Rotary Screw Compressors SM Series - Kaeser Kompressoren

Rotary Screw Compressors SM Series - Kaeser Kompressoren

Rotary Screw Compressors SM Series - Kaeser Kompressoren

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

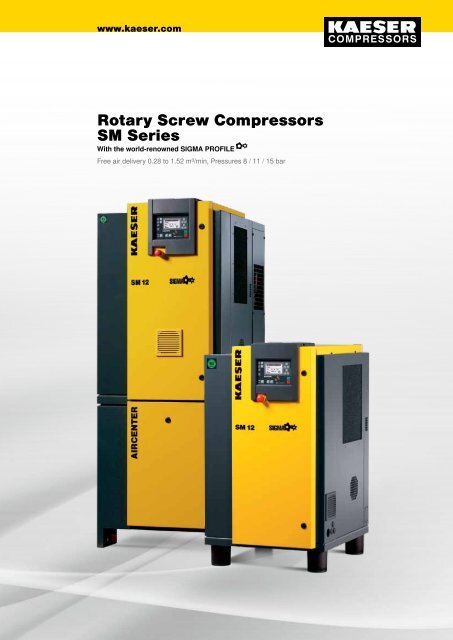

www.kaeser.com<strong>Rotary</strong> <strong>Screw</strong> <strong>Compressors</strong><strong>SM</strong> <strong>Series</strong>With the world-renowned SIGMA PROFILEFree air delivery 0.28 to 1.52 m³/min, Pressures 8 / 11 / 15 bar

www.kaeser.com<strong>SM</strong> <strong>Series</strong>Quiet, dependable performance<strong>SM</strong>: Long-term savingsToday’s users expect maximum availability and efficiency from their compressors, regardless of size.<strong>SM</strong> series rotary screw compressors meet all of these needs and more. Not only do they deliver morecompressed air for less power consumption, but they also combine ease of use and maintenance withexceptional versatility and environmentally responsible design.More air for your money<strong>Kaeser</strong>’s engineers have significantly boosted theperformance of <strong>SM</strong> series compressors comparedto previous models. This impressive feat has beenachieved both through airend optimisation and theminimisation of internal pressure losses.Energy-saving performanceThe efficiency of a machine depends on the totalcosts incurred throughout the equipment’s entireservice life. With compressors, energy costs accountfor the lion’s share of total expenditure. <strong>Kaeser</strong>therefore designed its <strong>SM</strong> series compressors withoptimum energy efficiency in mind. Refinementsto the energy-saving Sigma Profile airend rotorsand the use of IE3 premium efficiency motors havesignificantly contributed to the increased performanceof these versatile compressors. The addition of theSIGMA CONTROL 2 internal controller and <strong>Kaeser</strong>’sunique cooling system have helped to push theboundaries of efficiency even further.Optimised designThe new <strong>SM</strong> models all share logical and userfriendlydesign throughout. For example, the lefthandenclosure panel can be removed in a fewsimple steps and allows excellent visibility of thesystem’s intelligently laid out components. Needlessto say, the new <strong>SM</strong> series was designed to ensurebest possible access to all service points. Whenclosed, the sound-absorbing compressor enclosurekeeps operational sound levels to a minimum therebyensuring a pleasantly quiet work environment. Inaddition, the enclosure features four inlet openingsfor separate airflow cooling of the compressor, themotor and the control cabinet and for compressorintake air. Last, but not least, <strong>SM</strong> series compressorsare impressively compact, which makes them theperfect choice for applications where space is at apremium.Potential energy cost savingsthrough heat recoveryCompressed air system investmentMaintenance costsFig.: <strong>SM</strong> 12Energy cost savings throughsystem optimisationEnergy costsPotential energy cost savings2 3

www.kaeser.com<strong>SM</strong> <strong>Series</strong>Design is in the detailsName:Level:Valid until:SIGMA PROFILE airendAt the heart of every <strong>SM</strong> system lies a premium qualityairend featuring <strong>Kaeser</strong>’s SIGMA PROFILE rotors.With optimised flow characteristics, these rotors play akey role in setting the new standard in specific powerperformance.SIGMA CONTROL 2The SIGMA CONTROL 2 ensures efficientcontrol and system monitoring. The large displayand RFID reader provide effective communicationand maximum security. Multiple interfaces offerexceptional flexibility, whilst the SD card slot makesupdates quick and easy.4Maximum efficiency: IE3 motors<strong>Kaeser</strong> rotary screw airends are powered byIE3 drive motors for maximum performanceand reliability. Use of these motors will becomemandatory in the EU from the 1st of January 2015,but users can already enjoy the benefits that thesepremium efficiency motors have to offer by choosing<strong>Kaeser</strong> <strong>SM</strong> series rotary screw compressors.Dual-flow fanThe dual-flow fan supplies cooling air to both thedrive motor and the entire package. Crescent-shapedfan blades help keep operating sound levels to anabsolute minimum.5

www.kaeser.com<strong>SM</strong> T (SFC) <strong>Series</strong>Also available with refrigeration dryerand variable speed control<strong>SM</strong> with energy-saving dryerThe compressed air refrigeration dryer is installed ina separate enclosure to shield it from heat radiatedby the compressor; this design approach thereforeenhances reliability. The automatic dryer shutdownfeature further aids energy-efficient performance.Variable speed control also availableThe use of variable speed control can providedefinite advantages for specific applications, which iswhy the <strong>SM</strong> 12 is also available with this feature. Thefrequency converter is integrated into the compressorsystem’s control cabinet.Fig.: <strong>SM</strong> 12 TEven quieterThe new cooling system provides outstanding coolingperformance and enables optimum sound-proofing.Normal conversation can take place right next to therunning compressor.Maintenance friendlyAll maintenance work can be carried out from oneside of the unit. The left housing cover is easilyremoved to allow excellent component accessibility.67

www.kaeser.comAIRCENTERThe compact and efficientcompressed air packageConnect and goAll this compact compressed air package needs is tobe connected to the power supply and compressedair distribution network. That’s it!Long-lasting air receiverThe 270-litre air receiver is especially designedfor installation in AIRCENTER systems. All innerand outer surfaces are coated to provide excellentcorrosion protection and ensure long service life.Fig.: AIRCENTER 12Service-friendly designThe left-hand housing cover is easily removed toallow excellent accessibility to all service points.Inspection glasses allow convenient inspectionof fluid levels and drive belt tension whilst the unitis in operation.Excellent component accessAll maintenance and service components are easilyaccessible, which significantly reduces the downtimeassociated with service and maintenance tasks.This helps to increase compressed air availability andminimises operating costs.89

www.kaeser.com1011

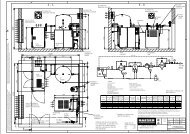

www.kaeser.comEquipmentViewsComplete unitReady-to-run, fully automatic, supersilenced,vibration damped, all panelspowder coated. Suitable for use inambient temperatures up to +45°C.AirendGenuine KAESER rotary screw, singlestage airend with SIGMA PROFILErotors and cooling fluid injection foroptimised rotor cooling.Electric motorPremium efficiency IE3 motor, qualityGerman manufacture, IP 54.Refrigeration dryer(with ‘T’ version)With electronically-controlledcondensate drain. Refrigerantcompressor with energy-saving,cycling shutdown feature; linked tooperational status of the compressorwhen inactive. Alternatively,continuous operation can be selectedon site.Electrical componentsVentilated IP 54 control cabinet,automatic star-delta starter, overloadrelay, control transformer.control modes as required. Interfaces:Ethernet; additional optionalcommunication modules for: ProfibusDP, Modbus, Profinet and Devicenet.SD-card slot for data-logging andupdates. RFID reader, web server.<strong>SM</strong> series rotary screw compressors also optionally availablewith SIGMA CONTROL BASIC.Standard model1100630762Front view Left view Right view Rear viewModel with integrated refrigeration dryerFluid and air flowSIGMA CONTROL 2“Honeycomb” air intake filter,pneumatic inlet and venting valves,cooling fluid separator tank with tripleseparation system, pressure reliefvalve, minimum pressure / checkvalve, thermostatic valve and fluid filterwithin the cooling fluid circuit, fluid /compressed air combination cooler.Red, yellow and green LEDs showoperational status at a glance. Alsofeatures a plain text display, 30selectable languages, soft-touchkeys with icons; fully automatedmonitoring and control. Selection ofDual, Quadro, Vario and Continuous11001074630Front view Left view Right view Rear viewGeneral designModel with refrigeration dryer and variable-speed driveStandard versionIntake filterInlet valve1100AirendDrive motor1074630Fluid separator tankFront view Left view Right view Rear viewCompressed air aftercoolerFluid coolerFluid filterAIRCENTER seriesFan17161200630Front view Left view Right view Rear view1213

www.kaeser.comTechnical SpecificationsStandard versionAIRCENTER – Version with refrigeration dryer and compressed air receiverModellBertriebsüberdruckWorkingpressureLiefermengeFAD*)*)Max. max.Überdruck operatingpressureMotor-Ratednenn-leistungmotorpowerKältetrockner-Refrigerationdryer leistungs-aufnahmepowerconsumptionAnschluss Airconnection DruckluftAbmessungenDimensionsW B x T D x HSchall-Soundpressure druck-pegel level**)Weight MasseModellBertriebsüberdruckWorkingpressureLiefermengeFAD*)*)max. Max.Überdruck operatingpressureMotor-Ratednenn-leistungmotorpowerKältetrockner-Refrigerationdryer leistungs-aufnahmepowerconsumptionAnschluss Airconnection DruckluftAbmessungenDimensionsW B x T D x HAir BehältervolumenreceiverSchall-Soundpressure druck-pegel level**)Weight Massebar m³/min bar kW kW mm dB(A) kgbar m³/min bar kW kW l mm dB(A) kg<strong>SM</strong> 97.510130.900.750.56811155.5 – G 3 / 4 630 x 762 x 1100 64 200AIRCENTER 97.510130.900.750.56811155.5 0.31 270 G 3 / 4 630 x 1200 x 1716 64 390<strong>SM</strong> 127.510131.201.010.77811157.5 – G 3 / 4 630 x 762 x 1100 65 210AIRCENTER 127.510131.201.010.77811157.5 0.31 270 G 3 / 4 630 x 1200 x 1716 65 400<strong>SM</strong> 157.510131.501.260.99811159 – G 3 / 4 630 x 762 x 1100 66 220AIRCENTER 157.510131.501.260.99811159 0.32 270 G 3 / 4 630 x 1200 x 1716 66 410T-version with integrated refrigeration dryer (refrigerant R 134a)AIRCENTER SFC – Version with variable speed driveModellBertriebsüberdruckWorkingpressureLiefermengeFAD*)*)Max. max.Überdruck operatingpressureMotor-Ratednenn-leistungmotorpowerKältetrockner-Refrigerationdryer leistungs-aufnahmepowerconsumptionAnschluss Airconnection DruckluftAbmessungenDimensionsW B x T D x HSchall-Soundpressure druck-pegel level**)Weight MasseModellBertriebsüberdruckWorkingpressureLiefermengeFAD*)*)max. Max.Überdruck operatingpressureMotor-Ratednenn-leistungmotorpowerKältetrockner-Refrigerationdryer leistungs-aufnahmepowerconsumptionAnschluss Airconnection DruckluftAbmessungenDimensionsW B x T D x HAir BehältervolumenreceiverSchall-Soundpressure druck-pegel level**) **)Weight Massebar m³/min bar kW kW mm dB(A) kgbar m³/min bar kW kW l mm dB(A) kg<strong>SM</strong> 9 T7.510130.900.750.56811155.5 0.31 G 3 / 4 630 x 1074 x 1100 64 275AIRCENTER 12 SFC7.510130.35 - 1.240.34 - 1.040.30 - 0.78811157.5 0.31 270 G 3 / 4 630 x 1200 x 1716 67 410<strong>SM</strong> 12 T7.510131.201.010.77811157.5 0.31 G 3 / 4 630 x 1074 x 1100 65 285*) FAD complete system as per ISO 1217 : 2009, Annex C: absolute inlet pressure 1 bar (a), cooling and air inlet temperature 20 °C**) Sound pressure level as per ISO 2151 and the basic standard ISO 9614-2, tolerance: ± 3 dB(A)<strong>SM</strong> 15 T7.510131.501.260.99811159 0.32 G 3 / 4 630 x 1074 x 1100 66 295T-SFC - Version with variable speed drive and integrated refrigeration dryerModellBertriebsüberdruckWorkingpressureLiefermengeFAD*)*)Max. max.Überdruck operatingpressureMotor-Ratednenn-leistungmotorpowerKältetrockner-Refrigerationdryer leistungs-aufnahmepowerconsumptionAnschluss Airconnection DruckluftAbmessungenDimensionsW B x T D x HSchall-Soundpressure druck-pegel level**)Weight Massebar m³/min bar kW kW mm dB(A) kg<strong>SM</strong> 12 SFC7.510130.35 - 1.240.34 - 1.040.30 - 0.78811157.5 – G 3 / 4 630 x 762 x 1100 67 220<strong>SM</strong> 12 T SFC7.510130.35 - 1.240.34 - 1.040.30 - 0.78811157.5 0,31 G 3 / 4 630 x 1074 x 1100 67 2951415

www.kaeser.comChoose the required grade of treatment according to your field of application:Air treatment using a refrigeration dryer (pressure dew point +3°C)Application examples: Selection of treatment classes to ISO 8573-1 (2010)Pure air and clean roomtechnology, dairies, breweriesFoodstuff productionVery clean conveying air,chemical plantsPharmaceutical industrySolids Water123144441111OilDHSDHSDHSDHSFFFE FD ACT FFFFFFGInstallation for heavilyfluctuating air demandARAROptionalfiltration RD* ZKACTAQUAMATDDDHSAREDFB / FCFDFE / FFFFGFGRDTHNFZKExplanationActivated carbon adsorberAQUAMATDesiccant dryerAir-main charging systemAir receiverECO DRAINPre-fi lterParticulate fi lterMicrofi lterActivated carbon and microfi lter combinationActivated carbon fi lterRefrigeration dryerBag fi lterCentrifugal separatorWeaving machines, photolabs241DHSRD*EDCompressorTHNFCompressed air quality classes to ISO 8573-1(2010):Solid particles / dustPaint spraying, powdercoating142DHSFFClassmax. particle count per m³ of aparticle size with d [µm]*Packaging, control andinstrument air242DHSFE00.1 ≤ d ≤ 0.5 0.5 ≤ d ≤ 1.0 1.0 ≤ d ≤ 5.0e.g. Consult KAESER regardingpure air and cleanroom technologyGeneral works air, high-gradesand blastingShot blasting444733DHSFCAQUAMAT1 ≤ 20,000 ≤ 400 ≤ 102 ≤ 400,000 ≤ 6,000 ≤ 1003 Not defi ned ≤ 90,000 ≤ 1,0004 Not defi ned Not defi ned ≤ 10,0005 Not defi ned Not defi ned ≤ 100,000Low-grade shot blastingConveying air for wastewater systemsNo quality requirements56X7-X7-XX44XFor KAESER rotary screw compressorsOther machinesFB* FE microfilters canbe optionally installedin TG to TI seriesrefrigeration dryers.Class Particle concentration C p in mg/m³ *6 0 < C p ≤ 57 5 < C p ≤ 10X C p > 10WaterClass Pressure dew point, in °CFor non frost protected air systems: Compressed air treatment with a desiccant dryer(down to -70 °C pressure dew point)Pure air and clean roomtechnology, pharmaceuticals,dairies, breweriesMicrochip production,optics and foodstuffsPaint sprayingProcess air, pharmaceuticalsPhoto labsEspecially dry conveyingair, paint spraying, finepressure controllersSolids Water1231231-31-31-31-31-31-3111112OilDHSDHSDHSDHSDHSDHSFFFEFFFDFGACTFDInstallation for heavilyfluctuating air demandARAROptionalfiltration DD** FE ZKDD** FE ED Compressor THNFAQUAMAT** An aftercooler is required where applicablefor heat regenerated desiccant dryers.0e.g. Consult KAESER regardingpure air and cleanroom technology1 ≤ – 70 °C2 ≤ – 40 °C3 ≤ – 20 °C4 ≤ + 3 °C5 ≤ + 7 °C6 ≤ + 10 °CClass Concentration of liquid water C W in g/m³ *Oil7 C W ≤ 0.58 0.5 < C W ≤ 59 5 < C W ≤ 10X C W > 10Class0Total oil concentration(fluid, aerosol + gaseous) [mg/m³]*e.g. Consult KAESER regardingpure air and cleanroom technology1 ≤ 0.012 ≤ 0.13 ≤ 1.04 ≤ 5.0X > 5.0*) At reference conditions 20°C, 1 bar(a), 0% humidityKAESER <strong>Kompressoren</strong> SEP.O. Box 2143 – 96410 Coburg – GERMANY – Tel +49 9561 640-0 – Fax +49 9561 640130e-mail: productinfo@kaeser.com – www.kaeser.comP-651/24ED.8/14 Specifications are subject to change without notice.