atc/filer/DNV Standard 2-7-3 May 2011.pdf

atc/filer/DNV Standard 2-7-3 May 2011.pdf

atc/filer/DNV Standard 2-7-3 May 2011.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

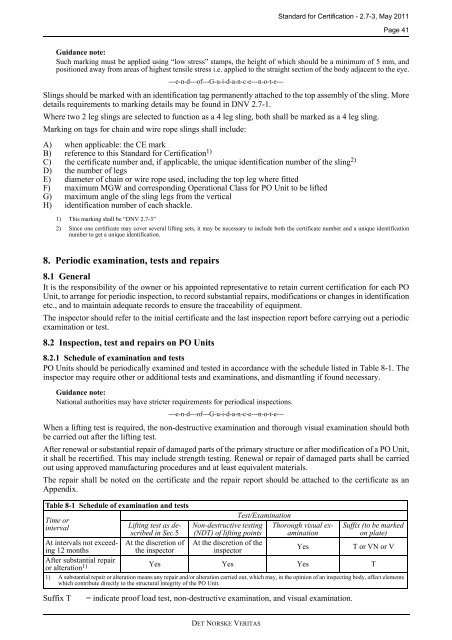

<strong>Standard</strong> for Certification - 2.7-3, <strong>May</strong> 2011Page 41Guidance note:Such marking must be applied using “low stress” stamps, the height of which should be a minimum of 5 mm, andpositioned away from areas of highest tensile stress i.e. applied to the straight section of the body adjacent to the eye.---e-n-d---of---G-u-i-d-a-n-c-e---n-o-t-e---Slings should be marked with an identification tag permanently attached to the top assembly of the sling. Moredetails requirements to marking details may be found in <strong>DNV</strong> 2.7-1.Where two 2 leg slings are selected to function as a 4 leg sling, both shall be marked as a 4 leg sling.Marking on tags for chain and wire rope slings shall include:A) when applicable: the CE markB) reference to this <strong>Standard</strong> for Certification 1)C) the certificate number and, if applicable, the unique identification number of the sling 2)D) the number of legsE) diameter of chain or wire rope used, including the top leg where fittedF) maximum MGW and corresponding Operational Class for PO Unit to be liftedG) maximum angle of the sling legs from the verticalH) identification number of each shackle.1) This marking shall be “<strong>DNV</strong> 2.7-3”2) Since one certificate may cover several lifting sets, it may be necessary to include both the certificate number and a unique identificationnumber to get a unique identification.8. Periodic examination, tests and repairs8.1 GeneralIt is the responsibility of the owner or his appointed representative to retain current certification for each POUnit, to arrange for periodic inspection, to record substantial repairs, modifications or changes in identificationetc., and to maintain adequate records to ensure the traceability of equipment.The inspector should refer to the initial certificate and the last inspection report before carrying out a periodicexamination or test.8.2 Inspection, test and repairs on PO Units8.2.1 Schedule of examination and testsPO Units should be periodically examined and tested in accordance with the schedule listed in Table 8-1. Theinspector may require other or additional tests and examinations, and dismantling if found necessary.Guidance note:National authorities may have stricter requirements for periodical inspections.---e-n-d---of---G-u-i-d-a-n-c-e---n-o-t-e---When a lifting test is required, the non-destructive examination and thorough visual examination should bothbe carried out after the lifting test.After renewal or substantial repair of damaged parts of the primary structure or after modification of a PO Unit,it shall be recertified. This may include strength testing. Renewal or repair of damaged parts shall be carriedout using approved manufacturing procedures and at least equivalent materials.The repair shall be noted on the certificate and the repair report should be attached to the certificate as anAppendix.Table 8-1 Schedule of examination and testsTest/ExaminationTime orintervalLifting test as describedin Sec.5 (NDT) of lifting points aminationon plate)Non-destructive testing Thorough visual ex-Suffix (to be markedAt intervals not exceeding12 monthsthe inspectorinspectorAt the discretion of At the discretion of theYesT or VN or VAfter substantial repairor alteration 1) Yes Yes Yes T1) A substantial repair or alteration means any repair and/or alteration carried out, which may, in the opinion of an inspecting body, affect elementswhich contribute directly to the structural integrity of the PO Unit.Suffix T= indicate proof load test, non-destructive examination, and visual examination.DET NORSKE VERITAS