Thermal Spray Powders

Thermal Spray Powders

Thermal Spray Powders

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

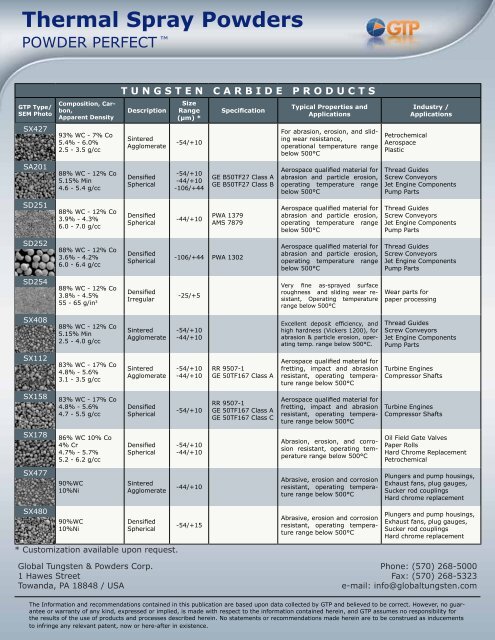

<strong>Thermal</strong> <strong>Spray</strong> <strong>Powders</strong>POWDER PERFECT T U N G S T E N C A R B I D E P R O D U C T SGTP Type/SEM PhotoComposition, Carbon,Apparent DensityDescriptionSizeRange(µm) *SpecificationTypical Properties andApplicationsIndustry /ApplicationsSX42793% WC - 7% Co5.4% - 6.0%2.5 - 3.5 g/ccSinteredAgglomerate-54/+10For abrasion, erosion, and slidingwear resistance,operational temperature rangebelow 500°CPetrochemicalAerospacePlasticSA20188% WC - 12% Co5.15% Min4.6 - 5.4 g/ccDensifiedSpherical-54/+10-44/+10-106/+44GE B50TF27 Class AGE B50TF27 Class BAerospace qualified material forabrasion and particle erosion,operating temperature rangebelow 500°CThread GuidesScrew ConveyorsJet Engine ComponentsPump PartsSD25188% WC - 12% Co3.9% - 4.3%6.0 - 7.0 g/ccDensifiedSpherical-44/+10PWA 1379AMS 7879Aerospace qualified material forabrasion and particle erosion,operating temperature rangebelow 500°CThread GuidesScrew ConveyorsJet Engine ComponentsPump PartsSD25288% WC - 12% Co3.6% - 4.2%6.0 - 6.4 g/ccDensifiedSpherical-106/+44 PWA 1302Aerospace qualified material forabrasion and particle erosion,operating temperature rangebelow 500°CThread GuidesScrew ConveyorsJet Engine ComponentsPump PartsSD25488% WC - 12% CoDensified3.8% - 4.5%Irregular55 - 65 g/in 3-25/+5Very fine as-sprayed surfaceroughness and sliding wear resistant,Operating temperaturerange below 500°CWear parts forpaper processingSX40888% WC - 12% Co5.15% Min2.5 - 4.0 g/ccSinteredAgglomerate-54/+10-44/+10Excellent deposit efficiency, andhigh hardness (Vickers 1200), forabrasion & particle erosion, operatingtemp. range below 500°C.Thread GuidesScrew ConveyorsJet Engine ComponentsPump PartsSX11283% WC - 17% Co4.8% - 5.6%3.1 - 3.5 g/ccSinteredAgglomerate-54/+10-44/+10RR 9507-1GE 50TF167 Class AAerospace qualified material forfretting, impact and abrasionresistant, operating temperaturerange below 500°CTurbine EnginesCompressor ShaftsSX15883% WC - 17% Co4.8% - 5.6%4.7 - 5.5 g/ccDensifiedSpherical-54/+10RR 9507-1GE 50TF167 Class AGE 50TF167 Class CAerospace qualified material forfretting, impact and abrasionresistant, operating temperaturerange below 500°CTurbine EnginesCompressor ShaftsSX17886% WC 10% Co4% Cr4.7% - 5.7%5.2 - 6.2 g/ccDensifiedSpherical-54/+10-44/+10Abrasion, erosion, and corrosionresistant, operating temperaturerange below 500°COil Field Gate ValvesPaper RollsHard Chrome ReplacementPetrochemicalSX47790%WC10%NiSinteredAgglomerate-44/+10Abrasive, erosion and corrosionresistant, operating temperaturerange below 500°CPlungers and pump housings,Exhaust fans, plug gauges,Sucker rod couplingsHard chrome replacementSX48090%WC10%NiDensifiedSpherical* Customization available upon request.-54/+15Abrasive, erosion and corrosionresistant, operating temperaturerange below 500°CPlungers and pump housings,Exhaust fans, plug gauges,Sucker rod couplingsHard chrome replacementGlobal Tungsten & <strong>Powders</strong> Corp.1 Hawes StreetTowanda, PA 18848 / USAPhone: (570) 268-5000Fax: (570) 268-5323e-mail: info@globaltungsten.comThe Information and recommendations contained in this publication are based upon data collected by GTP and believed to be correct. However, no guaranteeor warranty of any kind, expressed or implied, is made with respect to the information contained herein, and GTP assumes no responsibility forthe results of the use of products and processes described herein. No statements or recommendations made herein are to be construed as inducementsto infringe any relevant patent, now or here-after in existence.

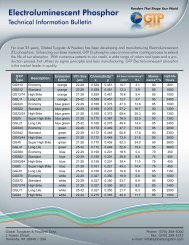

<strong>Thermal</strong> <strong>Spray</strong> <strong>Powders</strong>POWDER PERFECT GTP products are used worldwide by spray shops and original equipment manufacturers (OEMs) in industriesranging from aerospace and automotive to oil exploration and paper processing. GTP is a verticallyintegrated facility from raw material to final product. This provides us with the ability to maintain a tightcontrol of our manufacturing process and produce a quality product.GTP branded products are identified by a GTP type number and arranged in sections according to theirgeneral chemical composition. Technical Information Bulletins (TIBs) that provide more comprehensiveinformation on individual products are available upon request.GTP Type/SEM PhotoSX195SX199Composition,Carbon,Bulk Density75% Cr 3C 225% Ni/Cr9.0% - 10.1%2.6 - 3.8 g/ccWC-Cr 3C 2-Ni/Cr5.5% - 6.5%4.7 - 5.6 g/ccC H R O M E C A R B I D E P R O D U C T SDescriptionDensifiedSphericalDensifiedSphericalSizeRange(µm) *-54/+10-44/+10-54/+10SpecificationGE B50TF263-S2Typical Properties andApplicationsHigh temperature abrasive, fretting,erosion, impact and slidingwear resistant. Aerospace qualifiedmaterial. Operating temperaturerange below 750°CAbrasive, fretting, erosion andcorrosion resistant.Operating temperature rangebelow 500°CIndusty /ApplicationsPower generation/componentsPetrochemical/oil drillingHard chrome replacementCumbustors, Automotive valvesPaper and Steel mill rollsSeal & bearings for fluid pumpsCutters for food processingHard chrome replacementPaper, Plastic, PetrochemicalGTP Type/SEM PhotoSA101Composition,Carbon,Bulk Density99.5% MoNA2.0 - 2.7 g/ccDescriptionSinteredAgglomerateM O L Y B D E N U M P R O D U C T SSizeRange(µm) *-90/+44-44/+10SpecificationPWA 1313Typical Properties andApplicationsExcellent sliding, lubricatingand low friction metal contactmaterial.Industy /ApplicationsAutomotivePlasticBlend ComponentSD15199.5% MoNA5.0 g/cc minDensifiedSpherical-90/+44 PWA 1313Excellent sliding, lubricatingand low friction metal contactmaterial. Aerospace qualifiedmaterialAutomotivePlasticTurbine EnginesSD15299.5% MoNA5.0 g/cc minDensifiedSpherical-44/+10Excellent sliding, lubricatingand low friction metal contactmaterial.AerospaceAutomotivePlasticTurbine EnginesSA901CSA101 + Carbon +Nickel Alloy Blend2.0% - 3.0%2.0 - 4.3 g/ccSinteredAgglomerate-90/+44Excellent sliding, lubricating andlow friction metal contact material.Nickel alloy blend add abrasiveresistance.AutomotivePiston RingsSX276Mo - Mo2C1.8% - 2.4%2.0 - 4.3 g/ccSinteredAgglomerate-90/+44Excellent sliding, lubricating andlow friction metal contact material.Excellent sliding wear properties.AutomotivePlastic ProcessingSychronizer RingsSteel-mill machinerySX391Mo2C5.8% - 6.1%43 - 53 g/in 3 (ScottDensity)SinteredAgglomerate* Customization available upon request.Global Tungsten & <strong>Powders</strong> Corp.1 Hawes StreetTowanda, PA 18848 / USA-90/+44Excellent sliding, lubricating andlow friction metal contact material.Excellent sliding wear properties.AutomotiveBlend ComponentPhone: (570) 268-5000Fax: (570) 268-5323e-mail: info@globaltungsten.comThe Information and recommendations contained in this publication are based upon data collected by GTP and believed to be correct. However, no guaranteeor warranty of any kind, expressed or implied, is made with respect to the information contained herein, and GTP assumes no responsibility forthe results of the use of products and processes described herein. No statements or recommendations made herein are to be construed as inducementsto infringe any relevant patent, now or here-after in existence.

<strong>Thermal</strong> <strong>Spray</strong> <strong>Powders</strong>Cross Reference GuideGTP TypeCompositionHC StarckAmperit ® Praxair Sulzer Metco Woka Stellite / DeloroSX19575% Cr3C225% Ni/Cr584CRC-3001375VMAmdry 5260 7202 JK 135SX42793% WC7% CoSA20188% WC12% Co516WC-489-1WC-114Sulzer Metco 5810Diamalloy 2004Metco 72F –NS3101, 3102, 3103 JK 114SD25188% WC12% Co515 WC-726Amdry 301Metco 71VF-NS-5Diamalloy 20033101 JK 112SD25288% WC12% Co515 WC-726Amdry 302Metco 71NS3101 JK 112SD254SX40888% WC12% Co88% WC12% Co515 WC-114 JK 112518 WC-727-1 Sulzer Metco 5812 3201SX11283% WC17% Co526 WC-128-22005NS / 200673F/SF, 5826JK 119SX15883% WC17% Co526WC-559WC-729Amdry 9830/983173F-NS-1JK 117SX17886% WC10% Co / 4% Cr553554WC-7311350VMAmdry 5843Sulzer Metco 584736513652JK 120JK 7109SX199 WC - Cr 3C 2- Ni/Cr 552 WC-496 JK 125SX477SX48090% WC10% Ni90% WC10% NiWC-724 3301, 3302, 3303 JK 6189WC-724 3301, 3302, 3303 JK 6189SA101 99.5% Mo 105 MO-103SD151 99.5% Mo 109 MO-102SD152 99.5% Mo 109 MO-10263NSAmdry 313X63NSAmdry 313XSA901CSA101 + Carbon NickelAlloy BlendAI-1054SX276 Mo - Mo 2C 110SX391 Mo 2C 599 Metco 64Global Tungsten & <strong>Powders</strong> Corp.1 Hawes StreetTowanda, PA 18848 / USAPhone: (570) 268-5000Fax: (570) 268-5323e-mail: info@globaltungsten.comThe Information and recommendations contained in this publication are based upon data collected by GTP and believed to be correct. However, no guaranteeor warranty of any kind, expressed or implied, is made with respect to the information contained herein, and GTP assumes no responsibility forthe results of the use of products and processes described herein. No statements or recommendations made herein are to be construed as inducementsto infringe any relevant patent, now or here-after in existence.