong>for</strong> <strong>the</strong> turbomachinesdescribed in Chapter 3:Mechanical testing of all– compressors as per API 617,– steam turbines as per API 612 and– gear boxes as per API 613,and <strong>the</strong>rmodynamic test runs eachinvolving one axial flow compressor,one LP centrifugal compressor andone HP centrifugal compressor asper ASME PTC-10.8