Featuring Plywood in Buildings - Engineered Wood Products ...

Featuring Plywood in Buildings - Engineered Wood Products ...

Featuring Plywood in Buildings - Engineered Wood Products ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

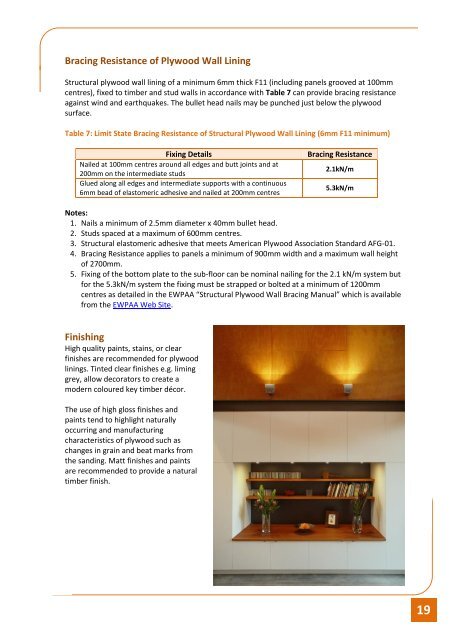

Brac<strong>in</strong>g Resistance of <strong>Plywood</strong> Wall L<strong>in</strong><strong>in</strong>gStructural plywood wall l<strong>in</strong><strong>in</strong>g of a m<strong>in</strong>imum 6mm thick F11 (<strong>in</strong>clud<strong>in</strong>g panels grooved at 100mmcentres), fixed to timber and stud walls <strong>in</strong> accordance with Table 7 can provide brac<strong>in</strong>g resistanceaga<strong>in</strong>st w<strong>in</strong>d and earthquakes. The bullet head nails may be punched just below the plywoodsurface.Table 7: Limit State Brac<strong>in</strong>g Resistance of Structural <strong>Plywood</strong> Wall L<strong>in</strong><strong>in</strong>g (6mm F11 m<strong>in</strong>imum)Fix<strong>in</strong>g DetailsNailed at 100mm centres around all edges and butt jo<strong>in</strong>ts and at200mm on the <strong>in</strong>termediate studsGlued along all edges and <strong>in</strong>termediate supports with a cont<strong>in</strong>uous6mm bead of elastomeric adhesive and nailed at 200mm centresBrac<strong>in</strong>g Resistance2.1kN/m5.3kN/mNotes:1. Nails a m<strong>in</strong>imum of 2.5mm diameter x 40mm bullet head.2. Studs spaced at a maximum of 600mm centres.3. Structural elastomeric adhesive that meets American <strong>Plywood</strong> Association Standard AFG-01.4. Brac<strong>in</strong>g Resistance applies to panels a m<strong>in</strong>imum of 900mm width and a maximum wall heightof 2700mm.5. Fix<strong>in</strong>g of the bottom plate to the sub-floor can be nom<strong>in</strong>al nail<strong>in</strong>g for the 2.1 kN/m system butfor the 5.3kN/m system the fix<strong>in</strong>g must be strapped or bolted at a m<strong>in</strong>imum of 1200mmcentres as detailed <strong>in</strong> the EWPAA “Structural <strong>Plywood</strong> Wall Brac<strong>in</strong>g Manual” which is availablefrom the EWPAA Web Site.F<strong>in</strong>ish<strong>in</strong>gHigh quality pa<strong>in</strong>ts, sta<strong>in</strong>s, or clearf<strong>in</strong>ishes are recommended for plywoodl<strong>in</strong><strong>in</strong>gs. T<strong>in</strong>ted clear f<strong>in</strong>ishes e.g. lim<strong>in</strong>ggrey, allow decorators to create amodern coloured key timber décor.The use of high gloss f<strong>in</strong>ishes andpa<strong>in</strong>ts tend to highlight naturallyoccurr<strong>in</strong>g and manufactur<strong>in</strong>gcharacteristics of plywood such aschanges <strong>in</strong> gra<strong>in</strong> and beat marks fromthe sand<strong>in</strong>g. Matt f<strong>in</strong>ishes and pa<strong>in</strong>tsare recommended to provide a naturaltimber f<strong>in</strong>ish.19