FLEX LNG brochure

FLEX LNG brochure

FLEX LNG brochure

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

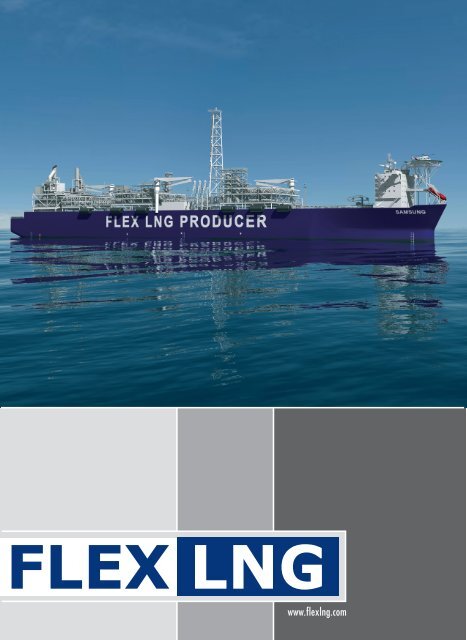

www.flexlng.com

Liquefaction Process• Optimized dual nitrogen expander cycle• Proven track record onshore and on <strong>LNG</strong> carriers with reliquefaction• Designed for a large range of feed gas compositions, from rich to lean• Operational simplicity, quick start up and shut down, low equipment count and easiercontrol• Improved safety by avoiding the use of hydrocarbon refrigerants• Single phase N 2refrigerant, not sensitive to vessel motions• High production availability achievable with low complexity• Overall efficiency equivalent to on-shore <strong>LNG</strong> plants achieved through processoptimisations and high efficiency equipment for power generation and compression incombination with waste heat recovery• Minimum space, weight and equipment required for the generic liquefaction, providingfor maximum space and weight reserve for field specific equipmentGeneric TopsideFieldspecificTopsideUnique Field Specific Adaptability• Upstream of the generic topside the feed gas is treated in the field specific modulesto separate bulk amounts of condensate and water. Other process systems as requiredis also located in the field specific modules, such as MEG reclamation, N 2rejection andbulk CO 2removal and reinjection• The generic topside receives feed gas with the equivalent of pipeline specification(

Hull and Marine SystemsDesign:Samsung Heavy IndustriesStorage (<strong>LNG</strong>):170,000 m 3 (4 x SPB Tanks)Storage (LPG/Condensate): 40,000 - 50,000 m 3<strong>LNG</strong> Cargo Pumps:8 x Submerged Cargo Pumps (1,250m 3 /h each)Main Dimensions:L x B x D = 336 x 50 x 31.6 mPropulsion:2 x Azimuth thrusters (4,500kW each) powered by DFDEClassification:DNVDesign Life:20 yrs permanently moored on siteHull form:Ship shaped, double sides/double bottom, large freeboardAccommodations:120/150 personsOffloading:SBS/Tandem OffloadingTopside Process FacilitiesDesign:<strong>LNG</strong> Production:Material Handling:Layout:Generic Modules:Field Specific Modules:Turret Mooring SystemDesign:Risers capacity:Buoy Locking:Mooring Systems:Samsung Heavy Industries / Kanfa Aragon1.7 - 2.0 MTPA3 x Knuckle Boom Cranes, 20MT @ 50 metersModularised topside design for high field specific adaptabilityFeed gas pre-treatment (Acid Gas Removal, Dehydration,Mercury Removal) and LiquefactionInlet Separation, Water Treating, Condensate Handling,LPG Handling, Bulk Acid Gas Removal and Reinjection,Nitrogen Rejection, MEG Reclamation, Chemical InjectionAdvanced Production and Loading (APL)Turret accommodates up to 6 risers and 6 umbilicalsEasy disconnect/reconnect turret featuresMooring system for harsh weather conditions and a wide range ofwater depths (from 20 m to 2500 m)<strong>FLEX</strong> <strong>LNG</strong> has its registred address at:Craigmuir ChambersP.O. Box 71Road Town, TortolaBritish Virgin IslandsRepresentative offices:LONDON<strong>FLEX</strong> <strong>LNG</strong> Management LtdLector Court, Ground Floor151-153 Farringdon RoadLondon, EC1R 3AFUKOSLO<strong>FLEX</strong> <strong>LNG</strong> Management Norway ASEyvind Lyches vei 19 APostboks 607NO-1303 SandvikaNORWAYFor general enquiries:london@flexlng.comFor general enquiries:oslo@flexlng.com