Aarhus – Capital of Wind Energy - Aarhus.dk

Aarhus – Capital of Wind Energy - Aarhus.dk

Aarhus – Capital of Wind Energy - Aarhus.dk

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

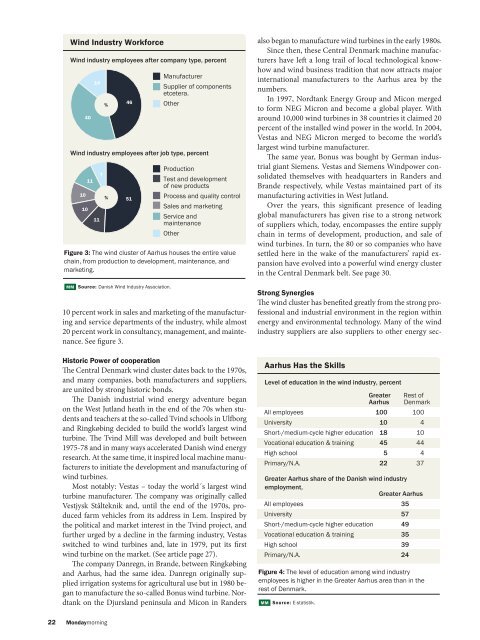

<strong>Wind</strong> Industry Workforce<strong>Wind</strong> industry employees after company type, percent1040101114117%%4651ManufacturerSupplier <strong>of</strong> componentsetcetera.Other<strong>Wind</strong> industry employees after job type, percentProductionTest and development<strong>of</strong> new productsProcess and quality controlSales and marketingService andmaintenanceOtherFigure 3: The wind cluster <strong>of</strong> <strong>Aarhus</strong> houses the entire valuechain, from production to development, maintenance, andmarketing.also began to manufacture wind turbines in the early 1980s.Since then, these Central Denmark machine manufacturershave left a long trail <strong>of</strong> local technological knowhowand wind business tradition that now attracts majorinternational manufacturers to the <strong>Aarhus</strong> area by thenumbers.In 1997, Nordtank <strong>Energy</strong> Group and Micon mergedto form NEG Micron and become a global player. Witharound 10,000 wind turbines in 38 countries it claimed 20percent <strong>of</strong> the installed wind power in the world. In 2004,Vestas and NEG Micron merged to become the world’slargest wind turbine manufacturer.The same year, Bonus was bought by German industrialgiant Siemens. Vestas and Siemens <strong>Wind</strong>power consolidatedthemselves with headquarters in Randers andBrande respectively, while Vestas maintained part <strong>of</strong> itsmanufacturing activities in West Jutland.Over the years, this significant presence <strong>of</strong> leadingglobal manufacturers has given rise to a strong network<strong>of</strong> suppliers which, today, encompasses the entire supplychain in terms <strong>of</strong> development, production, and sale <strong>of</strong>wind turbines. In turn, the 80 or so companies who havesettled here in the wake <strong>of</strong> the manufacturers’ rapid expansionhave evolved into a powerful wind energy clusterin the Central Denmark belt. See page 30.tors and major environmental and energy-tech companiesin the area <strong>–</strong> like the world’s largest pump manufacturer,Grundfos, to name one.According to the Danish <strong>Wind</strong> Industry Association,there are significant cross-sector synergies between thewind cluster and these other supply chains.One significant effect is that the skill and educationlevels are higher than in the rest <strong>of</strong> Denmark. An analysisfrom eStatistic shows that the Central Denmark region hasa greater share <strong>of</strong> employees with higher education in thesefields than Copenhagen, the Danish capital, whose generallevel <strong>of</strong> education is considerably higher in practically anyother area. If you look specifically at the Greater <strong>Aarhus</strong>area, where the wind cluster has its centre, the trend is evenmore distinct.Almost 60 percent <strong>of</strong> the wind industry employees witha university education work in the Greater <strong>Aarhus</strong> area. In<strong>Aarhus</strong>, more than 25 percent have a higher education. Inthe rest <strong>of</strong> Denmark, the ratio is one to six. See figure 4.The Greater <strong>Aarhus</strong> area has by far the greatest proportion<strong>of</strong> decision-makers in the wind industry. Almost 60percent <strong>of</strong> all top executives, and more than half <strong>of</strong> otherhigh-ranking employees, work in the Greater <strong>Aarhus</strong> areawind cluster. See figure 5.<strong>Aarhus</strong> is High-End<strong>Wind</strong> industry employees after socio-economic status,percentGreater Rest <strong>of</strong><strong>Aarhus</strong> DenmarkAll employees 100 100Top executives 7 3High-skill employees 13 6Medium-skilled employees 22 10Other 58 81Greater <strong>Aarhus</strong>’ share <strong>of</strong> Danish wind industryemployment, percentGreater <strong>Aarhus</strong>All employees 35Top executives 57High-skill employees 53Medium-skilled employees 55Other 28Figur 5: The <strong>Aarhus</strong> wind cluster has a higher percentage <strong>of</strong>high-skilled employees than the rest <strong>of</strong> the country.Source: E-statistik.Source: Danish <strong>Wind</strong> Industry Association.10 percent work in sales and marketing <strong>of</strong> the manufacturingand service departments <strong>of</strong> the industry, while almost20 percent work in consultancy, management, and maintenance.See figure 3.Strong SynergiesThe wind cluster has benefited greatly from the strong pr<strong>of</strong>essionaland industrial environment in the region withinenergy and environmental technology. Many <strong>of</strong> the windindustry suppliers are also suppliers to other energy sec-Historic Power <strong>of</strong> cooperationThe Central Denmark wind cluster dates back to the 1970s,and many companies, both manufacturers and suppliers,are united by strong historic bonds.The Danish industrial wind energy adventure beganon the West Jutland heath in the end <strong>of</strong> the 70s when studentsand teachers at the so-called Tvind schools in Ulfborgand Ringkøbing decided to build the world’s largest windturbine. The Tvind Mill was developed and built between1975-78 and in many ways accelerated Danish wind energyresearch. At the same time, it inspired local machine manufacturersto initiate the development and manufacturing <strong>of</strong>wind turbines.Most notably: Vestas <strong>–</strong> today the world´s largest windturbine manufacturer. The company was originally calledVestjysk Stålteknik and, until the end <strong>of</strong> the 1970s, producedfarm vehicles from its address in Lem. Inspired bythe political and market interest in the Tvind project, andfurther urged by a decline in the farming industry, Vestasswitched to wind turbines and, late in 1979, put its firstwind turbine on the market. (See article page 27).The company Danregn, in Brande, between Ringkøbingand <strong>Aarhus</strong>, had the same idea. Danregn originally suppliedirrigation systems for agricultural use but in 1980 beganto manufacture the so-called Bonus wind turbine. Nordtankon the Djursland peninsula and Micon in Randers<strong>Aarhus</strong> Has the SkillsLevel <strong>of</strong> education in the wind industry, percentGreater Rest <strong>of</strong><strong>Aarhus</strong> DenmarkAll employees 100 100University 10 4Short-/medium-cycle higher education 18 10Vocational education & training 45 44High school 5 4Primary/N.A. 22 37Greater <strong>Aarhus</strong> share <strong>of</strong> the Danish wind industryemployment,Greater <strong>Aarhus</strong>All employees 35University 57Short-/medium-cycle higher education 49Vocational education & training 35High school 39Primary/N.A. 24Figure 4: The level <strong>of</strong> education among wind industryemployees is higher in the Greater <strong>Aarhus</strong> area than in therest <strong>of</strong> Denmark.Source: E-statistik.22 Mondaymorning <strong>Aarhus</strong> <strong>–</strong> <strong>Capital</strong> <strong>of</strong> <strong>Wind</strong> <strong>Energy</strong> 23