Nautilus® CC plus - Bego USA

Nautilus® CC plus - Bego USA

Nautilus® CC plus - Bego USA

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

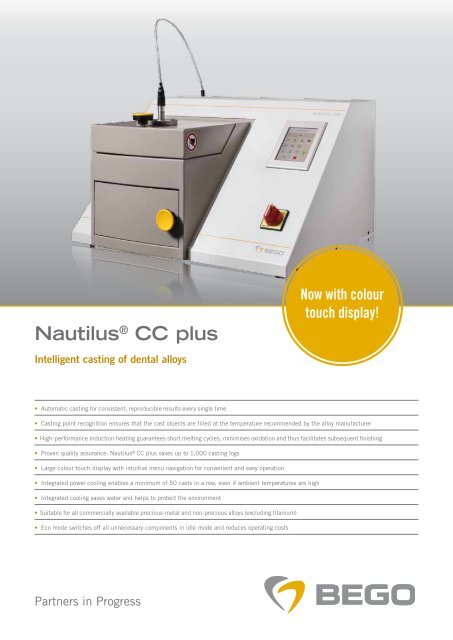

Combination of high-frequency melting andvacuum pressure castingNautilus ® <strong>CC</strong> <strong>plus</strong> combines the advantages of high-frequencymelting with those of vacuum pressure casting: the alloy ismelted in the area around the crucible opening. Using a highlyefficient vacuum pump, the oxygen level in the entire castingchamber is greatly reduced within a very short space of time andthe alloy is melted by means of a high-frequency magnetic field.The melt then flows directly under vacuum from the hot area intothe mould without temperature loss. Within fractions of a second,the still molten alloy is then pressed into the finest crevicesof the object.The advantages for you:• Efficient use of the alloy as, generally, a casting cone does nothave to be used• Short melting cycles in the vacuum minimise oxidation of theobjects and facilitate subsequent finishing• For the casting of precious-metal alloys, a graphite or glasscarbon ingot is additionally used which binds the remainingoxygen during melting and thus actively further reduces oxideformationUser-friendly operation via the 5.7 inchcolour touch displayThe Nautilus ® <strong>CC</strong> <strong>plus</strong> is operated and controlled via a 5.7 inchcolour touch display which offers quick response times andsimple menu navigation accompanied by recommendations onwhat to do. The large active area of the touch display and thesimple menu navigation present a real improvement in terms ofoperation compared to more conventional concepts.Acoustic signals are an additional aid to ensure safe processing.It couldn't be simpler: All of the casting programs for BEGOalloys are already stored in the Nautilus ® <strong>CC</strong> <strong>plus</strong>. “Non-BEGOalloys” and their parameters can be simply and easily saved withalloy names.The advantages for you:• Convenient, intuitive operation; direct and quick access to allnecessary parameters• Orientation and control at all times!BEGO vacuum pressure casting conceptSimple storage and large transferThe new Nautilus ® <strong>CC</strong> <strong>plus</strong> boasts a large internal memory: up to1,000 casting logs can be saved and transferred to a PC via aUSB data interface.Colour touch display with intuitive menu navigationThe advantages for you:• Quality assurance: Casting data can be simply transferred,casting logs simply archived and individual diagnosis logs canbe sent by e-mail to the BEGO hotline for careful analysis andrapid troubleshooting• Updates: Thanks to software and alloy database updates via aUSB interface, this high-tech casting unit always representsthe state of the art

Integrated power cooling systemThe Nautilus ® <strong>CC</strong> <strong>plus</strong> boasts integrated power cooling.The advantages for you:• More than 50 casts in a row are possible, even if ambienttemperatures are high• Does not require a water supply or outlet – can be used immediatelyanywhere• No water consumption, no water damage and no reliance onlocal water quality• Furthermore, the costs of installing an expensive water systemare saved• Since the unit does not require a water supply, condensationforming on the crucible coil in the winter months is no longer aconcern; “explosions”, mould cracks and the resulting flawedcasts are a thing of the past• Should you occasionally require an open cooling cycle, it onlytakes a few seconds to switch operating modes!Fully automatic temperature measuringsystemExcept for pure titanium, all precious metal and non-preciousalloys can be cast with casting temperatures of between 700°Cand 1,550°C and always with the lowest possible casting temperature.Casting time recognition is fully automatic with a multi-channeltemperature control. Material-specific fluctuations of the hotmelt due to reflection and emission are recorded in short timesequences in the ms range and automatically compensated forby the system.The advantages for you:• The melt cannot overheat• Measuring accuracy well in excess of 99%!Eco modeThe unit switches off all unnecessary components in idle mode.The unit can be restarted in less than 1 second at any time.Consumption in Eco mode (10 W) is extremely efficient comparedto consumption in the operating mode (3700 W).Measuring system – functional principleHeat radiationObject measured EnvironmentOpticsDetector(multiple-channelrecording)Digital signalprocessingThe optics of the measuring system route the measured data to the digitalsignal processing unitThe advantages for you:• Active reduction of operating costs• Environmentally friendlyOperation 3700 WEco mode 10 WThe molten mass flows from the hot zone of the crucible directly into thecasting mould

Compressed air tankIn case of unreliable compressed air conditions or a laboratorycompressor unit that is possibly too small, the BEGO compressedair tank system can be installed as a precaution.The advantages for you:• Active support of the compressor unit• Safer casting processNautilus® <strong>CC</strong> <strong>plus</strong>Scope of delivery Unit Qty REF• Nautilus ® <strong>CC</strong> <strong>plus</strong> 230 V, 50/60 Hz 26355• Ceramic crucible 1 pack 4 crucibles,eachmadeof 2halves52488• Plastic handles for ceramic crucibles 1 pack 2 52436• Ceramic handles for ceramiccrucibles1 pack 2 52467• Graphite ingot 1 pack 6 52468• Glass carbon ingot 1 pack 1• Forceps 1 30002• Mould holder plate, ceramic 1 30259Compressed air tank – ideal for insufficient compressed air conditions• Mould holder (ceramic)for sizes 1 and 9• Mould holder (ceramic)for sizes 3 and 6• Mould holder grid for partial denture(25 mm high)1 122571 133621 37618Nautilus® <strong>CC</strong> <strong>plus</strong>Technical data• Height• Height with optical waveguide• Width• Depth• Rated voltage• Special voltages420 mm650 mm700 mm665 mm230 V, 50/60 Hz200 - 240 V• Mould holder grid for partial denture(15 mm high)• Base socket mould former,sizes 3, 6 and 9• Partial denture funnel former 1Accessories• Compressed air tank with wallbracket1 100731 each1 16260• Mould tongs, 55 cm long 1 39754• Glass carbon ingot 1 pack 4 52473• Power at rated voltage 230 V• Compressed air connection(connection thread 1/4")• Air consumption• Water supply (connection thread 3/4")• Water discharge• Weight• CE16 Aat least 5 bar[0.5 MPa]approx. 180 l/minat least 3 l/minwashbasin or siphon70 kg• Base socket size 3mould former size 6size 9Subject to modifications in design, scope of delivery and composition. Our instructions for useand recommendations are based on our own experience and trials and can only be regarded asguidelines. Date of issue: January 2012.BEGO Bremer Goldschlägerei Wilh. Herbst GmbH & Co. KGTechnologiepark Universität · Wilhelm-Herbst-Strasse 1 · 28359 Bremen, Germany · Tel. +49 421 2028-0 · Fax +49 421 2028-100 · E-mail: info@bego.com1 set1 set1 set444526275262852629• Partial denture funnel former 1 pack 10 52066• Auromelt HF melting powder• Wiromelt melting power(non-precious)Powderdispenser,65 g1 52525Tin, 80g 1 52526• Stainless steel tray for casting tools 1 set 52469REF 82745/06 · BLO · © 2012 by BEGO · 2012-01