GEothErmal DIStrICt hEatING - EGEC

GEothErmal DIStrICt hEatING - EGEC

GEothErmal DIStrICt hEatING - EGEC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

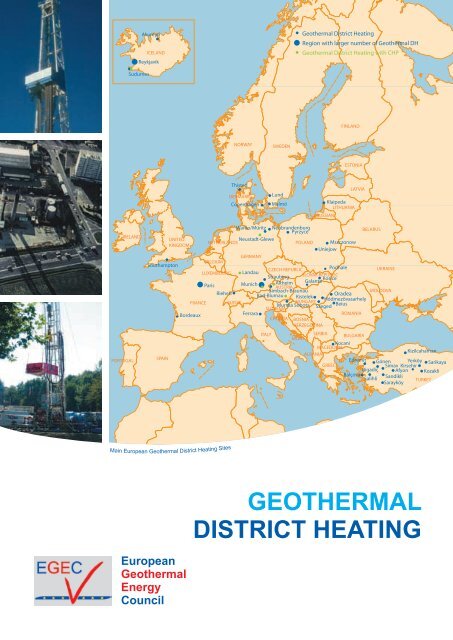

Akureyri Geothermal District HeatingICELANDReykjavikSudurnesRegion with larger number of Geothermal DHGeothermal District Heating with CHPFINLANDNORWAYSWEDENESTONIAThistedDENMARKLundCopenhagen Malmö KlaipedaRUSSIANLITHUANIALATVIAIRELANDPORTUGALSouthamptonSPAINUNITEDKINGDOMFRANCEBordeauxNETHERLANDSBELGIUMLUXEMBOURGParisRiehenSUISSEWaren/Müritz NeubrandenburgPyrzyceNeustadt-GleweGERMANYMszczonowUniejowPodhaleLandauStraubingMunich Altheim Galanta KosiceSimbach-BraunauBad-Blumau KistelekHódmezövasarhelyMurska Sobota SzegedBeiusFerraraCZECH REPUBLICSLOVAK REPUBLICSLOVENIAITALYAUSTRIACROATIAPOLANDHUNGARYBOSNIAHERZEGOVINAMONT.SERBIAOradeaKocaniMACEDONIAALBANIAGREECEROMANIABULGARIABELARUSUKRAINEMOLDOVAKizilcahamanEdremit Gönen Yerköy SarikayaSimav KirsehirBigadiç Afyon KozakliBalçovaSalihliSandikliSarayköyTURKEYMain European Geothermal District Heating SitesEuropeanGeothermalEnergyCouncilGeothermalDISTRICT HEATING

Reykjavik todaygeothermaldistrict heatingLocation of ParisBasin geothermaldistrict heatingdoubletsChaudes-Aigues, PARspring(exploited since1330 AD)BackgroundDistrict heating – DH – is a system which distributesheat from a centralised generationplant to end (residential, tertiary, commercial,recreational facilities…) users, connected via a heatinggrid and substations. DH has replaced, in mostinstances, traditional central heating systems whereeach building is heated by an individual boiler.Clearly, DH achieves higher energy, economic andenvironmental performance. Heat supply is bestadjusted to users demand. Individual building boilersare replaced by a heat exchanger three wayvalve piping outfit, fuel supplies and operation/maintenanceare optimised, all factors resulting in significantcost savings. Last but not least, it reducesgreenhouse gas emissions and excess heat losses,thus securing upgraded environmental control.As of early 2000’s European DH market penetrationstands as follows (percentage of district heatedhouses) : Iceland: 96%; Baltic States / Poland/ Sweden / Denmark / Finland: 50-60%; Austria /Germany: 12-15%; UK/Netherlands: 1-4%.This record reflects (i) the fact that Iceland enjoysabundant geothermal resources added to a consistentenergy policy of the state in favour of energysavings and renewable energy sources (RES), thelatter adopted by Scandinavian, Baltic and Polishstates, and (ii) an almost negligible DH share in theUK and Netherlands, most likely attributed to an adversenatural gas lobby competition and, at a lesserextent, to milder climatic conditions.Despite its “modernity” DH is nothing new. As amatter of fact, it dates back to Roman ages as witnessedby remnants evidencing city homes andbaths heated via natural hot water catchments andpiping. At Chaudes Aigues, in Central France, a cityDH system, pioneered in year 1330, fed by the Parhot spring at 82°C, is still operating to date. Heatedhomes were charged, in those times, a tax by thelocal landlord in exchange of maintenance duties,as reported in the city annals.Noteworthy is that these early DH systems could becompleted thanks to local hot springs and shallowwells, i.e. (sub)surface evidence of geothermal heatconveyed by water.So, everything considered, engineering of geothermaldistrict heating – GDH – ambitions nothing more thanrevisiting DH sources. However, no way does this “revival”imply a geothermal archaeological itinerary, buta thorough technological accomplishment instead.StatusGDH represents 35% of the European installedpower dedicated to direct uses, i.e.an online capacity nearing 5,000 MWt.Major GDH sites (over 35 exceeding 5 MWt capacity)highlight the dominant role played by Icelandand Turkey, two countries enjoying favourable,volcanically and tectonically active, geodynamicsettings on the Mid Atlantic Ridge and the Aegeanfaçade/Anatolian plateau respectively, demonstratingalso relevant entrepreneurial skills. The twolargest schemes address the heating of the city ofReykjavik and of the Paris suburban area.GDH provides almost the whole of the Reykjavikdemand with an installed capacity of 830 MWtserving 180,000 people, 60 million m 3 /yr of waterat an average 75°C (user inlet) temperature. Thecity grid elsewhere exhibits several distinctive featurescompared to most of its European replica. Animportant part of the hot water supply is piped fromdistant wells and there is no injection whatsoever ofthe heat depleted water (ca 35°C) underground.The Paris Basin GDH system is based on a dependablesedimentary resource environment andon the doublet concept of heat extraction. Here,hot waters at an average 70°C temperature arehosted in permeable carbonate rocks (the Doggerlimestone reservoir) at depths of 1500 to 1800 m.The geothermal fluid, a hot saline brine includinga solution gas phase, is pumped to surface froma production well and the heat depleted brinepumped back into the source reservoir via an injectionwell; the doublet well spacing is designed inorder to avoid premature cooling of the productionwell.

The thirty-four geothermal doublets (and as manyheating grids), operating since the early 1980’s inthe Paris area, totalise installed power and generatingcapacities of 230 MWt and 1,000 GWht/yrrespectively and serve over 100,000 equivalentdwellings, each 70 m 2 in area. They achieve thesavings of 500,000 tons of CO 2emissions.Oradea, in Western Romania, is an example ofthe insertion of a geothermal heating system intothe existing city, coal fired/back pressure, combinedheat and power (CHP) network, typical ofprevious Central/Eastern Europe district heatingpractice. Eleven geothermal wells (2500-3450 m;72-106 °C), among which two doublet arrays, areserviced for heat and sanitary hot water – SHW– supply amounting to ca 100,000 MWht/yr, via theCHP grid substations.Technology outlookWorth recalling is that a GDH system hasto comply with variable heat loads andexisting building designs and heatingmodes. These conditions become acute for lowoutdoor temperatures (peak loads) and conventional,temperature demanding, heaters (such ascast iron radiators). Therefore base load supplyand retrofitting are the rule.With the exception of Iceland, another prerequisiteprevails respective to the geothermal resource toheat load adequacy. Both resource and demandneed to be geographically matched.The two major components of a typical GDH gridare the geothermal loop and heating grid mains,interfaced by the geothermal heat exchanger.Modern doublet designs (in known areas) includetwo wells drilled in deviation from a single drillingpad. Bottomhole spacings are designed to securea minimum twenty year span before cooling of theproduction well occurs.Well depths (deviated) of 2000 to 3500 m are notuncommon; often located in sensitive, denselypopulated urban environments, they require heavyduty, silent rigs (up to 350 tons hook loads, dieselelectric drive).Similar environmental constraints apply to periodicalwell maintenance (workover) operations which occasionallytake place in landscaped sites. Fiberglas linedproduction/injection wells, first completed in 1995, area material solution to steel casing corrosion. Continuousdownhole chemical inhibition lines are anotheralternative to defeat corrosion/scaling shortcomingsin hostile thermochemical environments.Geothermal fluid production is usually sustainedby artificial lift, i.e. submersible, variable speeddrive, pump sets of either the electric or (enclosed)lineshaft type. Whenever self flowing productionmay be substituted, low well head pressures andsubsequent escape of solution gases require theinstallation of a degassing/abatement unit. To combatcorrosion damage and ease periodical cleaning,geothermal heat exchangers need to conformto titanium plate design and manufacturing.Heat pumpsBack up heat, below outdoor transition temperature(5 to 10 °C), can be supplied partlyby heat pumps and totally by boilers.Heat pumps of the water/water type may upgradegeothermal heat recovery, from heat exchangealone, by depleting rejection temperatures andboosting grid distribution temperatures downstreamfrom the geothermal heat exchanger. Accordingly,various heat pump configurations maybe contemplated and heat pump units combinedin either serial, parallel or hybrid modes. In severalinstances (Denmark, Germany, Iceland) absorptionheat pumps, often associated with geothermalCombined Heat & Power plants (CHP), have beensuccessfully implemented.District coolingGeothermal district cooling is actually poorlydeveloped in Europe, hardly 30 MWt installedcold power. This development issuewhich could provide additional summer loadsto GDH systems should therefore be challengedby geothermal operators (and users).Cooling based on absorption chillers (heat pumps),using water as a refrigerant and lithium bromideGDHconceptualdesignNeustadt-GleweCHP Schematic

(or ammoniac) as an absorbent seems anappropriate answer, provided minimum geothermaltemperatures stand above 70 °C. Therefrigerant, liberated by heat from the solutionproduces a refrigerant effect in the evaporatorwhen cooling water is circulated through thecondenser and absorber.In the Paris Basin, for instance, absorptionchillers can be placed in grid substations andthe primary hot fluid supplied by the geothermalheat plant. The chilled water can be pipedto consumers via the same flow circuit used forheating and the same heaters although, in thisrespect, alternative devices (fan coils, ceilingcoolers) would be preferable. Note that eachabsorption chiller unit needs to be equippedwith a cooling tower.SustainabilityGiven economic (project life), reservoirlongevity (cooling breakthrough time)and well physical lifetimes of say thirtyyears, the question often arises as whetherthere is a life after these critical thresholdsand, if so, for how long. These issues havebeen thoroughly investigated, in particular inthe Paris Basin, where GDH lives extendingover 75 to 100 years, i.e. far beyond project lifeexpectations, could be assessed provided theproduction/injection wells be periodically (every25-30 years) (re)completed and drilled atadequate reservoir locations, according to corrosionresistant designs. Hence, the projectedscenarios meet sustainability requirements.CostsGeothermal undertakings at large, andGDH in particular, are capital intensiveowing to the high infrastructure (mining– geothermal wells – and surface – piping)investments required. Those are, on the otherhand, compensated by the low running – operation/maintenance– costs. Depending onlocal geothermal settings (high/low heat flows,shallow/deep seated sources), socio-economicconditions and pricing policies (kWht or m 3of hot water) the average MWht selling priceto GDH subscribers varies between 30 and60 €/MWht.Environmental impactClose to zero atmospheric emissions ofgreen house gases. Among the indirectnon quantified benefits, known asexternalities, of GDH ought to be mentionedthe contribution to significant reduction of environmentallyprovoked diseases (asthmaamong others).Contact:<strong>EGEC</strong>European Geothermal Energy Council a.s.b.l.Renewable energy HouseSupported by63-65 rue d’ArlonB-1040 BrusselsT : + 322 400 10 24F : + 322 400 10 10W : www.egec.orgE : info@egec.orgThe sole responsibility for the content of this publication lies with the authors. It does not necessarily reflect the opinion of the European Communities.The European Commission is not responsible for any use that may be made of the information contained therein.Photo and graphical elements credits : <strong>EGEC</strong>, GPC IP, GTN, City of Altheim, City of Chaudes-Aigue, Geothermal Education Office/Reykjavik,BRGM/ADEME, SEDCO-FOREX. Published in September 2007 - Text : Pierre Ungemach -Design: ACG Brussels. Printed on ecologically friendly paper (chlorine-free paper)