How to Hotrod Corvair Engines - CaliforniaBills.com

How to Hotrod Corvair Engines - CaliforniaBills.com

How to Hotrod Corvair Engines - CaliforniaBills.com

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

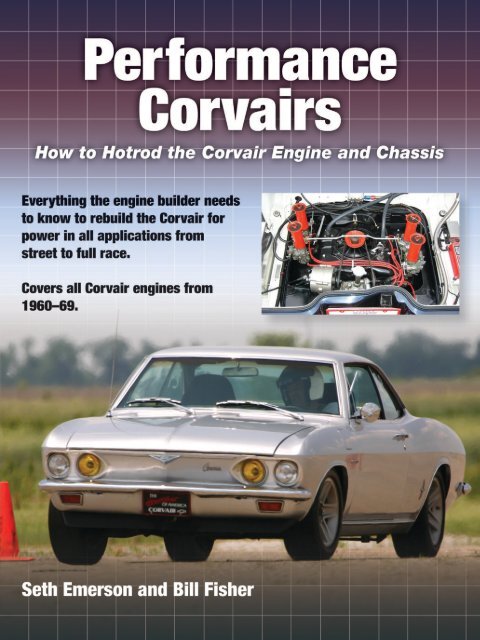

Performance<strong>Corvair</strong>s<strong>How</strong> <strong>to</strong> <strong>Hotrod</strong> the <strong>Corvair</strong> Engine and ChassisSeth Emerson and Bill FisherTucson, Arizona

Publishers<strong>How</strong>ard FisherHelen FisherEdi<strong>to</strong>r<strong>How</strong>ard FisherCover DesignGary Smith, Performance DesignText Design and ProductionDoug GoeweyPublished byCalifornia Bill’s Au<strong>to</strong>motive HandbooksP.O. Box 91858Tucson, AZ 85752-1858520-547-2462www.californiabills.<strong>com</strong>ISBN-10 1-931128-22-7ISBN-13 978-1-931128-22-3Ebook 978-1-931128-37-7© 2013 Seth EmersonPrinted in the United States of AmericaPrinting 10 9 8 7 6 5 4 3 2 1Front Cover1966 Corsa silver coupe, pho<strong>to</strong> by Ned Madsen, BushStadium, Indianapolis, Indiana, 2008.1965 Corsa engine <strong>com</strong>partment pho<strong>to</strong> bySeth Emerson.Back CoverDave Edsinger’s #18 white and blue 1966 Yenko Stinger,pho<strong>to</strong> by Rick Norris. Detroit, Michigan, 2007.Seth Emerson’s #46 yellow and black 1965 YenkoStinger, pho<strong>to</strong> by Di<strong>to</strong> Milian, gotbluemilk.<strong>com</strong>.Mo<strong>to</strong>rsports Pho<strong>to</strong>graphy. Thunderhill Raceway,Willows, California, 2012.John Eger<strong>to</strong>n’s #6 white 1964 Monza, pho<strong>to</strong> by RickNorris. Detroit, Michigan, 2007.Seth Emerson with <strong>Corvair</strong>-powered Lola T320, pho<strong>to</strong>by Silicon Valley Corsa, Oakland, California, 1993.Title PageSeth Emerson #46 1965 Yenko Stinger, pho<strong>to</strong> byDi<strong>to</strong> Milian, gotbluemilk.<strong>com</strong>. Mo<strong>to</strong>rsportsPho<strong>to</strong>graphy. Thunderhill Raceway, Willows,California, 2012.<strong>Corvair</strong> Society of AmericaCORSA is a world-wide organization with 4,800members and 125 local chapters worldwide. Foundedin 1969, it is a large and enthusiastic group of au<strong>to</strong>mobileenthusiasts and one of the best single marque clubsin the world. The organization’s monthly magazine iscalled the CORSA Communique, www.corvair.orgAll rights reserved. No part of this book may be reproducedor transmitted in any form or by any means,electronic or mechanical, including pho<strong>to</strong>copy, recordingor any information s<strong>to</strong>rage and retrieval system,without written permission from the publisher, exceptby a reviewer who may quote brief passages in a review.Notice: The information in this book is true and<strong>com</strong>plete <strong>to</strong> the best of our knowledge. It is offeredwithout guarantees on the part of the author orCalifornia Bill’s Au<strong>to</strong>motive Handbooks. The authorand publisher disclaim all liability in connection withthe use of this book.

Table of ContentsAbout the Authors / Acknowledgments.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ivIntroduction.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii1 An Unusual Au<strong>to</strong>mobile —Yearly Changes.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Measuring Horsepower, Performance Theory, and Tradeoffs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113 Carburetion and Fuel Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 Ignition.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335 Exhaust.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 386 Cylinder Heads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 417 Camshafts and Valve Train Basics.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 508 Pis<strong>to</strong>ns, Pins, and Rings.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 589 Cylinders and Boring.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6510 Lower End.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6711 Engine Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7312 Lubrication, Cooling, and Breathing.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8313 Clutch and Flywheel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9714 Transmissions, Gearing, and Axle Ratios. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10015 Tuning.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10316 Spyders and Other Turbocharged <strong>Corvair</strong>s.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10617 Making It Handle.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11518 Brakes, Wheels, and Tires.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12719 <strong>Corvair</strong> <strong>Engines</strong> in Dune Buggies, Porsches, and Volkswagens.. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13520 V8 and Other Engine-Swap <strong>Corvair</strong>s.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14521 Interior Modifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14922 Cars Gallery.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

About the AuthorBill FisherAuthor Bill Fisher got involved with cars early on.His grandfather owned Chevrolet agencies in Illinoisand from age six he played behind the garagestringing old au<strong>to</strong> batteries <strong>to</strong>gether <strong>to</strong> producemore power.His publishing career began in 1947 whilepursuing a master’s degree in education at theUniversity of Southern California. As it came time<strong>to</strong> write his Master’s thesis, he decided <strong>to</strong> <strong>com</strong>binehis love of au<strong>to</strong>mobiles and English. He wrote<strong>How</strong> <strong>to</strong> Construct a Hot Rod for High School Au<strong>to</strong>Shop Classes. This thesis was the basis of his firstpublished au<strong>to</strong>mobile book. Later, in 1948, he hada speed equipment shop in Eagle Rock, Californiaand supplied speed parts <strong>to</strong> racers <strong>com</strong>peting atBonneville, El Mirage, and Muroc Dry Lakes. Thiswas in addition <strong>to</strong> his flourishing mail-order au<strong>to</strong>motivebook business. Parts as well as books weresold <strong>to</strong> hot rodding enthusiasts across the country.Bill was a huge fan of Chevrolet inline sixcylinderengines and when the <strong>Corvair</strong> came out inan opposed-six configuration he dug in <strong>to</strong> learn allhe could.In 1963, he founded HP Books (HP for horsepower) and authored the original <strong>How</strong> <strong>to</strong> <strong>Hotrod</strong><strong>Corvair</strong> <strong>Engines</strong> in 1964, revising it twice by 1969.He loved mo<strong>to</strong>rcycles and cars. He rode them,tuned them, hot rodded, and raced them at thedry lakes. In 1981 he became a member of theBonneville 200 Mile Club, breaking a record inhis C Coupe at the Bonneville Salt Flats.AcknowledgmentsBill Fisher passed away in May, 1999. These are hisacknowledgments from the 1969 Revision III of<strong>How</strong> <strong>to</strong> <strong>Hotrod</strong> <strong>Corvair</strong> <strong>Engines</strong>.No book of this type is ever produced singlehandedly.I am deeply indebted <strong>to</strong> the many menand organizations who have been lavish in theirassistance, both in the writing of the original edition,and now in this revised version. The TechnicalProjects Department of Chevrolet Public Relationshas provided outstanding help in answeringtechnical questions, and in providing technicalinformation and pho<strong>to</strong>graphs that have been usedthroughout this book. Chevrolet’s MerchandisingDepartment has also been very helpful. GM policiesprevent naming these gentlemen, but I ammost grateful <strong>to</strong> each of them.Over two years were spent in creating the originaledition. This revised edition represents continuousdigging and research in<strong>to</strong> the use of <strong>Corvair</strong>ssince the original was published. Encouragementfrom Frank McGurk of McGurk Engineeringand Jerry Light of Vic Hubbard Au<strong>to</strong>motive wereespecially helpful in keeping the original projectunderway. Three men have been especially helpfulin providing information on their <strong>com</strong>petitionexperiences with <strong>Corvair</strong>s: Don Eichstadt, DougRoe, and Ted Trevor. They have helped me <strong>to</strong> makethis revised version better in dozens of details.Special thanks is due <strong>to</strong> several friends: AngusMcDonald for the original cover design, John Jossfor editing advice, and C.E. Camp for invaluabletechnical advice on various aspects of mechanicalengineering relating <strong>to</strong> high-performance engines.– iv –

About the AuthorSeth EmersonI bought my first <strong>Corvair</strong> in 1967, after explodinga clutch in my latest/last 1955 Chevy. My parentsokayed a “Chevrolet OK Used Car” purchase, andeven co-signed for the loan, as long as it wasn’t a’55 Chevy. They figured it was so different than theother cars I had been modifying that I would leaveit alone and concentrate on college instead. Sorry,Mom! I think I s<strong>to</strong>pped in and bought an IECOcatalog on the way home! In the last 45 years, I haveraced <strong>Corvair</strong>s in every type and class of racing inwhich they run (except off-road racing), includingSCCA au<strong>to</strong>cross and road racing, drag racing, andrallying. I have driven <strong>Corvair</strong>s as street cars formany years, though not as my only car. My Corsaconvertible still has the engine that my girlfriendhelped me build. I am so thankful that I marriedher, 40 years ago. In the late ’70s, I responded<strong>to</strong> friends’ laments about the poor quality ignitionwires available for their race cars by startingSilicone Wire Systems. I have supplied thousandsof 8mm silicone ignition wire sets <strong>to</strong> most of the<strong>Corvair</strong> Parts vendors. I joined The <strong>Corvair</strong> Societyof America (CORSA) in 1973, just missing the Anaheim,California, convention. By 1980, I was fullyengaged and I haven’t missed a CORSA conventionsince. I was a Corsa direc<strong>to</strong>r for more than fifteenyears and President of Corsa twice. I have driven<strong>Corvair</strong>s <strong>to</strong> FTD trophies at conventions and placeda car in<strong>to</strong> Senior Division Concours status as well.In short I have lived the <strong>Corvair</strong> life deeply over thepast 45 years. I don’t plan on s<strong>to</strong>pping soon. And Iwill continue <strong>to</strong> research new ways of applying technology<strong>to</strong> our older cars. Why don’t you join me?AcknowledgmentsAs Bill Fisher said many years ago, a book like thiscannot be produced by one person. First Bill andthen <strong>How</strong>ard Fisher supported my efforts in theupdate. Bob Helt and Richard Finch, both prolific<strong>Corvair</strong> authors, also encouraged me <strong>to</strong> <strong>com</strong>pletethe work. A big thank you goes out <strong>to</strong> those whoare still building <strong>Corvair</strong> race cars and puttingthem on the track in front of an often skepticalpublic. The <strong>Corvair</strong> hasn’t quite outlasted all of itscritics, but it is well on its way <strong>to</strong> doing just that.Every time a <strong>Corvair</strong> puts the hurt on anothercar at the track, at the au<strong>to</strong>cross, or even on thestreet(!), it validates Ed Cole’s concept, Bob Benzingerand Maurice Olley’s design, and countless<strong>Corvair</strong> developers from Bill Thomas <strong>to</strong> Doug Roe<strong>to</strong> Don Yenko <strong>to</strong> John Fitch.To my <strong>Corvair</strong> friends, Bob Coffin, Chuck Sadek,Dave Edsinger, Rick Norris, Jim Schardt, EddieMeadows, Warren LeVeque and a dozen others, yourperseverance has always been my inspiration. No<strong>to</strong>nly did you share your hot rodding techniques, youshared your cars with me at the track. I cannot thankyou all enough, this is about the best I can do. Mywife, of course, put up with my endless Corsa events,track trips, hours in the garage, and various amountsof money stuffed in<strong>to</strong> <strong>Corvair</strong>s and “parts.” ThanksBarbara, and thanks <strong>to</strong> you all. I hope you enjoyreading the book as much as I enjoyed writing it.– v –

IntroductionThe original <strong>How</strong> <strong>to</strong> <strong>Hotrod</strong> <strong>Corvair</strong> <strong>Engines</strong>(HTHCE) book was released in 1964.“California Bill” Fisher, a long time hot rodder andauthor had been enamored with the <strong>Corvair</strong> forsome time. (Undoubtedly through his friendshipwith Ted Trevor, owner of Crown Manufacturing.)Bill had <strong>com</strong>pleted an engine swap of a <strong>Corvair</strong>mo<strong>to</strong>r in<strong>to</strong> his Porsche 356 and was about <strong>to</strong> buyand drive a 1966 <strong>Corvair</strong> as his daily driver. The<strong>com</strong>pany that released HTHCE was called HPBooks. The <strong>Corvair</strong> book was HP Book numberone. The success of that book spawned a publishingempire that went on <strong>to</strong> publish hundreds ofdifferent high performance au<strong>to</strong>motive titles,created a crockery cookbook series, and finallyevery other type of book for do-it-yourselfers.Ownership of the <strong>com</strong>pany, HP Books, changedhands a few times, but Bill, along with his wife,Helen; and son, <strong>How</strong>ard; continued <strong>to</strong> releasebooks on varying subjects, including cars and carperformance. The last revised issue of HTHCE,done in about 1973, was reprinted a few timesby <strong>Corvair</strong> vendors, and hasn’t been available formany years, except at swap meets. Back in about1993, Bill and I agreed that a new revision of thebook was needed. Because I was eager <strong>to</strong> write andhe was busy with other projects, we agreed thatI would update and rewrite the book, gatheringin 20 more years of experience. The 20 years ofexperience has turned in<strong>to</strong> 35, as other activities,both <strong>Corvair</strong> and otherwise, displaced much of mywriting time. Progress was being made, however.And at the time of Bill’s death in 1999, <strong>How</strong>ardFisher, his son, and I agreed that I should continuethe effort.Ironically, the <strong>Corvair</strong>, for a car 50 plus yearssince first production, is still inspiring authors<strong>to</strong> produce books about it. As the cars age,authenticity be<strong>com</strong>es harder <strong>to</strong> achieve andpreserve. When it debuted, the original HTHCEwas the only book about <strong>Corvair</strong>s and the bookcovered the year-<strong>to</strong>-year differences in detail, atleast from the performance point of view. Since thattime, many books have been released <strong>to</strong> documentwhat Chevrolet produced and how they went aboutbuilding the cars. In this latest book, much ofthat authenticity data has been minimized, unlessneeded <strong>to</strong> indicate parts differences or sources. Inshort wel<strong>com</strong>e <strong>to</strong> Performance <strong>Corvair</strong>s—<strong>How</strong> <strong>to</strong><strong>Hotrod</strong> the <strong>Corvair</strong> Engine and Chassis.– vii –

12Lubrication, Cooling,and BreathingEverything you do <strong>to</strong> increase<strong>Corvair</strong> power increases theproduction of heat simultaneously.To maintain engine temperatures atusable levels requires increasing coolingabilities while ac<strong>com</strong>plishing othermodifications. Because oil is used as anessential element in eliminating heatfrom the <strong>Corvair</strong> engine, lubricationhas been discussed in this chapter asinseparable from air and oil cooling.You cannot, except at great expense,increase the cooling-fin surface of thecylinders or heads. General Mo<strong>to</strong>rscarefully engineered these items <strong>to</strong>provide maximum heat removal fromthe available cooling air consistent withthe limitations of modern volumeproductiontechniques.You can greatly improve coolingby changing <strong>to</strong> a folded aluminum fincooler 1960 <strong>to</strong> 1962 <strong>Corvair</strong> part, aslong as you are a regular at keepingthe area clean. The 12-plate coolerintroduced on the last Spyder and carriedon for all high-performance use,probably cools as well as the earlier,smaller folded-fin cooler, but is muchless likely <strong>to</strong> get plugged up with debris.Some additional help can be suppliedby improving the heat-radiatingcharacteristics of the engine’s cast-ironand aluminum surfaces, both finnedand otherwise. A little improvement ispossible through exchanging certainof the sheet metal parts for finnedaluminum<strong>com</strong>ponents. Added coolingis also available through better use ofthe oil’s heat-removal characteristicsvia increased flow made possiblethrough bearing and oil-pump modifications.Adequate crankcase breathingis also important <strong>to</strong> keep engineLubrication-system changes are essential for engine life when building a racing engine.This chapter tells why the changes are needed and how <strong>to</strong> make them.temperatures at reasonable levels. Allof the foregoing modifications are fullydescribed in this chapter.Chevrolet improved fan-belt life bychanging <strong>to</strong> a magnesium blower fan(1964), but the lesser inertia of this new<strong>com</strong>ponent didn’t help belt-loss problemsvery much. The added belt guidesdid help. Information is provided oninstalling the magnesium blower andperhaps more importantly, minor idlerpulleyimprovements <strong>to</strong> ensure beltretention. Details of the pros and consof changing blower speed through useof special pulleys are additional featuresof this chapter.No matter what you do <strong>to</strong> helpthe fan belt installation and coolingperformance, you need <strong>to</strong> pay attention<strong>to</strong> the belt. No matter how muchcare you take in pulley alignment, beltlubrication and maintenance, you willeventually throw a belt. The first indicationyou will see is the temp-press light

84 Chapter 12<strong>com</strong>ing on as the alterna<strong>to</strong>r is no longercharging. If you are “enthusiastically”driving the car, you will probably feelthe few extra horsepower that you haveat your foot’s disposal, since you are notspinning the fan. There is a new indica<strong>to</strong>rkit available that will tell you almostimmediately if the belt <strong>com</strong>es off andcooling air pressure has dropped offabove the mo<strong>to</strong>r. Levair Performanceis selling a kit that reads the pressurein the upper shroud and turns on awarning light if the pressure dropsbelow a safe threshold. If the belt <strong>com</strong>esoff at an inopportune time, you migh<strong>to</strong>nly have a minute until the high headtemps convince the valve seats <strong>to</strong> leave.CORVAIR ROAD LOAD COOLINGS<strong>to</strong>ck Cooling SystemAlthough it might appear that the <strong>Corvair</strong>is the same yesterday, <strong>to</strong>day, and<strong>to</strong>morrow, nothing could be fartherfrom the truth regarding its coolingsystem. Detailed changes that havebeen made deserve your careful considerationand understanding.The <strong>Corvair</strong> uses forced-air cooling.Engine enclosure by sheet metalshrouding directs air over the cylinderheads, cylinders, and oil cooler. Thermostaticcooling control is provided on1961 and later engines by bellows-controlleddamper doors at each side of theengine. These doors open when temperatureof the air under the cylindersattains 205° F. Thus, even on cold days,the engine is operated as if it were in anambient temperature of approximately80° F. An engine blower fan is mountedhorizontally a<strong>to</strong>p the engine. It is beltdriven at 1.58 times engine speed. 1960models differ in that cooling air is controlledby a thermostatically controlledring on the blower-fan inlet.<strong>How</strong> Hot Is the Engine Getting?The fac<strong>to</strong>ry keeps you in the dark onthis question, at least when you aredriving the car. Nothing warns youof an overheat condition except aninstrument-panel light which illuminatesin the event of low oil pressureor an overheat condition sensed a<strong>to</strong>ne cylinder head. Oil temperatureis neither measured nor indicated.Although cylinder-head overheat isindicated immediately by the light, oilpressure indication is far <strong>to</strong>o slow. Bythe time the light <strong>com</strong>es on the damagehas probably already occurred. For thisreason an oil-pressure gauge should beconsidered even more important thanthe cylinder-head and oil-temperaturegauges or warnings which are detailedherein. It should be mentioned thatthe Spyder head temperature circuitincludes a buzzer <strong>to</strong> “sound off ” andprovide an insistent indication that itis time <strong>to</strong> “back off.” This feature wascarried on for the Corsa model, whenturbo equipped. On non-turbos, thewiring is still there, they just left thebuzzer out. The Temp-Press indica<strong>to</strong>rlights up simultaneously on the dash.The importance of knowing moreabout temperatures in a modified engineis stressed by the following curves anddescription for the original SAE Paper140C, “The Chevrolet <strong>Corvair</strong>.”“An air-cooled engine is operatedover a considerable temperature rangeunder normal operation. From 20miles an hour at road-load conditions<strong>to</strong> maximum speed, the cylinder-headtemperature increases from about 300<strong>to</strong> 435 degrees. This represents theworst road-load cooling condition: thesame temperature also prevails at lowerspeeds during full-throttle operation.The temperature characteristic curveof this engine follows quite closely afterthe indicated mean effective pressurecurve. The peak for our engine, occurringat about 2,600 RPM representsthe worst cooling conditions we canobtain—about 30 degrees hotter than atmaximum speed.”The foregoing statements related<strong>to</strong> the 80 HP engine as originallyintroduced and failed <strong>to</strong> mention tha<strong>to</strong>il temperature simultaneously soared<strong>to</strong> 280° F, which is higher than can beconsidered safe. According <strong>to</strong> Mackerle,oil temperatures should be maintainedabove 176° F <strong>to</strong> keep down friction lossand dilution by gasoline, and shouldnot exceed 230° F for continuous operation.Up <strong>to</strong> 230° F may be consideredpermissible for short bursts.Measuring Cylinder HeadTemperaturesAll Spyders and the 1965–66 Corsamodels have cylinder head temperaturegauges operating from one cylinderhead. Like many low-production parts,these devices are quite high pricedshould you choose <strong>to</strong> build your ownfrom the s<strong>to</strong>ck parts, if they are available.You could install just the onegauge, but it would require a separatehousing, and the marked lens must bemounted in the housing that you fabricate.The harder part relates <strong>to</strong> removalof your standard cylinder heads and

Lubrication, Cooling, and Breathing 85machining an opening for the sender—that must match the one used in theTurbo 140 head, so you’ll need one ofthose for a sample. Several sources sellan adapter which lets you install thefine-threaded sender in place of theoriginal coarse-threaded unit. Perhapsa simpler method would be <strong>to</strong> change<strong>to</strong> an aftermarket Cylinder Head Temp(CHT) gauge. They used <strong>to</strong> be <strong>com</strong>monlyavailable from most gauge manufacturers,but since Porsche left the“air-cooled” scene, many of them havebeen dropped. VDO still sells an appropriategauge. Westach Instruments inPetaluma, California, makes both asingle and a dual CHT gauge. Au<strong>to</strong>meterstill sells one, as long as your CHTwill never exceed 340° F. The GM gaugewas a “thermis<strong>to</strong>r” based gauge, wherethe sending unit changed its resistance<strong>to</strong> ground as the temperature rose. Allof the aftermarket gauges are “thermocouple”based, where a pair of wires ofdifferent metallurgy, crimped <strong>to</strong>gether,Westberg Manufacturing makes Westachgauges, including this dual cylinder headtemp unit.This single head temp gauge makes a greatreplacement for the fac<strong>to</strong>ry unit on theSpyder and Corsa.will actually send a small current downthe wire pair, when the junction is subjected<strong>to</strong> the change in heat. The gaugeon the dash is calibrated <strong>to</strong> show thatsmall current as a temperature reading.The aftermarket gauges <strong>com</strong>e with amethod of installing the thermocouplein<strong>to</strong> or on<strong>to</strong> the head. Many of themuse a ring under the sparkplug <strong>to</strong> carrythe thermocouple. The most accurateones use a thermocouple probe whichcan be placed in the original thermis<strong>to</strong>rlocations, up inside the cylinder head.Be sure that the gauge will display arange of temperatures up <strong>to</strong> 600° F.A Chevy dealer bulletin advisedSpyder cylinder-head temperaturesas: 200° <strong>to</strong> 300° at idle; 350° <strong>to</strong> 475°at 30 <strong>to</strong> 60 MPH cruise; and 460° <strong>to</strong>575° from 3,000 <strong>to</strong> 5,000 RPM at fullthrottle. Overheat-warning switchesare used on all <strong>Corvair</strong> engines, andthese have changed as the fac<strong>to</strong>ry hasupped the horsepower produced by theengine. The unit used on the Spyderand 140 HP engines operates at 575° F,but uses a 3/8 inch-24 thread insteadof the 3/8 inch-16 thread used on theother switches. ’60–’64 engines, if no<strong>to</strong>riginally supplied with air conditioning,can have a switch that operatessomewhere close <strong>to</strong> this 575° F temperatureby installing Part No. 1993574(identified by grooves on the hex nut).Oil Temperature MeasurementOil temperature can be measured witha sending unit coupled <strong>to</strong> a gauge.Although all special oil pans include aboss for the addition of such a sender,the bot<strong>to</strong>m of the oil sump gives afalse (<strong>to</strong>o-cool or <strong>to</strong>o-hot) reading thatcannot be relied on for accuracy. Thebest place <strong>to</strong> measure oil temperaturein the <strong>Corvair</strong>—as the oil leaves thecooler—is not easy <strong>to</strong> get <strong>to</strong> because therear accessory cover delivers the cooledoil directly <strong>to</strong> the main oil passages. Asecond-best choice for early enginesis <strong>to</strong> insert the temperature sender inthe right side of the block where thepressure sender was originally located.If this spot is used, an aluminum heatshield must be constructed for thesender. Later blocks have a boss nearthe cooler. This boss can be drilled andtapped for sender installation.Ford oil-temperature switch closes at 280° F,flashing panel light in warning when wiredas shown.If you merely want <strong>to</strong> be warnedwhen oil temperature reaches thedanger point, some small amount ofmoney will buy the system Ford useswith their 427s. The schematic diagramshows how <strong>to</strong> wire the parts <strong>to</strong> workwith your TEMP-PRESS warning light.When oil temperature rises above270°+/– 48° F, the instrument-panelwarning light flashes on and off untiltemperature drops below that point.The low-pressure warning (2 <strong>to</strong> 6 psi)operates as it was intended <strong>to</strong>. Fordparts required are: oil temperature relayAu<strong>to</strong>meter makes several different seriesof instruments, many of them resemble theoriginal GM-style gauges.

86 Chapter 12ClTFlOB840-A, oil-temperature flasherC3AZ9E296-A, and oil-temperaturesending unit C3AZlOB921-A. Thesender will require some specialmounting techniques.Pressure SwitchWhen your <strong>Corvair</strong> engine’s oil pressuredrops <strong>to</strong> 2 <strong>to</strong> 6 psi, the oil-pressurewarning light tells you that youhave insufficient oil pressure. Racerssometimes call the original switch, the“Engine Destruct Indica<strong>to</strong>r,” because it<strong>com</strong>es on at such a low pressure, tellingyou why the mo<strong>to</strong>r just broke—youdid not have enough oil pressure.This inadequate warning system isthe primary reason for installing anoil-pressure gauge. 1960–62 pressureswitches failed and leaked frequentlydue <strong>to</strong> design and location in an areaof extreme heat in the air-exhaust duct.The switch was improved and relocated.Modify your ’60–’61 model <strong>to</strong> relocatethe new switch in<strong>to</strong> the <strong>to</strong>p of theoil-filter adapter. Use a six-point 1-1/16socket, not pliers or a 12-point socke<strong>to</strong>r you will dis<strong>to</strong>rt the switch, causingquick failure.Oil Pressure Gauge Choices—Electric versus MechanicalInstallation of an electrical-type gaugeis <strong>com</strong>paratively easy, as it is only necessary<strong>to</strong> mount the s<strong>to</strong>ck oil-pressureswitch with the pressure sender on<strong>to</strong>a tee. It is important <strong>to</strong> keep the oilpressure switch and warning light inthe system. You might just be lookingthe other way when the oil filterbolt falls out. The light will draw yourattention. It is safer, and therefore moredesirable, <strong>to</strong> measure the pressure ata point more remote from the pumpoutput, such as at the main oil gallery.The tapped hole on the right side ofthe block where the oil-level gaugetube enters the block connects directlyin<strong>to</strong> one main oil gallery. Measuringpressure nearer the pump outlet maynot disclose a blocked oil gallery, butthat is pretty rare. Should you choose<strong>to</strong> use the remote location for thepressure-measuring point, then thesender should not be mounted directlyon<strong>to</strong> the block below the cylinders.The first <strong>Corvair</strong>s (’60 and ’61) sufferedfrom pressure switch failure due <strong>to</strong>high ambient temperatures and thislocation was abandoned in favor ofplacing the switch by the genera<strong>to</strong>r. A45-degree elbow can be screwed in<strong>to</strong>the boss and a copper tube used <strong>to</strong>carry the oil <strong>to</strong> the pressure switch thatcan be bracket supported just a<strong>to</strong>p thecenter of cylinders 1 and 3. Take carenot <strong>to</strong> obstruct the airflow, of course.Mechanical pressure gauges, even withthe long pressure tubes needed whenlocating the actual gauge at the dash,used <strong>to</strong> be preferred <strong>to</strong> the mechanicalgauges, because the electrical ones werelimited <strong>to</strong> a 90-degree movement. Themechanical pointer could sweep about270 degrees, giving finer definition ofthe temps. Newer electric gauges, nowwith internal stepper mo<strong>to</strong>rs, can sweepthe larger area.Gauge InstallationsIf you are preparing an early modelthat didn’t start out as a Spyder, youcan switch <strong>to</strong> the Spyder dash and theinstrument feeds <strong>to</strong> provide the data.That will present you with a few extragauges. But you will still be missing anoil pressure and oil temp gauge. A smallpanel underneath the radio will provideyou with room for three extra gauges.I suggest an oil pressure, an oil temp,and a voltmeter. Late models can addgauges in the dash above the radio, evenangling them <strong>to</strong>ward the driver. But ifyou start with the Corsa dash, you canadd several gauges in the dash itself,without sawing new holes or addingmounting plates underneath, maintainingthat “s<strong>to</strong>ck” look. If you are not runninga turbo, you can dump the vacuumgauge along with the small clock thathasn’t worked since the Carter administration.You can replace the lame Corsatachometer and even install a GPSenabled speedometer if you wish. Nowon the market is a set of four mountingplates that attach <strong>to</strong> the back side of theCorsa dash, using the original mountingholes. The plates retain the standardaftermarket gauges of your choice,four in the middle, 2-1/16" gauges, andtwo on the side, 3-3/8" gauges. The late<strong>Corvair</strong> used the standard 0-90 ohmfuel level sender and all the gaugemanufacturers make <strong>com</strong>patible gauges.The plates are removable and the installationcan be returned <strong>to</strong> s<strong>to</strong>ck if youchange your mind. See the pictures andstart picking out your gauges. You neednot replace the Corsa speedometer, if itis working okay, unless you spend a lo<strong>to</strong>f time over 140 MPH.<strong>Corvair</strong> Engine Blowers (Fans)Four types of <strong>Corvair</strong> fans have beenused during 1960–64. All are describedhere and three are pictured.1960–mid-1961—11-inch diametersteel fan with 24 vanes on an outerring. 1,800 CFM at 4,000 engine RPM.This view of the back side of a Corsa dash shows how individual gauges can be replacedwith aftermarket gauges, including those important oil pressure and temperature gauges.Everything screws on<strong>to</strong> the original mounting points and is <strong>to</strong>tally reversible.

Lubrication, Cooling, and Breathing 87Blower-hub <strong>com</strong>parison. Later models placeload near center of double-row bearing forincreased life.Installation drawing shows height requiredfor installing late hub and shaft assembly in<strong>to</strong>the crankcase cover.Poor air-delivery characteristics at highRPM. Ring on inlet probably reducedtheoretical output.1961–1963—Production-line “runningchange” made in mid-1961 <strong>to</strong> a 10.7-inch diameter steel fan with 16 vanesextending <strong>to</strong> the center of the blowerhub. 1,460 CFM at 4,000 engine RPM.1962 Plastic Fan—1962 engines weresupposed <strong>to</strong> be equipped with a plasticfan (nylon) and GM literature indicatedthis fact. Few, if any, got in<strong>to</strong> the handsof private owners as these were withdrawnfrom production and replacedby dealers at fac<strong>to</strong>ry request.1964–1969—11.2 inch diameter magnesiumblower fan. Design almost identical<strong>to</strong> plastic fan that was abandoned.Same air delivery as 1961–63 models,but weighs 1/3 as much. Provides greatlyimproved belt following at high RPM.Belt is less subject <strong>to</strong> stretch or slip onacceleration and deceleration becausethere is less fan mass. Installation ofthis blower requires minor blowerbearing and hub changes for best bearinglife. The ’64 unit can be installeddirectly on<strong>to</strong> the 1960–63 hubs withoutchange if desired.NOTE: CFM = Cubic Feet per Minute<strong>How</strong> To Install the 1964 Blower(Magnesium) on Earlier ModelsRemove the main shroud and the oldblower. Install the 1964 blower fandirectly on<strong>to</strong> the hub. The magnesiumfan, Part No. 3828742 sold for $6.40new, and are <strong>com</strong>monly found at swapmeets. The ’65 and later fan used differentbolts and isn’t a direct bolt-on forthe ’60–’64. If the engine is <strong>to</strong> be usedin an all-out-racing situation, 1/2 inchcan be turned off the major diameterof the magnesium blower, according <strong>to</strong>an article in <strong>Corvair</strong> Communiqués,Vol. 2, No. 3.While you have the shroud and oldblower off, you should first check thebearing condition prior <strong>to</strong> installingthe new fan. If the bearing is noisy orgritty feeling, it should be replaced. Animproved bearing and hub assemblyAnother American Pi production. The fanbearing assembly <strong>com</strong>es apart <strong>to</strong> replacethe bearings.As assembled. The special <strong>to</strong>ol holds thefan bearing in place as you remove the <strong>to</strong>pretainer.was introduced on 1963 models onengines beginning with TO 913.This design placed the blower-pulleycenterline 5/8-inch closer <strong>to</strong> the bearingcenterline, thereby improving lifethrough a better load distribution. Partsrequired are an Engine Blower PulleyHub, 3826474 and a Blower Bearing& Shaft Assembly, 907448. Note thatboth hub and bearing are designed asa pair and must be installed <strong>to</strong>gether.Remove the crankcase cover. Supportcrankcase cover and press blower shaf<strong>to</strong>ut. Remove blower bearing and shaftassembly from hub by pressing onbearing outer race with a 7/8-inch socket(deep type). Install new bearing andshaft <strong>to</strong> hub.WARNING: Press only on bearing outerrace when removing or installing bearingand shaft assembly <strong>to</strong> blower hub. Do notpress on inner race or shield.Coat shaft with hypoid lubricant orLubriplate. While supporting crankcase

88 Chapter 12cover, press on shaft <strong>to</strong> install hub/bearing assembly <strong>to</strong> height shown indrawing.Before replacing the crankcase coveryou will want <strong>to</strong> read the section oncrankcase breathing <strong>to</strong> see what furtherchanges or additions may be neededprior <strong>to</strong> reassembly. Also read detailson special pulleys.Fan BeltThe best data on fan belts was publishedin Chevrolet Service News inthe January 1962 issue. “Since theintroduction of the <strong>Corvair</strong> vehicle line,exhaustive labora<strong>to</strong>ry and field testinghas been conducted <strong>to</strong> develop a <strong>Corvair</strong>engine blower belt that will providemaximum durability. As a result of thisconstant testing and improvement, it isfelt that the currently used blower belt#3780981 will provide very satisfac<strong>to</strong>ryservice . . . the only fan belt now knownwhich will meet Chevrolet engineeringspecifications. <strong>Corvair</strong> owners shouldbe <strong>to</strong>ld that if in an emergency, it isnecessary <strong>to</strong> install a different belt, itwould be advisable <strong>to</strong> replace that beltwith #3780981, as soon as convenient.”Of course, Chevy hasn’t supplied thatbelt in a long time. Ot<strong>to</strong> parts supplieda fine belt, the Ot<strong>to</strong> Parts “Super Belt.”Fan Power TableRPM S<strong>to</strong>ck Pulley Adjustable Eelco Pulley1.58:1 ratio 1.4 1.32 1.25 1.202,000 1.0 0.9 0.8 0.6 0.53,000 3.5 2.6 2.5 2.0 1.94,000 8.0 7.0 5.2 4.0 3.75,000 15.6 10.6 8.3 8.0 7.56,000 27.0 18.5 16.5 13.4 11.8Numbers in these 5 columns are HP required by fan at RPM shownEelco’s adjustable pulley, now available fromClark’s, provides four fan ratios <strong>to</strong> increase HP.Installation also requires use of a longer belt.BLOWER POWER REQUIREMENTSDrawings adapted from SAE 140c.

Lubrication, Cooling, and Breathing 89That belt is still supplied by Clark’s<strong>Corvair</strong>. Clark’s also offers their ownHD belts. I have found the narrow beltsthat ride farther down in the pulleyshave better life. The Gates 3VX560belt has also worked well. If you ask 10<strong>Corvair</strong> racers, you will get 10 answers,maybe 12.“Most owners carry a spare belt foremergencies. If a belt flips over, replaceit. Some of its strands probably partedwhen it assumed the reverse position.”If you are going <strong>to</strong> s<strong>to</strong>re a belt for emergencies,don’t coil it up <strong>to</strong>o tight, as itwill have <strong>to</strong> be stretched <strong>to</strong> operate.Keeping the Fan Belt IntactIn mid-1964, Chevy introduced simplebelt guides <strong>to</strong> restrain the belt fromflipping over or leaving the pulleys athigh RPM. These guides have provedespecially helpful, both for normal and<strong>com</strong>petition driving. <strong>How</strong>ever, they dohave sharp spots on them as they <strong>com</strong>efrom the Chevrolet s<strong>to</strong>re, and it is agood idea <strong>to</strong> round off all of the sharpedges. The rear guide installs easily onthe idler pulley mounting studs, butthe front guide requires a homemadewedge-shaped shim <strong>to</strong> make the installationon shrouds supplied prior <strong>to</strong> theintroduction of the guides. It is easiest<strong>to</strong>day, <strong>to</strong> just swap out the <strong>to</strong>p shroud.Don Eichstadt points out that fanbeltthrowing can be caused by crankpulley or balancer run out. He suggestssix radial paint marks around the balancerrim so that creeping of the outerrim can be noticed easily, no matterwhat position the balancer is in whenthe engine is s<strong>to</strong>pped.Fan-belt life can sometimes beimproved with a spring-loaded idlerassembly, but this is not a cure-all.Careful attention <strong>to</strong> the alignment ofall pulleys and the use of s<strong>to</strong>ck beltguides will usually keep the belt intactand on the job. The spring-loaded kitswere made by EMPI, OTTO Parts, BillThomas, and <strong>Corvair</strong> Underground.Installation of the spring-loadedidler is extremely simple, especiallywith some of the kits that are available.A bracket is screwed <strong>to</strong> the sheet metalat the rear of the engine <strong>com</strong>partment.The idler is removed and a hole drilledfor spring attachment. The Ot<strong>to</strong> partsSpring-loaded idler is easily installed, acts asa shock absorber <strong>to</strong> keep belt on pulleys and<strong>to</strong> increase belt life. 1964–65 magnesium fanre<strong>com</strong>mended. Ot<strong>to</strong> Parts idler illustrated.Spring idler kit as received.<strong>Corvair</strong> Underground fan belt idler kit withpulley installed.kit used a twisted metal rod for attachment.A 1/2-inch drill is used <strong>to</strong> enlargethe existing hole in the idler bracket.An oversize bolt is used as a pivotpoint. The forward stud is equippedwith a large flat washer adjusted witha lock nut. Both sides of the idler arecoated with high-temperature Lubriplate<strong>to</strong> allow the idler <strong>to</strong> pivot freelyin the fore and aft directions. Detailsfor installation are included in the kits.This aluminum fan drive pulley fromAmerican PI replaces the s<strong>to</strong>ck, stampedsteelunit.This aluminum idler pulley uses readilyavailable bearings and is machined <strong>to</strong> atight <strong>to</strong>lerance.The <strong>Corvair</strong> alterna<strong>to</strong>r rotates the oppositedirection from the V8 units. This <strong>Corvair</strong>specificfan unit will pump more air than thes<strong>to</strong>ck unit and look great as well.This is the fully assembled unit.

90 Chapter 12After installing the belt on the crank,fan, and idler pulleys, the spring isattached. Then, while holding the idlerin the forward position, the belt isslipped on<strong>to</strong> the genera<strong>to</strong>r pulley.Incidentally, the most-importantalignment is that of the genera<strong>to</strong>r pulley,which must be positioned about1/4-inch rearward of what would appear<strong>to</strong> be an optimum straight line connectingwith the crankshaft pulley. GM testsshowed that this eased the belt on<strong>to</strong> thelarger crankshaft pulley and preventedthe tensioned belt from flipping over.The same tests showed that alignmen<strong>to</strong>f the belt leaving the crank pulley hadthe least effect on belt life.The newest kit on the market is theone from <strong>Corvair</strong> Underground. Thespring-loaded portion of the idler isbuilt in<strong>to</strong> the pulley. No need <strong>to</strong> attacha spring <strong>to</strong> the rear body work. The unithas an adjustable spring assembly soyou can adjust the amount of tensionapplied <strong>to</strong> the belt. This has a lock nutwhich must be tightened up beforerunning the unit. The mounting on theengine is about the same as the olderkits. The trick is providing a restrainedmount that allows easy travel fore andaft for belt tension, but almost no side<strong>to</strong> side movement which would affectthe fan drive pulley and the dampenergroove alignment. Finally, for theracers, a new <strong>com</strong>plete kit is on themarket, the half-speed fan kit fromLeVair Performance Products. This kithas you replace a number of differentInstallation of 1964-65 belt retainers requiresusing 1/16-inch shim between belt and retainerby idler, then tensioning belt and tighteningidler. Shim is next used <strong>to</strong> set clearance byfan pulley. Illustration from 1965 <strong>Corvair</strong>Shop Manual.parts on the mo<strong>to</strong>r. The fan drivepulley on <strong>to</strong>p is larger, the vibrationdampener is replaced by a modifieddampener inner pulley, with the outerring removed and a smaller-than-s<strong>to</strong>ckdriving pulley installed, and finally, theupper oil-filter/genera<strong>to</strong>r adapter ismodified for special alignment. Withthe smaller driving pulley and thelarger driven pulley, the actual speedof the fan is much slower than s<strong>to</strong>ck atany given engine RPM. But with thosetwo modified pulleys, the plane that thealterna<strong>to</strong>r rotates in has changed andthe plane that the spring loaded idlerpulley rotates in also has <strong>to</strong> change.The upper adapter housing determinesthose planes because both items attach<strong>to</strong> the sides of the adapter. The LeVairmodified adapter has both sides remachined<strong>to</strong> better align the pulleys withthe relocated drive and driven pulleys.It is slick and it works. It also uses theregular <strong>Corvair</strong> fan belt. It is for racing/au<strong>to</strong>cross use only, however, becauseeven with the full size s<strong>to</strong>ck fan, notenough air is moved at slow speeds <strong>to</strong>adequately cool the mo<strong>to</strong>r. It is fine athigh RPM, but not for street use. I usethis kit with the <strong>Corvair</strong> Undergroundpulley on my au<strong>to</strong>cross/track car.Why Special Fan Pulleys?Adequate cooling for the worst loadand ambient-temperature conditions,including full-throttle operation insummer temperatures is providedby the s<strong>to</strong>ck system. Turning at1.58 times engine speed, the fanproduces 1,460 CFM at 4,000 RPM(engine speed). This air quantity isjust sufficient for continuous fullthrottleoperation and is absolutelynecessary for hard driving in hotclimates or for road racing.Horsepower is needed <strong>to</strong> drive the<strong>Corvair</strong> fan and the same is true fora water-cooled engine’s fan and waterpump. But, the water-cooled job has theadditional task of pushing air throughthe radia<strong>to</strong>r. This means no streamlinedairflow and increased wind resistance.Thus, when all fac<strong>to</strong>rs are considered,the air-cooled engine probably requiresless HP for cooling especially at partthrottlecruising. Look at the graphsand notice that only 3.5 <strong>to</strong> 5.5 HP is1) Smaller drive pulley replaces harmonicdampener. 2) Larger driven pulley resultsin slower fan rotation. 3) Alterna<strong>to</strong>r adapteris modified <strong>to</strong> align the belt guides <strong>to</strong> thealtered pulleys. (Oil filter was moved <strong>to</strong> thefront of the car.)required at 60 <strong>to</strong> 70 MPH in high gear.Fan-power requirement increases asthe cube of speed and is dramaticallydetailed for s<strong>to</strong>ck and special-ratio pulleysin the Fan Power Table, page 88.For street or highway operationwhere ambient temperatures are notextreme, reducing fan speed addshorsepower that you can feel! Whena special pulley is installed you mustbe<strong>com</strong>e alert <strong>to</strong> the overheat indica<strong>to</strong>rbecause less cooling is available at agiven speed. And, you may want <strong>to</strong>install oil-temperature warning devicesas described elsewhere in this chapter.To install just a special pulleyrequires using a longer belt and realigninggenera<strong>to</strong>r and idler pulleys. Becausethe longer belt runs at the same speed(crankshaft-pulley diameter has notbeen altered), belt wear stays the same.But, because the longer belts are notspecifically engineered for the <strong>Corvair</strong>’s<strong>to</strong>rtuously twisted layout, life may notbe equal <strong>to</strong> the s<strong>to</strong>ck <strong>com</strong>ponent. Inany event, the use of a spring-loadedidler is re<strong>com</strong>mended for best belt life.One of the slickest <strong>Corvair</strong> accessorieswas Eelco’s adjustable fan pulley,also sold by Ot<strong>to</strong> Parts, still availableat Clark’s. The pulley is made in twopieces that are held <strong>to</strong>gether by fourbolts that also attach the device <strong>to</strong> theblower hub. Construction is such thatthe parts can be rotated in relation <strong>to</strong>

Lubrication, Cooling, and Breathing 91each other, then bolted solid, <strong>to</strong> obtainfour separate ratios as shown in thepreceding table. The 1.2:1 groove isat s<strong>to</strong>ck groove height, but the lowerratios (smaller diameters) move thegroove upward. This places the 1.4ratio 1/4-inch <strong>to</strong>o high for perfect alignment.To make best use of these lowerratios the blower-bearing shaft can bepressed farther in<strong>to</strong> the crankcase cover<strong>to</strong> place the groove at s<strong>to</strong>ck height. Ire<strong>com</strong>mend that 1.32:1 be the slowestratio used so as <strong>to</strong> maintain adequategroove depth.If a single-ratio pulley is used, theblower-bearing shaft can be shifted <strong>to</strong>keep the groove at s<strong>to</strong>ck height.Damper DoorsOne of the bits of misinformation thatprompted this book was the widelybelieved fiction that the <strong>Corvair</strong>’s thermostaticallycontrolled cooling systemshould be disabled. One performancemanual went so far as <strong>to</strong> re<strong>com</strong>mendthat the damper doors should bepropped open permanently or theinlet-damper ring eliminated on the1960 models. This same writer furtherstated that “no damage could resultand this would reduce the amount ofhorsepower required by the blowerfan.” Thus, many <strong>Corvair</strong> owners haveobtained two misconceptions.Let us examine these “re<strong>com</strong>mendations”in detail. First, blockingthe dampers open increases fanhorsepowerrequirements. When anincreased volume of air is moved, aswhen the dampers fully open for maximumcooling, it takes more power <strong>to</strong>push the air through the cylinders andthe oil cooler. Fan HP requirements arereduced by closing the dampers andthe recirculation ducts. For drag racingyou can block the dampers closed forthe race, then open them immediatelyafterward. If a working genera<strong>to</strong>r isnot required by the rules, then removethe belt for the race and simplify theentire procedure. This assumes that youhave installed the spring-loaded idler<strong>to</strong> make this a convenient procedure.Secondly, blocking the dampers openincreases engine wear by lengtheningthe warm-up time. Open damperseliminate one of <strong>Corvair</strong>’s mostBrian O’Neill’s track car uses an electric mo<strong>to</strong>r drive for a full-size fan. Proven in cool weather, ithas yet <strong>to</strong> be tested in hot conditions.Left Blower Doors ShownEarly model shroud and thermostat assembly.Late model drawing shows that lower shroud and thermostats were revised in ’65, placingthe thermostat just behind the center cylinders and shortening the operating rod.

92 Chapter 12desirable features—quick warm-ups. Aquickly warmed up engine suffers lesswear, especially when it is allowed <strong>to</strong>reach and maintain its normal operatingtemperature for a period of timeprior <strong>to</strong> shutting it off.Short hops during which an enginenever warms up increase crankcasedilution by gasoline, build up varnishand sludge accumulations, and greatlyincrease cylinder wear. The high-wearrate is caused by <strong>com</strong>bustion productsthat condense on the cylinder walls<strong>to</strong> cause etching and rapid wear. Coldcylinders also mean thick oil thatincreases the friction that pis<strong>to</strong>ns mus<strong>to</strong>ver<strong>com</strong>e. The hotter the cylinderwalls, the less friction loss, especiallywith high-viscosity oils. This is anothergood argument for the use of multiviscosityoils: <strong>to</strong> decrease frictionduring the critical warm-up period. Ifyou are operating the <strong>Corvair</strong> engine inan extreme environment for extendedperiod—over 100° F and high loads,you could remove the lower shroudsfor those conditions. Put them back onwhen the temps drop back <strong>to</strong> normal.You can check this oft-proved andwell-documented series of facts in anyinternal <strong>com</strong>bustion engine textbook.<strong>Corvair</strong> Damper Door AssemblyWhen adjusting thermostat linkage thefollowing detail must be observed. Thethermostat-rod swivel, at both the leftand right damper door, must alwaysbe assembled <strong>to</strong> the inboard side ofthe door bracket. The swivel pin mustalways point outboard as it is insertedin<strong>to</strong> the door bracket. Improper assemblywill cause a bind at the thermostatstem, resulting in leakage and failureof the thermostat when the engine isoperated. There are several tricks <strong>to</strong>connecting up the link <strong>to</strong> the doors.It is important that you do not let thedoors snap closed during installation orremoval of the shrouds. That hard snapclosing will damage the thermostat inshort order, and good ones are gettingexpensive. I assembled a special <strong>to</strong>olfor connecting the thermostats. It canusually be used for removal as well. I usean old thermostat rod with a long finethread nut installed and double-nuttedin<strong>to</strong> place, halfway on<strong>to</strong> the rod. I pullthe door open and screw the other endof the double-long nut on<strong>to</strong> the tip ofthe installed rod. You can now pull gentlyon the rod <strong>to</strong> take the pressure off thethermostat and allow the door <strong>to</strong> movefreely. A screwdriver tip can lift up the“pal” portion of the clip and you can justslide the swivel pin out and the clip off.It works for the installation as well.Oil CoolersLike the cooling fans, the oil coolershave also been subject <strong>to</strong> considerablechange since the introduction of the<strong>Corvair</strong> engine in its original form.At least four coolers have been suppliedduring the 1960–67 period. Theoriginal folded-fin aluminum oil cooleras used on 1960–62 models is the bes<strong>to</strong>ne you can get. It dissipated about 160BTUs per minute, keeping lubricatingoil temperature at 280° F with theengine under full-throttle operation inan ambient temperature of 100° F. In1963, the production-economy typesintroduced a new design 3-plate cooleron standard and 102 HP engines,and an 8-plate job on the Spyders.Experience showed that more coolingwas needed for the 164-inch enginesintroduced in ’64, so those used the8-plate design on standard and 110 HPengines, and a 12-plate on the Spyders.The ’65 Corsa and 140 HP enginesall use the 12-plate models, lower HPmodels got the 8-plate. When bothare perfectly clean, the 12-plate typedoesn’t shed as much heat as the originalfolded fin cooler, according <strong>to</strong> all ofthe information that I have been able <strong>to</strong>glean from various sources.If you are going <strong>to</strong> race your <strong>Corvair</strong>in hill climbs or road races, thenimproved cooling must be suppliedby installing a large, remote-mountedcooler that is connected through1/2-inch inside diameter (AN-8) orlarger hoses. The hoses can be connected<strong>to</strong> the s<strong>to</strong>ck oil cooler adaptermanifold after it has been modified byheliarcing female pipe fittings (aluminum)<strong>to</strong> it and opening up the holes.The reason for the large lines is that oilis quite viscous when cold and largelines ensure that the bearings will beadequately supplied under warm-upconditions. The pressure-relief valveThree of the four oil coolers supplied for<strong>Corvair</strong>s from 1960-2 (<strong>to</strong>p), 1963 Spyderand ’64–’69 standard and high-performance(center), and (bot<strong>to</strong>m) is the 12-plate coolerfor ’64 Spyders, ’65 140–180 HP engines, andall air-conditioned engines.Doug Roe’s Spyder-engined “Desert Rat”never exceeded 260° F oil temperature in aone-hour race in 90° ambient temperatureusing Harrison “big car” oil cooler installedas you see it here. Body is cut away behindcooler for airflow. Hose is cool-air inlet forcarbure<strong>to</strong>r.in the filter adapter must be removedand plugged. Otherwise, the restrictioncaused by the cooler and filter <strong>com</strong>binationwill cause the relief valve <strong>to</strong>open and the oil will bypass the cooler.Before modifying the oiling systemin any way study page 6A-6 of the ’61<strong>Corvair</strong> Shop Manual where lubricationsystem functioning and routing isthoroughly explained and diagrammed.

Lubrication, Cooling, and Breathing 93The best externally mounted oilcooler is the s<strong>to</strong>ck car racer’s modelthat Harrison Division of GMmanufactured. Because that is no longeravailable, the aftermarket has steppedup with dozens of different coolersavailable in every size and shape. Themounting shown in Doug Roe’s car isgenerally accepted as the best positionas cool air can be ducted <strong>to</strong> the cooler,and it is close <strong>to</strong> the engine so thatthe lines can be kept short. Most raceorganizations now allow the cooler <strong>to</strong>be mounted up front, usually behindthe license plate area, the final Stingerlocation. If you are ducting air <strong>to</strong> theoil cooler, it pays dividends <strong>to</strong> duct airaway on the outlet side.Oil FiltersThe s<strong>to</strong>ck <strong>Corvair</strong> oil filter is adequatefor most road use, but when the engineis being modified for <strong>com</strong>petition, use alarger filter. It will give added oil capacityas well as improved filtering. A nons<strong>to</strong>ckfilter will also be easier <strong>to</strong> mountremotely on Porsche/VW installationswhere the s<strong>to</strong>ck filter has <strong>to</strong> be cut off<strong>to</strong> get the engine in<strong>to</strong> the chassis. Perhapsthe easiest full-flow filters <strong>to</strong> adaptare those made by Ford. The racingaftermarket has embraced this designand produced many adapters <strong>to</strong> allowremote mounting of single or dual filters.The Ford filter, and the aftermarketequal, contains a bypass valve insideeach filter, unlike the Chevy V8 filterswhich have the bypass mounted inthe block. The remote adapters start atabout $15. Trans-Dapt P/N 1028. Anyof the better Ford replacement filterswill work. I re<strong>com</strong>mend the K&N spinonHP-3001. It is a Ford replacementand is a very well-made part. There arealso smaller filters that fit, if you have aspace problem.Hoses <strong>to</strong> and from the oil filter mustbe 1/2-inch diameter minimum, I useAN-10 hose. These inside diameters areabsolutely essential <strong>to</strong> avoid oil starvationwhen the oil is cold and viscous.Attaching the hoses at the engine endis another problem, especially with thedie cast oil filter adapters used after1961. Adding threaded holes <strong>to</strong> attach1/2-inch I.D. hoses will probably requireheliarcing on<strong>to</strong> one of the 1960–61permanent-molded adapters as thesehave more “meat” and are more easilymodified. Do not hesitate <strong>to</strong> reroutethe passages in the adapter <strong>to</strong> permitgetting the hoses in the correct position.You may want <strong>to</strong> bring the newhoses in under the genera<strong>to</strong>r, or in<strong>to</strong>the <strong>to</strong>p of the adapter, depending onthe rest of the installation problems.Avoid interference with the fan beltand genera<strong>to</strong>r. Arrange the hoses sothat they do not have <strong>to</strong> be removed<strong>to</strong> install a new fan belt.Oil Pans: S<strong>to</strong>ck or Special?Finned sump covers should only bediscussed after understanding the engineeringfacts of the matter. Fortunately,several authorities on engine constructionhave written a considerableamount of material that we can study<strong>to</strong> improve our knowledge. Besideshis mo<strong>to</strong>rcycle design experience(Vincent mo<strong>to</strong>rcycles) Mr. Irving wasthe designer behind the F1 ChampionRepco Brabham V8 engine.P. E. Irving, in his excellent bookMo<strong>to</strong>rcycle Engineering has this <strong>to</strong> say,(p. 239):“While oil is good at collectingheat, it is very bad at getting rid of itagain, because the layer directly incontact with a cool surface increasesin viscosity and simply stays there,acting as an insula<strong>to</strong>r and effectivelypreventing heat being dissipated fromthe hotter oil in the interior. Ribbinga sump which contains a quantity ofoil is not very effective unless there aresome internal ribs also <strong>to</strong> transfer asmuch heat as possible from the body ofthe oil, but ribs placed on areas againstwhich hot oil is violently thrown bycentrifugal action can be made <strong>to</strong> radiatea lot of heat. In this connection, thepolishing of crankcases, though pleasing<strong>to</strong> the eye, may cost almost as muchas the whole of the machining and cutsdown the heat-radiating ability <strong>to</strong> afraction of what it would be if the metalwere left “as cast.”In another part of the same book (p.183) Mr. Irving says,“. . . a polished surface emits lessheat by radiation than a black one. Therate of emission from a polished surfaceis approximately one-tenth that fromthe same surface covered with a thinfilm of lamp-black, and the emissivityof a cast-aluminum surface is increasedabout 10 per cent by a thin coating ofblack paint.”Note that a black surface is tentimes as efficient as a polished one.The Alcoa Engineering Handbookindicates that Irving’s <strong>com</strong>ment maybe quite conservative. Alcoa <strong>com</strong>paresan as-cast surface with one which hasbeen black-anodized <strong>to</strong> a depth of1.7 thousandths. The black surface ismore than ten times better in heatradiatingability than a plain castsurface. Remember these facts whenyou are tempted <strong>to</strong> start polishing andchroming various engine parts thatcould conceivably contribute <strong>to</strong> coolingefficiency.Another noted mechanical engineer,Mr. Julius Mackerle in his book Air-Cooled Mo<strong>to</strong>r <strong>Engines</strong> states that it isan error <strong>to</strong> assume that using a greaterquantity of oil will reduce oil temperature.He further remarks that, “A finnedsump does not aid cooling <strong>to</strong> any greatextent as the oil does not flow downthe cooled sump walls. Cooling is moreintense on the crankcase walls, overwhich the oil flows in a thin film…Bes<strong>to</strong>il cooling is obtained by a tube-typeradia<strong>to</strong>r . . . ”The reader should take note of thewords “thin film” as these are the key<strong>to</strong> understanding the removal of heatfrom oil. If you choose <strong>to</strong> use the s<strong>to</strong>ck<strong>Corvair</strong> oil pan, do not chrome plateit! Additional heat-removal capabilitycan be added by welding or brazingsheet metal fingers and/or baffles <strong>to</strong>extend in<strong>to</strong> the hot oil <strong>to</strong> transmit theheat <strong>to</strong> the radiating surface. The panis black as received from the fac<strong>to</strong>ry. Ifyou have <strong>to</strong> refinish it, use a thin coa<strong>to</strong>f flat-black paint. The s<strong>to</strong>ck pan hasapproximately 178 square inches ofradiating surface.Should you decide on one of themore exotic special pans made of castaluminum you will find that there areseveral <strong>to</strong> choose from. Most of themoffer similar features including:1. Baffles, which slow oil in sloshingaway from the pump pickup in cornersor on hard acceleration and deceleration.These baffles serve an important

94 Chapter 12The newest Clark’s pan is finned on the bot<strong>to</strong>mside <strong>to</strong> maximize temperature shedding.Ot<strong>to</strong> Parts finned oil pan and rocker coversare black anodized <strong>to</strong> improve coolingefficiency. Pan has 314 square inches ofcooling surface area; covers add another 316square inches.Inside the pan, these fins gather heat fromthe oil, by maximizing contact area.function in conducting heat <strong>to</strong> theradiating surface of the pan, providingthe pan is not polished. Some panshave no baffles, or very short bafflesthat should be lengthened <strong>to</strong> at leastprovide one central baffle equivalent <strong>to</strong>that provided by the s<strong>to</strong>ck pan. In someinstances it will be necessary <strong>to</strong> millaway a portion of the short baffles. Thiswill permit locating the pump pickupon the bot<strong>to</strong>m of the pan <strong>to</strong> take advantageof the extra oil capacity. The cooloil lies closest <strong>to</strong> the radiating surface.2. An undrilled boss for the addition ofan oil-temperature sender.3. Quieting—because the external finsand/or internal baffles make the pan aribbed structure, it will not resonate asmuch as the unbraced s<strong>to</strong>ck item. Thus,your engine will be somewhat quieter.4. Additional oil capacity up <strong>to</strong> threequarts more than s<strong>to</strong>ck. This is a mixedblessing on any engine other thanone for all-out road racing purposes.Additional oil capacity, as alreadymentioned, does not lower oil temperature—itjust increases the time requiredfor the oil <strong>to</strong> attain a stable operatingtemperature, which is not usually ofany real importance. Oil changes costInterior construction of Ot<strong>to</strong> parts panincludes 24 posts which extend in<strong>to</strong> hottestportion of oil <strong>to</strong> transmit heat <strong>to</strong> cooledsurface. Baffle construction allows s<strong>to</strong>ckpickup location at coolest part of sump. Panadds one pint <strong>to</strong> oil capacity.more and the engine requires longer<strong>to</strong> cool off after it has been run. Additionaloil capacity is helpful in a longrace, providing the pickup is moved<strong>to</strong> the bot<strong>to</strong>m <strong>to</strong> make all of the oilavailable for use. Additional capacityis insurance against losing an enginein the event that unexpected oil-consumptionproblems develop in a racingsituation, or for engines on whichthe breathing problem has not beenproperly worked out. Big-capacity pansusually offer about 240 square inches ofheat-radiating area, which is reduced<strong>to</strong> the equivalent of 24 square inches bysurface polishing. In general, it can besaid that an oversize pan is essential fora non-dry-sumped, road-racing engine.5. Appearance. Most special aluminumparts are purchased for looks insteadof function—that is, show, not go! Donot let your desires for a good-lookingengine confuse you when final-assemblytime arrives. Avoid polished fins!Cragar oil pans provide additional oil capacity;may give ground-clearance problems.Baffles must be cut away <strong>to</strong> relocate theoil pickup on the bot<strong>to</strong>m. Polished surfaceshould be eliminated and pan black anodizedfor maximum cooling effect.If you are tempted <strong>to</strong> retain themreread engineer Phil Irving’s <strong>com</strong>ments.If you already have such parts,“de-polish” them by sandblasting thepolished surfaces. Black anodize theparts or cover the exterior surfaces witha thin coating of self-etching flat-blackpaint of the non-insulating variety.Black anodizing is a plating processthat many plating shops can provide foryou at reasonable cost. Incidentally, theblack obtained by anodizing may turnout somewhat spotty as castings do notusually anodize perfectly. This will notimpair the heat-removal characteristics.Although seemingly insignificant,these efforts will reward you with acooler-running, longer-lasting engine.The same efforts should be applied <strong>to</strong>rocker-arm covers of the cast variety.6. Better sealing surfaces. The machinedsurface of the pan that contacts the casebot<strong>to</strong>m is much stiffer than the stampedsteel original pan. The same is true foraluminum valve covers. Some are betterthan others. The s<strong>to</strong>ck valve cover gasketshave tabs that aid in retaining thegasket during installation. Some of the

Lubrication, Cooling, and Breathing 95sources is <strong>com</strong>petition proven, it waspreviously marketed as Kendall Oil, afavorite of racers, but <strong>com</strong>es from thesame wells and fac<strong>to</strong>ry as the originalKendall. No matter which oil youchoose, always change your oil whenit is hot <strong>to</strong> get the best flushing action.Avoid oil additives as they may not be<strong>com</strong>patible with the additives that theoil manufacturer has used.Internal Oil-Sump BafflingShirok Enterprises of Colorado Springs, Colorado, makes this high volume oil pump kit. It isvery useful if you are using a front-mounted cooler and filter.Output volume of the <strong>Corvair</strong> oil pump isboosted one-third by addition of special Ot<strong>to</strong>Parts pump cover <strong>to</strong> house Chevrolet 409oil-pump gears. Installation can be madewithout removing engine from car.aluminum valve covers have the spacesfor the tabs.Drawbacks? The pan will hangdown beneath the already low engine.Ground clearance could be an issue.Improving the Oil PumpAs has been mentioned previously,improving the flow of oil reducesbearing temperatures. This statementassumes that the oil-pump capacity canbe increased <strong>to</strong> provide the additionalflow. Fortunately, the <strong>Corvair</strong>’s pump islocated so that it lends itself <strong>to</strong> a simplemodification for increasing its outputvolume. A spacer can be installed <strong>to</strong>house the 1/3 longer gears from a 409Chevrolet thereby increasing output <strong>to</strong>12 gallons per minute (GPM) at 4,000RPM. This spacer is an aluminumcasting that bolts directly <strong>to</strong> the s<strong>to</strong>ckaccessory drive housing. Such anadapter casting, <strong>com</strong>plete with gears, ismanufactured by Ot<strong>to</strong> Parts.Although the 409 gears are 0.397-inch longer than the <strong>Corvair</strong> gears, thes<strong>to</strong>ck idler gear shaft can be used. Thedrive-gear shaft is relocated slightly <strong>to</strong>match with the <strong>Corvair</strong>’s distribu<strong>to</strong>rdrivetang.OilsThe <strong>Corvair</strong> needs the best oils <strong>to</strong> providegood viscosity under the extremeconditions of temperature encounteredin an air-cooled engine, especially amodified one. Multi-grade oil acts likea 20-weight <strong>to</strong> reduce cold friction andretains the viscosity of a 40-weight oilas the temperature is increased. Shell“Rotella” oils, in various grades, haveworked well in the <strong>Corvair</strong>. Don Eichstadtand other <strong>Corvair</strong> racers reportgood experience with D-A Speed Spor<strong>to</strong>ils. There are several synthetic oils thatwork great in the <strong>Corvair</strong>, RedLine,Amsoil, and Mobil1 all have their proponents.The high-temperature capabilitiesof the synthetics are perfect <strong>to</strong> helpthe <strong>Corvair</strong> cylinder head temps in<strong>com</strong>petition usage. If you decide <strong>to</strong> gowith a synthetic oil in your new mo<strong>to</strong>r,I suggest you run the mo<strong>to</strong>r on normalnon-synthetic oil for the first 500 milesor so. The extreme lube capability of thesynthetic may prevent certain new parts,like pis<strong>to</strong>n rings, from mating with theircounterparts, resulting in long-termoil consumption. There are still somenon-synthetic oils that perform verywell. Brad-Penn oil, from PennsylvaniaReference <strong>to</strong> the need for internalbaffles in the sump has already beenmade in the discussion of special pans.Baffles extending <strong>to</strong> the underside ofthe crankcase separa<strong>to</strong>r wall, whichseparates the rotating parts from the oilsupply, assist in drawing heat from theoil <strong>to</strong> the cooled cover and reduce oilfrom sloshing away from the pickup. Inaddition, still another set of baffles isneeded for hard cornering as is experiencedin au<strong>to</strong>crossing or road racing.While the pushrod tubes are protectedfrom receiving oil from the crankshaft,Splash baffles prevent loading rocker coverswith oil in cornering with possible starvationof pump. Holding screw goes between lifterbores, exits inside crankcase. Use 1-1/2 inch8-32 screw in<strong>to</strong> tapped hole.Two crankcase cover oil separa<strong>to</strong>rs. Coverat left was introduced on Spyders in ’62,was soon made standard throughout engineline. It reduces oil pull over in<strong>to</strong> the positiveventilationbreathing system. Additionalopening area is the secret of its success.