Process Control Technology Flow Module PCT-M1

Process Control Technology Flow Module PCT-M1

Process Control Technology Flow Module PCT-M1

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

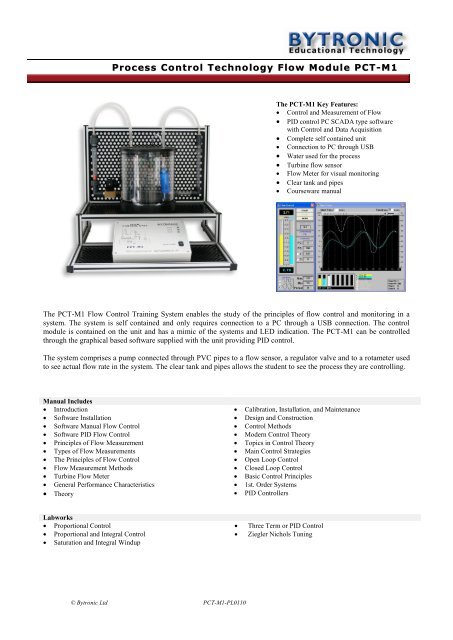

<strong>Process</strong> <strong>Control</strong> <strong>Technology</strong> <strong>Flow</strong> <strong>Module</strong> <strong>PCT</strong>-<strong>M1</strong>The <strong>PCT</strong>-<strong>M1</strong> Key Features: <strong>Control</strong> and Measurement of <strong>Flow</strong> PID control PC SCADA type softwarewith <strong>Control</strong> and Data Acquisition Complete self contained unit Connection to PC through USB Water used for the process Turbine flow sensor <strong>Flow</strong> Meter for visual monitoring Clear tank and pipes Courseware manualThe <strong>PCT</strong>-<strong>M1</strong> <strong>Flow</strong> <strong>Control</strong> Training System enables the study of the principles of flow control and monitoring in asystem. The system is self contained and only requires connection to a PC through a USB connection. The controlmodule is contained on the unit and has a mimic of the systems and LED indication. The <strong>PCT</strong>-<strong>M1</strong> can be controlledthrough the graphical based software supplied with the unit providing PID control.The system comprises a pump connected through PVC pipes to a flow sensor, a regulator valve and to a rotameter usedto see actual flow rate in the system. The clear tank and pipes allows the student to see the process they are controlling.Manual Includes Introduction Software Installation Software Manual <strong>Flow</strong> <strong>Control</strong> Software PID <strong>Flow</strong> <strong>Control</strong> Principles of <strong>Flow</strong> Measurement Types of <strong>Flow</strong> Measurements The Principles of <strong>Flow</strong> <strong>Control</strong> <strong>Flow</strong> Measurement Methods Turbine <strong>Flow</strong> Meter General Performance Characteristics TheoryCalibration, Installation, and MaintenanceDesign and Construction<strong>Control</strong> MethodsModern <strong>Control</strong> TheoryTopics in <strong>Control</strong> TheoryMain <strong>Control</strong> StrategiesOpen Loop <strong>Control</strong>Closed Loop <strong>Control</strong>Basic <strong>Control</strong> Principles1st. Order SystemsPID <strong>Control</strong>lersLabworks Proportional <strong>Control</strong> Proportional and Integral <strong>Control</strong> Saturation and Integral WindupThree Term or PID <strong>Control</strong>Ziegler Nichols Tuning© Bytronic Ltd <strong>PCT</strong>-<strong>M1</strong>-PL0110

<strong>Process</strong> <strong>Module</strong>Reservoir TankPipesPump Type<strong>Flow</strong> RateDelivery height<strong>Flow</strong> Sensor TypeOperating pressureBurst pressureOperating temperatureInput powerAccuracyRepeatability<strong>Flow</strong> range<strong>Flow</strong> MeterMaximum Fluid Pressure at 20 o CMaximum Fluid TemperatureAccuracyScaling<strong>Control</strong> elementDrain Valve<strong>Control</strong> ConsoleFront of ConsoleConnectionsNumber of LEDNumber of SwitchesPower Supply voltageClear , Approximately 3 Litre CapacityClear 16mm PVC12v Submersible Pump8 Litres per MinuteMax 7 metre at (0.7 bar)Run dry up to 2 hours without damageTurbine <strong>Flow</strong> Rate Sensor14 bar maximum170 bar-20°C to 100°C (ambient +80°C for cable)5 to 24 VDC @ 8mA±3% of reading0.5% of full scaleLitres per Minute 0.5-5In Line Variable <strong>Flow</strong> meter PVC10 bar60 o C+2.5% full scaleLitre per Hour plus 0 to 100%1 x Proportional control valve 24v d.c.1 x Finger type valve fitted to rear of unitGraphical representation of process module1 x Power connector1 x USB connection3 x Power On, Pump On, Valve Open1 x Power Switch100-250V AC @ 50/60Hz.SoftwareWindows based graphical software with SCADA type interface with control and data logging.Un-PackedApproximate Dimensions (mm)Approximate Weights500W x 550D x 420H9KgWeights and DimensionsPackedApproximate Dimensions (mm)Approximate Weights580W x 630D x 560H15KgRequired:A PC with Minimum; Pentium processor, 1GB RAM, 20GB HDD, CDROM Drive, USB 2 interface and Windows XP or above.Model Number:Consists of:Ordering Information<strong>PCT</strong>-<strong>M1</strong>1 x <strong>Flow</strong> <strong>Control</strong> <strong>Process</strong> <strong>Module</strong> with <strong>Control</strong>ler1 x 24v d.c. Power Supply1 x USB connector cable1 x User and courseware Manual1 x CD with Windows Based SCADA type SoftwareBytronic Limited124 Anglesey Court, Towers Business Park,Rugeley, Staffordshire, WS15 1UL.United KingdomTel; +44(0)8456 123 155 Fax; +44(0)8456 123 156Email: sales@bytronic.net Website: www.bytronic.net© Bytronic Ltd <strong>PCT</strong>-<strong>M1</strong>-PL0110