Validation of Cryopreservation Bags - CBMTG

Validation of Cryopreservation Bags - CBMTG

Validation of Cryopreservation Bags - CBMTG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

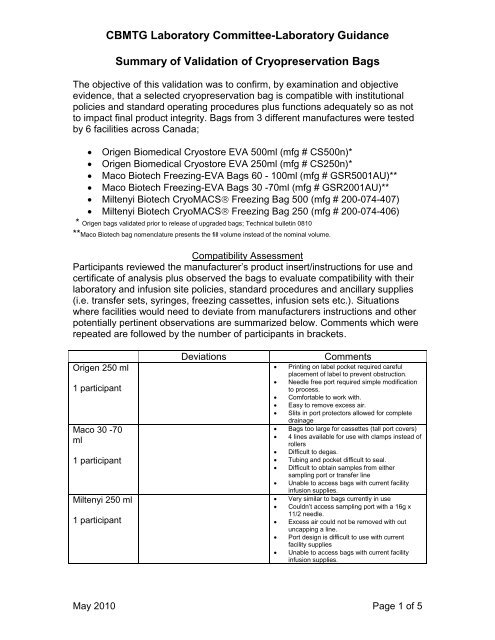

<strong>CBMTG</strong> Laboratory Committee-Laboratory GuidanceSummary <strong>of</strong> <strong>Validation</strong> <strong>of</strong> <strong>Cryopreservation</strong> <strong>Bags</strong>The objective <strong>of</strong> this validation was to confirm, by examination and objectiveevidence, that a selected cryopreservation bag is compatible with institutionalpolicies and standard operating procedures plus functions adequately so as notto impact final product integrity. <strong>Bags</strong> from 3 different manufactures were testedby 6 facilities across Canada; Origen Biomedical Cryostore EVA 500ml (mfg # CS500n)* Origen Biomedical Cryostore EVA 250ml (mfg # CS250n)* Maco Biotech Freezing-EVA <strong>Bags</strong> 60 - 100ml (mfg # GSR5001AU)** Maco Biotech Freezing-EVA <strong>Bags</strong> 30 -70ml (mfg # GSR2001AU)** Miltenyi Biotech CryoMACS Freezing Bag 500 (mfg # 200-074-407) Miltenyi Biotech CryoMACS Freezing Bag 250 (mfg # 200-074-406)* Origen bags validated prior to release <strong>of</strong> upgraded bags; Technical bulletin 0810**Maco Biotech bag nomenclature presents the fill volume instead <strong>of</strong> the nominal volume.Compatibility AssessmentParticipants reviewed the manufacturer’s product insert/instructions for use andcertificate <strong>of</strong> analysis plus observed the bags to evaluate compatibility with theirlaboratory and infusion site policies, standard procedures and ancillary supplies(i.e. transfer sets, syringes, freezing cassettes, infusion sets etc.). Situationswhere facilities would need to deviate from manufacturers instructions and otherpotentially pertinent observations are summarized below. Comments which wererepeated are followed by the number <strong>of</strong> participants in brackets.Origen 250 ml1 participantMaco 30 -70ml1 participantMiltenyi 250 ml1 participantDeviationsCommentsPrinting on label pocket required carefulplacement <strong>of</strong> label to prevent obstruction.Needle free port required simple modificationto process.Comfortable to work with.Easy to remove excess air.Slits in port protectors allowed for completedrainage<strong>Bags</strong> too large for cassettes (tall port covers)4 lines available for use with clamps instead <strong>of</strong>rollersDifficult to degas.Tubing and pocket difficult to seal.Difficult to obtain samples from eithersampling port or transfer lineUnable to access bags with current facilityinfusion supplies.Very similar to bags currently in useCouldn’t access sampling port with a 16g x11/2 needle.Excess air could not be removed with outuncapping a line.Port design is difficult to use with currentfacility suppliesUnable to access bags with current facilityinfusion supplies.May 2010 Page 1 <strong>of</strong> 5

Origen 500 ml5 participantsMaco 60 - 100ml5 participantsMiltenyi 500 ml5 participants<strong>CBMTG</strong> Laboratory Committee-Laboratory GuidanceSummary <strong>of</strong> <strong>Validation</strong> <strong>of</strong> <strong>Cryopreservation</strong> <strong>Bags</strong>DeviationsThe Mfg instructions require cuttingsealed tubing so that the end <strong>of</strong> thestub is below the spike port tops.This helps prevent damage fromabrasion by the cassettes. Currentfacility procedure requires 2 seals onthe tubing after aliquoting whichresulted in a stub which extendedbeyond the spike ports.Mfg instructions state that labelsshould not be applied directly to thebag. Current facility labelling includesapplying regulated labels to the bagsurface.Mfg instructions require use <strong>of</strong> overwrap bags during freezing andstorage. Current facility proceduresdo not include the use <strong>of</strong> over wrapbags (2).Mfg instructions require transfer toLN2 vapour for at least 4 hours afterstorage in liquid phase LN2. Facilityprocesses do not include this step.CommentsNeedle free injection port.No over wrap provided.Tubing closest to the bag (approx. 15mm) isthicker than the remainder <strong>of</strong> the tubing andcould not be sealed effectively. Sealing afterthis section leaves tails that are snug to thecassette (X2).Spike protectors cause tight fit in cassettes(X2).Difficult to remove all bubbles due to longspiking guards (x2).Full lot number is not imprinted on the bag asit appears on the wrapper.Close proximity <strong>of</strong> infusion ports makesaccessing awkward.Infusion port tabs are difficult to remove.Drained well.Difficult to drain completely due to large spikeprotectors.Incompatible with current sampling sitecouplers used for infusion by syringe.Certificate <strong>of</strong> analysis and instructions for usemust be obtained from mfg.No over wrap provided (x2).Sterile packaging.Label pocket fits labels without folding.Label pocket too large.Label pocket is at the bottom <strong>of</strong> the bagtherefore does not show when product is inmetal presses.Fits current metal presses and cassettes.Tight fit in cassettes.Seams on all sides <strong>of</strong> bag: breakage risk?Injection port is situated perpendicular to thetubing limiting needle access (X2)4 transfer lines all with different connectortypes not be compatible facility processes(X2).Difficult to degas.Tubing by bag takes longer to seal (X3).Bag dimension results in a thicker aliquotwhich was quite noticeable during thawing.Incompatible with current sampling sitecouplers used for infusion by syringe.Easy to spike.Long spike guards with splits to allow cells todrain.Good drainage.Individual packaging.Comes with over wrap.Lot number is imprinted on bag but not expirydate.Packaging difficult to open.Injection/sampling port may be restrictive forsome needle sizes (X2).Mfg requirement to transfer liquids containingDMSO only through the injection port may notbe compatible with some facility processes.Difficult to degas.Spike ports are tight (x2).Good drainage.Incompatible with current sampling sitecouplers used for infusion by syringe.Product was not licensed as a Medical Devicewith Health Canada as <strong>of</strong> 2010-05-05 (x3).May 2010 Page 2 <strong>of</strong> 5

<strong>CBMTG</strong> Laboratory Committee-Laboratory GuidanceSummary <strong>of</strong> <strong>Validation</strong> <strong>of</strong> <strong>Cryopreservation</strong> <strong>Bags</strong>Freeze/Store/Thaw Test<strong>Bags</strong> were frozen, stored and thawed following standard facility processes.Minimum and maximum fill volumes were challenged. The processes wererepeated for a total <strong>of</strong> 3 freeze/store/thaw cycles on each bag tested. Criticalprocess data, such as actual storage and thawing temperatures weredocumented by individual facilities. No significant process deviations werereported.Allowable RangesFacility # Pre storageTempStorageTemperatureTransportTemperatureThawTemperature1 -60 o C - 150 o C - 150 o C 35 - 40 o C2 -90 o C - 150 o C - 150 o C 37 - 40 o C3 -90 o C -120 o C to -196 o C -120 o C to -196 o C 38 - 40 o C4 -90 o C - 180 o C - 185 o C 37 - 42 o C5 -100 o C -150 o C to -196 o C -120 o C to -150 o C 35 - 39 o C6 < -130 o C < -130 o C < -130 o C 36 - 38 o COrigen Biomedical Cryostore EVA 250ml (mfg # CS250n)CRYO SOLUTION FREEZING STORAGE TRANSPORT THAW10%DMSOother uncontrolled controlledliquidphaseLN2vapourphaseLN2dry shipper# <strong>of</strong>bagstested 14 0 0 14 0 14 14 0 14 0# <strong>of</strong>failures 0 0 0 0 0 0 0 0 0 0otherwaterbathotherMaco Biotech Freezing-EVA <strong>Bags</strong> 30 -70ml (mfg # GSR2001AU)CRYO SOLUTION FREEZING STORAGE TRANSPORT THAW# <strong>of</strong>bagstested# <strong>of</strong>failures10%DMSOother uncontrolled controlledliquidphaseLN2vapourphaseLN2dry shipper14 0 0 14 0 14 14 0 14 00 0 0 0 0 0 0 0 0 0otherwaterbathotherMay 2010 Page 3 <strong>of</strong> 5

<strong>CBMTG</strong> Laboratory Committee-Laboratory GuidanceSummary <strong>of</strong> <strong>Validation</strong> <strong>of</strong> <strong>Cryopreservation</strong> <strong>Bags</strong>Miltenyi Biotech CryoMACS Freezing Bag 250 (mfg # 200-074-406)# <strong>of</strong>bagstestedCRYO SOLUTION FREEZING STORAGE TRANSPORT THAW10%DMSOother uncontrolled controlledliquidphaseLN2vapourphaseLN2dry shipper14 0 0 14 0 14 14 0 14 0# <strong>of</strong>failures0 0 0 0 0 0 0 0 0 0otherwaterbathotherOrigen Biomedical Cryostore EVA 500ml (mfg # CS500n)CRYO SOLUTION FREEZING STORAGE TRANSPORT THAW10%DMSO5%DMSOuncontrolledcontrolledliquidphaseLN2vapourphaseLN2dry shipperotherwaterbathother# <strong>of</strong>bagstested 24 2 2 24 8 18 26 0 26 0# <strong>of</strong>failures 0 0 0 0 0 0 0 0 0 0Maco Biotech Freezing-EVA <strong>Bags</strong> 60 - 100ml (mfg # GSR5001AU)CRYO SOLUTION FREEZING STORAGE TRANSPORT THAW# <strong>of</strong>bagstested10%DMSOother uncontrolled controlledliquidphaseLN2vapourphaseLN2dry shipper24 2 2 24 8 18 26 0 26 0otherwaterbathother# <strong>of</strong>failures0 0 0 0 *3 0 0 0 0 0*leaking from end <strong>of</strong> segment after cycle 3 (seal broke after cycle 2 but didn’tleak)May 2010 Page 4 <strong>of</strong> 5

<strong>CBMTG</strong> Laboratory Committee-Laboratory GuidanceSummary <strong>of</strong> <strong>Validation</strong> <strong>of</strong> <strong>Cryopreservation</strong> <strong>Bags</strong>Miltenyi Biotech CryoMACS Freezing Bag 500 (mfg # 200-074-407)# <strong>of</strong>bagstestedCRYO SOLUTION FREEZING STORAGE TRANSPORT THAW10%DMSOother uncontrolled controlledliquidphaseLN2vapourphaseLN2dry shipper24 2 2 24 8 18 26 0 26 0# <strong>of</strong>failures0 0 0 0 0 0 0 0 0 0otherwaterbathotherParticipant contact information:Angeline Giftakis, agiftakis@exchange.hsc.mb.caBrenda Letcher, brenda.letcher@blood.caGiovanna Cameron, GCameron2@bccancer.bc.caMike Halpenny, mike.halpenny@blood.caPamela O’Hoski, ohoskpam@hhsc.caSusan Berrigan, susan.berrigan@cls.ab.caMay 2010 Page 5 <strong>of</strong> 5