Low Frequency Magnetic Shielding - Interference Technology

Low Frequency Magnetic Shielding - Interference Technology

Low Frequency Magnetic Shielding - Interference Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

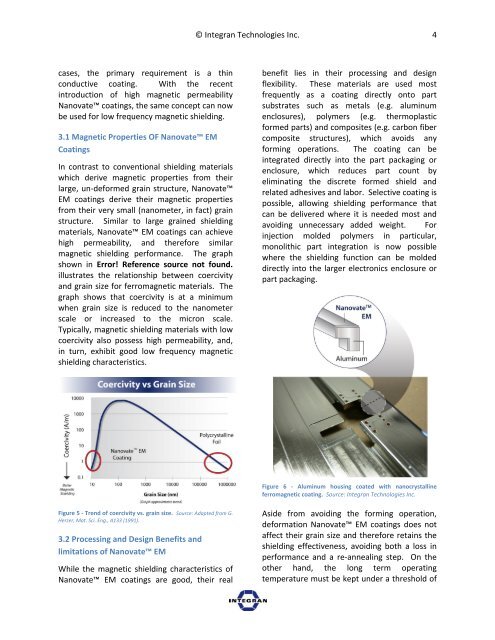

© Integran Technologies Inc. 4cases, the primary requirement is a thinconductive coating. With the recentintroduction of high magnetic permeabilityNanovate coatings, the same concept can nowbe used for low frequency magnetic shielding.3.1 <strong>Magnetic</strong> Properties OF Nanovate EMCoatingsIn contrast to conventional shielding materialswhich derive magnetic properties from theirlarge, un‐deformed grain structure, NanovateEM coatings derive their magnetic propertiesfrom their very small (nanometer, in fact) grainstructure. Similar to large grained shieldingmaterials, Nanovate EM coatings can achievehigh permeability, and therefore similarmagnetic shielding performance. The graphshown in Error! Reference source not found.illustrates the relationship between coercivityand grain size for ferromagnetic materials. Thegraph shows that coercivity is at a minimumwhen grain size is reduced to the nanometerscale or increased to the micron scale.Typically, magnetic shielding materials with lowcoercivity also possess high permeability, and,in turn, exhibit good low frequency magneticshielding characteristics.benefit lies in their processing and designflexibility. These materials are used mostfrequently as a coating directly onto partsubstrates such as metals (e.g. aluminumenclosures), polymers (e.g. thermoplasticformed parts) and composites (e.g. carbon fibercomposite structures), which avoids anyforming operations. The coating can beintegrated directly into the part packaging orenclosure, which reduces part count byeliminating the discrete formed shield andrelated adhesives and labor. Selective coating ispossible, allowing shielding performance thatcan be delivered where it is needed most andavoiding unnecessary added weight. Forinjection molded polymers in particular,monolithic part integration is now possiblewhere the shielding function can be moldeddirectly into the larger electronics enclosure orpart packaging.Figure 6 ‐ Aluminum housing coated with nanocrystallineferromagnetic coating. Source: Integran Technologies Inc.Figure 5 ‐ Trend of coercivity vs. grain size. Source: Adapted from G.Herzer, Mat. Sci. Eng., A133 (1991).3.2 Processing and Design Benefits andlimitations of Nanovate EMWhile the magnetic shielding characteristics ofNanovate EM coatings are good, their realAside from avoiding the forming operation,deformation Nanovate EM coatings does notaffect their grain size and therefore retains theshielding effectiveness, avoiding both a loss inperformance and a re‐annealing step. On theother hand, the long term operatingtemperature must be kept under a threshold of

![[ thursday ] morning sessions 8:30 am-noon - Interference Technology](https://img.yumpu.com/23176841/1/190x247/-thursday-morning-sessions-830-am-noon-interference-technology.jpg?quality=85)