Beissbarth ICperform â - Autobas 77 SA

Beissbarth ICperform â - Autobas 77 SA

Beissbarth ICperform â - Autobas 77 SA

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

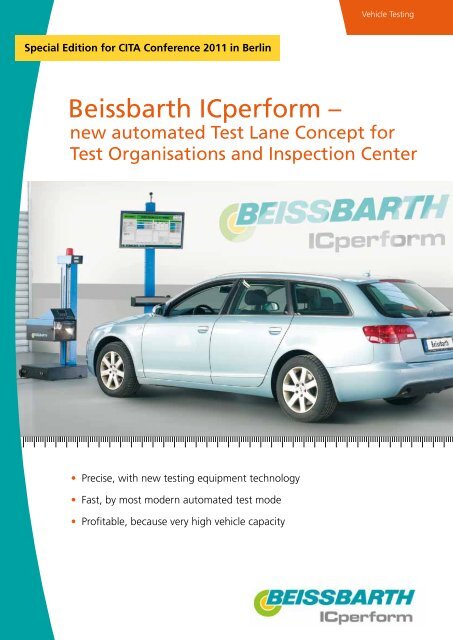

Tyre Changers Wheel Balancers AC Service Units Lifts NetworkingVehicle Testingtedme of testsContentsPageCustomer Reception 4Terminal 1: Vehicle Data entry 5Terminal 2: Light and Emission test 6-7Terminal 3: Track, Suspenisonand Brake Test 8-9Terminal 4: Noise measurementand visual vehicle check 10-11Main Terminal and Server 12Equipment and order numbers 13Benefits for the Inspection Center 14Vehicle Testing Capacity 15<strong>Beissbarth</strong> Service 163

Wheel Alignment Brake Testers Vehicle TestingCustomer reception: Data entrysimplified by <strong>ICperform</strong> officeAt the customer reception begins the preparationfor the periodical technical inspection of thevehicle. The specifications of the vehicle owner andthe vehicle, according to vehicle documents, will beentered in the input screen of the software <strong>ICperform</strong>office. The customer pays the inspection fee.Depending on the country legislation the car tax,insurance and possibly open penalty notices mustto be paid. Finally a document for the inspector willbe created with the important details. Additionallya barcode will be printed on the inspection order.The car keys and inspection order will be handedover to the inspector.Through the Video recording system <strong>ICperform</strong>watch, it is possible for the customer to follow thetest sequence of his vehicle in the waiting hall onthe monitors. Up to 8 cameras can be connected toone Video recording system. The last 7 days can berecorded on the integrated hard disk. Bosch SecuritySystems developed this Videosystem specially forAirports, Shopping malls and Sport centers.Everything under control by Bosch SecuritySystemsThrough modern technology and the open designpossibilities, from hardware to the software, enablethe <strong>ICperform</strong> concept the easy extension andadaptation to your specific needs and your operationalgrowth.The Bosch Security Systems provide security fromthe first moment the digital video recording systemtechnology at its best. The super-slim LCD monitorincludes the complete technology and the keypad.This eliminates the cable between the VCR andmonitor, which guarantees the big display withexcellent readability.<strong>ICperform</strong> watch – Video recording systemVideosystemDisplayHard disk drive <strong>SA</strong>TAPAL/NTSCLCD/TFT Panel320 GB4

Wheel Alignment Brake Testers Vehicle TestingTerminal 2: Light and emissions inspection.Fast, automated and very preciseLight and emission inspection in less than 2 minutes.<strong>ICperform</strong> beam – Automatic Headlight TesterOne highlight of the <strong>ICperform</strong> Test Lane is the automaticHeadlight Tester <strong>ICperform</strong> beam. With new technology ofCMOS machine vision camera and high-speed DSP (digitalsignal processor), all parameters of high-beam and low-beamare tested accurately and automatically. With strong softwarefunctions and LCD display, inspection, calibration and adjustmentcan be completed quickly. Using technology of lightimage alignment, external interference can be eliminated,accurate and fast follow-light aiming is ensured, high-beam /low-beam inspection takes about 35 seconds.<strong>ICperform</strong> beam – Automatic Headlight-TesterMeasuring Range: Light Intensity 0 ~ 120,000cdOptic Axis Deviation: up 1º30‘ ~ Down 3º,up 25cm/10m ~ Down 50cm/10m,Left 3º ~ Right 3º,Left 50cm/10m ~ Right 50cm/10mOptic Axis Deviation of High-beam ±12‘Optic Axis Deviation of Low-beam ±15‘Central Height of Headlight±1cmDifference of Measurement Values 15‘Inspection Distance1mIt is especially suitable for inspection center for testing twoheadlights synchronously. Efficiency can be improved: twoheadlight synchronous inspection takes about 25 seconds.Special security functions are programmed in the intelligentsoftware <strong>ICperform</strong> soft. The instructions for the inspectorand the measuring values are shown directly on the big42”-LCD-Monitor.6

Tyre Changers Wheel Balancers AC Service Units Lifts NetworkingVehicle Testingg.<strong>Beissbarth</strong> Test Lane(BD 641-Speed-Power, <strong>SA</strong> 640, ST 600)After completion of the headlight test the order is automaticallysent to the terminal of the test lane. By crossing the sideslip tester ST 600 the order is activated. The inspector nowmoves the car to the suspension tester <strong>SA</strong> 640. This determinesthe weight of the front axle and starts one after the teston the two sides of the wheel. The suspension tester operateson the principle EU<strong>SA</strong>MA. Here, the maximum road grip ismeasured at the wheels. Valuation is the difference betweenthe left and right.Afterwards the vehicle is moved to the brake tester BD 641-Speed-Power. Again, the test takes place automatically withthe press of the two slip rollers that are located between thedrive wheels. The all-wheel detection occurs automaticallytoo. The inspector follows the instructions here, which can beseen at the <strong>ICperform</strong> ident 42“-LCD-monitor of the terminal.He brakes to slip off and goes out of the roller set. The wholeprocess is repeated for the rear axle.The brake tester was developed to meet the needs of TestingOrganisations and InspectionCenter with a lot of throughput.He offers from increased weldedconstruction with reinforceddrive rollers, to meet the requiredthrough put. The motorsare in contrast to the standardroller sets increased output of5 kW and with electro magneticengine brakes for easy drive-off.The engines are equipped withthe electronics of the soft startmodules, which are integrated inconjunction with the main switchin the main switch box stand.Brake Tester BD 641-Speed-PowerDimensions (L x W x H)660 x 2360 x 250 mmCoefficient of friction (dry) 0,8Coefficient of friction (wet) 0,7Roller length700 mmRoller diameter205 mmMaximum test width2200 mmMinimum test width800 mmPermissible test/axle load3500 kgMax. permissible driveover load4000 kgMax. braking force per wheel7,5 kNDegree of protection (as per DIN 40 050) IP 54Power of drive motors2 x 5,0 kWTest speed5,2 km/hSuspension Tester <strong>SA</strong> 640Measurement system Bending bar with strain gaugeDimensions (L x W x H)440 x 2360 x 280 mmMaximum test width2200 mmMinimum test width820 mmPermissible test load per axle2000 kgMax. permissible driveover load per axle4000 kgDegree of protection (as per DIN 40 050) IP 54Rated power of drive motors2 x 2,5 kWMax. test frequency25 HzStroke6 mmSide Slip Tester ST 600Dimensions (L x W x H)1100 x 440 x 47 mmDegree of protection (as per DIN 40 050) IP 54Max. permissible driveover load per axle4000 kgPermissible test/axle load per axle2000 kgMeasurement systemPrecision potentiometer orresistance strain gaugeMeasuring range± 20 mm/mBy activating the inspection ordera photo of the tested vehicle canbe created with the camera. Onthe one hand, this image is shownin the terminal and to another isstored in the database with themeasured values.Main Switch Box and Softstarter Stand.9

Tyre Changers Wheel Balancers AC Service Units Lifts NetworkingVehicle Testing<strong>Beissbarth</strong> Play Detector GST 651The <strong>Beissbarth</strong> play detector GST 651 is part of the standardequipment for any Test Organisation and Inspection Center.It enables you to diagnose and localise damage and signs ofwear and tear on steering swivel pins, bushings, joints, springbolts, tie rod ends, steering components, etc. The movementof both test plates in a total of eight directions each is realisedby means of a hydraulic power pack which can be controlledvia a cabled remote control or which can be operated inautomatic mode.Play Detector GST 651.Play Detector GST 651Maximum axle load4,000 kgMaximum overdrive weight4,000 kgTest speed75 mm/sDimensions test plate (L x W)730 x 730 mmMaximum slide test plate80 mmSlide force per cylinderApprox. 12,000 NMotor power1.1 kWOperating pressure120 barDegree of protection IP 54<strong>Beissbarth</strong> Lifts<strong>Beissbarth</strong> offers Test Organisations and Inspection Center abig range of different types of lifts:• 2-Post-lifts• 4-Post-Lifts• Scissor-Lifts<strong>Beissbarth</strong> Scissor Lift.The lifts are developed together with Test Organisations tofulfil the daily needs:• Special load capacities• Bigger Lifting heights• Longer Runways11

Main Terminal and Server:Data Management and Data Storage<strong>ICperform</strong> report – Main TerminalThe Main Terminal <strong>ICperform</strong> report is the “brain”of the test lane. This Terminal is responsible forfollowing issues:• Test lane management / administration• Surveillance mode for supervisior• Test lane configuration• Print-out of Test Report- Customer specific report can be printed- Customer specific draft can be used• Input of Inspector list• Input of vehicle categories• Input of visual inspection lists• Input of error codes• Definition of vehicle test evaluation• Database replication for offline test / mode• Logging files of each vehicle testMain Terminal <strong>ICperform</strong> report.<strong>ICperform</strong> collect – Inspection Center ServerThe Inspection Center Server <strong>ICperform</strong> collectcollects all measured values of each test lane in thetest station. Additional functions are:• Database Management• Client Communication• Communication with administration consoleA big advantage is the back-up-solution. In thecase of a server break down all started vehicle testscan be finished and will stored locally to the Mainterminal. With re-connecting the server a synchronisationwill take place.The <strong>ICperform</strong> collect is also ready to be connectedto a 3rd party Database (f. e. governmental server).Server room of Inspection Center.12

Wheel Alignment Brake Testers Vehicle TestingEquipment andarticle numbers at a glanceTestline for Passenger CarsArt.No.<strong>ICperform</strong> lane: Passenger Car Test Lane 1 692 107 000contains:<strong>Beissbarth</strong> Brake Tester BD 641-Speed-PowerUSB Converter-Set Standard for Brake Tester<strong>Beissbarth</strong> Suspension tester <strong>SA</strong> 640Installation Frame for Test Lane<strong>Beissbarth</strong> Side Slip Tester ST 600 V3.0Installation Frame for Side Slip Tester<strong>Beissbarth</strong> Play Detector GST 651Installation Frame for GST 651Bosch Emission Tester BEA 460 Gasoline and DieselRetrofit Set NO (5-Gas)Emission Tester Stand with Cable Holder<strong>ICperform</strong> sound - Sound Level Meter<strong>ICperform</strong> beam - Headlight TesterRails for Headlight Tester<strong>ICperform</strong> ident - Terminal 1: Input & Visual Terminal<strong>ICperform</strong> ident - Terminal 2: Emission & Headlight Terminal<strong>ICperform</strong> ident - Terminal 3: Testlane Terminal<strong>ICperform</strong> ident - Terminal 4: Sound & Visual Terminal<strong>ICperform</strong> report - Line Main Terminal<strong>ICperform</strong> soft - Network-Solution Software for CarsCalibration Device for Headlight Tester 1 692 104 950<strong>ICperform</strong> collect - Station Server-System (1 Server) 1 692 107 111<strong>ICperform</strong> collect - Station Server-System (2 Server for Backup-Solution) 1 692 107 112<strong>ICperform</strong> collect - Server-Software 1 692 107 122<strong>ICperform</strong> office - Office-PC Software 1 692 107 123<strong>ICperform</strong> office - Office Terminal 1 692 107 130<strong>ICperform</strong> watch - 1 Set Monitor with 4 Cameras cpl. Digital 1 692 107 300<strong>ICperform</strong> control - Surveillance System 1 692 107 310<strong>Beissbarth</strong> 2-Post-Liftson request<strong>Beissbarth</strong> 4-Post-Liftson request<strong>Beissbarth</strong> Scissor-Liftson request13

<strong>Beissbarth</strong> Service –in Germany and worldwide<strong>Beissbarth</strong>, based in Munich, also guarantees you peaceof mind with our all-round after-sales service. Withtelephone support, reliable service, individual maintenancecontracts and a rapid supply of replacement parts.Initial product instruction, device installation and serviceis undertaken within Germany by <strong>Beissbarth</strong> Service andby certified partner firms. This guarantees you comprehensive,rapid availability on site. Internationally, ourown <strong>Beissbarth</strong> branches and over 90 sales partners areavailable to help you in any way we can.This means that <strong>Beissbarth</strong> is always there for you.We reserve the right to modify technical specifications and equipment.Images may contain optional extras.Local distributor:<strong>Beissbarth</strong> GmbHA Bosch Group CompanyHanauer Strasse 10180993 Muenchen (Munich, Bavaria)GermanyTel. +49-89-149 01-0Fax +49-89-149 01-240www.beissbarth.comsales@beissbarth.comB/Drucknorm 148/04.2011 - 1 692 107 900 - EN