Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Boyer and his Government Affairsstaff. As a result, AOPA partiallyoffset the cost of the HarradineDwerlkotte reports.ABS also sent advance copies ofthe engineers' reports to GAMI , andtook Dwerlkotte and Harradine toGAMI's facility in Ada, Oklahoma, todiscuss their iindings. GAMl's consultingengineer reported essentiallyidentical opinions as a result of a paralleland independent investigation.Subsequently, all members of theABS Technical ConUllittee and severalother Board members have visitedAda and seen GAMl's plans for a testset-up. GAMI is working on anAlternate Means of Compliance andABS is enthusiastic about the workthey are doing. Through their work onthis and other unrelated problems, theyare developing inspection and repairtechniques that may become useful onour airplanes.Looking farther into the future,ABS has also visited the NationalInstitute for Aviation Research 'sAging Aircraft laboratory at WichitaState Uni versity. NIAR conductsmuch of the engineering work contractedby the FAA and has experiencede veloping airframe longevityprograms to detect and repair theeffects of fatigue.T-34s and otherfatigue issuesOther. much more serious wingfat igue issues face owners of T-34s,Cessna twins, the Twin Beech and T-6/SNJs. ABS has been in contact withofficers of the T-34 Association sincethei r issue resurfaced in December2004. ABS attended the FAA's publicmeeting on the T-34 in <strong>February</strong>2005, taking engineer Dwerlkotte asan advisor.ABS has also kept in close touchwith the Cessna Pilots Association'sTwin Cessna technical consultantregarding their wing spar AD. Closelymonitoring other type clubs' experienceswith aging aircraft regulationABS <strong>February</strong> <strong>2006</strong>helps ABS better plan for any workwe' re called upon to do in this arena.The FAA has repeatedly told usthat they do not see the T-34 ADissues carrying over into other Beechairplanes. Significant design differences-includingthe lack of a fuselagedoor cutout in T-34s, the additionalupper longerons in those airplanes,and differences in the carrythrudesign- may create substantiallydifferent stress patterns.In addition, the use of those airplanes,particularly those that havehad in-flight failures, is unique anddrastically different than our fleet.However, we are keenly interested inwhat the T-34 investigations wi llyield in the way of a better understandingof the structure. GAM I engineerGeorge Braly di scussed lessonslearned from hi s work for the T-34Association in an ABS Conventionsemjnar.Further, at the T-34 public meeting.the FAA highlighted its conceptof "Safety by Retirement"-a possibleoption for the FAA at some pointin the future to ground whole fleets ofairplanes when a pattern of airworthinessissues appears. This FAA conceptprovides yet another reason thatmakes proactive studies by ABSimperative.Beginning in late 2004 the FAA'sSmall Aircraft Directorate has beenoverwhelmed with these other investigations,putting our spar web issueon hold until further notice. This providesABS an opportunity to learn asmuch as we can about spar webcracks before the FAA's attentionreturns to our airplanes.It al so gives us the opportunity tolearn more about <strong>Bonanza</strong>lBaronstructures, and what (if any) lessonsfrom the T-34 may apply directly toour airplanes.ABS continues to be in frequentcontact with the FAA for statusupdates on the spar web issue. Watchwww.bonanza.org for furure updates.~www.bonanza.orgGUEST EDITORIALBY NEIL POBANZCominued from page 9445good shop can get bad reviews because anowner doesn't want to accept what it will take torepair his aircraft. Please be honest about whatyou say. Let us know of good experiences.We also want to hear about your experienceswith new products. I'm guilty of sayingthere are no new good ideas left after duct rape,tie wrap and RTV. Actually, you need to useapproved tie wraps; the others get hard andbreak. The good duct rape has high fiber contentand some RTV is acid base and corrosive.Keep records currentKeep all the paperwork that comes withmodifications you have done to your airplane.It's hard to maintain an airplane thathad a mod 20 years ago when there is nopaperwork, the company went out of businessand the survivors have no interest in theproduct. You wonder why the mechanicspent hours on the phone trying to figure outhow to make the airplanes airworthy.Some vendors don 't provide much documentationeither; and some FAA officesseem to have approved everything, whileothers don't want to approve anything.Don 't throw away the paperwork' Whenyou buy an airplane, have a good prebuy thatincludes the paperwork reviewed by amechanic who knows what he's looking at.Get regular qualified trainingGet a good checkout and regular training.Find an instructor who really knowsyour airplane. Just because an instructor is"legal" to give instruction in your airplanedoes not mean he is qualified.Even Beech airplanes differ significantlyover the years, and knowing part of themodel line does not mean your instructorknows yours. ABS and BPPP are workingtogether on a project to give Beech-specifichelp to local CFls who do most of the iilltialcheckouts and flight review s.Fix the airplanes! eet good pilot training!Help ),our mechanic become better anddo a complete job!Support your type club, ABS and"alphabet" organizatiolls (AOPA, EAA,NATA ), and help them help you keep YOllrairplalle flyillg.-@-Page 9447

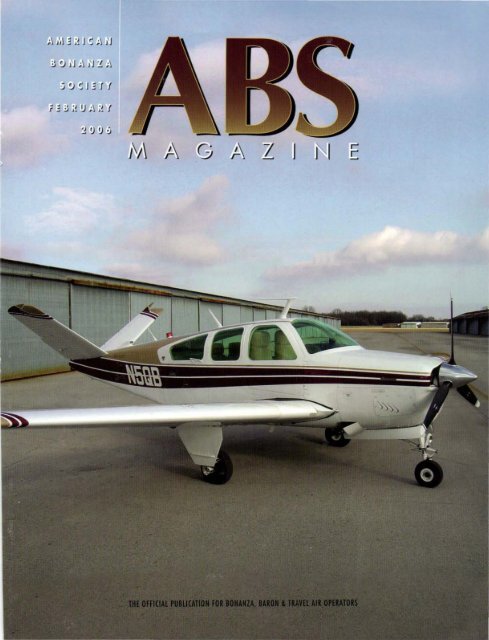

9EECHC~AfT Df THE MD~THNSOBThomas PayneTulsa. OklahomaANOTHER BONANZA1979V35BInever dreamed of owning and flyinga <strong>Bonanza</strong> when I was growing up. Infact, I really didn't become interestedin flying until I was a student atOklahoma State University inStillwater in the early I 960s.While taking advanced ArmyROTC training at OSU, I was given theopportunity to receive up to 39.5 hoursof government-paid fixed-wing flighttraining at the university's flight school.Once I was able to solo, I loved it.After completing that training, Ipaid for an extra hour and a half to getmy final checkride. I became a licensedprivate pilot and, in the process. Iobligated myself to the U.S. Army flightschool and three years of militaryservice.After graduation, I began flighttraining at Ft. Wolters in Mineral Wells,Texas, and later at Ft. Rucker, Alabama.My completion of U.S. Anny helicopterflight training in June 1966 was followedby a one-year tour in Vietnam where Iflew with the I I 8th Assault HelicopterCompany "Thunderbirds" for more thanI ,250 combat flight hours.Back in the U.S., I instructed primaryhelicopter at Ft. Wolters. Afterhours, I had time to earn my FAA commercialfixed-wing ticket at MineralWells. Following my second tour toVietnam in 1970-71, I was based al Ft.Bliss. Texas. Again I worked after hourson my FAA tickets, earning my instrumentand multiengine certification at EIPaso International.Flying was now in my blood. Iremained in the U.S. Army untilSeptember 1973 when my wife Wandaand our three kids all returned toOklahoma to help with numerous familybusinesses.1976 F33ATo facilitate our increased amountof necessary business travel, J foundand purchased a new 1976 F33A fromTulsa Air, one of the original Beech distributors.N I 872L, with her green andgold stripes on pure white, was a beautyand a dream to fly. No vertical vibrations.gyro copic precession or autorotationsto consider. Only a smooth andconsistent 170+ knots. eedless to say.I became a <strong>Bonanza</strong> fan , big time!72L served us well for almost eightyears. Then our business changed, andthe decision was made to sell it. Wewere without a <strong>Bonanza</strong> for almost twoyears when again the need for an airplanereturned.1980 V35BAfter a short period of searching, apristine 1980 V35B came into view,flashing her green and gold suipes onpure white at me. She was a beauty and Icaved in and bought N6688U. Onceagain, flying was a dream and we flewfrom coast to coast and from Canada toMexico. We had 88U for almost fouryears until the sale of our businesses in1989.We moved on with our lives, withouta plane or flying. II looked like itwou ld be for good. But fate intervenedand by 2002, almost 14 years later, bothollr sons had become pilots-5teve as anofficer in Ihe USAF, Martin as an ASARJ pilot with a Masters degree in aviationmanagement from OSU (and also ahelicopter pilot in the USAF Reserves).There was a ri sing chorus of "Whydon't you gel another <strong>Bonanza</strong>?" fromthe family, and it was growing louderand louder. So I started looking.Bingo' I found one that lookedpromising: A 1979 V35B with low timeand very well-equipped. Instead ofgreen and gold stripes on pure while,however, it had maroon and gold stripeson pure white. No malter. We becamethe proud owners of N5QB as shown onthe cover. It was a dream come true, onemore time.

Enter ABSThis time around. I j oined ABS. Ifonly I had done so before, I might neverhave had the gaps in our past <strong>Bonanza</strong>ownerships. I think the opportunitiesABS offers to help owners understandand maintain their fabulous aircraft willgo a long way in preserving all Beechaircraft, and especially <strong>Bonanza</strong>s, foryears to come.I have auended a BPPP course, ashas Martin. We both plan to attendfuture conventions and more BPPP andmaintenance courses to help us be betterpilots in an older airplane. I say "older,"even though <strong>Bonanza</strong>s do seem to betimeless in their design and efficiency.I am fortunate to have been able toown and to fly three Beech <strong>Bonanza</strong>s inmy lifetime-proving that dreamsdefinitely do come true.-@.-ENGINE:Continental 10-520 BB(heavy case)Engine preheat systemAero electric standby vacuumInsight 610 GEMJPI fuel scan 450AIRFRAME:New DuPont Imron pointThree-point strobesYaw damperCygnet dual yokeAVIONICS:King KMA-24 audio ponelApollo GX55 GPS coupledDual King KY-196 ComsKing KNS-80 RNAV. DME.glideslopeKing KN-53 NAVKing KR-87 ADFKing KT-76 transponderwI encoderCentury III autopilot wI alt.holdWX 950 stormscopeKCS-55 HSI-slaved

Larry Ball. author of the definitive history of the <strong>Bonanza</strong> and a lang-time friend of ABS. passed away in October. Larry hadalready submitted several articles to the ABS Magazine for future use. To honor his famlly's wishes and to shore Larry's commitmentto and passion far the Beechcraft community. we are publishing these remaining articles. - EdiforThere are few secrets in the Wichita aviation community.Therefore, it was cammon knowledge that Cessna was working ona turbocharged version of the Cessna 210-the <strong>Bonanza</strong>'s mostdirect competition. First flight occurred on June 18, 1965. Theirengine was the Continental 285-hp TSIO-520-C.Beech distributors in the western mounloin states had beenpressing the factory for some time to develop a turbocharged<strong>Bonanza</strong>. The Cessna activity helped persuade Executive VicePresidenl Frank E. Hedrick that we must meet this challenge. But itwas nal an easy sell.Hedrick was going through a period where he fell vendars whowanled to do business with Beech should participate (or even lotalIy fund) certificatian expense. In his mind, he was tired of buildingairtrames to carry the equipment ot ather companies alaft unlessthey corried, or at least shored ta the greatest extent possible, in thecertification expense.Since AiResearch (a division of the GarreH Corporation) was toprovide the turbocharger, Hed rick felt they should bear the developmentand certification expense. We, in return, would obligate ourselvesto buy a minimum of 200 units.Continental Motors would provide the lawer compression ratio(necessary for turbochorging) TS10-520-D. which developed 285-hpwith the Ai Research turbocharger. Since Cessna used the some turbocharger,the results, at least theoretically, would be the same(maybe even beHer).Ai Research agreed to the deal and would own the SupplementalType Certificate (STC). Thus we were able to announce at the 1966annual Beechcraft sales meeting not only the new V35 <strong>Bonanza</strong>. butalso the new V35TC. Both models were enthusiastically receiVed, especiallyby those distributors and dealers located west of us.During 1966 and 1967 we sold 79 V35TCs. ln 1968 the V35Aand V35ATC were introduced. These models were offered during both1968 and 1969 and a total af 46 units of the turbocharged voriationwere sold.In 1970, the V35BTC was introduced, but only seven units weresold before productian was terminated. At that time, we considered aproduction rate of less than two airplanes a month not economicallyfeasible. The grand total of turbocharged V-tails was 132 <strong>Bonanza</strong>s.And this subpar pertormance took four and one-half years.Turbocharging had seemed a sure thing ... something for nothing.Why not put the exhaust gases to work before they left the airplane?Only it was far from being that simple.Our most recent experience in bocsting manifold pressure hadbeen with the Lycoming IGSO-480-A 1 A6 used on the Twin <strong>Bonanza</strong>and later the Queen Air. This engine used a gear-driven supercharger-morecomplex, expensive and. most would agree, a tender andtroublesome system. We almost surely satisfied the mountain pilotswith the Turbocharged <strong>Bonanza</strong>, but as sales numbers indicate, itwas a passing fancy for many of our Beechcraft distributors anddealers (and their customers).

Stepping back in time for a moment, and beginning withthe 1957 H35 <strong>Bonanza</strong>s, we had started using the new"0" series Continental engines with "wet sump" oil systems.No external oil tank or lines to cause problems-afairly self-contained system compared to the earlier "E"series COnLinentals.With the V35TC, we had in effect inLroduced an entirelynew and additional component to the "0" series Continental:A pressurized exhaust system (once the wastegate staned closing),external oil lines again to keep the turbocharger shaftlubricated and control the automatic wastegate, a hotter enginecompanment (even with the additional cowl flaps) and a tOlalincrease in empty weight of 63 pounds. There was /10 free lll/lchafter all.My first flight in the first V35TC demonstrator (N9456S)occurred on April 8, 1966. It was the first production anicJeand, while it was not an experimental airplane, it wasn't farfrom qualifying as a prototype.Within two weeks, I received a call from DickWeeghman, managing editor for Flying magazine. They wantedto do the first-ever check pilot repon on the newturbocharged <strong>Bonanza</strong>. He told me they wanted to do a trip tothe Virgin Islands. I eagerly agreed and we set a date. I knowhe said the "Virgin Islands," but my mind at the time recorded"The Bahamas," and I thought, what the heck, only 90 milesor so over open water.I depaned Beech Field on April 28 for our grand adventure.It wasn't until I arrived in New York City that I discoveredour destination was to be much, much farther. But I wasThe Quthor using locol transportation on Sf. Martin Island.young and inunonal; Dick was game (we had gotten to knoweach other earlier on a B33 Debonair check pilot repon) ; andthe weather was good.We departed the next day for West Palm Beach, Rorida,where we picked up four life vests and a four-man raft. Thenwe flew southeast to the Virgin Islands with a stop at SouthCaicos Island for fuel and R&R.Upon arrival in the Virgin Islands, we found our roomreservations had disappeared. There was no room at the inn,any of them.After a few telephone calls, we found lodging on SaintManin Island, about 45 minutes directly east. Not our originaldestination, but it would have to do. So our final "Island in theSun" was 2300 miles from New York City, not 90 miles off thecoast of Florida.A V35TC on sialic display althe Dunes Hotel. las Vegas, Nevada, for the 1966 Flying Physicians Convention.ABS <strong>February</strong> <strong>2006</strong> www.bonanza.org Page 9451

It was a successful trip, but more open water than I evercare to see again in a single-engine airplane. Our longest overwaterleg was from South Caicos to St. Thomas. It was twoand a half hours with no land in sight.Safely back at Beech, and after the check pilot report waspublished (September 1966 Flying), Jack Funsch, one of mycontemporaries (and a former naval officer) asked me whatmade me believe we could all have gotten out of the airplaneif we had gone down at sea. Would we have been able to getthe life raft out before the airplane sank? Would it have inflated?He had a long litany of "what ifs" that ended with, "Didyou really expect someone to see that little yellow dot (liferaft) in that big ocean and rescue you?"Demonstrations to distributors, dealers and retailprospects began in earnest soon after my return to Beech.Although by now we had six different models of the <strong>Bonanza</strong>in production, our schedules for the next four years wereheavy with V35TC and then later V35ATC demonstrations.The distributors were of course working their airplanes,but especially after the production rate of the turbocharged<strong>Bonanza</strong> fell to two airplanes per month, we felt a special obligationto sell and maintain that rate. We were under no illusionsas to the TBO on our demonstrators. With all those shortup-and-down demonstration flights, the engines and the turbosystems were bound to be taking a lot of punishment.We got new demonstrators about every 200 hours, so weexpected no problems. The harsh treatment of the engines wasjust a cost of doing business.Alan Wharry, one of my assistants, did have the startlingexperience of landing, shutting down, walking away and thenhaving someone stop him to tell him his airplane was on fire.Smoke was pouring from the cowling. It was coming from theturbocharger.An internal seal had failed and oil was burning. The firewas safely contained inside the turbocharger. Still, it didn'tleave the best impression on a prospect! 1 have other storiesbut I'll spare you all but one.One day we borrowed a turbocharged 210 from theCessna factOlY to see how the two airplanes compared. Theywere about equal on takeoff and initial climbout. But as westarted reaching altitude, the 210 Centurion began slowlypuLling ahead. I called a stop to the flight comparison and wereturned to Beech Field. It was obvious to me the turbocharged<strong>Bonanza</strong> 1 was flying had either a serious leak in the inductionair system or the exhaust system or both.It also occurred to me that AiResearch may have unintentionallysupplied us with a certificated but inferior system.Cessna only had to deal with Continental Motors in their program.We, on the other hand, were primarily involved withAiResearch since they were responsible for certification.Beech was not in the strongest position to influence eitherContinental Motors or AiResearch, or their cooperation withone another.1 transferred to our Program Management Division inJune 1969, so my successor (Jerry Warner) inherited this possiblyunsolved problem. To my knowledge, it was neverlooked into further since production of the V35BTC endedduring the first part of 1970.Beech did not produce turbocharged <strong>Bonanza</strong>s again until1979 when the A36TC was introduced. This time a new-generationimproved TSIO-520-UB engine was used and theentire package was purchased from Continental Motors.Certification was a joint venture between Beech andContinental.Larry Ball began his 40 years 01 8eechcraft as a <strong>Bonanza</strong> service rep, held 13different positions in sales and administration and retired as a v.P. of IndianaBeechcraff. He authored four books about Beech aircraft; of( con be purchasedthrough Ihe AB5 Company 510re.1967 PRIVATE PILOT V35Te REVtEWPrivale Pilal reviewed the then·new V35TC in 1967, ftying the first Turbo<strong>Bonanza</strong> with lorry Boll and marveling at its fine appOintments at a bose price of537,750. The unidentified author was impressed at the AiReseorch turbocharger'sability to hold 32.5 inches of manifold pressure to 16,000 feet through use of onautomatic wostegote, and discussed oxygen requirements at length while applaudingBeech's foctory·instolled 0' system. He quoted lorry Boil's description of the-bootstrapping" phenomenon and highlighted the -Magic Hand" automatic georextensionsystem.The test flight hit 224 mph in cruise at 21.000 feet. The author concluded:-Hereis a fine, efficient. completely appointed 'time saver' that's comfortable and fun to flY:ABS member Greg Throop of Spokane, WA sent us a copy of the article and thisnote: -My father bought [a V35TC] in 1967. It was his fourth <strong>Bonanza</strong>. My fatherprobably couldn·t resist ... offer all, density altitude was the some in 1967 as it istoday. I still have N360T. [It has] only 1400 IT and it's just as sleek and fast as theday my father bought it." -@-Page 9452 www.bonanza .org ABS <strong>February</strong> <strong>2006</strong>

M~ WJSiC techniqueBY BILL COMPTON, EAGLE RIVER. ALASKAe fly out of Anchorage, with frequent trips toWthe lower 48 and occasional trips to Europeand the Caribbean. When flying cross-countryaround or out of Alaska, a pilot spends quitea bit of energy avoiding weather, mountains andicing. The coastal route from Anchorage toSeattle usually requires IFR flight, often with thepotential for inflight icing. Range is a priority.My son Steve and I obtained our 1966V3STC in 1981. There were two persistent questions. Why thebad rep? Some described it as a cylinder-eating gas hog. Also,now that we own one, how would we operate it? It was ourfirst experience with a turbocharged airplane, and we wantedto understand it and treat it right.Our airplane had the optional factory single-point analogEGT. The POH says, "Continuous operation is recommendedonly on the rich side of peak exhaust gas temperature at 2So Formore below peak." We had read Fly the Engine, by Kas Thomasand felt that more enrichment was wise. So initially we cruisedat 75% power and SO-75° rich of peak (ROP) .Soon after purchase, we replaced Engine #1 with a factoryreman. Engine #2 lost compressions after 400 hours. Aftera top overhaul, we did better, going to 1600 hours (200 pastTBO), perhaps because we had backed off to 6S% for cruise at7So ROP. Also, we had installed a six-cylinder digital EGT andleaned referencing the first cylinder to peak.After a major overhaul on the reman, now Engine #3, wefound ourselves pulling a cylinder yearly for low compression.We installed a JPI engine monitor and set alarms for 380° CHTand 16S0° turbine inlet temperature. We also installed GAMIfuel injectors and started running the engine lean of peak EGTin line with articles by aviation writer John Deakin. Thereafter,we made it yet again to 1600 hours and 10 years on Engine #3,with three of the original cylinders still on board.Though Engine #3 was running well, we have now pulledit for a major overhaul. We could have run it longer, but due tothe nature of our flying, we were getting a little edgy. We arealso springing for a Hartzell three-blade prop, D'Shannon bafflekit and side louvers which will replace those strange sidemountedcowl flaps.Finally, we think we knaw how to manage Engine#4. Here's our operational formula derived fromGAMl's recommendations:Take off and climb: Full thronJe 32.S", 2700 rpm, full rich,cowl flaps open, I OS knots. If EGT approaches 380° for anycyLinder, fuel pump low boost, increase airspeed to 120 knots.Bill and Steve Compton with their V35TC.Level off at altitude: Cowl flaps closed. JPl is activated to"Lean-Find" function. Now for "The Big Pull." Mixture isbrought back over about 5 seconds to where all cylinderEGTs have inverted on the JPI, meaning lean side of peakEGT, and just short of roughness. RPM is brought backbetween 2S00 and 2200, depending on the mission.Fine tuning: The JPI shows which cylinder was the last toreach peak EGT and therefore has the richest flow, and thatcylinder becomes the reference for resetting the mixtureLOP. The mixture is advanced slowly as that cylinder'sEGT increases back to its peak, and then the mixture isagain retarded to decrease the EGT to 20-S0° LOP. Nowhere we are at the fabled wide-open throttle, lean of peak,standard operating procedure (WOTLOPSOP).Note that when LOP, the richest cylinder is referenced.Since all the other cylinders are leaner, they are in a safezone. What we avoid is the area around peak EGT at highpower settings - the "red box" described by John Deakin(see www.gami.com/articles).Let down: Precool a bit by decreasing rpm to 2200 for aminute or so. Then bring throttle back to 19 inches, richenthe mixture to peak EGT, lower the nose and start down.Every few thousand feet on the letdown, run the mixtureback and forth to make sure we're at peak EGT and maintainingheat in the engine.Go around: Mixture full rich, prop high rpm, then full throttle,flaps , gear, cowl flaps, etc.Nuts and boltsEach of the six cylinders flows a different amount of air.Does it make more sense to give each the same amount offuel-the Continental method-or to inject fuel proportionalto the air flow- the GAMI method?GAM! calibrates fuel injectors so all cylinders reach peakEGT at about the same mixture setting.LOP cruise is only practical if all cylinders peak their EGTswithin maybe O.S gph of each other; otherwise, the enginewill stumble and you will freak out. (Been there!)ABS <strong>February</strong> <strong>2006</strong> www.bonanza.org Page 9453

The GAMI website has data showing you are not helpingyour engine by decreasing throttle and rpm on climbout. Itis a wealth of great information. We love full power, guiltfreeclimbouts!"The Big Pull" is scary the first few times, but it does makesense. You can get to the same place by reducing throttleand rpm, then learling, then adding throttle and releaning,but you've done an unnecessary heat cycle.LOP technique controls power primarily with mixture and rpm.When ROP, leaning is done referencing the leanestcylinder, but LOP, you must reference the richest cylinder.CyLinder head temps run about 30° cooler cruising LOP.• Operating LOP, fuel flow is decreased, range increased, withthe same airspeed.On letdown, peak EGT is used to keep the engine warm.After all, higher airspeed, less power results in cooling ofthe cylinders.• When LOP, fuel flow is proportional to power. Withcompression ratio 7.5:1, horsepower = fuel flow X 13.7.Then HP/rated power = % power.• Cylinders 2 and 6 tend to run hotter on 520 <strong>Bonanza</strong>s.GAM! and D'Shannon make baffle kits for this.• GAM! has shown that combustion pressure is smootherwhen LOP, with less peaking around top dead center whereit is less productive.• If curious about this technology for your airplane, turbo ornot, start by downloading the lean test technique fromwww.gami.com and do a test run.Why the bad rep for the V35TC? Remember that the POHwas wrillen in 1966, before digital monitors and fullappreciation of EGT.Here are some numbers from the POH:OAT 0° F, PA 10,000 ft.RPM 2500 MP 24.3", specified as "lean"FF 15.7 gph 184 KTAS214 HP, 75% powerI found that leaning to 15.7 gph at 75% power puts theengine right at peak EGT. Our experience and all I have readtells me that this is a recipe for early cylinder replacement.Traditionally, pilots have run 50°_75° ROP. John Deakinhas written that, should you choose to run ROP at 75% power,75° ROP is not enough, that 180° ROP is needed to avoid the"Red Box." Enrichening to 75° ROP goes to 17 gph; 180°ROP will take the fuel flow up around 19 gph.So this poses a dilemma: Should you run at peak EGT, asin the POH, more conservatively at 75° ROP, or way moreconservatively at 180° ROP where the airplane truly becomesa gas hog?We believe that LOP operations solve this dilemma for us,and that LOP ops are the salvation of this airplane.For interest, here is a typical cruise setting we loggedLOP, with tuned injectors:OAT IIF PA 12,000RPM 2500 MP 28" 30° LOP on richest cylinder.Highest CHT 352° TIT 1567°FF 14.1 gph KlAS 155 KTAS 184193 hp 68% powerWe tend not to push it on up to 75%.The solutionLess power (and less fuel flow) is produced at a givenRPMlMP setting when LOP. With a turbocharged engine, onecan easily compensate by adding 2-3" MP. Thus turbochargingand LOP operation fit nicely together.There are special heat concerns with turbocharging. Thecompressor packs air into the intake manifold, raising airtemperature well above ambient.At the same time, the higher altitudes flown offer lessdense air to carry heat away from the cylinders. Since cylinderhead temps run about 30° cooler LOP than ROP for the samepower output, here is yet another reason that turbochargingand LOP fit together so well.The V35TC is not intercooled. Its critical altitude is 17,000feet at standard temperature. Above that altitude, at fullthrottle, it "bootstraps." You get a downdraft, raise the nose,the airspeed decreases, so the marlifold pressure decreases,and you slow down more. An updraft does the opposite. It'sa little unnerving.Above 18,000 feet, you need an oxygen mask rather thanthe more comfortable nasal cannula.Above 18,000 feet, an oxygen system glitch gives you lesstime to problem-solve or descend.The airplane seems happiest at I3-l7 ,000 feet, WOTLOPSOP.13-17,000 feet tops an awful lot of weather, as well as traffic.• 17,000 is mostly high enough, and this airplane will get youthere.• Turbocharging is great. Imagine getting some ice at 10,000feet. Normally aspirated, you might get 60% power.Turbocharged, you climb out of it with 100% power.• The later turbocharged <strong>Bonanza</strong>s are more expensive thanthe V35TC, and a bit slower.ConclusionThe V35TC will slurp fuel and gobble cylinders withoutproper instrumentation and procedures. With a JPI,GAM!jectors and some operational knowledge, it is an outstandinglyefficient and reliable airplane. Tip tanks and IFRGPS make ours a capable long-range performer. We love it.--@--Page 9454 www.bonanza.org ASS <strong>February</strong> <strong>2006</strong>

There was a man at BAL who bought a Piper J-2 Cub and hired a localinstructor to teach him to fly in it. He qualified for a Private PilotCertificate and practiced for a short time. Then he called some Texasdealer who was selling a P-51 at a very reasonable price and orderedit. It was to be delivered by air to BAL.When the pilot arrived with the plane. he gave the Cub pilota cockpit check on the ground and left for his return to Texas,obviously not aware that the Cub pilot was experienced Dillyin a Cub.When the Cub pilot was alone with that big powerfulairplane, he started the engine and asked the tower for aclearance to take off, which was given. He opened the throttlewide, an absolute no-no for any single-engine plane withsuch a powerful engine as the Rolls Royce and such a bigpropeller. It would have so much more thrust on the rightside down-moving blades, that the plane would be forced tomake an uncontrollable turn to the left, the rudder being incapableof counteracting it.Well. the Cub pilot obviously was unable to hold the airplanein a straight line on the runway for takeoff, but would not give up.So the P-51 made a wide turn to the left, off the runway, the grass andone or two taxyways and runways, and finally got off after a completereversal of direction, downwind. much to the consternation of the toweroperator and everyone concerned.The Cub pilot was too busy to reply to the frantic calls on the radioand was unfamiliar with the radios in the airplane anyway. He quickly disappearedfrom sight of the tower and evidently wandered around for a timeuntil he was able to find time to call the tower and ask for help in locatinghis position.The tower was somehow able to get a Washington National Airport(DCA) radar operator to try to locate the P-51 by radar. But in the meantime,all traffic in the BAL-DCA areas was restricted due to the P-51 flounderingaround in unknown locations.It became a fully dark night, but the radar operator was able to locatethe P-51 by having its pilot make identity turns and guided him back toBAL. He then began to direct the Cub pilot in the P-51 to make practiceapproaches to a runway at the airport. I do not know how many, but he dida fine job and the Cub pilot safely landed the P-51 in the dark without damage(without even knowing how to rum on the position lights or the landinglights).The next day an FAA inspector arrived to investigate. No damage hadoccurred, except for the destruction of the airline schedules during theevent. and there had been no crash or near miss. The Cub pilot had a single-enginerating signed in his logbock and was legal as far as the inspectorjudged. At any rate, all had ended safely and happily, so he advised theCub pilot not to fly the P-5l any more. He probably sold it.So. now all you P-51 and other hot fighter pilots can quit bragging aboutflying those airplanes. I have never flown any of those hot rods either, notsince the pre-war open-cockpit fighter biplanes. But maybe, now with eightdecades of flying behind me, r could do it-in daylight, at least.Oh! I would love to meet that guy, if he is still alive. --@-

58P checklistI have a really neat 58P checklist. Itis part FlightSafety, Simcom, BPPP,ABS articles and the POH. It can beprinted on both sides of six pages in a 4"by II " format.Tabs are included for preflight, normaland emergency procedures.Emergency procedures are grouped intofire, systems, electrical and engine procedures.By laminating and spiral binding,you can have an easy-to-use quickreference. It is also easy to edit.My airplane is TJ-472 so some systemdifferences may exist. I'll e-mail mycheckli st free to anyone interested.jshan @aol.com.-Jock Shannon, Bellevue, WashingtonEconomical linkFor those (all of us) concerned wi ththe ever-increasing cost of current charts.the various FAA chart products can beordered online from the NationalAeronautical Charting Office (NACO) athttp://www.nacoJaa.gov/. The advantageof ordering directly, either online orat the provided 800 number, is that thereare no taxes or shipping charges.Charts can be ordered either singlyor by subscription. Subscription ordersdo not include the current chart, butbegin with the next issue following theentry of your subscription.-Barrie Hiem, Shannon. GeorgiaAlternator failureA recent alternator failure on a1996 Baron 58, TH-1791, did not illuminatethe panel annunciator lamp. Ispoke with Bob Leewright, supervisorof technical service for electrical systemsat Raytheon Aircraft. He led me tothe Alternator Out sensor, Part 36-380000-9, as installed on our aircraft.This sensor was designed to cause theannunciator lamp to flash when lessthan normal voltage is delivered fromthe alternator AUX ternlinal to the redinput wire of the sensor.In tracking down this problem, Ispoke with Lamar, manufacturer of thesensor for Raytheon. It appearsRaytheon was aware of a failure modeof the sensor in 1996/97 and had achange made to the circuitry. It becamea 36-380000-11, vs. the -9 as installedin our aircraft.It appears a sensor failure of the -9version not only does not flash thelamp, but fails to illuminate it at all!Pilots relying on the annunciator lampto alert them to an alternator failurewhen their aircraft is outfitted with the-9 sensor version may find themselveswith no alternators or battery powerwhen needed.I feel this is a life-threatening situation,and all Beech pilots should bealerted to this potential.-Gary James, Reynoldsburg. OhioABS RESPONDS: According to Beech,the -9 sensor was installed starting in1980 and, after a 1990's failure rate "notacceptable" to Raytheon, the -II sensorwas designed and has been standardsince sometime in the 1999 or 2000model years.The Limitations Section of A36 andBaron 58 POHs show all alternatorloadmeters Low Buss Volts/AlternatorOut annunciators must be operationalfor flight in all conditions. It behooves apilot to check the operation of the loadmetersand annunciators before flight,especially at night and/or in IMe. Onemethod is, after engine start, to pull onethrottle to idle, which should reducerpm to below the alternator's operatingspeed.Note that when the associated loadmeterindicates zero in Barons, the otherload meter picks up the load and thean nunciator for the throttled engineflashes. In a Baron, advance the affectedengine to 900 rpm or higher and repeatthe exercise with the other engine.If reducing an engine's speed to thepoint its 10admeter no longer indicates aload does not cause the annunciator toflash, ask your mechanic to check thesensor. In flight, periodically scan theannunciator(s) and loadmeter(s) to confirmalternator output.-Tom TurnerIced-up outboardfuel tank ventI have a 1963 P35 that encounteredicing of the fuel tank vent. It emptiedmy starboard tank onto my hangar floorafter a flight in lMe. 1 have read inColvin's Clinic that the "S" model put aT-fitting in the wing that allowed ventingof the tank if the outboard vent wasiced up.Is there an STC or a field approvalout there to retrofit these older models?If any member has an approved anti-icevent for the P35, please contact me atastoriavision@qwest.nel.-Steve Scruggs. Astoria, OregonLoosening acold throttle cableMy V35 had a throttle cable thatwould be very hard to move when it wascold. After a flight, it wo uld loosen upand seem normal. I thought it might beoil that had seeped into the housing andcongealed.1 got a piece of half-inch ID Tygontubing and cut it to about eight incheslong. Then I split it, being careful tosplit it in a straight line. I placed itaround the throttle cable and used anelectrical cable tie to seal it to the throttlehousing as close as possible to theend. Then 1 used Kroil to fill up thelUbe. I think WD-40 or a good penetrantwou ld also work.After working the throttle back andforth and letting it soak for a while, ithas loosened up to almost like new.- V. Gary Holden, Upland. CaliforniaNonfunctioningHSI & autopilotAt the beginning of a trip from myhome in Oregon to California and on toFlorida, I noted that my HSI and

autopilot had become nonfunctional. Ilanded at Sacramento and went toExecutive Autopilots on the field. Theyhad worked on the AC convener in myairplane in the past. With in 10 minutes,they were on the problem, and becausethey needed a few days to work on myunit, they lent me one. This worked wellfor the remainder of my trip.Their friendly approach to helpingme out with no advance notice was verymuch appreciated, and I was on my wayin a little over an hour. I think theydeserve recognition for this outstandingservice.- Charles S. TannenbaumSpringfield, OregonThank you to 01/On December II , a huge surprisebinhday pany was held for me fourdays ahead of time by my eldest grandsonat a club where he is a member. Atleast 100 guests were there. It was wonderfulto meet so many old friends andacquaintances, all younger than me, ofcourse.On my actual binhday, December15, ABS member Scott Thomas of LakeSaranac, New York, arrived inPoughkeepsie in his Baron and flew mydaughter Trisha and me to Kitty Hawk,Nonh Carolina, for the I02nd anniversaryof the Wright brothers' flights. Ihad attended the 98th, 99th and IOOthanniversary celebrations, but not the10 I st. I was really impressed withScott's piloting skills.A binhday pany was also held inthe very popular Black Pelican restaurant,which had been the GovernmentLifesaving Station when the Wrightsmade their flights.On December 17, First Flight ceremonieswere held at Kill Devil Hills. Aformation was flown above the monumenton top of the huge sand dune fromwhich the Wrights made their early glid·ing flights.That eveni ng a banquet with about200 people attending was held in thelarge building next to the level groundfrom which the Wrights had made theirfirst powered and controlled flights intheir flying machine. Pictures of me andsome of my various career aircr.aft wereprojected on a large screen-a real surpriseto me!I also had many e-mail greetingsand cards and letters when I got home. Iwant to thank all of those who panicipatedin making this IOOth birthday sospecial for me.-John M. Miller. Poughkeepsie, New YorkARSAviatorAwardCONGRATULATIONS TOTHE FIRST THREE ASS AVIATORSThree members have qualified to dotefor the ASS AVIATOR deSignation. which rec·ognizes those who go for beyond the mini·mum requirements to beoome sofer. more knowledgeable pilots.Dr. lorne Sheren, Cholham. New Jersey. earned our first ASS AVIATORstatus with SPPP training in Manchester. New Hampshire. and by complet·ing three AOPA Air Sofety founDation on·line courses.Next comes John Wiebener, Edgewood. New Mexico, who earned thisdesignation by completing a new FAA type rating. on FAA WINGS level. andfive Operations or Maintenance track seminars at the 2005 ASSConvention. for a total of 155 ASS AVIATOR points.Our third ASS AVLllTOR is Robert Castle, Midwest City. Oklahoma. whoachieved recognition by adding a Mulliengine Instructor rating to his FlightInstructor certificote, and completing the AOPA Air Safety Foundation an·lineEngine and Propeller Course.So for. we hove received completion certificotes toward the ABS AVlA·TOR program from 47 members. Congratulations to 01147. and especiolty tothese first three ASS AVIATORS.For more information on how you, too. con achieve the designation ofASS AVIATOR. see the ASS website or the October 2005 issue of the ABSMagazine.Bolts of two different lengths were used tosecure the wheel halves together. Which lengthbolt is correct? And do you know why?See poge 9478 for the 01 \VOl

KNOW BEFORE YOU SAY "GO"On a winter Friday evening about a year ago, a TexasbasedABS member loaded three fanuly members intohIs Baron and flew to Kansas City for the weekend.One of the aircraft's vacu um pumps failed over Oklahoma.Upon landingat MKC, the owner asked the FBO if they couldreplace the faIled pump in time for his planned departure lateSunday afternoon. They said yes, and the owner gave them ago-ahead.When the owner and his family returned to MKC onSunday afternoon, he was pleased that the pump had beenreplaced as advertised. But when he gave the FBO his creditcard to pay the bill, he was told that the invoice wouldn't beready until Monday when the bookkeeper returned to work.The FBO insisted that the owner sign a blank credit cardslip to cover the work. The owner was initially unwilling, butultimately capitulated when it became obvious that was theonly way to get the FBO to release his airplane.When the FBO's charge finally showed up on the owner'scredit card. it turned out to be over $1.900. The pump wasinvoiced at $1 ,400-well above the list price of $1,090 andalmost twice the usual "street price" of $800. The labor chargewas about $500 for a job that shouldn 't have taken more thanan hour.The owner was upset, of course. He fired off a nastygramto the owner of the FBO and vowed never to patronize themagain. But in the final analysis, the owner was stuck paying abill he appropriately considered outrageous.This sort of thing is hardly uncommon. [know one ownerwho was charged nearly $1,000 to have his Cessna 210 deicedin Memphis; another was charged $350 for one hour in aheated hangar to melt the snow off his light twin near Boston ;and yet another was charged $180 at Washington Dulles tohave two tires aired up on his Skylane.Most of these incidents occurred at large FBOs that catermostly to the bizjet se!. But such FBOs certainly aren't theonly offenders.Recently, a mechanic removed a leaking fuel selectorvalve from a <strong>Bonanza</strong> and sent it to a well-known FAAapprovedrepair station for overhaul. After inspecting thevalve, the repair station quoted $2,000 to overhaul i!.At this point, the aircraft owner wisely intervened, directedthe repair station to return the leaky valve, and sent it to aCalifornia repair station where it was overhauled for $375.While these may be extreme cases, I sincerely doubt thereare many aircraft owners who haven't fe lt blindsided by whatwe considered to be an unreasonable maintenance invoice.(Been there, done that, got the T-shirt to prove i!.)The First Commandment[n almost every such case, these unpleasant surprisesoccur because the aircraft owner authorized the work withoutfirst asking the cos!. In doing that, the owner broke the firstcommandment of aircraft maintenance:Never permit a shop or mechanic to perform maintenanceon your aircraft until you haye received and approl'ed a statementof work and cost estimate (preferably in writing). If andwhen you approve them. instruct the shop or mechanic not toexceed the cost estimate without fltSt obtaining your explicitapproval.I find it amazing how often this commonsense commandmentis broken. In almost every other sort of commerce, itwould be absolutely unthinkable for someone to purchasegoods or services without knowing what they will cos!. Mostof us would never buy a headset, a pair of sunglasses or agallon of IOOLL without checking the price. Nor would weconsider hiring a plumber to install a new water heater aroofer to fix a leak, or a garage to replace a muffler with~utfirst obtaining a quotation or estimate.Yet more often than not, aircraft owners put their plane ina shop and authorize work to be done without obtaining evena verbal estimate, much less a written quote. Frequently, thefirst time they learn whal the work will cost is when it isfinished and they are presented with the invoice. At that point,it is too late to influence the outcome; they can only complainand lick their wounds.Why do we do this? [ can think of three reasons:I. We're uncomfortable asking the shop or mechanic for acost estimate.2. The aircraft has a known problem, but we don 't yetunderstand what's wrong sufficiently for the shop or mechanicto estimate how much work needs to be done or what partsneed to be replaced.3. The aircraft is in the shop for an inspection, so we don'tyet know what problems are going to be found , much lesswhat parts and labor will be needed.Let's consider these three cases in turn.Case 1 : Uncomfortable askingI suspect the Baron owner was uncomfortable about askingthe Kansas City FBO for an estimate to replace his failedvacuum pump. Perhaps he felt the FBO was doing him a favorto do the work over the weekend. (They weren't-their laborrate was top dollar, and they charged time and a half for theweekend labor.) Or perhaps it was because this big-city FBOwas one that catered largely to the bizjet crowd-you know,the "if you have to ask, you can't afford it" guys.

Perhaps the Cessna 210 owner was uncomfortable aboutasking the FBO in Memphis what it wou ld cost to de-ice hisairplane because he thought it couldn't possibly be enough toworry about. (He found out otherwise.) Or perhaps it wasbecau e he felt he had no alternative but to have the airplanede-iced, no matter what it cost. (There's always an alternative.)Whatever the reason for their discomfort, failure to askfor an estimate before authorizi ng it cost them dearly. It nevermakes sense to purchase goods or services without first askingwhat they will cost.Purchasing aircraft maintenance is just like any other purchase.The fact that it is not your field of experti se shouldnever intimidate you into failing to ask key questions. In fact,the less you know about something, the more questions youshould ask before making a decision.Never feel embarrassed to ask for an estimate beforeauthorizing work to be done on your aircraft. The only time it'sbad form to ask the price is when someone gives you a gift!Case 2: Don't know what's wrongBut what if you don't know what's wrong? Say you putthe airplane in the shop because the engine was running rough,but you don 't know why. How can you possibly ask your shopor mechanic for a cost estimate under such circumstances?My answer is simple: ever ask a shop or mechanic to fixa problem unless you know what's wrong. That's like going infor surgery before your illness is diagnosed. Aircraft ownersdo this all the time, and it's an expensive mistake.I spend a lot of time discussing owner-performed troubleshootingin my seminars, and I'll be discussing it at lengthin future ABS Magazille columns. In a nutshell , I advise aircraftowners to do as much troubleshooting as possible beforeputting their aircraft in the shop. In my view, it's primarily theowner's job to troubleshoot and the mechanic 's job to fix.It's often difficult or impossible for a mechanic to reproduceproblems in the maintenance hangar. If we owners don'tdiagnose a problem before our aircraft is in the shop, ourmechanic often has no choice but to resort to guesswork, tryingvarious things and hoping he gets lucky. When mechanicsguess, owners pay.Returning to your rough-running engine: In a perfectworld, you use your digital engine monitor and well-honedtroubleshooting skills to diagnose the problem, e.g. a cloggedinjector nozzle or faulty bottom spark plug in cylinder #3.Then you put your aircraft in the shop and obtain a cost estimateto fix the problem.But what if you can't figure out why the engine is runningrough? In that case, you put your aircraft in the shop andauthorize your mechanic to spend up to two hours (or whateverseems reasonable to you) troubleshooting, and instruct himto report back to you with his diagnosi s. Only then. when theproblem has been diagnosed, do you ask for a cost estimateand-if the estimate is acceptable-authorize the repair.Case 3: Annual InspectionIn the case of an annual inspection, where by definitionyou don 't know what problems will be found, my advice issi milar. Put yo ur aircraft in the shop and instruct your mechanicto perform the inspection (normally done at an agreed-to flatrate) and prepare a detailed list of discrepancies with a costestimate for each one.At this point, sit down with the mechanic, go over the discrepancylist and estimates in detail, and come to an agreementon exactly what repairs are to be done and what they will cost.Only then should you authorize the repair work to proceed. (I'llhave a lot more to say about annuals in a forthcoming column.)No matter what the si tuation is, there is never a good reasonto authorize a shop or mechanic to perform maintenanceon your aircraft until you have received a cost estimate, preferablyin writing.Always know before you say. "Ga."Questions for Mike Busch may be e-mailed to.Mite Busch has flown for more than 40 years and 7.000 hours. Mike cofoundedAVweb and served as irs editor·in-chief for more than 7 yeors. His "Savvy OwnerSeminars teach aircraft owners how to obtain better aircraft maintenance whifespending a 101 less money. www.savvyoviator.com

(gerefratw~ at P/(ilty f!KawhBY CHARLIE DAVIDSON, ABS DIRECTOR Kill DEVil HillS, NORTH CAROLINAJohn Miller draws a crowd of aviation enthusiasts at lhe airport.Some of the ASS members took a four of the locol Christmas lights.A large number of ASS members turned out 10 help John Miller celebrates his 1 DOth birthday at the Firstf light <strong>Society</strong> Ball In Kilty Hawk. North Carolina.At the ABS convention in Dallas there was some discussion concerning theupcoming IOOth birthday of our esteemed member, John Miller. Let's face it. howmany organizations have members who reach that milestone and are still activelycontributing monthly magazine articles and traveling great distances to porficipalein <strong>Society</strong> actIVities?ASS Presidenl Craig Boiley, John Miller and Kent Ewing ofter theircruise over the First Flight Monument in Kent's V3SB.Ihad not seen John since his serious automobile accident in<strong>February</strong> 2003. I knew he had suffered through a longrecovery with several months in the hospital. But John,being the trooper he is, was enthusiastic about joining us at theABS convention to sign copies of his book.Jack Threadgill and I arrived at Dallas InternationalAirpon to pick up John. I was concerned that we might need awheelchair. No way. As I stood watching the gate, I spiedJohn's traditional khaki shin and bolo tie bounding up the tunnelfrom the airplane. He was passing those slow youngsters infront of him. I later found John gelling his legs in shape byclimbing the 12 flights of stairs to his room each day in the conventionhotel. This man will not slow down!John's December 15 binhday comes just two days beforethe anniversary ofthe first powered flight by the Wright brothers.We discussed the possibility of ABS joining the FirstFlight <strong>Society</strong> in a celebration of flight and the centennialcelebration of John Miller's binh. This all came together in agrand couple of days, December 16-17.Several ABS members contributed to making this eventhappen. In parricular, Scott Thomas, a Baron driver fromSaranac Lake, ew York, graciously flew John and his daughterTrish Taylor to the Outer Banks from their homes inPoughkeepsie, New York.On the night of the 16th. several ABS members had a parryfor John at the Black Pelican Restaurant in Kitty Hawk, NonhCarolina. It is in the original lifesaving building where theWrights sent their message to Dayton in 1903 that they had successfullycompleted their flight I It seemed appropriate that Johnshould be in a historic place with such a significant connection tohis life's work.Joining John's private binhday parry to kick off a busy 24hours for the centenarian were ABS President Craig Bailey andwife Connie; ABS board members and their wives, Bill andPhyllis Stovall and Charlie and Patti Davidson, ABS ExecutiveDirector Nancy Johnson, a <strong>Bonanza</strong> formation group andseveral others.The next moming brought mild temperatures and a highovercast, great flying weather for the annual First Flight<strong>Society</strong> event. The f1yover opened with the Green Beret jumpteam landing on the grounds of the Wright Brothers NationalPark in front of a crowd of a thousand spectators gathered onKill Devil Hills and near the visitor pavilion.Shonly thereafter, at exactly 10:35 a.m. (the time theWright's launched their first flight ), a lone V-tai I <strong>Bonanza</strong>cruised over the monument at 1,000 feet. At the controls wereJohn Miller and Kent Ewing, Capt. USN/ret. They were inKent's V35B that is based in Virginia Beach, Virginia. CraigBailey accompanied Kent and John, followed by a formationof one Baron and three <strong>Bonanza</strong>s.Page 9460 www.bononza.org ABS <strong>February</strong> <strong>2006</strong>

'Mi, 'lJi'('(·kJ'll!, 6J1/jfI(~ ~,rf th(, /1IIf'h((("ross th(, JJlII/III/II('1I1thid S/I/I/(Ij(J/rrlll (firi Ij,./ri/rim.rf ~y (Doflsl !fllIflY!"(lII(f/Vir bJorN' (ti'llril/('.~ (1/1,( th;,• !JOfrlr;1I g(il{r;hi·~illJlIl'/('(1/1/,Scott Thomas, ASS Executive Director Nancy Johnson and ABSDirector Bill StovallCharHe Davidson (at right) MC'd the Beechcratt flyover althe Wright Monument.The four-ship formation was made up of Scott Thomas inhis B55 and V-tail drivers Ritchie Jones and Glenn Wimbushof Burlington. North Carolina. and Bill Doty of Chapel Hil l.North Carolina. They cruised over the monument at 1.000 feetfor three passes in perfect formation. I narrated for the audience,explaining the significance of the <strong>Bonanza</strong> aircraft andits history.Next, ABS member Steve Oxman and his son Warrenflew over the park in Steve's beautifully restored Beech 18.The Beechcraft brigade led the pack across the monument thatsunny Saturday, fo llowed by Coast Guard and Air Forceairplanes and the Golden Knights jump team.John, Craig and Kent circled back and landed at the FirstFlight Airport and were brought to the crowd in much the sameenthusiastic manner as Oshko h air show performers. Johnwas surrounded by many well-wishers-adults and children.The night of December 17 is the annual First Flight <strong>Society</strong>Ball. In existence since 1928, this <strong>Society</strong> was founded to commemoratethe Wright's achievement at Kill Devil Hills.The highlight of the evening, in ABS' eyes at least, was aPowerPoint program narrated by Craig Bailey. A pictorialhistory of John's life in aviation was displayed and examples ofJohn's ad ventures from his book, "Flying Stories" were read tothe audience.John also received a congratulatory certificate from U.S.Senator Richard Burr of NOith Carolina, a painting of Johnand his beloved autogiro, and a huge chocolate cake.As John told us at hi s party, "Chocolate is good for you inmoderation. It may even help you live to be a hundred yearsand two days old !"Many thanks fa all the ABS members who participated and to theFirst Flight <strong>Society</strong> for working with ABS to celebrate the fife of thisextraordinary aviator and genffeman.-@-John Miller and his daughler Trish at the First Flight <strong>Society</strong> Boll.WE COULDN'T USE ALL THE GAEAT PICTURES WE RECEIVED, so THANKS TO ALLTHE CONTRIBUTORS WHO SENT PHOTOS IN; CONNIE BAILEY, CHARLIE DAVIDSON,KENT EWING, AND BILL & PHYLLIS STOVALLABS <strong>February</strong> <strong>2006</strong> www.bonanza.org Page 9461

Kill Devil Hills, N.C. -I'm writing this at the end of2005 and it will be in the <strong>February</strong> issue. Sorry I didnot get a medical subject into the January issue.I have a valid excuse: I was trying to keep up withJohn Miller while he was here for his Decemberbirthday bash. and frankly, I didn't have the timeor the energy for a column. I'm sure John haspenned his usual entertaining columns for bothJanuary and <strong>February</strong>. but he's a spry 100 whileI'm an aging 57. Go, John. Go!FORM 8500 FOLLOW UPIalso spent several hours in December doing my AMEhome study course, required for continuing education.AMEs must either attend a two·day seminar or participatein a home study course provided by the Civil Aviation MedicalInstitute (CAMI) every three years. The course I chose was onaviation physiology and was quite informative. It coveredeverything from barotraumas to vibration as they pertain to thefunctioning of the pilot.At about the same time, I was reading the January AOPAPilot. John Yodice, an attorney, writes an interesting column inthat magazine. This month he was discussing the insidious lossof privacy due, in his opinion, to the worrisome ability of variousgovernment agencies and departments to access andcross-reference different databases.[n particular, Yodice pointed out the Form 8500 that airmenmust fill out to apply for each new medical. I recently discussedsome of the chronically overlooked items on the form.In his article, Yodice said he will not be putting his SocialSecurity number on the form in the future and will ask that theSecretary of the Department of Transportation remove it fromprevious forms. (I didn't know you could do that, but [ guessyou can if you ask.)My comments re the SS# were all related to how muchsimpler it was for the AMEs to type in the number rather thanto search for the pilot by name. I don 't think I mentioned thatgiving the SS# on the form is voltmtal),. If you are concernedabout privacy issues, you certainly don't have to put it down.One problem I have had is when a pilot initially does notgive his SS, then at a later examination forgets that he previouslywithheld it. This time he does put the number on theform.When the AME tries to find the airman by the SS#, he willbe told that the airman does not exist in the files. Trying again,by name, will show the airman with a random "pseudo" numberpreviously put in that field by the AeromedicalCertification Division (AMCD). The AME has to sort out withAMCD the new number associated with that person. I guessthe point is that it is helpful to your AME if you are consistentwith your anonymity IAnother interesting point made in the AOPA article wasrelated to the ability of the FAA to cross-reference the informationon the Form 8500 with the National Driver's Registryto check for driving violations that relate to alcohol.The point made in the article was again directed towardthe insidious use of information that we VOluntarily give.Yodice commented that we voluntarily give "permission" toaccess the databases with our signature, but asks if it is trulyvoluntary if the only way one can get the medical is to agreeto the computer search of the Driver 's Registry. He questionsif this might be a violation "of the spirit, if not the actual wording,of the Privacy Act."Well, I was pondering that question having just gone overthe physiology questions. One topic was alcohol use and flying.Hot in my little brain was the statistic that in the I 960s, 40percent of aviation accidents were reportedly related to alcoholand by the 1990s, only 6 to 8 percent were alcohol-related.There were qualifying comments related to the moresophisticated methods used today versus in the 1960s for postmortemevaluation for alcohol in the deceased. That is, theremay have been more victims of aircraft accidents identified asalcohol-related in the '60s because of erroneous samplingtechniques and poor understanding of how the body, afterdeath, may produce alcohol-related substances.But the statistics beg these questions: Has the use of thecross-referencing reduced the number of alcohol accidents? Ifso, does it outweigh any loss of personal privacy? Is there asacrifice of some privacy for the "greater good" at work here?Certainly quantitative proof of whether the cross-referencingaffected the statistics might be very difficult to produce.Recent decades have brought increasing public awarenessof alcohol toxicity and alcoholism. Groups like MothersAgainst Drunk Driving (MADD) and the alcohol beverageproducers themselves advertise against misuse of alcohol.The FAA, together with commercial airlines, implementeda very effective program that allowed airline pilots to admitproblems with alcohol and get trearment, with the futureoption of continued employment and monitoring. General aviationhas no such program, and the detection of GA pilots withalcohol-related problems is difficult.Insidious is also the word that can be used to describe theprogression of alcoholism. Many alcoholics function formonths or years in home and at work without clues that theyare addicted. In general practice, with multiple encounters

with a patient and other possible clues from blood tests (abnormalliver values), the practitioner may have enough to suspectthe patient is slipping into problems with drinking. The AMEmay not have this luxury.The ability to differentiate between a social drinker whonever progresse to troublesome behavior and someone who isstarting down the lippery slope to alcoholism can be very difficult.The FAA educational material relates that the pilot witha ingle DUI may be twice a likely to have an accident as apilot with no DUI conviction s.I think more and more of these private versus publicissues will arise. Our individual tolerances for giving up personalfreedoms or information for the general good will vary.The family of someone who was injured by a driver or pilotunder the influence of alcohol would certainly lobby for evenmore stringent early detection and removal of potentiallyimpaired drivers and pilots.In the end, we all must act responsibly-individuals, governmentsand organizations.Charles S. Davidson, M.D .• holds board ceriiffcolian in family medicine and emer·gency medicine. He has been on aviation medical examiner since 1978 andserves as a senior AME. He holds a private pilot license with multi.engine andInstrument rating. He is an active pilot using general aviation for business andpleasure tor 23 years and is a/so an ABS board member. He flies an A36 and is amember of AOIl\ and EM.Age limitQ. Is there an age limit on taking a flight physical?A. A person of any age can take a flight physica l. The minimumage for being able to solo an aircraft is 16 years. Theduration of validity for a Class Tn medical for someone in hisor her teens is three years.The medical is needed before one can solo. Therefore,getting the medical more than three years before the 16thbirthday might not benefit the aspiring pilot unless there werehealth issues of concern for passing the exam. In that case,contacting the AMCD or an AME might be prudent beforespending the time and money for the exam.There is no upper age limit for taking an aviation medicalexamination.Vision standardsQ. What are the vision standards for a third class physical?A. 20/40 in each eye, corrected or uncorrected.QUESTIONS OF THE MONTHMonovisionQ. My son is preparing to get his license. He is legallyblind in one eye. I know there are pilots with vision in onlyone eye. What is involved?A. You are correct that pilots wi th only one eye or blind inone eye can gain a medical certificate and pilot's license. If thesingle "good" eye passes standards, and your son otherwisepasses the AME exam for whatever class he desires, the AMEcan issue a medical certificate limited to "Flight as a StudentPilot Only."Some time before his checkride for his private pilot'slicense (or simultaneous with the checkride) he will need tohave a medical checkride. He will fly with an AME or physicianfrom the FAA who will assess his ability to fu nction withthe si ngle eye. Once he has passed this, he will receive a waiverfor his mono vision.IFYOU HAVE A MEDICAL QUESTION. SEND IlTO <strong>American</strong> <strong>Bonanza</strong><strong>Society</strong>, Attn: Aeromedical News, P.O. Box 12B88, Wichita, KS67277. Or use fax: 316-945-1710 or e·mail Who said being nice doesn't pay the rent?Introduce yourself the next time you run across a non-ABS Beech pilot and get' emto join. You can get another month added onto your ABS membership forevery new recruit you sign up. MfflIbenhip forms are avail4bk at www.bonanza.org.Have the new recruit enter your name in the space "/ karned about ABS from" to receive credit.

Speed and fuelChristopher SextonFillmore, CaliforniaQ: (I) I have an 10-520 in a 1962P35. I have great difficulty getting thisairplane to slow down or descend unlessI pull the manifold pressure back toabout 13 or 14 inches to establish a slowdescent. This is below the green arc. Ihave a GEM and have not noticed thatthis practice causes the temperatures todrop rapidly.(2) There are yellow marks on boththe left and right fuel gauges at 1/4 tank.The POH states that you should not takeoff with the fuel below this level, butdoesn't explain why. Is this a weight andbalance issue? An issue of unporting thefuel pickups?A: (I) One drawback of addingpower to an older <strong>Bonanza</strong> is that ittakes more advance plann ing to arrive ata target airspeed. A gradual powerreduction to 13 to 14 inches longenough to slow down shouldn't hurt.Starting with a reduction in rpm mayhelp as well. You may need to adjust themixture to maintain CHTs. A more radicalsolution is to install speed brakes.See www.preciseJlight.com.(2) The "yellow arc" fuel !imitationsare designed to prevent you frominadvertently taking off into a "Iowfuel"situation with limited options forrecovery. Nonetheless, having at leastthe yellow arc's worth of fuel in bothtanks is a legal limitation on the airframe,and must be observed. This is not to beconfused with the "no tuming takeoffs"(for airplanes with unbaffled fuel cells)and maximum slip duration limitationsthat are to prevent fuel unporting in anuncoordinated maneuver. -ITTip tank troublesL.ewis WolkerIndependence. VirginiaQ: I have a problem with the automaticshutoff valves on the Osborne tiptanks on my A36. I have replaced theswitches and pumps several times sinceinstallation. John Osborne has been graciousto provide materials, but we haveno solution yet. I'm in westernVirginia, so where should I take my airplane?A: Kalamazoo Aircraft (260-381-0790) in Michigan, or HagerstownAircraft Services (301-733-7604) inMaryland may be able to help. -NPWindow air leakEric KochJasper. TexasQ: I am experiencing an air leakaround my V35's emergency windowbehind the pilot's seat. I have had themolding replaced, but there is still an airleak. Do you have any suggeslions?A: Check the new seals to verifythey are the correct ones and in positionto make good contact with the windowframe. If thi s all looks good, I would Jlythe aircraft with someone in the rearseat to locate the leak. You might temporarilytry using door/window caulkingto find the leak.Once you find the area that is leaking,try shimming it by putting some Jlatrubber behind the seal to give it bettercontact with the window frame. It's notunusual to need thi s.I have heard of people bending thewindow frame to get it to fit better.Doing this comes with the risk of breakina the seal between the window andoframe or worse yet, breaking the window.-AMGear lube and extensionRobert BisbeeEast Falmouth. MassachusettsQ: What is the type of grease andgrease gun to lube the landing gear ofmy S35? Can I do it or must an A&P?Also, what is the amount of extension ofthe nose gear strut?A: For all landing gear lubrication,you will need to use grease with a MlLG-81322 rating. One such brand isAeroshell 22. Other manufacturers mayhave a different name; but as long as itcomplies with the MIL spec number, itwill be correct.A standard automotive grease gunwill work on most fittings; for some fittingsyou will need a needle fittingadaptor, which goes on the end of thegun to grease these type of fittings. Themaintenance manual shows what typematerial and where to lube in the servicingarea (Section 2).- An owner may lube any fitting thatdoes not require removal of componentsfor access. Nose shock distance shouldbe 3 1/16" when serviced correctly. (Asa good rule of thumb, you can use thewidth of your four fingers and you willbe very c1ose.)-BRGear tensionometerJames BrendelCordova. TennesseeQ: Can you tell me a good place tofind a "spring scale" tool to measure thelip and down lock tensions for the gearwhen doing an annual?A: You can rent this tool from IdealAviation (480-892-2529) or purchasefrom JLW Instruments (3 12-666-0595)model 800 and make a block to fit theend out of scrap stock.-NPAlternator whineThomas HainesWalkerville, MarylandQ: The alternator on my A36 (l0-550) has about 680 hours on it and I amdetecting a bit of a whine in the backgroundthrough the headsets, which tellsme it may be on its way out. Is the subtlewhine a good indicator that it is havingproblems?A: The whine could be a diode. Itwould show as AC voltage on the buss.

TECH NOTESTech Noles are from ASS Technical Consultant Neil Pobanz unless otherwise noted.TOP 10 FREQUE T DISCREPANCIES AT ABS SERVICECLINICS. which reflect the condition of our neet:I. Many landing gear are worn or out of rig. to the point of beingunairworthy. Motors are weak, uplock cables broken orfrayed , springs missing or frozen, rod ends cracked, linkagebent and parts assembled wrong. It's evident that the gearcheck on many annuals is just "run it up and down, check thehom and, if the doors close, send it out ,"2. Engine compartment findings: Lack of washer on engine controlrod ends, alternator exhaust vent duct missing and oil oninside of vent, holes in flexible intake duct aft from filter tomanifold, broken or weak springs in alternate air doors, enginemount heat shields installed wrong, hangers worn or broken,clamps too tight or too loose, poor baffle conditi on.3. Flight controls: Corrosion, unairworthy repairs, wear inhinges and linkages, flap rigging cracks, balance and auachmenthardware wrong.4. Cabin doors: Many are out of rig and many have worn cab inhinges and controls and tabs installed wrong.5. Required placards are missing.6. Fuel caps need reseal (both inner and outer) vents broken off.7. Dirty aft bulkheads, which could nO! have been inspected lAWAD94-20-04R2 but were signed off. Conversations reveal thatthe spar inspection is also many times not dye-checked whensigned off.8. Cracked cabin steps.9. Worn brake pedals near failure.10. Nose gear tunnels have cracks and undocumented repairs.There are many more items that occur less frequently.HOSKfNS ENOl E MONITORS: Instrument Tech in Dallas(800-229-9078) has approval to repair them.PREFLIGHT OF THE GEAR: Preflight of the gear shouldinclude looking for frayed uplock cables on the mains and rustysprings on the uplock.STALL WARNING WINGS: Early 35 airplanes had a small wingon top of the left wing to run the stall warning detector. Manyhave broken off or are partially there. Arrell (805-604-0439) hasreplacement wings. There are different wiring plans among eventhe early airplanes. When testing the stall warning, you may haveLO configure the airplane to accomplish the test. It is possible toinstall a leading edge stall warning switch similar to the later aircraft.Copy the location exactly from later models; also refer totheir wiring diagrams. Then use a 337 field approval.MASTER CYLINDER PARTS: Gerdes master cylinders werepurchased by Cleveland Wheel and Brake (800-272-5464).Cleveland has some drawings for parts that had independentapproval. Some master cylinder part numbers may be unsupportedby either Cleveland or Beech.ILLEGAL PARTS: These may be fake parts that are purposelyfalsely identified, or may just not have documentation, or bemade from raw stock that doesn't meet specifications.WET PUMP CO VERSION: Air Wolf has an STC and separaLOr. Airwolf.com.INTAKE LEAKS: Clamps on the hoses in the intake manifold. distortedor cracked hoses and cracked or worn balance tubes are allfrequent problems that cause leaks and unbalanced intake flow.ILLEGAL REPAIRS: These may nO! be accompli shed byacceptable means, methods or materials, or may just not havesupport ing data or documentation. The latter can many times justhave the paperwork completed and be fine. Sometimes these haveskipped through prebuys and annuals.AIRBORNE VACUUM SHUTTLE VALVES: These valves,which are subject to a bulletin, can be repaired with kits fromAvstat (888-287-8283 ). (multi-engines)550 MAGS: It's been reported that many times installing Unison"Slick" mags required double mag gaskets.PRESSURE WASHER: We prefer that pressure washers not beused, as they drive lubricant out and water and strong soap inwhere it doesn't belong. Be careful choosing soaps LO use. SimpleGreen, for instance. has one that is approved for aircraft use andone that causes corrosion and is not approved.WING BOLTS AND FITTINGS: We've heard of damage fromthem being assembled wrong and of using the wrong torque.Some parts that may seem all the same at f,rst glance but aren'tare worm drive clamps, ty wraps, duct tape and RTY. Worm drivehose clamps can have significantly different strengths, differentresistance to the screw backing off and different resistance to corrosion.Aero Seal and Breeze are two accepted brands.Ty wraps should be such that they don't slip, don't hardenfrom UV, and don't break. The MS standard is MS3367. Duct tapesuitable for use in tank lining, etc, must have properties unlikethat normally found in hardware stores, such as higher fiber content.GE102, 103, 108 and 109 silicon seal is not acidic and won'tcause corrosion. The difference is they are white, black, clear oraluminum colored.MOUNTI G PLATE PROBLEM: A member reported replacingthe right wing's 40-gallon fuel cell on a J35. The replacement cellwas manufactured by Uniroyal and purchased through Hartwig.After installation, they were unable to get a FULL reading onthe right fuel quantity gauge. The maximum it would indicate wasonly 112 to 3/4 full. The member had the fuel transmitters reconditionedbut got the same indications when the transmitters werereinstalled. The transmitters worked properly when removedfrom the fuel cell and operated manually.On investigation. the member discovered the new fuel cell'soutboard transmitter mounting plate was very thick. The leftwing's fuel cell, which was original to the airplane, has a muchthinner mounting plate. In operation, the right wing outer fueltransmitter's arm contacted this plate and would not go to thefuli-up position.Hartwig has sent the member a replacement, with a thinnermounting plate and adhesive to modify the cell, and has informedUniroyal of the problem.-RG-@--Page 9466 www.bonanza.org ABS <strong>February</strong> <strong>2006</strong>

Power Wheelj ~~1/I ,,""j l 'Power Wheel by Far West AviationSave Your Engine, The Easy Way!Know how much power your engine is producingwith the ABS Power Com puter by Far WestAviation, Inc. This E6B-style circular computer- made of high-strength Lexan - identifies thepower developed through manifold pressure,propeller speed, altitude, outside air tempand leaning technique. Valid at both rich andlean of peak settings, normally aspirated andturbonormalized. Specify 10-470 or 10-520/550(not applicable to 10-470C, factory-turbochargedor E-series engines)No. PW1 2625 $34.95No . PW22700 $34.95Save your backissues of themagazine in thesesturdy, attractivebinders. Holds a fullyear of issues withstrong wires fastenedto the binder spine.Specify burgundy~-or navy.--~==~~-~::~~::'""-"NO.3000 $9.00VIDEOS - Now also available on DVm<strong>Bonanza</strong>/Baron Pilot Proficiency Program Highlights VideoThis video addresses all <strong>Bonanza</strong> models with common information and tips to improveyour skills. Achieve the greatest performance from your aircraft. Approx. 80 minutes inlength. No. 4500 S59.50Owner-performed Maintenance VideoA SO-minute video describing the regular maintenance that can and should beperformed by the airplane owner. Detail is given to the scope and the proper techniQuesrecommended to perform these maintenance tasks. No. 4501 $31 .25living with a Thorough Pre-flight Inspection VideoThis 16-minute video applies to aU single·engine aircraft. It aids the pilot in understandingthe importance of a planned preflight inspection. The significance of using the POH isstressed, but it goes a step further by explaining, in detail, what we 're looking for. Thenarrator does an excellent job pointing out that a proper preflight inspection beginsas the pilot approaches the airplane. NO. 4502 $10 .00<strong>Bonanza</strong>/Baron Service Clinic Video With Norm ColvinA one·hour discussion by Norm Colvin of the most common discrepancies foundat ASS Service Clinics. The video also identifies areas reQuiring additional attention.A great reference video! No. 4503 $31 .25ABS BaD CapsTwill Cap with Suede VisorBlue, low-profile cap withbrown suede visor. ABSlogo em broidered on front.Tuck-away leather strapand slide-buckle closure.NO. 3120 $18.00Stadium BlanketPolarfleece blanket comes in bright Red with Black edgestitching or Black with Red edge stitching. Rolls up intoa convenient log with velcro close and nylon web strapfor carrying. Protected with nylon covering imprintedwith ABS logo. $15.00Twill Cap Green low-profile cap with beigevisor. ABS logo embroidered on frontand on visor. USA flag on side withABS website on the velcro closure.No. 3122 $15.00Phone: 316-945-1700 FAX: 316-945-1710Web site: www.bonanza.org E-mail: bonanza5@bonanza.org