Low Frequency Magnetic Shielding - Interference Technology

Low Frequency Magnetic Shielding - Interference Technology

Low Frequency Magnetic Shielding - Interference Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

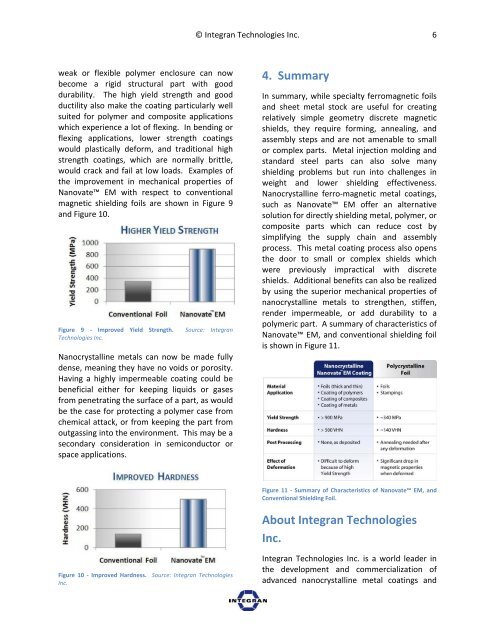

© Integran Technologies Inc. 6weak or flexible polymer enclosure can nowbecome a rigid structural part with gooddurability. The high yield strength and goodductility also make the coating particularly wellsuited for polymer and composite applicationswhich experience a lot of flexing. In bending orflexing applications, lower strength coatingswould plastically deform, and traditional highstrength coatings, which are normally brittle,would crack and fail at low loads. Examples ofthe improvement in mechanical properties ofNanovate EM with respect to conventionalmagnetic shielding foils are shown in Figure 9and Figure 10.Figure 9 ‐ Improved Yield Strength. Source: IntegranTechnologies Inc.Nanocrystalline metals can now be made fullydense, meaning they have no voids or porosity.Having a highly impermeable coating could bebeneficial either for keeping liquids or gasesfrom penetrating the surface of a part, as wouldbe the case for protecting a polymer case fromchemical attack, or from keeping the part fromoutgassing into the environment. This may be asecondary consideration in semiconductor orspace applications.4. SummaryIn summary, while specialty ferromagnetic foilsand sheet metal stock are useful for creatingrelatively simple geometry discrete magneticshields, they require forming, annealing, andassembly steps and are not amenable to smallor complex parts. Metal injection molding andstandard steel parts can also solve manyshielding problems but run into challenges inweight and lower shielding effectiveness.Nanocrystalline ferro‐magnetic metal coatings,such as Nanovate EM offer an alternativesolution for directly shielding metal, polymer, orcomposite parts which can reduce cost bysimplifying the supply chain and assemblyprocess. This metal coating process also opensthe door to small or complex shields whichwere previously impractical with discreteshields. Additional benefits can also be realizedby using the superior mechanical properties ofnanocrystalline metals to strengthen, stiffen,render impermeable, or add durability to apolymeric part. A summary of characteristics ofNanovate EM, and conventional shielding foilis shown in Figure 11.Figure 11 ‐ Summary of Characteristics of Nanovate EM, andConventional <strong>Shielding</strong> Foil.About Integran TechnologiesInc.Figure 10 ‐ Improved Hardness. Source: Integran TechnologiesInc.Integran Technologies Inc. is a world leader inthe development and commercialization ofadvanced nanocrystalline metal coatings and

![[ thursday ] morning sessions 8:30 am-noon - Interference Technology](https://img.yumpu.com/23176841/1/190x247/-thursday-morning-sessions-830-am-noon-interference-technology.jpg?quality=85)