Fine Filter Brochure - Cjc.dk

Fine Filter Brochure - Cjc.dk

Fine Filter Brochure - Cjc.dk

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

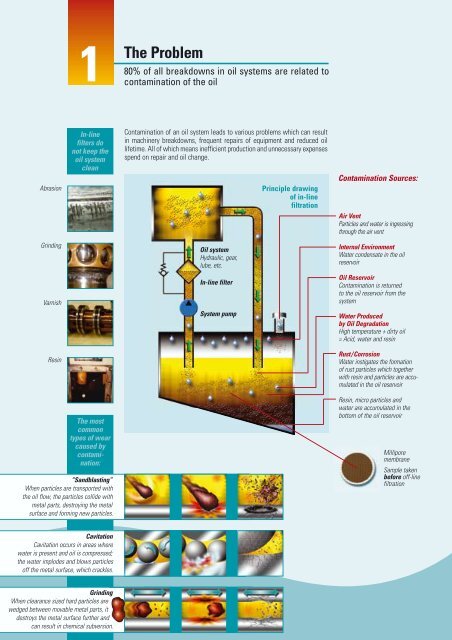

1The Problem80% of all breakdowns in oil systems are related tocontamination of the oilAbrasionIn-linefilters donot keep theoil systemcleanContamination of an oil system leads to various problems which can resultin machinery breakdowns, frequent repairs of equipment and reduced oillifetime. All of which means inefficient production and unnecessary expensesspend on repair and oil change.Principle drawingof in-linefiltrationContamination Sources:Air VentParticles and water is ingressingthrough the air ventGrindingOil systemHydraulic, gear,lube, etc.Internal EnvironmentWater condensate in the oilreservoirVarnishIn-line filterOil ReservoirContamination is returnedto the oil reservoir from thesystemSystem pumpWater Producedby Oil DegradationHigh temperature + dirty oil= Acid, water and resinResinRust/CorrosionWater instigates the formationof rust particles which togetherwith resin and particles are accumulatedin the oil reservoirThe mostcommontypes of wearcaused bycontamination:“Sandblasting”When particles are transported withthe oil flow, the particles collide withmetal parts, destroying the metalsurface and forming new particles.Resin, micro particles andwater are accumulated in thebottom of the oil reservoirMilliporemembraneSample takenbefore off-linefiltrationCavitationCavitation occurs in areas wherewater is present and oil is compressed;the water implodes and blows particlesoff the metal surface, which crackles.GrindingWhen clearance sized hard particles arewedged between movable metal parts, itdestroys the metal surface further andcan result in chemical subversion.