No. 4 St Paul's Square - Lindner Group

No. 4 St Paul's Square - Lindner Group

No. 4 St Paul's Square - Lindner Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

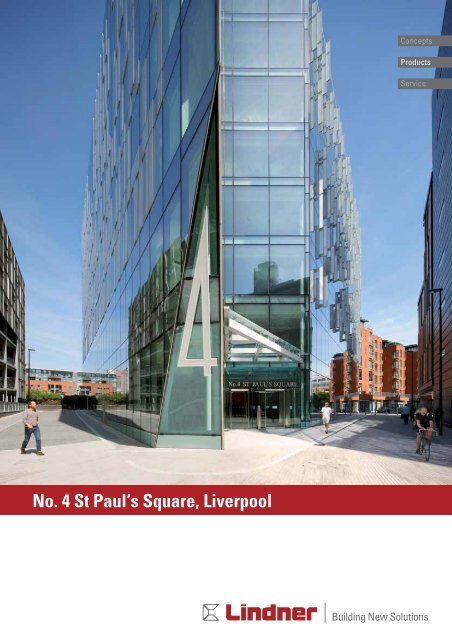

<strong>No</strong>. 4 <strong>St</strong> Paul‘s <strong>Square</strong>, Liverpool<br />

1<br />

Concepts<br />

Products<br />

Service

Project Report<br />

<strong>No</strong>. 4 <strong>St</strong> Paul‘s <strong>Square</strong>,<br />

Liverpool<br />

Regarded as one of the most signifi cant commercial developments in Liverpool city centre,<br />

the building provides a total of 10,000 m 2 of high quality Grade A offi ce space over eight<br />

fl oors and is the focal point for Liverpool’s Central Business District.<br />

<strong>No</strong>. 4 <strong>St</strong> Paul’s <strong>Square</strong> is rated BREEAM 'Excellent' and won an RICS award for best<br />

commercial development in the <strong>No</strong>rth West and includes sustainable features, such as a<br />

sedum roof, water-effi cient taps, cycle racks and a lighting system designed to minimise light<br />

pollution and to reduce carbon emissions by more than 22 %.<br />

Client: English Cities Fund<br />

Developer: Muse Developments<br />

Main Contractor: Shepherd Construction<br />

Project Architects: RHWL<br />

Facade Engineers: Buro Happold<br />

Completion date: 2011<br />

Photos: © HUFTON+CROW<br />

2

Building<br />

new solutions.<br />

<strong>Lindner</strong> undertakes major projects worldwide in all areas of interior fi t-out, insulation<br />

technology, industrial services and building facades. From pre-planning through to project<br />

completion <strong>Lindner</strong> is your partner of choice.<br />

The Company’s extensive manufacturing capability enables quality to be strictly<br />

maintained whilst allowing maximum fl exibility to meet individual project requirements.<br />

Environmental considerations are fundamental to all <strong>Lindner</strong>’s business principles.<br />

Through partnerships with clients <strong>Lindner</strong> turns concepts into reality.<br />

3

Unitised curtain<br />

wall facade<br />

The main envelope installation was achieved using a pre-fabricated and pre-glazed unitised form of<br />

construction and without the need for costly scaffolding. Elements were installed using our own fl oor<br />

cranes and the “Table Method” as shown below.<br />

This method allows facade elements to be passed over the top of the handrails and installed with the<br />

slab edge protection remaining in place providing a safety barrier for our operatives and others on site.<br />

The bespoke curtain wall elements, typically 1.5 m wide by 3.905 m high, were manufactured off-site at<br />

our Head Quarters in Arnstorf, Germany and delivered to site by road.<br />

The vertical feature fi ns, where required, were fi tted to the elements before installation.<br />

4

Scope of works<br />

Facade types and scope<br />

Design, manufacture and installation of bespoke structural silicone glazed<br />

curtain wall system including:<br />

- 5,500 m 2 unitised facade<br />

- Feature fi ns with Kapilux capillary tube insulation in glazed panels<br />

- Feature Kapilux double glazed shadow boxes and vision panels<br />

- Bolt fi xed glazed entrance and motorised doors<br />

- Bolt fi xed entrance canopy<br />

- Copings, metal panels and doors<br />

- Feature glazed “prow”<br />

Interior fi t out scope:<br />

- 200 m 2 fi re rated internal partitioning to entrance lobby<br />

5

6<br />

Unitised<br />

Facade<br />

to Offi ce<br />

Areas<br />

The main envelope is comprised<br />

of pre-fabricated and pre-glazed<br />

curtain wall elements with a natural<br />

anodised fi nish. The system is a<br />

structural silicone glazed (SSG)<br />

design which incorporates a small<br />

sub-frame to aid re-glazing. Vertical<br />

feature fi ns have an aluminium<br />

perimeter frame that has a double<br />

glazing unit with Kapilux capillary<br />

tube type insulation inside. This<br />

material is also used in parts of the<br />

vision glazing to add visual interest.

Technical details<br />

Facade performance test to CWCT sequence B<br />

- Watertightness static and dynamic: 600 Pa<br />

- Air permeability: 600 Pa<br />

- Thermal insulation curtain wall (typical): U cw 1.4 to 1.6 W/m 2 K<br />

- Thermal insulation glazing: U g 1.1 W/m 2 K<br />

- Solar shading / glazing g value: 0.33<br />

- Light transmission: 60 %<br />

7<br />

Typical elevation and<br />

section details of glazing<br />

system and fi ns<br />

The facade was tested to CWCT sequence B to 600 Pa, including dynamic aero engine test. Double glazed<br />

units to the vision areas had a combined high performance solar control and low-e coating to give high<br />

thermal insulation and high solar shading yet allow high light transmission through the glazing.

Glazed Kapilux feature fi ns<br />

8

Enlarged view of feature fi ns<br />

9

Offi ce interior view of feature fi ns<br />

Main entrance with fi re rated partitioning<br />

10

Shadow boxes and translucent Kapilux insulation<br />

11

We can do it all for you.<br />

<strong>Lindner</strong> Concepts:<br />

- Insulation Engineering<br />

- Clean Rooms and<br />

Laboratories<br />

- Airports and Airlines<br />

- Railways and Tunnels<br />

- <strong>St</strong>udios and Concert Halls<br />

- Interior Fit-out and Furnishings<br />

- Cruise Liner and Ship Fit-out<br />

- Hotels and Resorts<br />

- General Contracting<br />

<strong>Lindner</strong> Fassaden GmbH<br />

Georgstrasse 2<br />

94424 Arnstorf<br />

Germany<br />

Phone +49 (0)8723/20-35 00<br />

Fax + 49 (0)8723/20-35 35<br />

<strong>Lindner</strong>-Fassaden@<strong>Lindner</strong>-<strong>Group</strong>.com<br />

www.<strong>Lindner</strong>-<strong>Group</strong>.com<br />

<strong>Lindner</strong> Products:<br />

- Facades<br />

- <strong>St</strong>eel & Glass<br />

- Roofi ng Systems<br />

- Ceiling Systems<br />

- Lights and Lighting Systems<br />

- Partition Systems<br />

- Doors<br />

- Floor Systems<br />

- Heating and Cooling<br />

Technologies<br />

- Dry Lining Systems<br />

<strong>Lindner</strong> Service:<br />

- Green Building<br />

- Deconstruction and Gutting<br />

- Clearance of Harmful Substances<br />

- Industrial Scaffolding<br />

- Research and Development<br />

- Delivery<br />

- General Planning<br />

- Installation<br />

- Maintenance and<br />

Industrial Service<br />

- Public-Private Partnership (PPP)<br />

<strong>Lindner</strong> Facades Limited<br />

<strong>Lindner</strong> House<br />

317 Putney Bridge Road<br />

London SW15 2PG<br />

United Kingdom<br />

Phone +44 (0)20 8246 6300<br />

Fax +44 (0)20 8246 6301<br />

<strong>Lindner</strong>-Facades@<strong>Lindner</strong>-<strong>Group</strong>.com<br />

www.<strong>Lindner</strong>-<strong>Group</strong>.com<br />

This document is the intellectual property of <strong>Lindner</strong>, Arnstorf (Germany). All the information contained in this brochure agrees with the information<br />

available at the time of its printing and only serves as advance information. Any possible colour deviations there might be from the original product are<br />

caused by printing-related reasons. <strong>Lindner</strong> is the sole and exclusive owner of the copyrights as well as the ancillary copyright. All use, and in particular<br />

12<br />

any distribution, reprinting, exploitation or adaptation of this document shall only be allowed with express, written approval by <strong>Lindner</strong>.<br />

PR_F_4<strong>St</strong>P/E/1.0