Ford Ford - Steve Plucker

Ford Ford - Steve Plucker

Ford Ford - Steve Plucker

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

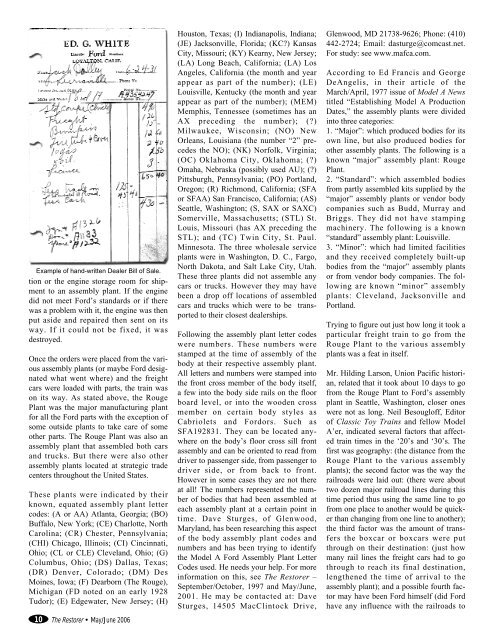

Example of hand-written Dealer Bill of Sale.tion or the engine storage room for shipmentto an assembly plant. If the enginedid not meet <strong>Ford</strong>’s standards or if therewas a problem with it, the engine was thenput aside and repaired then sent on itsway. If it could not be fixed, it wasdestroyed.Once the orders were placed from the variousassembly plants (or maybe <strong>Ford</strong> designatedwhat went where) and the freightcars were loaded with parts, the train wason its way. As stated above, the RougePlant was the major manufacturing plantfor all the <strong>Ford</strong> parts with the exception ofsome outside plants to take care of someother parts. The Rouge Plant was also anassembly plant that assembled both carsand trucks. But there were also otherassembly plants located at strategic tradecenters throughout the United States.These plants were indicated by theirknown, equated assembly plant lettercodes: (A or AA) Atlanta, Georgia; (BO)Buffalo, New York; (CE) Charlotte, NorthCarolina; (CR) Chester, Pennsylvania;(CHI) Chicago, Illinois; (CI) Cincinnati,Ohio; (CL or CLE) Cleveland, Ohio; (G)Columbus, Ohio; (DS) Dallas, Texas;(DR) Denver, Colorado; (DM) DesMoines, Iowa; (F) Dearborn (The Rouge),Michigan (FD noted on an early 1928Tudor); (E) Edgewater, New Jersey; (H)10 The Restorer • May/June 2006Houston, Texas; (I) Indianapolis, Indiana;(JE) Jacksonville, Florida; (KC?) KansasCity, Missouri; (KY) Kearny, New Jersey;(LA) Long Beach, California; (LA) LosAngeles, California (the month and yearappear as part of the number); (LE)Louisville, Kentucky (the month and yearappear as part of the number); (MEM)Memphis, Tennessee (sometimes has anAX preceding the number); (?)Milwaukee, Wisconsin; (NO) NewOrleans, Louisiana (the number “2” precedesthe NO); (NK) Norfolk, Virginia;(OC) Oklahoma City, Oklahoma; (?)Omaha, Nebraska (possibly used AU); (?)Pittsburgh, Pennsylvania; (PO) Portland,Oregon; (R) Richmond, California; (SFAor SFAA) San Francisco, California; (AS)Seattle, Washington; (S, SAX or SAXC)Somerville, Massachusetts; (STL) St.Louis, Missouri (has AX preceding theSTL); and (TC) Twin City, St. Paul.Minnesota. The three wholesale serviceplants were in Washington, D. C., Fargo,North Dakota, and Salt Lake City, Utah.These three plants did not assemble anycars or trucks. However they may havebeen a drop off locations of assembledcars and trucks which were to be transportedto their closest dealerships.Following the assembly plant letter codeswere numbers. These numbers werestamped at the time of assembly of thebody at their respective assembly plant.All letters and numbers were stamped intothe front cross member of the body itself,a few into the body side rails on the floorboard level, or into the wooden crossmember on certain body styles asCabriolets and <strong>Ford</strong>ors. Such asSFA192831. They can be located anywhereon the body’s floor cross sill frontassembly and can be oriented to read fromdriver to passenger side, from passenger todriver side, or from back to front.However in some cases they are not thereat all! The numbers represented the numberof bodies that had been assembled ateach assembly plant at a certain point intime. Dave Sturges, of Glenwood,Maryland, has been researching this aspectof the body assembly plant codes andnumbers and has been trying to identifythe Model A <strong>Ford</strong> Assembly Plant LetterCodes used. He needs your help. For moreinformation on this, see The Restorer –September/October, 1997 and May/June,2001. He may be contacted at: DaveSturges, 14505 MacClintock Drive,Glenwood, MD 21738-9626; Phone: (410)442-2724; Email: dasturge@comcast.net.For study: see www.mafca.com.According to Ed Francis and GeorgeDeAngelis, in their article of theMarch/April, 1977 issue of Model A Newstitled “Establishing Model A ProductionDates,” the assembly plants were dividedinto three categories:1. “Major”: which produced bodies for itsown line, but also produced bodies forother assembly plants. The following is aknown “major” assembly plant: RougePlant.2. “Standard”: which assembled bodiesfrom partly assembled kits supplied by the“major” assembly plants or vendor bodycompanies such as Budd, Murray andBriggs. They did not have stampingmachinery. The following is a known“standard” assembly plant: Louisville.3. “Minor”: which had limited facilitiesand they received completely built-upbodies from the “major” assembly plantsor from vendor body companies. The followingare known “minor” assemblyplants: Cleveland, Jacksonville andPortland.Trying to figure out just how long it took aparticular freight train to go from theRouge Plant to the various assemblyplants was a feat in itself.Mr. Hilding Larson, Union Pacific historian,related that it took about 10 days to gofrom the Rouge Plant to <strong>Ford</strong>’s assemblyplant in Seattle, Washington, closer oneswere not as long. Neil Besougloff, Editorof Classic Toy Trains and fellow ModelA’er, indicated several factors that affectedtrain times in the ‘20’s and ‘30’s. Thefirst was geography: (the distance from theRouge Plant to the various assemblyplants); the second factor was the way therailroads were laid out: (there were abouttwo dozen major railroad lines during thistime period thus using the same line to gofrom one place to another would be quickerthan changing from one line to another);the third factor was the amount of transfersthe boxcar or boxcars were putthrough on their destination: (just howmany rail lines the freight cars had to gothrough to reach its final destination,lengthened the time of arrival to theassembly plant); and a possible fourth factormay have been <strong>Ford</strong> himself (did <strong>Ford</strong>have any influence with the railroads to