Bredel SPX25 high performance hose pumps (US ... - Watson-Marlow

Bredel SPX25 high performance hose pumps (US ... - Watson-Marlow

Bredel SPX25 high performance hose pumps (US ... - Watson-Marlow

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

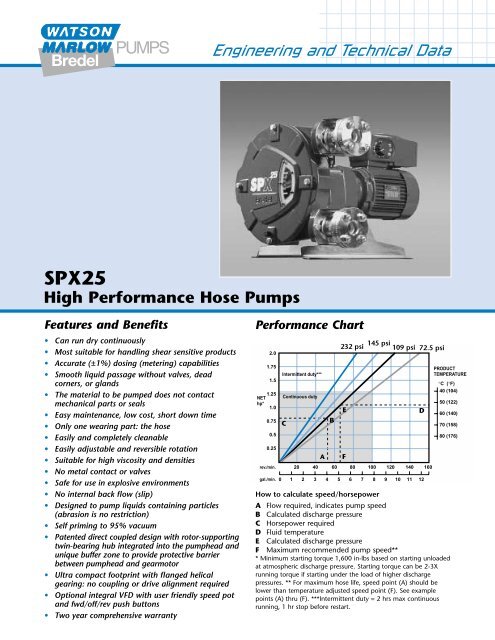

Engineering and Technical Data<strong>SPX25</strong>High Performance Hose PumpsFeatures and Benefits• Can run dry continuously• Most suitable for handling shear sensitive products• Accurate (±1%) dosing (metering) capabilities• Smooth liquid passage without valves, deadcorners, or glands• The material to be pumped does not contactmechanical parts or seals• Easy maintenance, low cost, short down time• Only one wearing part: the <strong>hose</strong>• Easily and completely cleanable• Easily adjustable and reversible rotation• Suitable for <strong>high</strong> viscosity and densities• No metal contact or valves• Safe for use in explosive environments• No internal back flow (slip)• Designed to pump liquids containing particles(abrasion is no restriction)• Self priming to 95% vacuum• Patented direct coupled design with rotor-supportingtwin-bearing hub integrated into the pumphead andunique buffer zone to provide protective barrierbetween pumphead and gearmotor• Ultra compact footprint with flanged helicalgearing: no coupling or drive alignment required• Optional integral VFD with user friendly speed potand fwd/off/rev push buttons• Two year comprehensive warrantyPerformance ChartNEThp*2.01.751.51.251.00.750.50.25rev./min.Intermittent duty***Continuous dutyCAB232 psi 145 psi 109 psi 72.5 psi20 40 60 80 100 120 140 160gal./min. 0 1 2 3 4 5 6 7 8 9 10 11 12EFPRODUCTTEMPERATURE°C (°F)40 (104)50 (122)60 (140)70 (158)80 (176)How to calculate speed/horsepowerA Flow required, indicates pump speedB Calculated discharge pressureC Horsepower requiredD Fluid temperatureE Calculated discharge pressureF Maximum recommended pump speed*** Minimum starting torque 1,600 in-lbs based on starting unloadedat atmospheric discharge pressure. Starting torque can be 2-3Xrunning torque if starting under the load of <strong>high</strong>er dischargepressures. ** For maximum <strong>hose</strong> life, speed point (A) should belower than temperature adjusted speed point (F). See examplepoints (A) thru (F). ***Intermittent duty = 2 hrs max continuousrunning, 1 hr stop before restart.D

Engineering and Technical Data<strong>SPX25</strong>High Performance Hose PumpsNotes:1. Dimension is dependent on selection of gearbox and/or motor2. All dimensions in inchesTechnical SpecificationsDisplacement: 0.079 gal/revSupply: 115/230 single phase or 230/460 three phaseor 575V three phaseOperating Speeds: up to 100 rpm continuousup to 140 rpm intermittentFluid Temperature Range*: -4° to 175°FAmbient Temperature Range**: -4° to 113°FHose Lubricant Required: 0.53 gallonsFlow Range: up to 11 gpmDischarge Pressure: up to 232 psiSuction Pressure: 28ft. lift to 55 psiAvailable Hose Materials: Natural Rubber, BUNA N,EPDM, HypalonAvailable Insert Materials: Polypropylene, 316SS,PVDF, PVCFittings: 1” 150# FlangeOptional High Level Hose Leak Sensor: NO or NC:1A max, 250V max, 50VA maxWhen installing, allow min 40” linear clearance fromports to facilitate <strong>hose</strong> changingMaterials of ConstructionPumphead: Cast Iron Rotor: Cast ironBearing Hub: Cast Iron Shoes: Aluminum or EpoxyShims: 316SSCover: Cast IronFlanges and Flange Brackets: Galvanized steel or 316SSSupport Frame: Galvanized steel or 316SSHardware: Zinc plated steel or 316SSHose Clamps: Galvanized Steel or 316SSShaft: Alloy steelSeals: Buna*Consult <strong>Watson</strong>-<strong>Marlow</strong> <strong>Bredel</strong> for lower or <strong>high</strong>ertemperature operation**Allowable ambient temperature is based on pumpcapabilities and may be further limited by gearmotorambient capabilitiesThe information contained in this document is believed to be correct, but <strong>Watson</strong>-<strong>Marlow</strong><strong>Bredel</strong> Pumps accepts no liability for any errors it contains, and reserves the right to alterspecifications without notice.<strong>Watson</strong>-<strong>Marlow</strong> <strong>Bredel</strong> Pumps37 UPTON TECHNOLOGY PARK, WILMINGTON, MA 01887-1018TEL: 800-282-8823, 978-658-6168 / FAX: 978-658-0041http://www.watson-marlow.comwd-spx25-us-01