New Isolator for Controlling BHA Vibrations - APS Technology

New Isolator for Controlling BHA Vibrations - APS Technology

New Isolator for Controlling BHA Vibrations - APS Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

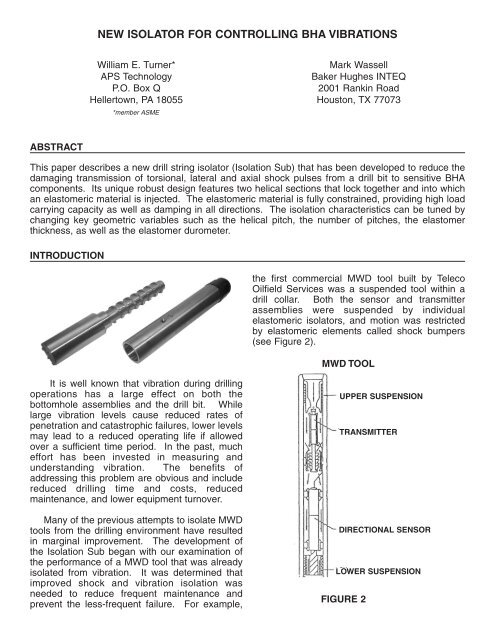

Under a steady load, such as when suspendedvertically or with a pressure differential actedacross the tool, the isolators provided support.Under dynamic loads, the isolators would flex,allowing the tool to move until contact was madewith the shock bumpers at which the stiffnessincreased exponentially. Torsional loads wereabsorbed entirely by the isolators. In general, thefield per<strong>for</strong>mance of this suspension wasfunctional, and the reliability was adequate.However, the isolators took a permanent set dueto the static load, and shock bumpers weresubject to erosion and breakdown of theelastomer, thus requiring frequent overhauls.Whenever the tool was returned to a maintenancefacility, the suspension was rebuilt, and allelastomeric components were replaced. Inaddition, occasional bond failures in the isolatorshad the potential of allowing rotation of the sensoror transmitter relative to the housing; there<strong>for</strong>e,these elements required special scrutiny. Theseproblems were determined to be unacceptable,and several improvements were attempted,including: improved elastomers, improvedbonding techniques,and replacement of HELICAL ISOLATORthe elastomericisolators and shockbumpers with coiledspring designs andwith belleville springdesigns. All ef<strong>for</strong>ts ledto some improvement,but no design was freeof the highmaintenance costs.These employ a similar conceptto the helical isolator but use twohelical elastomeric sections witha connecting shaft in between(see Figure 4). This design is aHooke style coupling and wasdeveloped and testedsuccessfully in the lab but hasnot yet been used downhole.This work allowed us to developthe torque transmitting capabilityof the Isolation Sub.Approximately 18 monthsago, we started development ofthe Isolation Sub design thatwould be used as a drill stringisolator (Figure 5). We felt thedesign would have severalapplications, including:FLEXCOUPLING• a drill string dampener toimprove per<strong>for</strong>mance of FIGURE 4bits.• an isolator to protect MWD tools from thedamaging high frequency vibrations,particularly <strong>for</strong> those tools which havecollar mounted electronics.• a flex sub to isolate drill stringcomponents from excessive bendingmoments.• an isolator <strong>for</strong> acoustic tools to preventechoes from corrupting the measurement.• a control of drill string vibratory frequency.<strong>APS</strong> <strong>Technology</strong>,along with BakerHughes INTEQ, hasbeen working onmethods of improvingthe shock isolation ofFIGURE 3sensitive componentsfrom the drilling environment. We proposed ahelical isolator concept about three years ago(see Figure 3) to address the problems. Initiallywe designed and built ten prototypes that weredeployed in the North Sea in 1994. These unitshave been running <strong>for</strong> two years with over 10,000accumulated downhole operating hours without asingle failure.Concurrently we had applications <strong>for</strong> improvedflex couplings <strong>for</strong> Moineau style downhole pumps.2Our initial ef<strong>for</strong>t focused on a 4-3/4" tool. Wecompleted manufacturing in August and have justcompleted static testing. It is anticipated that drillstring simulator tests will be per<strong>for</strong>med this springand downhole tests by the summer. The analysisand testing of this design will be outlined in thispaper.DESCRIPTION OF ISOLATION SUBThe Isolation Sub consists of two looselythreaded cylindrical members with rubber moldedinto the thread cavity. The rubber is one of thevariations of nitrile, which was selected <strong>for</strong> itsability to operate in the oilfield environment. Thespiral nature of the thread <strong>for</strong>m significantlyincreases the rubber-to-metal bond area. Therubber is constrained in all directions and

ISOLATIONSUSPENSIONbecomes relatively stiff. Verylarge axial and torsional loadscan be carried by this design,but it still provides shockisolation and damping ofvibrations. Stiffness anddamping are controlled byvarying the elastomer hardnessand geometry.Dareing has indicated that shock absorberscan lead to instability. This is overcome byincreasing the stiffness of the absorber 1,4 .Dareing demonstrated this by examining anabsorber with a stiffness of 43000 lb/in. This wasincreased by a factor of five and resulted in fullisolation of the drill string from cutter headvibrations. One goal of our design was to keepthe damping ratio as high as possible.Specifically, the jointassembly consists oflongitudinally arranged male andfemale threaded portions orsections. These sections arethreaded together to interlockwith one another butdimensioned such that atortuous helical space remainsbetween them. This space isentirely filled with an elastomerwhich is bonded to the threadedportions (Figure 5). By virtue ofthis structure, the elastomer isFIGURE 5 highly restrained by theinterlocked threading.Consequently, the elastomer isonly slightly compressible in the longitudinaldirection and somewhat more compressible inresponse to torque because of the continuoushelical nature of the elastomeric portion. The twoportions are pivotable with respect to one anotherin all directions to a limited, but sufficient, degree.Since torsional loads are transmitted by acombination of shear and compression via thejack screw effect through the entire helical length,the torsional load capacity is greatly increased.Thus, an important aspect of the concept isprovision of an elastomeric joint assembly withimproved torsional capacity. Further, because therelatively moving surfaces are completely isolatedfrom the surrounding environment, there is nopotential <strong>for</strong> abrasives or contamination to enter.The nature of the thread <strong>for</strong>m makes this a failsafedevice. In the event of bond failure, the partsscrew together due to drilling torque (right handthread). Four pins are installed prior to molding tomake this a fail-safe device in reverse rotation.This design is protected by US Patent 5,447,472and other US and <strong>for</strong>eign patent applicationspending.4-3/4" Tool Design SpecificationsParameterPropertyWeight on bit (lb) 36750Torque (ft-lb) 10000Rotary speed (rpm) 250Axial stiffness (lb/in) 1.2 x 10 6Torsional stiffness (in-lb/deg) 3200Axial critical damping 8%Temperature (°F) 300ANALYTICAL EXAMPLES OF EFFECT ON <strong>BHA</strong>The Isolation Sub was modeled through FiniteElement Analysis to determine its response toshock.The Drill String Model:Various shock excitations were analyzed,comparing a typical <strong>BHA</strong> to a <strong>BHA</strong> with anIsolation Sub position between the bit and anMWD tool. A time-history finite element modelwas used <strong>for</strong> the analysis. The time-historyanalysis predicts the isolation characteristics ofthe <strong>BHA</strong> above the isolator sub from excitationsand shocks induced at the bit. The <strong>BHA</strong> model(Figure 1) is made up of 150 feet of 4-3/4 drillcollars represented using beam elements. Amass on the uppermost node represents the drillpipe above the <strong>BHA</strong>. A vertical <strong>for</strong>ce on this nodeapplies the hook load achieving the proper WOB.The Isolation Sub is modeled as a damped springelement.Forced sinusoidal displacements at the bitapply the shock load into the <strong>BHA</strong>. Twoexcitations are applied to the bit. One is a highfrequencyshock of 100 Gs of an 11 millisecondsduration. This represents the shock due to animpact on the bit. The second shock is a lowerfrequencyshock of 1 G and 0.133 secondsduration. This excitation assumes the drill stringis rotating at 150 rpm over an upset of one third ofthe circumference.3

Figures 6 through 9 show the comparison ofthe bit response compared to the MWD toolwithout the Isolation Sub. Displacements andaccelerations are compared <strong>for</strong> differentexcitations, showing the effect of the IsolationSub.DISPLACEMENT - INACCELERATION - Gs<strong>BHA</strong> RESPONSEW/O ISOLATOR - 100 GS. 11 MSEC SHOCKTIME - SEC.FIGURE 6<strong>BHA</strong> RESPONSEW/O ISOLATOR - 100 GS. 11 MSEC SHOCKTIME - MSEC.FIGURE 7ACCELERATION - Gs<strong>BHA</strong> RESPONSEW/O ISOLATION SUB - 1G, .133 SEC SHOCKTIME - SEC.FIGURE 9Figures 10 through 13 show the samecomparisons with an Isolation Sub positionedbetween the bit and an MWD tool.DISPLACEMENT - IN<strong>BHA</strong> RESPONSEW/ ISOLATION SUB - 100 Gs, 11 MSEC SHOCKTIME - SEC.FIGURE 10<strong>BHA</strong> RESPONSEW/O ISOLATION SUB - 1G, .133 SEC. SHOCK<strong>BHA</strong> RESPONSEW/O ISOLATION SUB - 100 Gs, 11 MSEC SHOCKDISPLACEMENT - INACCELERATION - GsTIME - SEC.FIGURE 84TIME - SEC.FIGURE 11

aDISPLACEMENT - INACCELERATION - Gs<strong>BHA</strong> RESPONSEW/ ISOLATION SUB - 1 G, .133 SEC SHOCKTIME - SEC.FIGURE 12<strong>BHA</strong> RESPONSEW/ ISOLATION SUB - 1 G, .133 SEC SHOCKTIME - SEC.FIGURE 1350 percent. The increased damping capability ofthe Isolation Sub also dampens out the vibrationmuch quicker.APPLICATIONSThe tool is used below an MWD tool to damp thehigh-frequency shock and vibration and there<strong>for</strong>eincrease the reliability of the MWD tool. It will beparticularly useful <strong>for</strong> the new generation of toolsbeing developed, which are unsuspended or havecollar mounted electronics. The design isparticularly useful <strong>for</strong>:• Isolating sensitive components such as MWDelectronics and sensors from shock and highfrequencyvibration and whirl initiated by the drillbit or other sources.• Isolating downhole acoustical tools from noise.These new tools extend the radial detectionrange beyond current resistivity tools andprovide direct measurement of the well positionreferenced to acoustical reflectors. However,the tools are sensitive to excessive drillingDRILL STRING MODELHOOK LOADDRILL PIPE MASSThe damping <strong>for</strong> the <strong>BHA</strong> is .1% log decrement(.02% critical damping), which is the typicalmaterial damping <strong>for</strong> steel. The damping value <strong>for</strong>the isolation sub was determined to be 51% bytest-measuring the log decrement decay (8%critical). Figure 14 shows the hysteresis damping<strong>for</strong> an applied load of 8,600 lb. applied in 1second. The stiffness was determined by loadtesting.The analysis shows the isolation Sub providessignificant vibration isolating capabilities. Theshock from the high-frequency shock is reducedby 90 percent to the MWD tool. Figure 6 showsthe effects of the bit bouncing off bottom resultingin increased shocks of 300 Gs that are muchgreater than the applied 100 Gs. The IsolationSub absorbs this impact, reducing the shock atthe bit to the 100 Gs input excitation, whilereducing the MWD shock to 20 Gs. The lowfrequencyshock at the MWD tool is reduced by5DRILL COLLAR NODESISOLATORBITGROUND DISPLACEMENTFIGURE 14

noise and vibrations from mudmotors.Measurements are ideally per<strong>for</strong>med during pipeconnections 3 . The Isolation Sub may increase theconditions under which the acousticmeasurements can be successfully obtained.• Changing the natural frequencies of <strong>BHA</strong>s.• Improved PDC bit per<strong>for</strong>mance throughreduction of bit bounce by the ability to absorbshock, vibration, and whirl. Dareing has shownhow shearing action between drag bit cuttersand rock cause drillstrings to self-excite, leadingto dynamic instability 4 .• Absorbing the high-frequency shocks of tri-conebit teeth.• Isolating specialized tools from bendingmoments.Benefits include:• increased MWD tool life• increased bit life due to isolating it from drillstring bounce• damping and shock isolation over a wide rangeof drilling parameters• increased rate of penetration of PDC bits• short length (6') compared to shock subs (16')REFERENCES1. Zamudio, C.A., Tlusty, J., and Dareing, D.W., 1988, "Effect of Shock Absorber on Drag Bit Chatter,Proceedings," SPE 17194, 1988 IADC/SPE Drilling Conference, SPE, Richardson, TX, pp 153-160.2. Lindley, P.B., 1978, "Engineering Design With Natural Rubber," Malaysian Rubber Producer'sResearch Association, Hert<strong>for</strong>d, GB,3. Nakken, E.I., 1995, "A <strong>New</strong> MWD Concept <strong>for</strong> Geological Positioning of Horizontal Wells," SPE30454, SPE 1995 Annual Technical Conference and Exhibition, SPE, Richardson, TX, pp. 851-856.4. Zamudio, C.A., Tlusty, J.L., and Dareing, D.W., 1987, "Self-Excited <strong>Vibrations</strong> in Drillstrings," SPE16661, SPE 62nd Technical Conference and Exhibition, SPE, Richardson, TX, pp. 117-124.5. Schabtach, Carl and Fehr, R.O., June 1943, "Measurement of the Damping of EngineeringMaterials during flexural Vibration at Elevated Temperatures." Journal of Applied Mechanics, pp.A86-A92.6