Usan Project - TOTAL Nigeria

Usan Project - TOTAL Nigeria

Usan Project - TOTAL Nigeria

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

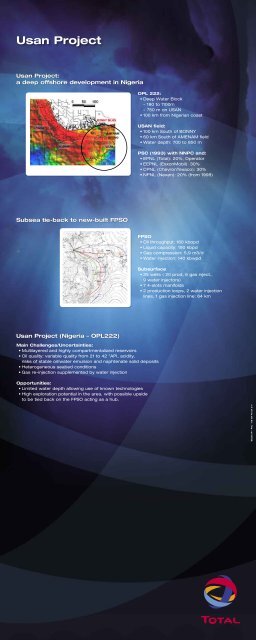

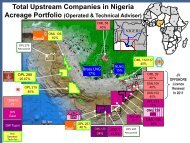

<strong>Usan</strong> <strong>Project</strong><strong>Usan</strong> <strong>Project</strong>:a deep offshore development in <strong>Nigeria</strong>OPL 222:• Deep Water Block- 180 to 1100m- 750 m on USAN• 100 km from <strong>Nigeria</strong>n coastUSAN field:• 100 km South of BONNY• 60 km South of AMENAM field• Water depth: 700 to 850 mPSC (1993) with NNPC and:• EPNL (Total): 20%, Operator• EEPNL (ExxonMobil): 30%• CPNL (ChevronTexaco): 30%• NPNL (Nexen): 20% (from 1998)Subsea tie-back to new-built FPSOFPSO• Oil throughput: 160 kbopd• Liquid capacity: 190 kbpd• Gas compression: 5,9 m3/d• Water injection: 140 kbwpdSubsurface• 35 wells ( 20 prod, 6 gas inject.,9 water injectors)• 7 4-slots manifolds• 2 production loops, 2 water injectionlines, 1 gas injection line: 64 km<strong>Usan</strong> <strong>Project</strong> (<strong>Nigeria</strong> – OPL222)Main Challenges/Uncertainties:• Multilayered and highly compartmentalized reservoirs• Oil quality: variable quality from 21 to 42 °API, acidity,risks of stable oil/water emulsion and naphtenate solid deposits• Heterogeneous seabed conditions• Gas re-injection supplemented by water injectionOpportunities:• Limited water depth allowing use of known technologies• High exploration potential in the area, with possible upsideto be tied back on the FPSO acting as a hub.Studio W - Pau - 05 59 40 27 2 7

AKPOThe Akpo <strong>Project</strong> is a <strong>Nigeria</strong> Deep offshoredevelopment based on a stand-alone facility featuring:• a new-built FPSO spread moored in 1,314 m of water• 44 subsea wells• insulated production flow lines and steel catenary risers• an export line for stabilised condensate via an offloading buoy,• and a gas export line to AmenamSurface facilities development schemeA total of 44 subsea wells arrangedaround dispersed and clustered subseaarchitecture and connected to theproduction facilities on the FPSO viainsulated production flow lines and steelcatenary risers. The subsea facilitieswill include 4 production loops with 9manifolds for 22 production wells, 4injection lines for 20 water injection wells,1 gas injection line for 2 gas injectors.The stabilised condensate will be produced ata design rate of 185 kbpd and stored on theFPSO prior to export via an offloading buoy intypical parcel sizes of 1 Mbbls (VLCC). A tandemoffloading could be used if the buoy is unavailble.The pressure in Akpo reservoir D will be maintainedby re-injecting associated gas with the balance ofthe a gas produced being treated for export viaa subsea pipeline to Amenam, Water injectionfacilities will be installed for pressure maintenancein the Akpo East and Akpo Central A,B,EF &G reservoirs. There will be no continuous gasflaring.A flow line / riser corridor has been identified andspace has been allocated on the west side of theFPSO for a tie-in of future risers and umbilicalsAKPO field development FPSOFPSO Design Capacity• Stabilised condensate (average)• Stabilised condensate (max)• Total fluids• Produced gas• Injected gas• Fuel gas• Exported gas• Injected water• Produced water• Crude StorageFPSO CharacteristicsDesign life20 years,Max POB 240 (sleeping capacity 220)Total topsides net dry weight 27,000te (incl accommodation module)Hull dimensions 310 x 61 x 31 m,Hull net dry weight51,000 te,Hull designed for deadweight 305,000 teTotal displacement410,000 teDouble hull design15 tanks (13 condensate, 2 x ballast),Separation4 stages (80, 24, 9 & 2 bara),Separators2 x 1st stage + test separator,Power generation120 MW (5 x 24 MW {(dual fuel} + 1 spare),Power loads86 MW (63 MW without gas export),Riser slots 40Spare slots18 of which 6 SCRStudio W - Pau - 05 59 40 27 2 7Challenges• 44 deviated or horizontal wells to be drilledwith qualified Dynamic Positioning deep waterdrilling units• reservoir sands are heterogeneous andunconsolidated requiring 4 different typesof sand control technologies and intelligentcompletions.