Thermal Spray Powders

Thermal Spray Powders

Thermal Spray Powders

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

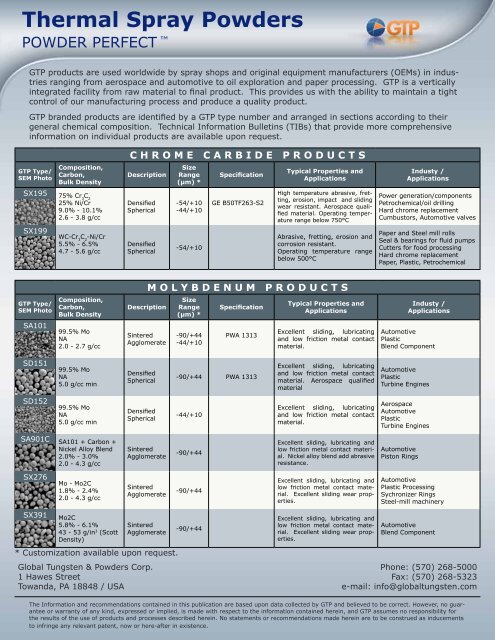

<strong>Thermal</strong> <strong>Spray</strong> <strong>Powders</strong>POWDER PERFECT GTP products are used worldwide by spray shops and original equipment manufacturers (OEMs) in industriesranging from aerospace and automotive to oil exploration and paper processing. GTP is a verticallyintegrated facility from raw material to final product. This provides us with the ability to maintain a tightcontrol of our manufacturing process and produce a quality product.GTP branded products are identified by a GTP type number and arranged in sections according to theirgeneral chemical composition. Technical Information Bulletins (TIBs) that provide more comprehensiveinformation on individual products are available upon request.GTP Type/SEM PhotoSX195SX199Composition,Carbon,Bulk Density75% Cr 3C 225% Ni/Cr9.0% - 10.1%2.6 - 3.8 g/ccWC-Cr 3C 2-Ni/Cr5.5% - 6.5%4.7 - 5.6 g/ccC H R O M E C A R B I D E P R O D U C T SDescriptionDensifiedSphericalDensifiedSphericalSizeRange(µm) *-54/+10-44/+10-54/+10SpecificationGE B50TF263-S2Typical Properties andApplicationsHigh temperature abrasive, fretting,erosion, impact and slidingwear resistant. Aerospace qualifiedmaterial. Operating temperaturerange below 750°CAbrasive, fretting, erosion andcorrosion resistant.Operating temperature rangebelow 500°CIndusty /ApplicationsPower generation/componentsPetrochemical/oil drillingHard chrome replacementCumbustors, Automotive valvesPaper and Steel mill rollsSeal & bearings for fluid pumpsCutters for food processingHard chrome replacementPaper, Plastic, PetrochemicalGTP Type/SEM PhotoSA101Composition,Carbon,Bulk Density99.5% MoNA2.0 - 2.7 g/ccDescriptionSinteredAgglomerateM O L Y B D E N U M P R O D U C T SSizeRange(µm) *-90/+44-44/+10SpecificationPWA 1313Typical Properties andApplicationsExcellent sliding, lubricatingand low friction metal contactmaterial.Industy /ApplicationsAutomotivePlasticBlend ComponentSD15199.5% MoNA5.0 g/cc minDensifiedSpherical-90/+44 PWA 1313Excellent sliding, lubricatingand low friction metal contactmaterial. Aerospace qualifiedmaterialAutomotivePlasticTurbine EnginesSD15299.5% MoNA5.0 g/cc minDensifiedSpherical-44/+10Excellent sliding, lubricatingand low friction metal contactmaterial.AerospaceAutomotivePlasticTurbine EnginesSA901CSA101 + Carbon +Nickel Alloy Blend2.0% - 3.0%2.0 - 4.3 g/ccSinteredAgglomerate-90/+44Excellent sliding, lubricating andlow friction metal contact material.Nickel alloy blend add abrasiveresistance.AutomotivePiston RingsSX276Mo - Mo2C1.8% - 2.4%2.0 - 4.3 g/ccSinteredAgglomerate-90/+44Excellent sliding, lubricating andlow friction metal contact material.Excellent sliding wear properties.AutomotivePlastic ProcessingSychronizer RingsSteel-mill machinerySX391Mo2C5.8% - 6.1%43 - 53 g/in 3 (ScottDensity)SinteredAgglomerate* Customization available upon request.Global Tungsten & <strong>Powders</strong> Corp.1 Hawes StreetTowanda, PA 18848 / USA-90/+44Excellent sliding, lubricating andlow friction metal contact material.Excellent sliding wear properties.AutomotiveBlend ComponentPhone: (570) 268-5000Fax: (570) 268-5323e-mail: info@globaltungsten.comThe Information and recommendations contained in this publication are based upon data collected by GTP and believed to be correct. However, no guaranteeor warranty of any kind, expressed or implied, is made with respect to the information contained herein, and GTP assumes no responsibility forthe results of the use of products and processes described herein. No statements or recommendations made herein are to be construed as inducementsto infringe any relevant patent, now or here-after in existence.