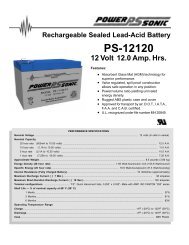

wind turbines“Small wind,” in our definition, starts with turbineswith rotors (turbine blades and hub) that are about 8 feet indiameter (50 square feet of swept area). These turbines maypeak at about 1,000 watts (1 kilowatt; KW), and generate about75 kilowatt-hours (KWH) per month with a 10 mph averagewind speed. <strong>Turbine</strong>s smaller than this may be appropriatefor sailboats, cabins, or other applications that require onlya small amount of electricity. But if you want a significantamount of energy, you need a rotor with significant sweptarea—it is, after all, the wind turbine’s “collector.”On the other end of the “small wind” scale, it’s reasonableto include turbines with rotors up to 56 feet in diameter(2,500 square feet of swept area). These turbines may peak atabout 90,000 watts (90 KW), and generate 3,000 to 5,000 KWHper month at a 10 mph average wind speed. <strong>Turbine</strong>s of this scaleare appropriate for very large homes, farms, small businesses,schools, or institutions that use a lot of electricity, or for heatingapplications, village power, and other major energy uses.In between 8 feet and 56 feet are various sizes of turbinesthat can accommodate a variety of energy appetites. It’scrucial that you have an accurate idea of what your energyusage is and the wind resource available at your site, so youcan match the turbine’s output to your energy needs.Sizing a wind-electric system is quite different thansizing a solar-electric (PV) system. With a PV system, spacepermitting, you can add capacity either as your needs grow,or as you can afford it. With a wind-electric system, this issimply not the case. A wind turbine is not incremental. Nordo people typically add more wind turbines and towers asmoney becomes available. Because wind is more cost effectiveas you increase in system size, most people put up only onewind turbine, with the intent of offsetting a large percentageof their electric bill or, in off-grid systems, meeting most orall of their electrical energy requirements.System ComponentsThe wind generator (or “turbine”) is only one componentin a wind-electric system, and very often is not even themost expensive component. You need all of the necessarycomponents to have a functional system. Plan ahead to buyquality components properly matched to each other and toyour energy use. A complete wind-electric system includes:• <strong>Turbine</strong>—generates electricity using the wind’s energy• Tower—supports the turbine, getting it up out of theturbulent zone created by trees and buildings, and exposesthe turbine to much more “fuel”• Wiring and conduit—carries the electricity down thetower and to power-conditioning equipment• Controller/Electronics—controls charging of battery orinput to inverter• Batteries—used for storage in off-grid systems or grid-tiedsystems with battery backup• Inverter—converts direct current (DC) electricity frombatteries or rectifier to alternating current (AC) for homeuse or “storage” on the utility grid• Metering—allows user to understand and manage systemoperationThe diameter of a wind turbine’s rotordefines its swept area, the most importantvariable in the final energy generated.In the wind turbine specifications on thefollowing pages, the blue circles representthe relative swept area of each turbine,drawn to scale.1 inch=10 feetThe world is full of small wind generators. Chinesemanufacturing numbers dwarf U.S. production, andEuropean companies make dozens of models as well.This article covers home-scale wind generators, eithermanufactured or imported, that are supported in NorthAmerica. The turbines profiled are readily available tobuyers in the United States and Canada. And service,parts, and support are also available, either directlythrough the manufacturers, or through dedicatedimporters.Other machines have been imported into North Americain limited numbers, by individual owners or companies.Some of these may end up having long-term supportfrom North American importers. Others may not. Wesuggest that you approach buying these machines withcaution. If you’re patient and willing to take a bit of risk,you may want to try one of these. You might end up witha real winner, or you may be stuck waiting for parts or aresponse from a distant manufacturer.Home-scale wind generators come and go. We do notknow enough about the quality of the equipment northe responsiveness of the manufacturers listed below tomake any firm recommendations. Our non-exhaustivelist of other turbines we know about in North Americaincludes:• Aircon—a German machine with a 23-foot-diameter rotor• Énergie PGE—from Canada, 36-foot-diameter rotor• Iskrawind—a UK machine with an 18-foot-diameter rotor• Tulipo—a Dutch machine with a 16-foot-diameter rotor• Various other machines, including Aeromax Lakota,Air-O-Power, Anhua, Exmok, E-Mark, Gryphon,Trillium, and CycloneOther machines are under development. It’s very hardto predict what will actually come to market, and howthey will perform. A few look promising to us. One isa new induction generator design from Earth <strong>Turbine</strong>s,a new company founded by David Blittersdorf of NRGSystems, which has long experience in wind monitoring.Another is the Endurance, developed by an engineeringteam in Utah, and also using an induction design. Applystandard cautions if considering these or any other newturbine—there’s nothing like a real-world track record!www.homepower.com35

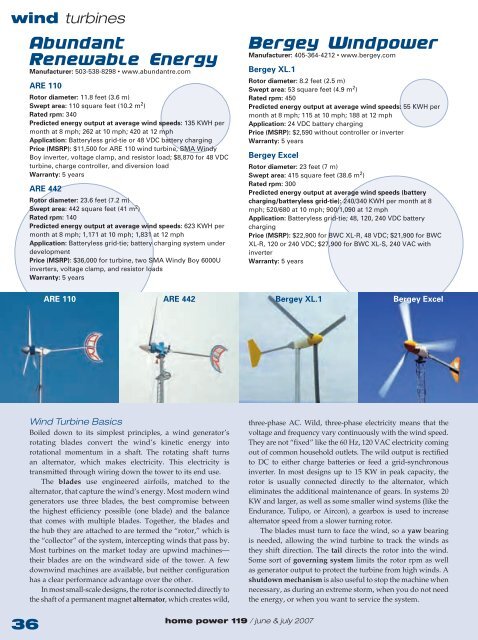

wind turbinesManufacturer: 405-364-4212 • www.bergey.comManufacturer: 503-538-8298 • www.abundantre.comARE 110Rotor diameter: 11.8 feet (3.6 m)Swept area: 110 square feet (10.2 m 2 )Rated rpm: 340Predicted energy output at average wind speeds: 135 KWH permonth at 8 mph; 262 at 10 mph; 420 at 12 mphApplication: Batteryless grid-tie or 48 VDC battery chargingPrice (MSRP): $11,500 for ARE 110 wind turbine, SMA <strong>Wind</strong>yBoy inverter, voltage clamp, and resistor load; $8,870 for 48 VDCturbine, charge controller, and diversion loadWarranty: 5 yearsARE 442Rotor diameter: 23.6 feet (7.2 m)Swept area: 442 square feet (41 m 2 )Rated rpm: 140Predicted energy output at average wind speeds: 623 KWH permonth at 8 mph; 1,171 at 10 mph; 1,831 at 12 mphApplication: Batteryless grid-tie; battery charging system underdevelopmentPrice (MSRP): $36,000 for turbine, two SMA <strong>Wind</strong>y Boy 6000Uinverters, voltage clamp, and resistor loadsWarranty: 5 yearsBergey XL.1Rotor diameter: 8.2 feet (2.5 m)Swept area: 53 square feet (4.9 m 2 )Rated rpm: 450Predicted energy output at average wind speeds: 55 KWH permonth at 8 mph; 115 at 10 mph; 188 at 12 mphApplication: 24 VDC battery chargingPrice (MSRP): $2,590 without controller or inverterWarranty: 5 yearsBergey ExcelRotor diameter: 23 feet (7 m)Swept area: 415 square feet (38.6 m 2 )Rated rpm: 300Predicted energy output at average wind speeds (batterycharging/batteryless grid-tie): 240/340 KWH per month at 8mph; 520/680 at 10 mph; 900/1,090 at 12 mphApplication: Batteryless grid-tie; 48, 120, 240 VDC batterychargingPrice (MSRP): $22,900 for BWC XL-R, 48 VDC; $21,900 for BWCXL-R, 120 or 240 VDC; $27,900 for BWC XL-S, 240 VAC withinverterWarranty: 5 yearsARE 110 ARE 442 Bergey XL.1 Bergey Excel<strong>Wind</strong> <strong>Turbine</strong> BasicsBoiled down to its simplest principles, a wind generator’srotating blades convert the wind’s kinetic energy intorotational momentum in a shaft. The rotating shaft turnsan alternator, which makes electricity. This electricity istransmitted through wiring down the tower to its end use.The blades use engineered airfoils, matched to thealternator, that capture the wind’s energy. Most modern windgenerators use three blades, the best compromise betweenthe highest efficiency possible (one blade) and the balancethat comes with multiple blades. Together, the blades andthe hub they are attached to are termed the “rotor,” which isthe “collector” of the system, intercepting winds that pass by.Most turbines on the market today are upwind machines—their blades are on the windward side of the tower. A fewdownwind machines are available, but neither configurationhas a clear performance advantage over the other.In most small-scale designs, the rotor is connected directly tothe shaft of a permanent magnet alternator, which creates wild,three-phase AC. Wild, three-phase electricity means that thevoltage and frequency vary continuously with the wind speed.They are not “fixed” like the 60 Hz, 120 VAC electricity comingout of common household outlets. The wild output is rectifiedto DC to either charge batteries or feed a grid-synchronousinverter. In most designs up to 15 KW in peak capacity, therotor is usually connected directly to the alternator, whicheliminates the additional maintenance of gears. In systems 20KW and larger, as well as some smaller wind systems (like theEndurance, Tulipo, or Aircon), a gearbox is used to increasealternator speed from a slower turning rotor.The blades must turn to face the wind, so a yaw bearingis needed, allowing the wind turbine to track the winds asthey shift direction. The tail directs the rotor into the wind.Some sort of governing system limits the rotor rpm as wellas generator output to protect the turbine from high winds. Ashutdown mechanism is also useful to stop the machine whennecessary, as during an extreme storm, when you do not needthe energy, or when you want to service the system.36home power 119 / june & july 2007