March 2003 - Trench Safety

March 2003 - Trench Safety

March 2003 - Trench Safety

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

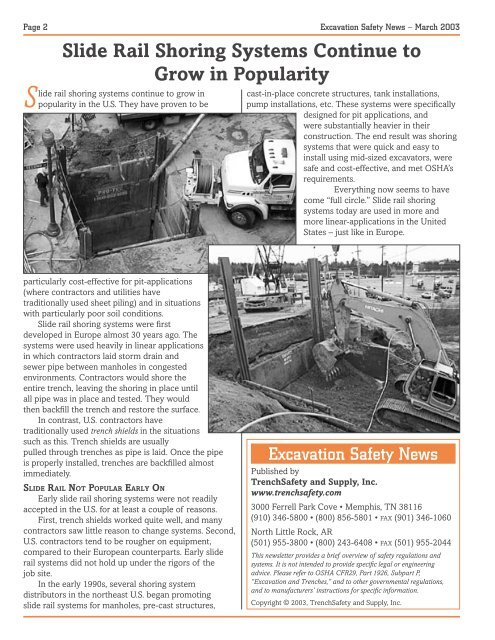

Page 2 Excavation <strong>Safety</strong> News – <strong>March</strong> <strong>2003</strong>Slide Rail Shoring Systems Continue toGrow in PopularitySlide rail shoring systems continue to grow inpopularity in the U.S. They have proven to becast-in-place concrete structures, tank installations,pump installations, etc. These systems were specificallydesigned for pit applications, andwere substantially heavier in theirconstruction. The end result was shoringsystems that were quick and easy toinstall using mid-sized excavators, weresafe and cost-effective, and met OSHA’srequirements.Everything now seems to havecome “full circle.” Slide rail shoringsystems today are used in more andmore linear-applications in the UnitedStates – just like in Europe.particularly cost-effective for pit-applications(where contractors and utilities havetraditionally used sheet piling) and in situationswith particularly poor soil conditions.Slide rail shoring systems were firstdeveloped in Europe almost 30 years ago. Thesystems were used heavily in linear applicationsin which contractors laid storm drain andsewer pipe between manholes in congestedenvironments. Contractors would shore theentire trench, leaving the shoring in place untilall pipe was in place and tested. They wouldthen backfill the trench and restore the surface.In contrast, U.S. contractors havetraditionally used trench shields in the situationssuch as this. <strong>Trench</strong> shields are usuallypulled through trenches as pipe is laid. Once the pipeis properly installed, trenches are backfilled almostimmediately.SLIDE RAIL NOT POPULAR EARLY ONEarly slide rail shoring systems were not readilyaccepted in the U.S. for at least a couple of reasons.First, trench shields worked quite well, and manycontractors saw little reason to change systems. Second,U.S. contractors tend to be rougher on equipment,compared to their European counterparts. Early sliderail systems did not hold up under the rigors of thejob site.In the early 1990s, several shoring systemdistributors in the northeast U.S. began promotingslide rail systems for manholes, pre-cast structures,Excavation <strong>Safety</strong> NewsPublished by<strong>Trench</strong><strong>Safety</strong> and Supply, Inc.www.trenchsafety.com3000 Ferrell Park Cove • Memphis, TN 38116(910) 346-5800 • (800) 856-5801 • FAX (901) 346-1060North Little Rock, AR(501) 955-3800 • (800) 243-6408 • FAX (501) 955-2044This newsletter provides a brief overview of safety regulations andsystems. It is not intended to provide specific legal or engineeringadvice. Please refer to OSHA CFR29, Part 1926, Subpart P,“Excavation and <strong>Trench</strong>es,” and to other governmental regulations,and to manufacturers’ instructions for specific information.Copyright © <strong>2003</strong>, <strong>Trench</strong><strong>Safety</strong> and Supply, Inc.