Download magazine - Mercedes-Benz

Download magazine - Mercedes-Benz

Download magazine - Mercedes-Benz

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ContentsRoad maintenance 14The roads must be clean! This is an attitudeshared by employees of the Salzburg roadmaintenance authoritiesPower industry 8Not the usual kindof workplace. AU 500 is animportant elementin the tasks carriedout by the e.oncompany’sengineers on highvoltagewiresFighting forest fires 20Pushing back the flames. A U 400 is a reliable tool for firefighters inthe mountains around Salamanca, SpainP u b l i s h e r ’ s d a t aPublisher:DaimlerChrysler AG, Unimog DivisionResponsible at publisher:Dieter Sellnau, Unimog DivisionCo-ordination:Martin Adam, Unimog DivisionEditorial committee:Martin Adam, Dieter Mutard,Karin WeidenbacherContributors to this issue:Texts and photos: Dieter Mutard, Stefan Loeffler,Petra Forberger, Unimog DivisionEnglish translations: Colin Brazier, MunichEditorial office address:DaimlerChrysler AG, Unimog Division,Sales Marketing, 76568 Gaggenau, GermanyProduction:Dieter Mutard DWM Pressebüro und Verlag,Ringstrasse 11, 89081 Ulm, GermanyThe next issue will be published in the autumn of2003. The publishers accept no responsibility forunsolicited copy or photographs.Printed on paper bleached without chlorinePrinted in the Federal Republic of GermanyPublic-authority use 4An indispensable helper at the municipalconstruction yard in GummersbachWinter services 7How Marktleuthen in Germany’s Fichtelgebirgeregion keeps its roads free of snowPower industry 8Working on high-voltage wiresPresentations 10Winter realitiesDaimlerChrysler Worldwide 12Road maintenance 14Spring-clean in SalzburgPower industry 16Unbeatable in ToggenburgOfficial snow clearing machines 18at the World Skiing ChampionshipsFighting forest fires 20A U 400 guarantees safe working conditionsfor firemen in SpainUNISCOPE 22Unimog museum in the Murg valley5,555 Unimogs in SwitzerlandTourist vehicleAfrica feverDaimlerChrysler WorldwideThe Shinkansen goes to Taiwan 12Cleaning up in the Land of the 13Rising SunUnimog 1|2003 3

Communal useAn indispensable helperThe public works experts in the town of Gummersbach know very wellhow important the Unimog is for their job. It can be used all the yearround. For external municipal service providers, too, the Unimog is anessential precondition for doing business with public works departments.KölnZentrumGenkeltalsperreAggertalsperreHagenDortmundSiegenGiessenFrankfurtThe town of Gummersbach, in Germany’sOberbergisches Land region and withinthe city triangle formed by Cologne/Bonn,Hagen/Dortmund and Siegen, has one or twoexceptional things to offer. It may not bewidely known that the German record championhandball team and multiple EuropeanHandball Cup winner VfL Gummersbachhails from here. The town’s total area of100 square kilometres (according to the map)is surprising enough, as is the fact that itspublic works department has to maintain300 kilometres of public roads and another300 of agricultural tracks. This is no easytask, in view of Gummersbach’s topography,which extends from 200 metres above sealevel at the lowest to 512 m at the highestpoint.Ekkehard Mesch, the active and highly experiencedmanager of Gummersbach’s publicworks depot, knows what he is talking about,and confesses frankly: “We couldn’t do withoutour Unimog implement carriers.” This isbecause of the region’s special geographicalfeatures and also the depot’s organisationaltasks within the overall pattern of municipalservices, which include road maintenance intown, canal maintenance, gully emptying andvarious environmental protection measures.KölnGummersbach, Germany, is very close to the denselypopulated urban areas of Cologne and DortmundOlpeMesch’s team is responsible for the structuralmaintenance of municipal buildingsand also various tasks for the horticulturaland cemetery authorities, grass and woodlandarea care and of course playgroundsand sports fields. Ekkehard Mesch commissionsselected external municipal serviceproviders from the Gummersbach area forsome of these extensive tasks. One of thefundamental preconditions when choosingthe service providers has always been thatthey should have one or more Unimog implementcarriers in their fleet, so that theworking attachments are fully compatiblewith Unimog technology – and thereforewith the equipment available at the municipaldepot. Three service providers based inthe direct vicinity and their Unimog implementcarriers work on behalf of the Gummersbachpublic works department. Additionaltrucks only have to be hired in thewinter, when large quantities of snow oftenhave to be removed.The main tasks of the yard’s own Unimogs(two U 300, two U 1400 and one U 1000) andthe external service providers’ vehicles arewinter services, mowing and trimming workand road maintenance. Ekkehard Mesch andthe group of qualified craftsmen and foremenwho work with the Unimog daily areconvinced: “In urban streets and similar oftenconfined spaces, the Unimogs are considerablyfaster and easier to manoeuvrethan conventional trucks. What’s more,these implement carriers built in Wörth possessa high safety potential in addition to alltheir other advantages.”The public works depot with its 67 employeesis an established element in the activitiesof the town of Gummersbach, partlydue to the fact that it has frequently been atthe centre of events during very bad weatherin the recent past. A sandbag filling machinedesigned by Ekkehard Mesch and his colleaguesReinhard Sauermann and OliverKarp, which passed its first crucial test at theturn of the year, has attracted a lot of attention.It was used by the depot staff to fill1,000 sandbags within a very short time inorder to protect an industrial company’spremises during a flood.Ekkehard Mesch had the idea for this devicewhen he saw TV pictures of hundreds ofhelpers with shovels filling sandbags duringThe complete Unimogfleet operated by thepublic works authority inGummersbach –including three U 1000sowned by externalcommunal serviceproviders (left)4 Unimog 1|2003

The public works department’s <strong>Mercedes</strong>-<strong>Benz</strong> Unimog and Atego are a familiar sight on Gummersbach’s streetsthe River Elbe floods in 2002. He didn’tunderstand why they had to do it this way,and immediately started developing a simpleyet practical piece of equipment with thehelp of his colleagues. They modified a winter-servicespreader attachment – and the resultof this inventive work is today highlypraised by the Gummersbach fire brigadeand the disaster teams of the TechnischesHilfswerk (THW). It is particularly useful tobe able to work directly where the sandbagsare needed. “We are logistically much moreflexible with this piece of equipment,” confirmsthe senior Gummersbach fire officer,Friedhelm Köster.Thanks to the dedication of its managerand the hard work of its staff, the municipalpublic works department has become wellknownthroughout the Oberbergisches Landregion. Its staff members are ever present,helpful and alert during practical day-to-dayactivities and at special events. It comes asno surprise, then, that shortly after reunificationa partnership with the East Germantown of Burg in Saxony-Anhalt was established.The aim of this was for EkkehardMesch and his team to support their colleaguesin Eastern Germany in word anddeed. The present handed over at the start ofthis partnership, incidentally, was a UnimogU 1000 that had been technically overhauledand prepared for use in Gummersbach. ■25-kilogram sandbags can be filled in a matter of seconds: With no injuries, no shovel and no lost sand! TheUnimog allows this important dam strengthening material to be stacked and built up directly in the flooded areaUnimog 1|2003 5

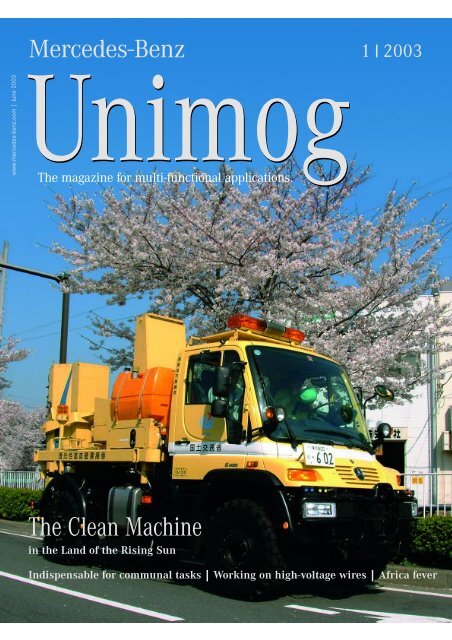

Japan DaimlerChrysler WorldwideCleaning up in the Land ofthe Rising Sun120 million people live in Japan, and own a total of 77 million cars.Residential areas are often located in the vicinity of busy roads. To keepthese clean, the Road Maintenance authority of the Japanese Land,Infrastructure and Transport Ministry in Yokohama has been operating aUnimog U 400 since the spring of 2002.The Yokohama road maintenance authorityis responsible for roads with a totallength of 240 kilometres. A Unimog U 1450,initially used for snow removal in the mountains,has so far been employed on this task.More Unimog-specific equipment such as atunnel cleaning device and a can collectingmachine have now been acquired. Accordingto the Unimog representative YANASE,based in Yokohama, no implement carrier asversatile as the <strong>Mercedes</strong>-<strong>Benz</strong> Unimog iscurrently available in Japan. A U 400 hasnow taken over from the U 1450 mentionedabove. For the new U 400 implement carrier,the same equipment as on the U 1450 can beused, together with a special cleaning devicefor curved transparent walls.These noise insulation walls are made ofpolycarbonate for optimum visibility. Thecleaning attachment for these transparentpanels is equipped with a curved, rotatingbrush, 75 centimetres in diameter, thatcleans the dirty area directly. The brush ismounted at the rear of the Unimog and canbe rotated through 90 degrees toward theedge of the road (on an axis vertical to thedirection of travel). Depending on how muchthe separating wall is curved, the brush canadopt a radius of between 2 and 4 metres.A private road maintenance company hasleased several Unimogs from the Yokohamaroad maintenance authority as a subcontractorand has been using them for some timealready. A company spokespersoncommented on the positive effects of theUnimog’s performance in the followingterms: “It used to take us six hours to cleana 600-metre noise insulation wall. Now wecan clean the 600 metres within an hour.”One of the road maintenance authority’semployees with many years’ standing hasthe following to say about his new vehicle:“Some service vehicles are basically trucks.The Unimog is much better than these,particularly our U 400 with its VarioPilotchangeover steering. Since we drive on theleft in Japan, we can see the side of the roadat all times. Using the changeover steeringguarantees optimum 360-degree visibilityand safe working. What’s more, our workingconditions are more pleasant all year roundthanks to the standard air-conditioning.”Smiling, he adds: “I am very happy to havethis vehicle to work with!”The person responsible for the equipmentadds to his colleague’s comments: “Thepurchase price of a Unimog chassis certainlycannot be compared with that of a singlepurposevehicle, but thanks to its front powertake-off shaft and the hydraulic system, theUnimog is very versatile and compatible withall kinds of add-on devices.”■Above: The brush of the cleaning device adjusts to thecurve of the transparent wallUnimog in Japan: cherry blossom and high-techUnimog 1|2003 13

Spring cleaning in SalzburgFor the first time this year, temperatures are rising above 20 degreesCelsius. A few tourists wearing T-shirts are sitting in street cafés and onrestaurant terraces. For them, winter is over for good. It’s not quite overyet for the Salzburg road maintenance authorities and their Unimogimplement carriers.Despite the fact that, with an area of justover 7,150 square kilometres, Salzburgis one of the smaller federal states in Austria,it has a varied and interesting topography. Inthe vicinity of the capital, which bears thesame name as the state itself, it is relativelyflat, becoming higher towards the south andreaching an altitude of 1,805 metres at theRadstädt Tauern pass. And halfway throughApril, when Salzburg citizens and Easterholiday visitors from Germany and Switzerlandare already lying in the warm springsun in the northern Flachgau near theGerman border, there are still up to twometres of snow on the mountain crests andpeaks, for instance at the 1,600-metre Gerlospass between Salzburg and Tyrol. “As late asmid-April this year, there were 40 centimetresof new snow in some of the moremountainous areas we are responsible for,”says Hans Gehmacher, who is the SalzburgState Government’s Deputy Road MaintenanceManager. It is his responsibility topurchase vehicles and equipment, includingthe newly four newly acquired UnimogU 400s and one U 500. The Second Presidentof Salzburg’s State Parliament , Johann Holztrattner,took delivery of the vehicles lastAugust with the words: “We decided topurchase the Unimog because it can be usedto carry a wide variety of equipment inwinter and summer, guarantees clean, snowfreeroads and is safe and convenient tooperate.”The 170-kW (230-hp) vehicles, all withpermanent four-wheel drive, Telligent gearshift, air-operated twin-circuit disc brakeswith ABS, hydraulic power steering and adual-circuit power hydraulic system, havebeen in use in Austria’s northernmostfederal state ever since. They are operated bythe road works departments in the Flachgau,Hallein and Bruck an der Glocknerstrasseand by the Salzburg ‘autobahn’ maintenanceauthority, which has also purchased anotherU 500 with 205-kW (280-hp) engine. HansGehmacher is responsible for up to 90 kilometresof ‘autobahn’ highway and some1,300 kilometres of federal and state roads.Altogether, 36 Unimog implement carriersare operated by the road authorities, and14 Unimog 1|2003

Power industrySt. Gallisch-AppenzellischeKraftwerke AG supply areaSAKSt. Gallentyred wheels (a Unimog with a tyre pressurecontrol system is still high up on the department’swish list), a loading crane, a radioremote controlled Werner cable winch and acrane support frame including a bridge tocarry a machine drill, the latter speciallydesigned and fitted by Swiss Unimogregional represenative LARAG AG in Wil(St. Gallen canton).Driver Engelbert Thoma, who has morethan 10 years of Unimog experience, isdelighted with his new “workmate”: “TheU 400 has a unique standard of drivingcomfort, which we naturally appreciate a lot,since more than 90 percent of our work isoff-road, and this is quite mountainous country.Working with this vehicle and its equipmentis a pleasure, thanks to its many technicalinnovations and advantages.” TheU 400 is primarily used by SAK for installingand erecting masts, but also for towing thecable drum trailer and transformers weighingup to 2.5 tonnes, and for transportingemergency power generators that can weighas much as 16 tonnes.Before tackling the task in hilly terrainthat this article describes, the wintry conditionscall for careful preparatory work by theSAK’s technicians. Hans Baumann, EngelbertThoma and Alois Herger together installthe twin-tyred wheels that are absolutelyessential due to the heavy load to be transportedand the low load-bearing capacity ofthe soil where they will have to work. Later,when the Unimog leaves made-up roadsbehind it, the importance of this measurebecomes clear. Even the U 400 strugglesslightly through these seemingly endlessmasses of snow, but in the end confirms whyit is considered unbeatable here in Toggenburgtoo. We reach the construction site atan altitude of about 1,000 metres above sealevel in freezing temperatures. The hourssimply fly by and evening approaches assnow is cleared from the construction site,the equipment is prepared for use and thehole for the mast is drilled. The three-manThe Swiss SAK’s supplyarea (right)Without “tirecontrol”,only twin tires help indeep snow (centrepicture)On the way to work at1,000 metres above sealevel. The SAK’s U 400with Werner cable winchand crane (below)GenevaZurichSwitzerlandSt. GallenSchweizAppenzellUznachUznachSargansDWM-Grafik©Unimog 1|2003 17

Power industryIn stark contrast to the beautiful, tranquil scenery:hard work for the SAK team and the equipment theyuse to maintain electric power supplies in the EasternSwiss Alpsteam is pleased with the results and returnsto the valley; once again, the U 400’sperformance has entirely satisfied theseexperienced technicians. But then: theyknew from the very start that they wouldn’tmake it without the Unimog!■Official snow ploughs for the World Skiing Championships400 athletes from 60 countries competedfor the title of World Champion in ten disciplinesin St. Moritz, the mecca of wintersport, from February 2 to 16, 2003. Altogether,fifteen Unimog implement carriersand three Actros four-wheel-drive truckscleared some 90 kilometres of roads; theinfrastructure had been specially built forthis event, often with extremely steep roadlinks to the championship sites. The vehiclespassed their first test early in the first weekof the championship, when approximately25 centimetres of snow fell in one night.More than 100,000 spectators,10,000 accredited persons such as officialsand sponsors’ representatives, 400 athletesand 2,000 journalists and radio and TV stafffrom all over the world were transportedfrom St. Moritz to Salastrains, the destinationat 2,000 metres above sea level. SwissPTT post buses were used exclusively forthis purpose.The 15 Unimog implement carriers weresupplied by the Unimog Division of RobertAebi AG (responsible for Unimog sales inSwitzerland), the St. Moritz municipalauthorities and the neighbouring communitiesof Pontresina, Celerina, Samedan andSilvaplana. The “World ChampionshipUnimogs” were equipped with snow ploughsand snow tillers by equipment-system partnerSchmidt Winterdienst und Kommunaltechnik,which is based in St. Blasien. The St.Moritz public works office operated a U 400with a plough/spreader combination, aU 140 with snow plough and ice scraper anda U 1000 to clear away snow. The Actros fourwheeldrive trucks (3340 AK 6x6 and 1838AK 4x4), also from the St. Moritz authoritiesand from DC Switzerland’s fleet, weremainly used for snow transport.In addition to permanent clearing andspreading of the access and other localroads, the car parks had to be kept clear ofsnow as well. Additional parking space for atotal of 2,500 vehicles was laid out for theWorld Championships in the entire areafrom Silvaplana to Samedan and in Pontresina.Spectators who travelled there by carwere able to use shuttle buses to get to thechampionship event sites.The snow clearing service experienced noproblems caused either by the topography orthe weather. This was confirmed bymembers of the organisational committeeand the local road maintenance authority. ■One of the “World Championship Unimogs” at work inSt. Moritz during this major skiing event18 Unimog 1|2003

AdvertisementsTechnology thatgrabs you!Loader attachmentType M 213Tel. +49 (0) 83 31/94 87-0 Fax -40 Industriestrasse 6 87734 Benningen Germany www.ematec.de

Fighting forest firesPaths to safetyThe mountains around Salamanca are high, steep and full of dry pine treesthat catch fire very easily. This is difficult terrain for fire-fighters, but noproblem for the <strong>Mercedes</strong>-<strong>Benz</strong> Unimog.The Unimog’s engine runs smoothly as thefour-wheel-drive vehicle moves down therough slope. “Whatever happens, this vehiclewill always do the job!” say the driverproudly, shifting down to the next lower gear.Like the legs of a large insect, the tyres creepacross the rocks, each block of their treadsfighting for grip with the thrust of 4,000litres of water to withstand. At one bend, aman with three days of beard stubble, wearinga helmet and neck protection, raises hishand to indicate that the vehicle is stabledespite the 20-degree slope on which it isstanding. His name is Joaquín Cascales andhe is the fire brigade commander. Hiscommands are short: “Vamos!”, “Let’s go!”,“Grab the hoses!”. The firemen open the rearflap and pull a 600-metre hose off the reel.“How far are you?”, a voice asks through thewalkie-talkie hanging from Joaquín Cascales’shoulders. “We’re in a good position,” heanswers. Everything is going according to20 Unimog 1|2003

A helmet and neck protection (small photograph onthe left) are essential for the firemen who work in theregion around the Spanish city of Salamanca,since the burning pinewood forests generateenormous heat (right)Fighting forest firesThe U 400 (bottom right) is an invaluable aid to thefirefighters as it can move them up into any terrainand also out of the flames safelyplan, and today’s target is to test how the U400 performs when a fire breaks out. JoaquínCascales deals with more than 100 fires ayear. “The most dangerous one was overthere in Los Arribes,” he says, gesticulatingsouthwards with his helmet. “Because of thestrong wind, the fire crept up on us fasterthan we could move with our heavy equipment,and then the wind suddenly changeddirection. I can tell you, it was then I discoveredhow fast I could run!” JoaquínCascales knows the risks: he is a forestryengineer who has been a forest fire expert forten years. A sound like a roaring waterfallcan be heard from the south, but it proves tocome from the flames that can be seen lickingup into the sky a few seconds later.Smoke fills the canyon and covers the sun.The engineer’s face is sweaty anddiscoloured with soot. “Get moving!” a voicedemands from the walkie-talkie. It belongs tosomeone from the second forest fire-brigadegroup, which is securing the other side of thecanyon with a second Unimog. A third groupis waiting at the summit. Joaquín Cascalesgrabs an object shaped like a watering canthat spits fire, lighting a counter-fire in thebushes so the flames cannot cross over thethe pine forest on the other side of the firebreakthat his men are creating down the hillwith chainsaws. Behind him, firemen withhuge rubber beaters are trying to suppressthe sparks that jump over the fire-break. TheUnimog follows Cascales downhill, occasionallystopping so that the smooth sound of its230-hp engine can be heard. The U 400 wasin frequent use last summer; sometimes fourfires had to be put out in one day. JoaquínCascales knows that the fires are oftenstarted by arsonists: “Some people try to gainadditional pasture land for their animals bydishonest means.” He thinks the Unimog isgreat: “It makes the work so much easier forour men. We used to have fire-fighting vehiclesfrom the Spanish Army, but they simplyweren’t able to tackle these steep hills.”Despite intensive service, the U 400’s yellowpaint still looks brand new. From the air, redvehicles are hard to distinguish from theflames, which is why pilots of fire-fightingaircraft sometimes give their colleagues onthe ground a shower instead of putting outthe flames. For this reason the vehicles arenow painted yellow. In addition to theUnimog implement carriers’ notable reliability,the most important features for the firemenon the ground, who are oftenconfronted with smouldering fires that growinto impenetrable fire walls within seconds,are their robust engines and legendary offroadcapabilities. “Every second counts,”says Joaquín Cascales, “and it’s good to knowthat the vehicles are reliable and will alwaysget you out safely.” He tells his men to beabsolutely cautious: “Don’t overestimateyourselves. Always leave the key in the ignitionswitch and park the Unimog so that thefront end is away from the fire so that youdon’t have to reverse it if you have to leavethe area in a hurry!” Jaime Vazquez, aged 33,wearing a pair of jeans and a leather jacket,strolls over from the mountain summit – asafe distance away. He is fleet manager at<strong>Mercedes</strong>-<strong>Benz</strong> Credit España (MBCE), aDaimlerChrysler Services subsidiary, andwants to see the U 400 in action after thestressful leasing negotiations. Metaphoricallyspeaking, he too went through fire forthe extinguishing vehicle’s financing andinsurance. The Castilla y León government’sinvitation to tender was a total challenge forhis company: insurance covering all risks, alimited budget for 30 vehicles including 20Unimogs. These were considered obstaclesnearly impossible to overcome in the trade,but not for Jaime Vazquez: “I knew we wouldmake it!” And this is why the firemen canfight their fires with the Unimog today. ■Unimog 1|2003 21

UNISCOPEThe Unimog museum in the Murg valleyOn November 5, 2002, some 150 Unimogenthusiasts founded the “Unimog-Museum e. V.” association with the purposeof establishing a Unimog museum at theentry to the Murg valley in front of RotenfelsCastle in Gaggenau, in Germany’s SouthBaden region. “We intend to give theUnimog’s successful history a permanentnew home at its former production site”,explains Hans-Jürgen Schöpfer, chairman ofthe new museum association. The associationis supported by a committee chaired byHans-Jürgen Wischhof, anavid supporter of the plan tobuild a museum. Variousmodels – the associationalready owns almost adozen exhibits, amongthem the last Unimog built in Gaggenau –add-on equipment and sectioned models ofthe principal Unimog working equipmentwill document the vehicle’s developmenthistory and its many applications all aroundthe world. DaimlerChrysler has alreadyagreed to supply the museum with interestingexhibits on loan. A shop with miniaturemodels, Unimog books and posters is alsoplanned. The initiators also consider itimportant to describe theindustrial history of theMurg valley and acknowledgelocal peoples’ work.Vehicles had after all beenbuilt in Gaggenau for morethan fifty years before Unimog productionstarted. The newly established associationalready has more than 500 members.You can obtain further information anddownload the application form atwww.unimog-museum.de.■The Unimog museum will probably look like this oneday. Construction is scheduled to start in 2004The 5,555th Unimog for SwitzerlandFrom left to right: Arthur Bühler, head of Meggendistrict council, Markus Imboden from supplierGebrüder Mengis and Markus Staubli from RobertAebi AG at the key handover ceremony for the 5,555thUnimogVarious Unimog models in front of Meggen fire station(below)This is a very unusual jubilee indeed. LastNovember, the 5,555th civil Unimog wasdelivered to Switzerland. It is a U 400 for usein Meggen, on the Vierwaldstättersee (LakeLucerne). This municipality. located in theheart of central Switzerland between thePilatus and Rigi mountains, began to operateUnimogs 20 years ago. In order to meetgrowing demands for road maintenanceeven more effectively, the town authoritiesdecided to purchase an implement carrierthat could handle the entire scope ofsummer and winter service work. Amongother items, the U 400 is equipped with aHiab goods handling crane and a three-waytipping body.■Tourist transportThe Plitvic lakes are located in Croatia’smost popular national park and are amongEurope’s most beautiful sights. Surroundedby dense forests, the 16 lakes are connectedby waterfalls. The organisers invite tourists totour the area in a U 400, which pulls twopassenger-carrying trailers. The total capacityof this unusual outfit enables 105 tourists toenjoy the beautiful scenery.22 Unimog 1|2003

UNISCOPEPowered by an upratedOM 906 LA engine, theU 500 entered by theItalian OverlookPromotion team drivesthrough a canyon in theSahara at full speedAfrica feverMany international rally specialists are infected with ‘Africa fever’every year, including seasoned professionals such as the highlysuccessful Italian Overlook Promotion team with thePanseri brothers and their colleagues Cambiaghi, Paccani, Vismaraand Sangalli, who invest tens of thousands of Euros in order to participatein the Pharoah Rally in Egypt and the legendary Paris-Dakarevent. Other participants are “true amateurs”, such as Unimog testdriver Klaus Bäuerle, for whom simply taking part is the most satisfyingaspect of the whole adventure. This year, he sacrificed a promisingposition in the Paris-Dakar event to help recover a broken-downMitsubishi after many hours of hard work. The Unimog first enjoyedthe limelight during the world’s toughest rally back in 1982, whenthe French team George Groine, Thierry de Saulieu and BernardMalfériol won in a U 1700 L and the Frenchmen Laleu/Langlois camein second in a U 1300. In 1985, the Italian team Capito/Capito wonthis event.■Klaus Bäuerle, Unimogtest driver and rallyenthusiast (at the rightin the left picture), tookpart in the 7,000-kilometre Paris – Dakarrally, both in the raceitself and as servicesupport for the PolishOrlen team. In theoverall evaluation, he“only” managed 16thplace, as the help heprovided cost him a lotof time. He was verymuch in demand as the“Good Samaritan withthe Unimog” and oftensaved the day in extremeemergenciesAnother aspect of theParis – Dakar rally:atmospheric pictures ofthe desert and savannaUnimog 1|2003 23