atc/filer/DNV Standard 2-7-3 May 2011.pdf

atc/filer/DNV Standard 2-7-3 May 2011.pdf

atc/filer/DNV Standard 2-7-3 May 2011.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

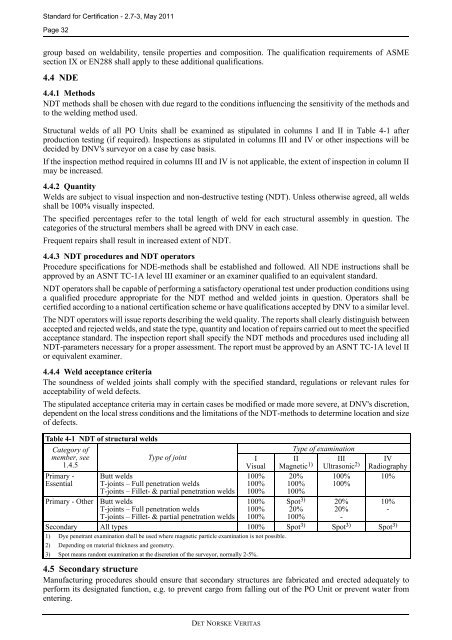

<strong>Standard</strong> for Certification - 2.7-3, <strong>May</strong> 2011Page 32group based on weldability, tensile properties and composition. The qualification requirements of ASMEsection IX or EN288 shall apply to these additional qualifications.4.4 NDE4.4.1 MethodsNDT methods shall be chosen with due regard to the conditions influencing the sensitivity of the methods andto the welding method used.Structural welds of all PO Units shall be examined as stipulated in columns I and II in Table 4-1 afterproduction testing (if required). Inspections as stipulated in columns III and IV or other inspections will bedecided by <strong>DNV</strong>'s surveyor on a case by case basis.If the inspection method required in columns III and IV is not applicable, the extent of inspection in column IImay be increased.4.4.2 QuantityWelds are subject to visual inspection and non-destructive testing (NDT). Unless otherwise agreed, all weldsshall be 100% visually inspected.The specified percentages refer to the total length of weld for each structural assembly in question. Thecategories of the structural members shall be agreed with <strong>DNV</strong> in each case.Frequent repairs shall result in increased extent of NDT.4.4.3 NDT procedures and NDT operatorsProcedure specifications for NDE-methods shall be established and followed. All NDE instructions shall beapproved by an ASNT TC-1A level III examiner or an examiner qualified to an equivalent standard.NDT operators shall be capable of performing a satisfactory operational test under production conditions usinga qualified procedure appropriate for the NDT method and welded joints in question. Operators shall becertified according to a national certification scheme or have qualifications accepted by <strong>DNV</strong> to a similar level.The NDT operators will issue reports describing the weld quality. The reports shall clearly distinguish betweenaccepted and rejected welds, and state the type, quantity and location of repairs carried out to meet the specifiedacceptance standard. The inspection report shall specify the NDT methods and procedures used including allNDT-parameters necessary for a proper assessment. The report must be approved by an ASNT TC-1A level IIor equivalent examiner.4.4.4 Weld acceptance criteriaThe soundness of welded joints shall comply with the specified standard, regulations or relevant rules foracceptability of weld defects.The stipulated acceptance criteria may in certain cases be modified or made more severe, at <strong>DNV</strong>'s discretion,dependent on the local stress conditions and the limitations of the NDT-methods to determine location and sizeof defects.Table 4-1 NDT of structural weldsCategory ofmember, seeType of joint1.4.5Type of examinationIVisualIIMagnetic 1) IIIUltrasonic 2)Primary - Butt welds100% 20% 100%Essential T-joints – Full penetration welds100% 100% 100%T-joints – Fillet- & partial penetration welds 100% 100%Primary - Other Butt welds100% Spot 3) 20% 10%T-joints – Full penetration welds100% 20% 20%-T-joints – Fillet- & partial penetration welds 100% 100% -Secondary All types 100% Spot 3) Spot 3) Spot 3)1) Dye penetrant examination shall be used where magnetic particle examination is not possible.2) Depending on material thickness and geometry.3) Spot means random examination at the discretion of the surveyor, normally 2-5%.IVRadiography10%4.5 Secondary structureManufacturing procedures should ensure that secondary structures are fabricated and erected adequately toperform its designated function, e.g. to prevent cargo from falling out of the PO Unit or prevent water fromentering.DET NORSKE VERITAS