Featuring Plywood in Buildings - Engineered Wood Products ...

Featuring Plywood in Buildings - Engineered Wood Products ...

Featuring Plywood in Buildings - Engineered Wood Products ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

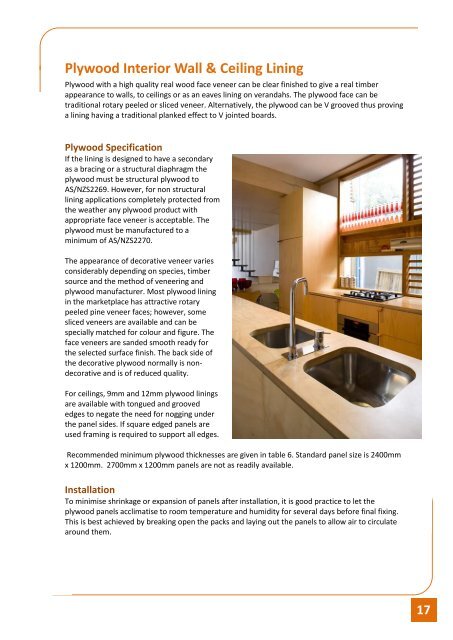

<strong>Plywood</strong> Interior Wall & Ceil<strong>in</strong>g L<strong>in</strong><strong>in</strong>g<strong>Plywood</strong> with a high quality real wood face veneer can be clear f<strong>in</strong>ished to give a real timberappearance to walls, to ceil<strong>in</strong>gs or as an eaves l<strong>in</strong><strong>in</strong>g on verandahs. The plywood face can betraditional rotary peeled or sliced veneer. Alternatively, the plywood can be V grooved thus prov<strong>in</strong>ga l<strong>in</strong><strong>in</strong>g hav<strong>in</strong>g a traditional planked effect to V jo<strong>in</strong>ted boards.<strong>Plywood</strong> SpecificationIf the l<strong>in</strong><strong>in</strong>g is designed to have a secondaryas a brac<strong>in</strong>g or a structural diaphragm theplywood must be structural plywood toAS/NZS2269. However, for non structurall<strong>in</strong><strong>in</strong>g applications completely protected fromthe weather any plywood product withappropriate face veneer is acceptable. Theplywood must be manufactured to am<strong>in</strong>imum of AS/NZS2270.The appearance of decorative veneer variesconsiderably depend<strong>in</strong>g on species, timbersource and the method of veneer<strong>in</strong>g andplywood manufacturer. Most plywood l<strong>in</strong><strong>in</strong>g<strong>in</strong> the marketplace has attractive rotarypeeled p<strong>in</strong>e veneer faces; however, somesliced veneers are available and can bespecially matched for colour and figure. Theface veneers are sanded smooth ready forthe selected surface f<strong>in</strong>ish. The back side ofthe decorative plywood normally is nondecorativeand is of reduced quality.For ceil<strong>in</strong>gs, 9mm and 12mm plywood l<strong>in</strong><strong>in</strong>gsare available with tongued and groovededges to negate the need for nogg<strong>in</strong>g underthe panel sides. If square edged panels areused fram<strong>in</strong>g is required to support all edges.Recommended m<strong>in</strong>imum plywood thicknesses are given <strong>in</strong> table 6. Standard panel size is 2400mmx 1200mm. 2700mm x 1200mm panels are not as readily available.InstallationTo m<strong>in</strong>imise shr<strong>in</strong>kage or expansion of panels after <strong>in</strong>stallation, it is good practice to let theplywood panels acclimatise to room temperature and humidity for several days before f<strong>in</strong>al fix<strong>in</strong>g.This is best achieved by break<strong>in</strong>g open the packs and lay<strong>in</strong>g out the panels to allow air to circulatearound them.17