HOTDOG Datalogger for Temperature and Humidity

HOTDOG Datalogger for Temperature and Humidity

HOTDOG Datalogger for Temperature and Humidity

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

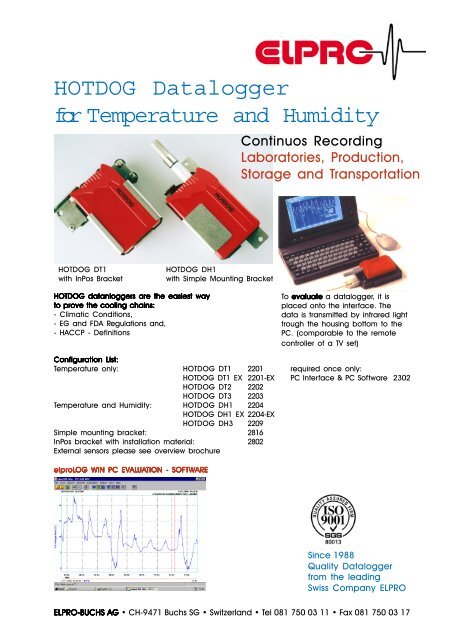

<strong>HOTDOG</strong> <strong>Datalogger</strong><strong>for</strong> <strong>Temperature</strong> <strong>and</strong> <strong>Humidity</strong>Continuos RecordingLaboratories, Production,Storage <strong>and</strong> Transportation<strong>HOTDOG</strong> DT1with InPos Bracket<strong>HOTDOG</strong> DH1with Simple Mounting Bracket<strong>HOTDOG</strong> datanloggers are the easiest wayto prove the cooling chains:- Climatic Conditions,- EG <strong>and</strong> FDA Regulations <strong>and</strong>,- HACCP - DefinitionsTo evaluate a datalogger, it isplaced onto the interface. Thedata is transmitted by infrared lighttrough the housing bottom to thePC. (comparable to the remotecontroller of a TV set)Configuration List:<strong>Temperature</strong> only: <strong>HOTDOG</strong> DT1 2201 required once only:<strong>HOTDOG</strong> DT1 EX 2201-EX PC Interface & PC Software 2302<strong>HOTDOG</strong> DT2 2202<strong>HOTDOG</strong> DT3 2203<strong>Temperature</strong> <strong>and</strong> <strong>Humidity</strong>: <strong>HOTDOG</strong> DH1 2204<strong>HOTDOG</strong> DH1 EX 2204-EX<strong>HOTDOG</strong> DH3 2209Simple mounting bracket: 2816InPos bracket with installation material: 2802External sensors please see overview brochureelproLOG WIN PC EVALALUAUATION - SOFTWARESince 1988Quality <strong>Datalogger</strong>from the leadingSwiss Company ELPROELPRO-BUCHS AG • CH-9471 Buchs SG • Switzerl<strong>and</strong> • Tel 081 750 03 11 • Fax 081 750 03 17

<strong>HOTDOG</strong> DT 1, DT2, DT3The <strong>HOTDOG</strong> DT1...3 is designed <strong>for</strong> continuous recording of temperature with NTC - probes.The measured values are stored in the Hotdog's internal memory <strong>and</strong> can be recalled at any time, printedout or illustrated in a <strong>for</strong>m of a graph.The data can be read by a PC through the external interface.Technical Data:Time range:2,2 / 4,4 hours to 500 daysMeasuring clock: 2 sec to 2 hoursNumber of stored values: 16’000DT1:-40°C ... +70°CDT2: Channel 2: (ext.) -40°C ... 140°CChannel 1: (int.) -40°C ... 70°CDT3: 2 Channel (ext.) -40°C ... 140°CAccuracy:see diagrammResolution:0.1°C (-20°C .. +70°C)0.25°C (-40°C .. +140°C)Temp.coefficient:(Housing)INPOS:< 1°C (-40°C ... 60°C)shows the time of themodule plugged into thefitting (Art.Nr.2802)Operational temperature: -40...+70°C (measure)0...+50°C (read out)Housing:Weigth:Connector:Battery life:Electrical interference:Magnetic interference:Ex protection:SAN, weld170gIP65up to 5 years, dependingof working, Batteriechangable by after-salesserviceTest with 10kVmodule is switched on<strong>for</strong> transfer by amagnetic field.on requestAccuracy of NTC <strong>Temperature</strong> Sensors±°CDT32 ext. SensorsDT21x external Sensor1x internal Sensor25mmPosition of theinternal SensorSensorConnector67mm<strong>HOTDOG</strong>DT11 internal Sensor114mmConnector: LEMO plug 2 Pin m,Type: FGG-0B-302Elpro-Part. No. 3202

<strong>HOTDOG</strong> DH1, DH3The <strong>HOTDOG</strong> DH1, DH3 is designed <strong>for</strong> continuous recording of temperature <strong>and</strong> air humidity. Thesensors are installed in the front part of the trunk <strong>and</strong> protected by a filter. The measured values are storedin the Hotdog's internal memory <strong>and</strong> can be recalled at any time, printed out or illustrated in a <strong>for</strong>m of agraph. The data can be read by a PC through the external interfaceTechnical Data:Time range:2,2 hours to 500 daysMeasuring clock: 2 sec to 2 hoursNumber of stored values: 16’000<strong>Humidity</strong>: 0 ... 100%Resulution: +/- 1%Temp.coefficient(Housing): < 2% (0°C ... 60°C)meas. methode: capazitiv<strong>Temperature</strong>:-40°C ... +70°CResulution: 0.2°C (-10 .. +40°C)0.3°C (-40 .. +70°C)Accuracy: 0.1°C (-10 .. +50°C)0.2°C (-40 .. 70°C)INPOS:shows the time of themodule plugged into thefitting (Art.Nr.2802)Operational temperature: -40...+70°C (measure)0...+50°C (read out)Housing:Weigth:Messsonde:Battery life:Electrical interference:Magnetic interference:Ex protection:SAN, weld190gIP65up to 5 years, dependingof working, Batteriechangable by after-salesserviceTest with 10kVmodule is switched on<strong>for</strong> transfer by amagnetic field.on requestPosition of the fitting:important with high humidity (> 80%)In case of high temperature fluctuations <strong>and</strong>high humidity, condensation water may <strong>for</strong>m,which will dry faster if the module is installed inthe correct position. Never install the moduledirectly above a source of humidity (humidity>100 % possible due to condensation).123451234525mm123451234512345<strong>HOTDOG</strong>1234512345*)67mm112mm<strong>Humidity</strong> <strong>and</strong> temperature sensorwith dust protection filter*) DH3 with second, externaltemperature sensor171mmCalibration Accessories:Calibration device Art.Nr. 29025 pieces 0% Art.Nr. 29075 pieces 35% Art.Nr. 29045 pieces 80% Art.Nr. 29055 pieces 95% Art.Nr. 2906

<strong>Humidity</strong> - CalibrationModules <strong>for</strong> measuring relative air humidityOur humidity data loggers are supplied with a precisely calibrated humidity sensor. It is recommended thathumidity sensors used in normal environments are checked every 6 - 12 months <strong>and</strong> recalibrated ifnecessary. In particularly contaminating environments, it may be necessary to clean the sensor verycarefully using water or a max. 40% alcohol solution.Method of humidity verification:Using our SCS calibrated calibration solutions <strong>for</strong>the operating points with relative humidity valuesof 0%, 10 %, 20%, 35%. 50%, 65%, 80% <strong>and</strong>90%.Verification is more important than calibration!Making use of the calibration solutions, it ispossible to simulate a variety of humidity levels atthe sensors. The module should then beevaluated <strong>and</strong> the results checked. There is noreal point in carrying out recalibration unless adeviation of more than ±2% is determined.RecalibrationThe PC software provides support <strong>for</strong> automaticrecalibration of the modules. The followingequipment <strong>and</strong> materials are required:- a calibration unit- calibration solutions <strong>for</strong> 0% .. 95%- a calibration box or thermally insulated box- evaluation software elproLOG WIN- a PC interface (only <strong>for</strong> Hamster <strong>and</strong><strong>HOTDOG</strong>)Recalibration of the modules is carried out byselecting “Extended Setup” from the programmenu. For most applications, calibration with the80% solution will be suitable. After the procedureis started, an automatic program runs in themodule <strong>for</strong> a period of 3 hours, after whichcalibration is complete. The logger status shows,if the calibration has been successful or not.sensor part of the module. The sealing ring can thenbe pulled on.The actual calibration process begins automaticallyafter 2.5 hours. It is necessary to keep the ambienttemperature constant during calibration. The module,with calibration unit fitted, must there<strong>for</strong>e be kept inan insulated box <strong>for</strong> a period of at least 3 hours afterthe start of the process. It can be evaluated at theend of this time. The module’s temperature <strong>and</strong> timeranges can, if necessary, be reprogrammed be<strong>for</strong>e itis put back into use.Clean well <strong>and</strong> dry in acurrent of airSelect a short timeinterval.Start “calibration”only if you wish torecalibrate.Empty calibration solution overfabric discClose the unit, push onto sensor<strong>and</strong> pull on sealing ringLeave in insulated containerthen evaluateIMPORTANT:The calibration unit must be absolutely clean <strong>and</strong>dry be<strong>for</strong>e it is used. The unit should, there<strong>for</strong>e,be disassembled, washed <strong>and</strong> then driedthoroughly in a current of air. The fabric discsupplied (except <strong>for</strong> 0%) is then inserted in thebaseplate of the unit. The ampoule containing thecalibration solution is broken open <strong>and</strong> the liquidpoured over the fabric disc. The unit, with thebaseplate underneath, is then pushed onto theIMPORTANT:<strong>Humidity</strong> probe <strong>and</strong> module are <strong>for</strong>ming a pair.Calibration values must be entered be<strong>for</strong>e the first use.D-DZ-6001E9.1999