INTRODUCTION OBJECTIVES - Plant Services

INTRODUCTION OBJECTIVES - Plant Services

INTRODUCTION OBJECTIVES - Plant Services

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

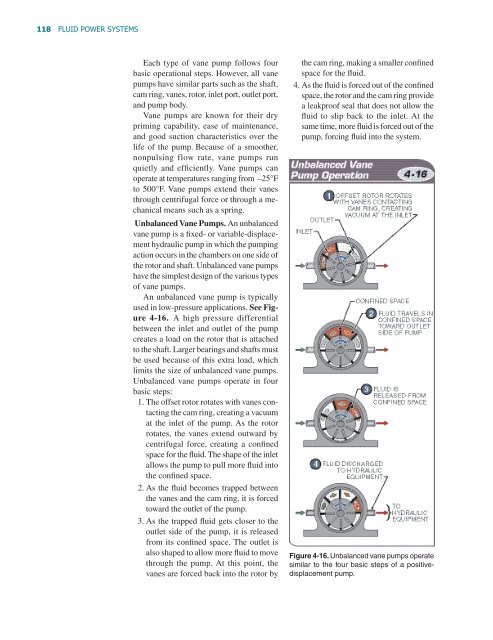

118 FLUID POWER SYSTEMSEach type of vane pump follows fourbasic operational steps. However, all vanepumps have similar parts such as the shaft,cam ring, vanes, rotor, inlet port, outlet port,and pump body.Vane pumps are known for their drypriming capability, ease of maintenance,and good suction characteristics over thelife of the pump. Because of a smoother,nonpulsing flow rate, vane pumps runquietly and efficiently. Vane pumps canoperate at temperatures ranging from –25°Fto 500°F. Vane pumps extend their vanesthrough centrifugal force or through a mechanicalmeans such as a spring.Unbalanced Vane Pumps. An unbalancedvane pump is a fixed- or variable-displacementhydraulic pump in which the pumpingaction occurs in the chambers on one side ofthe rotor and shaft. Unbalanced vane pumpshave the simplest design of the various typesof vane pumps.An unbalanced vane pump is typicallyused in low-pressure applications. See Figure4-16. A high pressure differentialbetween the inlet and outlet of the pumpcreates a load on the rotor that is attachedto the shaft. Larger bearings and shafts mustbe used because of this extra load, whichlimits the size of unbalanced vane pumps.Unbalanced vane pumps operate in fourbasic steps:1. The offset rotor rotates with vanes contactingthe cam ring, creating a vacuumat the inlet of the pump. As the rotorrotates, the vanes extend outward bycentrifugal force, creating a confinedspace for the fluid. The shape of the inletallows the pump to pull more fluid intothe confined space.2. As the fluid becomes trapped betweenthe vanes and the cam ring, it is forcedtoward the outlet of the pump.3. As the trapped fluid gets closer to theoutlet side of the pump, it is releasedfrom its confined space. The outlet isalso shaped to allow more fluid to movethrough the pump. At this point, thevanes are forced back into the rotor bythe cam ring, making a smaller confinedspace for the fluid.4. As the fluid is forced out of the confinedspace, the rotor and the cam ring providea leakproof seal that does not allow thefluid to slip back to the inlet. At thesame time, more fluid is forced out of thepump, forcing fluid into the system.Figure 4-16. Unbalanced vane pumps operatesimilar to the four basic steps of a positivedisplacementpump.