OSP-P Series Pneumatic Rodless Cylinders and ... - Parker ORIGA

OSP-P Series Pneumatic Rodless Cylinders and ... - Parker ORIGA

OSP-P Series Pneumatic Rodless Cylinders and ... - Parker ORIGA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Catalog 0951Conversion Table<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesELECTRIC ACTUATOR2D & 3DCAD Drawingscan be downloadedfrom websitewww.parkeroriga.comAttention!Contact PARKER-<strong>ORIGA</strong> for sizing software<strong>and</strong>/or technical assistance630-871-8300Application Sheet on Page 104All dimensions are in European-St<strong>and</strong>ard.Please convert all in US-St<strong>and</strong>ard.Conversion TableMultiply By to ObtainMillimeters .03937 InchesNewtons .2248 Lbs.(F)Newton-Meters 8.8512 In-LbsKilograms 2.205 Lbs.Inches 25.4 MillimetersLbs.(F) 4.448 NewtonsIn-Lbs .113 Newtons-MetersLbs. .45359 Kilograms<strong>ORIGA</strong>i<strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Notes<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesPARKER-<strong>ORIGA</strong> rodless pneumatic cylindersare the first rodless cylindersthat have been approved for use inpotentially explosive atmospheres inEquipment Group II, Category 2 GDThe <strong>Cylinders</strong> are to the ATEX Certification94/9/EG (ATEX 95) for <strong>Pneumatic</strong>Components.For the different classifications <strong>and</strong> detailsplease see pages 27 <strong>and</strong> 92.<strong>ORIGA</strong>for use in Ex-Areas+120°CHigh Temperature Versionfor temperatures up to +120°Cfor Clean Room Applicationscertified toDIN EN ISO 14644-1-40°CLow Temperature Versionfor temperatures up to-40°CStainless steel versionfor special applications0.005 m/sSlow Speed Versionv = 0.005 – 0.2 m/swith special pneumaticcushioning system for cycletime optimization,for Ø 16 to 50 mm– on request< 30 m/sHigh Speed Versionvmax. = 30 m/s<strong>ORIGA</strong>ii<strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Index<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesContents – Linear DrivesnewnewnewnewPageIntroduction – <strong>OSP</strong> Concept 1-3Modular Components Overview 4-5Control Examples for <strong>OSP</strong>-P 6<strong>OSP</strong>-P Application examples 7<strong>Rodless</strong> <strong>Pneumatic</strong> <strong>Cylinders</strong>Overview 9-13<strong>Series</strong> <strong>OSP</strong>-P ø10 to 80 mm 15-21Integrated Valves VOE 22-23Clean Room <strong>Cylinders</strong> 24-26ATEX-Version 27ATEX-Version Plain Bearing 27Guide SLIDELINEBi-parting Version 28-29Linear GuidesOverview 31-32Plain Bearing Guide SLIDELINE 33-34Roller Guide 35-38POWERSLIDEAluminium-Roller Guide 39-40PROLINEAluminium-Roller Guide 39-40– PROLINE with ACTIVE-BrakeRecirculating Ball Bearing Guide 41-43STARLINE– Variable Stop VS 44-46Heavy Duty Guide HD 47-49– Variable Stop VS 50BrakesOverview 51-52Page<strong>OSP</strong> – AccessoriesOverview 65-66Clevis Mounting 67-68End Cap Mounting 69Mid-Section Support 70Mountings for Linear Drives fitted 71-77with <strong>OSP</strong>-GuidesInversion Mounting 78Adaptor Profile 79T-Slot Profile 80Connection Profile 81Duplex Connection 82Multiplex Connection 83Magnetic Switches– St<strong>and</strong>ard Version 84-86new – T-Slot Version 88-91new – ATEX-Version 92-94Wireway Cover 87– Metric Conversion Fittings 87newDisplacement Measuring Systems<strong>ORIGA</strong> SENSOFLEXOverview 95-96– <strong>Series</strong> SFI-plus 97-99Service Packs 100Ordering Instructions 102-103Application Sheet 104Safety Guide 105-106Offer of Sale 107ACTIVE-BrakesACTIVE-Brake 53-56– for St<strong>and</strong>ard CylinderPlain Bearing Guide SLIDELINE 33-34– with ACTIVE-BrakeAluminium-Roller Guide 39-40PROLINE with ACTIVE-BrakePASSIVE-BrakesMulti-Brake: PASSIVE-Brake with 57-60Plain Bearing Guide SLIDELINEMulti-Brake: PASSIVE-Brake with 61-63Aluminium-Roller Guide PROLINE<strong>ORIGA</strong>1 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

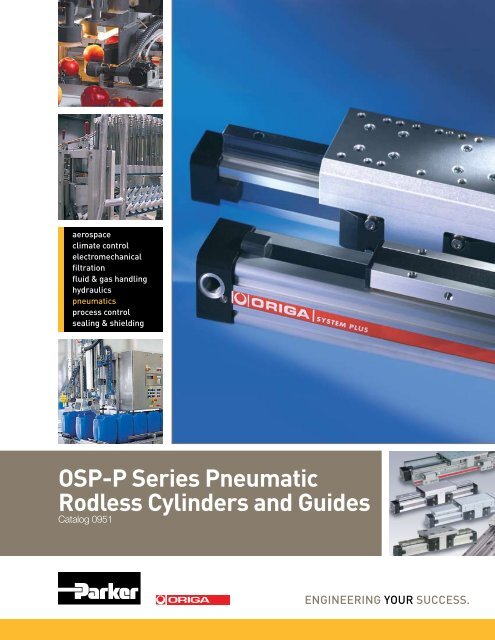

Catalog 0951The System Concept<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesOne Concept – Three Drive OptionsBased on the <strong>ORIGA</strong> rodless cylinder, proven in world wide markets, PARKER-<strong>ORIGA</strong> now offers the complete solution forlinear drive systems. Designed for absolute reliability, high performance, ease of use <strong>and</strong> optimized engineering the <strong>ORIGA</strong>SYSTEM PLUS satisfies even the most dem<strong>and</strong>ing applications.<strong>ORIGA</strong> SYSTEM PLUSis a totally modular concept whichoffers the choice of pneumatic orelectric actuation, with guidance <strong>and</strong>control modules to suit the exactneeds of individual installations.The actuators at the core of thesystem all have a common aluminiumextruded profile, with double dovetailmounting rails on three sides, theseare the principle building blocks of thesystem to which all modular optionsare directly attached.SYSTEM MODULARITY• <strong>Pneumatic</strong> Drive– For all round versatility<strong>and</strong> convenience,combining ease of control<strong>and</strong> broad performancecapability. Ideally suited forpoint-to point operations,reciprocating movements<strong>and</strong> simple traverse /transfer applications.• Electric Screw Drive– For high force capability<strong>and</strong> accurate path <strong>and</strong>position control.• Electric Belt Drive– For high speed appli cations,accurate path <strong>and</strong> position control<strong>and</strong> longer strokes.For additional information on electriclinear actuators, please contactfactory for <strong>OSP</strong>-E literature.• Different guidance options providethe necessary level of precision,performance <strong>and</strong> duty for variousapplications.• Compact solutions, which aresimple to install <strong>and</strong> can be easilyretrofitted.• Valves <strong>and</strong> control options can bedirectly mounted to the actuatorsystem.• Diverse mounting options to providetotal installation flexibility.<strong>ORIGA</strong>2 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951The System Concept<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesOne Concept – Three Drive Options* For information on Electric Linear Drives, contact factory for literatureBasic Linear DriveSt<strong>and</strong>ard VersionDuplex Connection● <strong>Series</strong> <strong>OSP</strong>-P● <strong>Series</strong> <strong>OSP</strong>-P● <strong>Series</strong> <strong>OSP</strong>-E*Belt driveBelt drive with integrated GuidesVertical belt drive with recirculatingball bearing guide● <strong>Series</strong> <strong>OSP</strong>-E*Screw drive (Ball Screw, Trapezoidal Screw)Air Connection on theEnd-face or both at One End● <strong>Series</strong> <strong>OSP</strong>-PClean Room Cylindercertified toDIN EN ISO 146644-1● <strong>Series</strong> <strong>OSP</strong>-P● <strong>Series</strong> <strong>OSP</strong>-E..SBProducts forATEX Areas● <strong>Series</strong> <strong>OSP</strong>-P<strong>Rodless</strong> <strong>Cylinders</strong>Products forATEX Areas● <strong>Series</strong> <strong>OSP</strong>-P<strong>Rodless</strong> <strong>Cylinders</strong>with Linear Guide SLIDELINEBi-parting Version● <strong>Series</strong> <strong>OSP</strong>-PMultiplex Connection● <strong>Series</strong> <strong>OSP</strong>-PLinear Guides– SLIDELINE● <strong>Series</strong> <strong>OSP</strong>-P● <strong>Series</strong> <strong>OSP</strong>-E Screw drive*Linear Guides– POWERSLIDE● <strong>Series</strong> <strong>OSP</strong>-P● <strong>Series</strong> <strong>OSP</strong>-E Belt drive*● <strong>Series</strong> <strong>OSP</strong>-E Screw drive*Linear Guides– PROLINE● <strong>Series</strong> <strong>OSP</strong>-P● <strong>Series</strong> <strong>OSP</strong>-E Belt drive*● <strong>Series</strong> <strong>OSP</strong>-E Screw drive*Linear Guides– STARLINE● <strong>Series</strong> <strong>OSP</strong>-PHeavy Duty Linear Guides– HD● <strong>Series</strong> <strong>OSP</strong>-P● <strong>Series</strong> <strong>OSP</strong>-E Screw drive*Brakes● Active BrakesIntegrated3/2 Way Valves● <strong>Series</strong> <strong>OSP</strong>-P● Passive BrakesClevis Mounting● <strong>Series</strong> <strong>OSP</strong>-P● <strong>Series</strong> <strong>OSP</strong>-E Belt drive*● <strong>Series</strong> <strong>OSP</strong>-E Screw drive*End Cap Mounting● <strong>Series</strong> <strong>OSP</strong>-P● <strong>Series</strong> <strong>OSP</strong>-E Belt drive*● <strong>Series</strong> <strong>OSP</strong>-E Screw drive*Mid-Section Support● <strong>Series</strong> <strong>OSP</strong>-P● <strong>Series</strong> <strong>OSP</strong>-E Belt drive*● <strong>Series</strong> <strong>OSP</strong>-E Screw drive*Magnetic Switches● <strong>Series</strong> <strong>OSP</strong>-P● <strong>Series</strong> <strong>OSP</strong>-E Belt drive*● <strong>Series</strong> <strong>OSP</strong>-E Screw drive*SENSOFLEX-Measuring System● <strong>Series</strong> SFI-plusVariable Stop VS● <strong>Series</strong> <strong>OSP</strong>-Pwith Linear Guide STL, HDInversion Mounting● <strong>Series</strong> <strong>OSP</strong>-P● <strong>Series</strong> <strong>OSP</strong>-E Belt drive*● <strong>Series</strong> <strong>OSP</strong>-E Screw drive*<strong>ORIGA</strong>3 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Modular Components Overview<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Cylinders</strong> <strong>Series</strong> <strong>OSP</strong>-PLinear Drives <strong>OSP</strong>-P10 <strong>OSP</strong>-P16 <strong>OSP</strong>-P25 <strong>OSP</strong>-P32 <strong>OSP</strong>-P40 <strong>OSP</strong>-P50 <strong>OSP</strong>-P63 <strong>OSP</strong>-P80Theoretical force at 6bar [N] 47 120 295 483 754 1178 1870 3010Effective force at 6bar [N] 32 78 250 420 640 1000 1550 2600Velocity v [m/s] > 0.005 > 0.005 > 0.005 > 0.005 > 0.005 > 0.005 > 0.005 > 0.005Magnetic piston (three sides) ✕ ❑ ❑ ❑ ❑ ❑ ❑ ❑Lubrication - Prelubricated ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑Multiple air ports ( 4 x 90° ) ✕ ❑ ❑ ❑ ❑ ❑ ❑ ❑Both Air Connections at End-face ✕ ❍ ❍ ❍ ❍ ❍ ❍ ❍Air Connection on the End-face ✕ ❍ ❍ ❍ ❍ ❍ ❍ ❍Cushioning ❑ ❑ ❑ ❑ ❑ ❑ ❑ ❑Cushioning length[mm] 2,50 11 17 20 27 30 32 39Stroke length [mm] ▲ 1 - 6000 1 - 6000 1 - 6000 1 - 6000 1 - 6000 1 - 6000 1 - 6000 1 - 6000Pressure range pmax [bar] 8.0 8.0 8.0 8.0 8.0 8.0 8.0 8.0Temperature range [°C] ❊ -10 – + 80 -10 – + 80 -10 – + 80 -10 – + 80 -10 – + 80 -10 – + 80 -10 – + 80 -10 – + 80Viton / chemical resistance ❍ ❍ ❍ ❍ ❍ ❍ ❍ ❍Stainless steel parts ❍ ❍ ❍ ❍ ❍ ❍ ❍ ❍Clevis Mounting ❍ ❍ ❍ ❍ ❍ ❍ ❍ ❍Slow speed lubrication ❍ ❍ ❍ ❍ ❍ ❍ ❍ ❍Duplex Connection / Multiplex Connection ✕ on request ❍ ❍ ❍ ❍ on request on requestT<strong>and</strong>em piston ❍ ❍ ❍ ❍ ❍ ❍ ❍ ❍Basic CylinderF [N] 20 120 300 450 750 1200 1650 2400Mx [Nm] 0.2 0.45 1.5 3 6 10 12 24My [ Nm] 1 4 15 30 60 115 200 360Mz [Nm] 0.3 0.5 3 5 8 15 24 48SlidelineF [N] ✕ 325 675 925 1500 2000 2500 2500Mx [Nm] ✕ 6 14 29 50 77 120 120My [Nm] ✕ 11 34 60 110 180 260 260Mz [Nm] ✕ 11 34 60 110 180 260 260ProlineF [N] ✕ 542 857 1171 2074 3111 ✕ ✕Mx [Nm] ✕ 8 16 29 57 111 ✕ ✕My [Nm] ✕ 12 39 73 158 249 ✕ ✕Mz [Nm] ✕ 12 39 73 158 249 ✕ ✕PowerslideF [N] ✕ 1400 1400 - 3000 1400 - 3000 3000 3000 - 4000 ✕ ✕Mx [Nm] ✕ 14 14 - 65 20 - 65 65 - 90 90 - 140 ✕ ✕My [Nm] ✕ 45 63 - 175 70 - 175 175 - 250 250 - 350 ✕ ✕Mz [Nm] ✕ 45 63 - 175 70 - 175 175 - 250 250 - 350 ✕ ✕StarlineF [N] ✕ 1000 3100 3100 4000-7500 4000-7500 ✕ ✕Mx [Nm] ✕ 15 50 62 150 210 ✕ ✕My [Nm] ✕ 30 110 160 400 580 ✕ ✕Mz [Nm] ✕ 30 110 160 400 580 ✕ ✕– variable Stop ✕ ❍ ❍ ❍ ❍ ❍ ✕ ✕<strong>ORIGA</strong>4 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Modular Components Overview<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Cylinders</strong> <strong>Series</strong> <strong>OSP</strong>-PLinear Drives <strong>OSP</strong>-P10 <strong>OSP</strong>-P16 <strong>OSP</strong>-P25 <strong>OSP</strong>-P32 <strong>OSP</strong>-P40 <strong>OSP</strong>-P50 <strong>OSP</strong>-P63 <strong>OSP</strong>-P80HD Heavy Duty GuideF [N] ✕ ✕ 6000 6000 15000 18000 ✕ ✕Mx [Nm] ✕ ✕ 260 285 800 1100 ✕ ✕My [Nm] ✕ ✕ 320 475 1100 1400 ✕ ✕Mz [Nm] ✕ ✕ 320 475 1100 1400 ✕ ✕– variable Stop ✕ ✕ ❍ ❍ ❍ ❍ ✕ ✕Active BrakeBraking force at 6 bar (brake surface dry) [N] ✕ ✕ 350 590 900 1400 2170 4000Slideline SL / Proline PL with BrakesActive BrakeSL Braking force at 6 bar (brake surface dry) [N] ✕ ✕ 325 545 835 1200 ✕ ✕PL Braking force at 6 bar (brake surface dry) [N] ✕ ✕ on request on request on request on request ✕ ✕Passive Brake MultibrakeSL Braking force at 6 bar (brake surface dry) [N] ✕ ✕ 470 790 1200 1870 2900 2900PL Braking force at 6 bar (brake surface dry) [N] ✕ ✕ 315 490 715 1100 – –Magnetic SwitchesSt<strong>and</strong>ard Version ❍ ❍ ❍ ❍ ❍ ❍ ❍ ❍T-Nut Version ❍ ❍ ❍ ❍ ❍ ❍ ❍ ❍ATEX Version for EX- Areas ❍ ❍ ❍ ❍ ❍ ❍ ❍ ❍Displacement measuring systemsSFI-plus incremental ✕ ✕ ❍ ❍ ❍ ❍ ❍ ❍Integrated valves 3/2 WV NO VOE ✕ ✕ ❍ ❍ ❍ ❍ on request on requestMountingsEnd Cap Mounting / Mid-Section Support ❍ ❍ ❍ ❍ ❍ ❍ ❍ ❍Inversion Mounting ✕ ❍ ❍ ❍ ❍ ❍ ❍ ❍Shock absorber for intermediate positioning ✕ ✕ on request on request on request on request ✕ ✕Adaptor Profile / T-Nut Profile ✕ ❍ ❍ ❍ ❍ ❍ ✕ ✕Special <strong>Cylinders</strong>Special <strong>Pneumatic</strong>al Cushioning System ✕ on request on request on request on request on request ✕ ✕Clean Room <strong>Cylinders</strong> to DIN EN ISO 14644-1 ✕ ❍ ❍ ❍ ✕ ✕ ✕ ✕ATEX Version for EX-Areas ❍ ❍ ❍ ❍ ❍ ❍ ❍ ❍Bi-parting Version ✕ ✕ ✕ ✕ ❍ ✕ ✕ ✕High-Speed up to 30 m/s ✕ on request on request on request ✕ ✕ ✕ ✕❑ = St<strong>and</strong>ard version▲ = longer strokes on request❊ = other temperature ranges on request❍ = Option✕ = not applicable<strong>ORIGA</strong>5 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Examples<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesControl Examples for <strong>OSP</strong>-PCircuit diagram for endof stroke application.Intermediate positioning isalso possible.Circuit diagram for endof stroke application.Intermediate positioning isalso possible.The optional integratedVOE Valves offer optimalcontrol, <strong>and</strong> allow accuratepositioning of intermediatepositions <strong>and</strong> the lowestpossible speeds.The cylinder is controlledby two 3/2-way valves(normally open). Thespeed can be adjustedindependently for bothdirections.The cylinder is controlledby a 5/3-way valve (middleposition pressurized).The speed can be adjustedindependently for bothdirections.Fast/Slow speed cycle controlwith pneumatic brake foraccurate positioning at highvelocities.Additional 3/2-way valveswith adjustable throttlevalves at the exhaust of thest<strong>and</strong>ard directional controlvalves for two displacementspeeds in each direction ofthe piston’s travel.The valve controlling thebrake is activated afterthe slow speed cycle isactvatedThe combination of an<strong>OSP</strong>-cylinder with the passiveMULTIBRAKE as shown here,allows accurate positioning<strong>and</strong> safety in case of loss ofpneumatic air pressure.<strong>ORIGA</strong>6 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Examples<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>OSP</strong>-P Application Examples<strong>ORIGA</strong> SYSTEM PLUS – rodless linear drives offer maximum flexibility for any application.The high load capacity ofthe piston can cope withhigh bending momentswithout additional guides.SLIDELINEPOWERSLIDEPROLINESTARLINEHD-GuideThe mechanical designof the <strong>OSP</strong>-P allowssynchronized movementof two cylinders.Integrated guides offeroptimal guidance forapplications requiring highperformance, easy assembly<strong>and</strong> maintenance freeoperation.Optimal system performanceby combiningmulti-axis cylinder combinations.When using externalguides, the clevis mountingis used to compensate fordeviations in parallelism.For further information <strong>and</strong> assembly instructions, please contact your localPARKER-<strong>ORIGA</strong> dealer.<strong>ORIGA</strong>7 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Notes<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>ORIGA</strong>8 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

<strong>ORIGA</strong><strong>Rodless</strong> <strong>Pneumatic</strong> <strong>Cylinders</strong><strong>Series</strong> <strong>OSP</strong>-PContentsDescriptionPageSt<strong>and</strong>ard <strong>Cylinders</strong>Overview 9-13Technical Data 15-17Dimensions 18-23Clean Room <strong>Cylinders</strong>Technical Data 24-25Dimensions 26<strong>Cylinders</strong> ATEX-VersionTechnical Data 27Dimensions 18-23<strong>Cylinders</strong> for synchronized bi-parting movementsTechnical Data 28Dimensions 29<strong>ORIGA</strong>9 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951System Concept & Componentsoriga system plus– innovation from A PROVEN design<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Pneumatic</strong> CylinderA completely new generation of linear drives which can be simply <strong>and</strong> neatlyintegrated into any machine layout.A NEW MODULAR LINEAR DRIVESYSTEMWith this second generation lineardrive PARKER-<strong>ORIGA</strong> offersdesign engineers complete flexibility.The well known <strong>ORIGA</strong> cylinder hasbeen further developed into a combinedlinear actuator, guidance <strong>and</strong>control package. It forms the basis forthe new, versatile <strong>ORIGA</strong> SYSTEMPLUS linear drive system.All additional functions are designedinto modular system componentswhich replace the previous series ofcylinders.Combined clampingfor inner <strong>and</strong>outer sealing b<strong>and</strong>with dust cover.MOUNTING RAILS ON 3 SIDESMounting rails on 3 sides of thecylinder enable modular componentssuch as linear guides, brakes, valves,magnetic switches etc. to be fitted tothe cylinder itself. This solves manyinstallation problems, especially wherespace is limited.Proven corrosion resistant steelinner sealing b<strong>and</strong> for optimumsealing <strong>and</strong> extremely low friction.Corrosion resistant steelouter sealing b<strong>and</strong> <strong>and</strong>robust wiper system on thecarrier for use in aggressiveenvironments.The modular system concept formsan ideal basis for additional customerspecificfunctions.Magnetic piston as st<strong>and</strong>ard- for contactless positionsensing on three sides of thecylinder.Stainless steelscrews optional.End cap can be rotated to any oneof the four positions (before or afterdelivery) so that the air connectioncan be in any desired position.Optimized cylinder profilefor maximum stiffness <strong>and</strong>minimum weight. Integralair passages enable both airconnections to be positionedat one end, if desired.Low friction piston seals foroptimized running characteristics<strong>ORIGA</strong>10 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951System Concept & ComponentsClean Room Versioncertified to DIN EN ISO 14644-1<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Pneumatic</strong> CylinderSLIDELINECombination withlinear guidesprovides forheavier loads.<strong>Rodless</strong> Cylinderfor synchronized bi-parting movementsPOWERSLIDERoller bearingprecision guidancefor smooth travel<strong>and</strong> high dynamicor static loads.ProlineThe compactaluminium rollerguide for high loads<strong>and</strong> velocities.New low profilepiston/carrier design.STARLINERecirculating ballbearing guide forvery high loads<strong>and</strong> precisionHeavy Dutyguide HDfor heavy dutyapplications.Adjustable end cushioningat both ends are st<strong>and</strong>ard.VARIABLE STOPVSThe variable stopprovides simplestroke limitation.Integral dovetail rails on three sidesprovide many adaptation possibilities(linear guides, magnetic switches,etc.).Modular system componentsare simply clamped on.INTEGRATEDVOE VALVESThe completecompact solutionfor optimal cylindercontrol.Passivepneu matic brakereacts auto maticallyto pressurefailure.SENSOFLEXSFI-plusincrementalmeasuring systemwith 0,1 (1,0) mmresolutionActive pneumaticbrake for secure,positive stoppingat any position.<strong>ORIGA</strong>11 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951AccessoriesOPTIONS AND ACCESSORIESFOR SYSTEM VERSATILITY<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Pneumatic</strong> Cylinder<strong>Series</strong> <strong>OSP</strong>-PSTANDARDVersions<strong>OSP</strong>-P10 to P80Pages 15-18St<strong>and</strong>ard carrier with integralguidance. End cap can be rotated4 x 90° to position air connection onany side.Magnetic piston as st<strong>and</strong>ard.Dovetail profile for mounting ofaccessories <strong>and</strong> the cylinder itself.STAINLESS VERSIONFor use in constantly dampor wet environments. Allscrews are A2 qualitystainless steelSLOW SPEED OPTIONSSpecially formulated grease 0.005 m/slubrication facilitates slow,smooth <strong>and</strong> uniform pistontravel in the speed rangefrom 0.005 to 0.2 m/s.Minimum achievable speeds aredependent on several factors. Pleaseconsult our technical department.Slow speed lubrication in combinationwith Viton ® on dem<strong>and</strong>.Oil free operation preferred.To solve special installation problems.SINGLE END PORTINGPage 21For simplified tubing connections<strong>and</strong> space saving.INTEGRATED VOE VALVESPage 22The complete compact solutionfor optimal cylinder control.BASIC CYLINDEROPTIONSClean Room <strong>Cylinders</strong>Page 24For use in clean room applications,certified with theIPA-Certificate(to DIN EN ISO 14644-1).The special design of the linear driveenables all emissions to be led away.ATEX-VersionPage 27For use in Ex-Areasviton ® VERSIONFor use in an environmentwith high temperatures orin chemically aggressiveareas.All seals are made of Viton ® .Sealing b<strong>and</strong>s: Stainless steelCORROSION RESISTANCE COA-TINGFDA Approved Xylan ® CoatingGood for food applications, causticwashdown, salt spray, dionized water<strong>and</strong> chemical resistance.end-Face AIR CONNECTIONPage 20DUPLEX ConnectionPage 82The duplex connection combines two<strong>OSP</strong>-P cylinders of the same size intoa compact unit with high performance.multiplex connectionPage 83The multiplex connection combinestwo or more <strong>OSP</strong>-P cylinders of thesame size into one unit.The orientation of the carriers can befreely selected.<strong>ORIGA</strong>12 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Accessories<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Pneumatic</strong> CylinderACCESSORIESMagnetic switchesTYPE RS, ES, RST, ESTPages 84-94For electrical sensing of end <strong>and</strong>intermediate piston positions, also inEX-Areas.MID-SECTION SUPPORTPage 70For supporting long cylinders ormounting the cylinder by its dovetailrails.MOUNTINGSclevis MOUNTINGPage 67-68Carrier with tolerance <strong>and</strong> parallelismcompensation for driving loadssupported by external linear guides.INVERSION mountingPage 78The inversion mounting transfers thedriving force to the opposite side, e. g.for dirty environments.END CAP MOUNTINGPage 69For end-mounting of the cylinder.<strong>ORIGA</strong>13 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Notes<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Pneumatic</strong> Cylinder<strong>ORIGA</strong>14 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

The right to introduce technicalmodifications is reservedCatalog 0951Technical DataCharacteristicsCharacteristics Symbol Unit DescriptionGeneral FeaturesType<strong>Series</strong>SystemWeight (mass) kgCylinder series(Basic cylinder)At 0 mm strokeWeight (Mass) kgper 100 mm stroke<strong>OSP</strong>-P10 0.087 0.052<strong>OSP</strong>-P16 0.22 0.1<strong>OSP</strong>-P25 0.65 0.197<strong>OSP</strong>-P32 1.44 0.354<strong>OSP</strong>-P40 1.95 0.415<strong>OSP</strong>-P50 3.53 0.566<strong>OSP</strong>-P63 6.41 0.925<strong>OSP</strong>-P80 12.46 1.262Size ComparisonPressures quoted as gauge pressure<strong>Rodless</strong> cylinder<strong>OSP</strong>-PDouble-acting, with cushioning,position sensing capabilityMountingSee drawingsAir ConnectionThreadedAmbient T min°C -10 Other temperature rangestemperature range T max°C +80 on requestWeight (mass) kg See table belowInstallationIn any positionMediumFiltered, unlubricated compressed air(other media on request)LubricationMaterialCylinder ProfileCarrier (piston)End capsSealing b<strong>and</strong>sSealsScrewsDust covers,wipersMax. operating pressure p maxbar 8Permanent grease lubrication(additional oil mist lubricationnot required)Option: special slow speed greaseAnodized aluminiumAnodized aluminiumAluminium, lacquered / Plastic (P10)Corrosion resistant steelNBR (Option: Viton®)Galvanized steelOption: stainless steelPlasticP10 P16 P25 P32 P40 P50 P63 P80<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Pneumatic</strong> Cylinder<strong>Rodless</strong><strong>Pneumatic</strong>Cylinderø 10-80 mm<strong>Series</strong> <strong>OSP</strong>-P..St<strong>and</strong>ard Versions:• double-acting with adjustableend cushioning• with magnetic piston for positionsensingSpecial Versions:• with special pneumaticalcushioning system (on request)• Clean room cylinders(see page 24)• ATEX-Version(see page 27)• Stainless steel screws• Slow speed lubrication• Viton® seals• Both air connections on one end• Air connection on the end-face• Integrated Valves• End cap can be rotated4 x 90° to position airconnection as desired• Free choice of strokelength up to 6000 mm(longer strokes on request)<strong>ORIGA</strong>15 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical DataLoads, Forces<strong>and</strong> MomentsChoice of cylinder is decided by:• permissible loads, forces <strong>and</strong>moments• performance of the pneumatic endcushions. The main factors here arethe mass to be cushioned <strong>and</strong> thepiston speed at start of cushioning(unless external cushioning is used,e. g. hydraulic shock absorbers).The adjacent table shows themaximum values for light, shock-freeoperation, which must not beexceeded even in dynamic operation.Load <strong>and</strong> moment data are basedon speeds v ≤ 0.5 m/s.When working out the action forcerequired, it is essential to take intoaccount the friction forces generatedby the specific application or load.Cushioning DiagramWork out your expected moving mass<strong>and</strong> read off the maximum permissiblespeed at start of cushioning.Alternatively, take your desired speed<strong>and</strong> expected mass <strong>and</strong> find thecylinder size required.Please note that piston speed atstart of cushioning is typically ca. 50% higher than the average speed,<strong>and</strong> that it is this higher speed whichdetermines the choice of cylinder. Ifthese maximum permissible values areexceeded, additional shock absorbersmust be used.M = F ·lBending moments arecalculated from thecenter of the linearactuatorCylinder- Theoretical effektive max. Moments max. Load Cushion<strong>Series</strong> Action Force Action Force F AMx My Mz F Length[mm Ø] at 6 bar [N] at 6 bar [N] [Nm] [Nm] [Nm] [N] [mm]<strong>OSP</strong>-P10 47 32 0.2 1 0.3 20 2.5 *<strong>OSP</strong>-P16 120 78 0.45 4 0.5 120 11<strong>OSP</strong>-P25 295 250 1.5 15 3 300 17<strong>OSP</strong>-P32 483 420 3 30 5 450 20<strong>OSP</strong>-P40 754 640 6 60 8 750 27<strong>OSP</strong>-P50 1178 1000 10 115 15 1200 30<strong>OSP</strong>-P63 1870 1550 12 200 24 1650 32<strong>OSP</strong>-P80 3016 2600 24 360 48 2400 39* A rubber element (non-adjustable) is used for end cushioning.To deform the rubber element enough to reach the absolute end position wouldrequire a Dp of 4 bar!Max. permissible piston speedat start of cushioning<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Pneumatic</strong> Cylinder Mass to be cushioned ** For cylinders with linear guides or brakes, please be sure to takethe mass of the carriage or the brake housing into account.If the permitted limit values are exceeded, either additional shockabsorbers should be fitted in the area of the center of gravity or you canconsult us about our special cushioning system– we shall be happy to advise you on your specific application.<strong>ORIGA</strong>16 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical Data<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Pneumatic</strong> CylinderMid-Section SupportsTo avoid excessive bending <strong>and</strong>oscillation of the cylinder, mid-sectionsupports are required dependenton specified stroke lengths <strong>and</strong>applied loads. The diagrams show themaximum possible support spacingsdepending on the load.Bending up to max. 0.5 mm is permissiblebetween supports. The midsectionsupports are clamped on tothe dovetail profile of the cylinder tube.They are also able to take the axialforces.Permissible Support Spacings: <strong>OSP</strong> - P10 - P32Load F Distance kPermissible Support Spacings: <strong>OSP</strong> - P40 - P80Load F Distance k<strong>ORIGA</strong>17 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951DimensionsCylinderStroke <strong>and</strong> Dead Length A• Free choice of stroke length up to6000 mm in 1 mm steps.• Longer strokes on request.<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Pneumatic</strong> CylinderDimensions of Basic Cylinder <strong>OSP</strong>-P10StrokeStroke + 2 x AT<strong>and</strong>em CylinderTwo pistons are fitted: dimension "Z"is optional. (Please note minimumdistance "Zmin").• Free choice of stroke length up to6000 mm in 1 mm steps.StrokeStroke + 2 x A + Z• Longer strokes on request.• Stroke length to order isstroke + dimension "Z"End Cap/Air Connection<strong>Series</strong> <strong>OSP</strong> -P10Please note:To avoid multiple actuation ofmagnetic switches, the secondpiston is not equipped withmagnets.Carrier<strong>Series</strong> <strong>OSP</strong>-P10Dimension Table (mm)Cylinder A B C D E G H I J K L M N P R S W X Y Z CF EM EN FB FH ZZ<strong>Series</strong>min<strong>OSP</strong>-P10 44.5 12 19 M5 12 M3 5 6 60 8.5 22 22.5 17.5 10.5 3.4 16 22.5 31 M3 64 32 9.5 2 17 17 6<strong>ORIGA</strong>18 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951DimensionsDimensions of Basic Cylinder <strong>OSP</strong> - P16-P80Stroke<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Pneumatic</strong> CylinderCylinderStroke <strong>and</strong> Dead Length A• Free choice of stroke length up to6000 mm in 1 mm steps.• Longer strokes on request.Stroke + 2 x AStrokeT<strong>and</strong>em CylinderStroke + 2 x A + ZEnd Cap/Air Connection can be rotated 4 x 90°<strong>Series</strong> <strong>OSP</strong>-P16 to P32Air connection DTwo pistons are fitted: dimension "Z"is optional. (Please note minimumdistance "Zmin").• Free choice of stroke length up to6000 mm in 1 mm steps.• Longer strokes on request.• Stroke length to order isstroke + dimension "Z"Please note:To avoid multiple actuation ofmagnetic switches, the secondpiston is not equipped withmagnets.Cushion adjustment screwEnd Cap/Air Connection can be rotated 4 x 90°<strong>Series</strong> <strong>OSP</strong>-P40 to P80Carrier<strong>Series</strong> <strong>OSP</strong>-P16 to P80Air connection DCushion adjustment screwDimension Table (mm)Cylinder A B C D E G H I J K M O S V X Y Z BW BX BY CF EN FB FH ZZ<strong>Series</strong>min<strong>OSP</strong>-P16 65 14 30 M5 18 M3 9 5.5 69 15 23 33.2 22 16.5 36 M4 81 10.8 1.8 28.4 38 3 30 27.2 7<strong>OSP</strong>-P25 100 22 41 G1/8 27 M5 15 9 117 21.5 31 47 33 25 65 M5 128 17.5 2.2 40 52.5 3.6 40 39.5 8<strong>OSP</strong>-P32 125 25.5 52 G1/4 36 M6 15 11.5 152 28.5 38 59 36 27 90 M6 170 20.5 2.5 44 66.5 5.5 52 51.7 10<strong>OSP</strong>-P40 150 28 69 G1/4 54 M6 15 12 152 34 44 72 36 27 90 M6 212 21 3 54 78.5 7.5 62 63 10<strong>OSP</strong>-P50 175 33 87 G1/4 70 M6 15 14.5 200 43 49 86 36 27 110 M6 251 27 – 59 92.5 11 76 77 10<strong>OSP</strong>-P63 215 38 106 G3/8 78 M8 21 14.5 256 54 63 107 50 34 140 M8 313 30 – 64 117 12 96 96 16<strong>OSP</strong>-P80 260 47 132 G1/2 96 M10 25 22 348 67 80 133 52 36 190 M10 384 37.5 – 73 147 16.5 122 122 20<strong>ORIGA</strong>19 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Dimensions<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Pneumatic</strong> CylinderAir Connection on theEnd-Face #5<strong>Series</strong> <strong>OSP</strong>-P16 to P32In some situations it is necessary ordesirable to fit a special end cap withthe air connection on the end-faceinstead of the st<strong>and</strong>ard end cap withthe air connection on the side. Thespecial end cap can also be rotated4 x 90° to locate the cushionadjustment screw as desired.Supplied in pairs.Cushion adjustment screwAir connection D<strong>Series</strong> <strong>OSP</strong>-P40 to P80142Cushion adjustment screwAir connection D53Note: Position #2 is thest<strong>and</strong>ard location.Dimension Table (mm)Cylinder B C D e G H BX BW<strong>Series</strong><strong>OSP</strong>-P16 14 30 M5 18 M3 9 1.8 10.8<strong>OSP</strong>-P25 22 41 G1/8 27 M5 15 2.2 17.5<strong>OSP</strong>-P32 25.5 52 G1/4 36 M6 15 2.5 20.5<strong>OSP</strong>-P40 28 69 G1/4 54 M6 15 3 21<strong>OSP</strong>-P50 33 87 G1/4 70 M6 15 – 27<strong>OSP</strong>-P63 38 106 G3/8 78 M8 21 – 30<strong>OSP</strong>-P80 47 132 G1/2 96 M10 25 – 37.5<strong>ORIGA</strong>20 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Dimensions<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Pneumatic</strong> Cylinder<strong>Series</strong> <strong>OSP</strong>-P16Air connection DCushion adjustment screwAir connection DSingle End PortingA special end cap with both airconnections on one side is availablefor situations where shortage ofspace, simplicity of installation orthe nature of the process make itdesirable.Air supply to the other end is viainternal air passages (<strong>OSP</strong>-P25 toP80) or via a hollow aluminium profilefitted externally (<strong>OSP</strong>-P16).In this case the end caps cannotbe rotated.<strong>Series</strong> <strong>OSP</strong>-P25Air connection DCushion adjustment screw* Versions of Air Connection Positions: 1 → 1 or 2 → 2<strong>Series</strong> <strong>OSP</strong>-P32 to P80Please note:When combining the <strong>OSP</strong>-P16single end porting with inversionmountings, RS magnetic switchescan only be mounted directlyopposite to the external air-supplyprofile.Air connection D<strong>OSP</strong>-P40 to P80<strong>OSP</strong>-P32Cushion adjustment screwDimension Table (mm)Cylinder B C D E G H I 1I 2BX BW EN EN 1EN 2FA FB FC FE FG FL FN<strong>Series</strong><strong>OSP</strong>-P16 14 30 M5 18 M3 9 5.5 – 1.8 10.8 3 – – 12.6 12.6 4 27 21 36 –<strong>OSP</strong>-P25 22 41 G1/8 27 M5 15 9 – 2.2 17.5 – 3.6 3.9 – – – – – – –<strong>OSP</strong>-P32 25.5 52 G1/8 36 M6 15 12.2 10.5 – 20.5 – – – – – – – – – 15.2<strong>OSP</strong>-P40 28 69 G1/8 54 M6 15 12 12 – 21 – – – – – – – – – 17<strong>OSP</strong>-P50 33 87 G1/4 70 M6 15 14.5 14.5 – 27 – – – – – – – – – 22<strong>OSP</strong>-P63 38 106 G3/8 78 M8 21 16.5 13.5 – 30 – – – – – – – – – 25<strong>OSP</strong>-P80 47 132 G1/2 96 M10 25 22 17 – 37.5 – – – – – – – – – 34.5<strong>ORIGA</strong>21 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Dimensions<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>Rodless</strong> <strong>Pneumatic</strong> CylinderDimensions VOE Valves <strong>OSP</strong>-P25 <strong>and</strong> P32Integrated exhaustthrottle valveDimension Table (mm)Cylinder AV BV C CV DV V1 V2 V3 V4 V5 V8 V9 V10 V11 V12 V13 V14 V15 V16 V17 V18 V19<strong>Series</strong><strong>OSP</strong>-P25 115 37 41 47 G1/8 11 46 90.5 22 30 18.5 32.5 2.5 3.3 18.5 26.5 20.5 24 5 4 14 G1/8<strong>OSP</strong>-P32 139 39.5 52 58 G1/4 20.5 46 96 22 32 20.5 34.7 6 5 20.5 32 26 32 7.5 6 18 G1/4Dimensions VOE Valves <strong>OSP</strong>-P40 <strong>and</strong> P50 Possiblepositions ofthe exhaustthrottle valveConnector - rotated 180°* End cap can be rotated 4x90°Possiblepositions ofthe exhaustthrottle valveConnector - rotated 180°Integrated exhaustthrottle valve*End cap can be rotated 4x90°Dimension Table (mm)Cylinder AV BV C CV DV V1 V2 V3 V4 V5 V6 V7 V8 V9 V10 V11 V12 V13 V14 V15 V16 V17 V18 V19<strong>Series</strong><strong>OSP</strong>-P40 170 48 69 81 G3/8 24 46 103 22 33 M5 6.7 24 42 8.3 8.3 24 39 42 32 7.5 6 18 G1/4<strong>OSP</strong>-P50 190 48 87 82 G3/8 24 46 102 22 33 M5 4.5 24 42 12.2 12.2 24 38 44 32 7.5 6 18 G1/4<strong>ORIGA</strong>23 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical Data<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesClean Room <strong>Cylinders</strong>CertificationBased on the PARKER-<strong>ORIGA</strong>rodless cylinder, proven in worldwide markets, PARKER-<strong>ORIGA</strong> nowoffers the only rodless cylinderon the market with a certificationfrom IPA Institute for the cleanroomspecification according toDIN EN ISO 14644-1.Function DiagramFunction:The clean room cylinders of the<strong>ORIGA</strong> SYSTEM PLUS (<strong>OSP</strong>-P)combines the efficiency of thePARKER-<strong>ORIGA</strong> slot sealsystem with vacuum protectionagainst progressive wear <strong>and</strong>contamination from the slidingcomponents. A partial vacuumdrawn between inner <strong>and</strong> outersealing b<strong>and</strong>s prevents emissioninto the clean room. To achieve thenecessary vacuum a suction flow ofca. 4 m 3 /h is required.Loads, Forces <strong>and</strong> MomentsMx = F . lMy = F . lMz = F . lCylinder Effective Max. Moment Max. Load Cushion<strong>Series</strong> Force length[mmØ] at 6 bar [N] Mx [Nm] My [Nm] Mz [Nm] Fz [N] [mm]<strong>OSP</strong>-P16 78 0.45 4 0.5 120 11<strong>OSP</strong>-P25 250 1.5 15 3.0 300 17<strong>OSP</strong>-P32 420 3.0 30 5.0 450 20Load <strong>and</strong> moment data are based on speeds v ≤ 0.2 m/s.The adjacent table shows the maximum values for light, shock-free operationwhich must not be exceeded even in dynamic operation.<strong>ORIGA</strong>25 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Dimensions<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesClean Room <strong>Cylinders</strong>Dimensions (mm)strokestroke + 2 x AVacuum connectionInternal diameterCyl. Ø16 = 4 mmCyl. Ø25 = 6 mmCyl. Ø32 = 6 mmCushioning screwAir connection DNote:End caps are not turnable.Dimension Table (mm)Cylinder A B C D E G H I J K M O S<strong>Series</strong><strong>OSP</strong>-P16 65 14 30 M5 18 M3 9 5.5 69 15 25 31 24<strong>OSP</strong>-P25 100 22 41 G1/8 27 M5 15 9 117 21.5 33 48.5 35<strong>OSP</strong>-P32 125 25.5 52 G1/4 36 M6 15 11.5 152 28.5 40 53.6 38Cylinder T V X Y BW BX BY CF EN FB FH GP ZZ<strong>Series</strong><strong>OSP</strong>-P16 29.6 16.5 36 M4 10.8 1.8 28.5 40 3 30 27.2 25.7 7<strong>OSP</strong>-P25 40.6 25 65 M5 17.5 2.2 40.5 54.5 3.6 40 39.5 41 8<strong>OSP</strong>-P32 45 27 90 M6 20.5 2.5 47.1 68.5 5.5 52 51.7 46.2 10<strong>ORIGA</strong>26 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical Data<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesAtex <strong>Cylinders</strong>The right to introduce technicalmodifications is reservedInformation for ATEX-DirectivesThe rodless pneumatic cylinders ofPARKER-<strong>ORIGA</strong> are the first lineardrive unit, for that Ex range in thegroup of equipment II, Category 2 GDare certified.Technical Data (deviant to the St<strong>and</strong>ard Cylinder )Characteristics Symbol Unit DescriptionAmbient T min°C -10temperature range T max°C +60Pressure quoted as gauge pressureMax. switching Hz 1 (double stroke/s) Basic cylinderfrequency0.5 (1stroke/s) Cylinder with guideOperating pressure range p maxbar Max. 8Max. speed v m/s 3 Basic cylindermax2 Cylinder with guideMediumFiltered, unlibricated compressedair – free from water <strong>and</strong> dirt toISO 8573-1Solids: Class 7 particle size < 40 µmfor GasWater content: pressure dew point+3 °C, class 4, but at least 5 °Cbelow minimum operatingtemperatureNoise level dB (A) 70Information forAluminium:materialssee data sheet "Material"(Contact factory forLubrication:additional details)see security data sheet "Grease foruse in Cylinder with guides"Sealing b<strong>and</strong>s:Corrosion resistant steelFor all other details for dimensions, weights, allowable loads, cushioningdiagrams <strong>and</strong> accessories see data sheets in this catalogue.Equipment Group II Categorie 2GD<strong>Rodless</strong> cylinder:II 2GD c T4 T135°C -10°C≤Ta≤+60°C<strong>Series</strong> Size Stroke range Accessories<strong>OSP</strong>-P Ø 10 to 80 1– 6000 mm MountingsprogramSLIDELINE Ø 16 to 80 1– 6000 mm MountingsprogramComponentsforEX-Areas<strong>Rodless</strong> Cylinderø 10 – 80 mmBasic Cylinder<strong>Series</strong>: <strong>OSP</strong>-P ....ATEXPlain BearingGuide SLIDELINEø 16 – 80 mm<strong>Series</strong>: SL -..ATEX<strong>ORIGA</strong>27 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Dimensions<strong>Rodless</strong>CylinderØ 40 mmfor synchronizedbi-parting movementsType <strong>OSP</strong>-P40-SL-BPFeatures:• Accurate bi-parting movementthrough toothed belt synchronization• Optimum slow speed performance• Increased action force• Anodized aluminium guide rail withprism-form slideway arrangement• Adjustable polymer slide units• Combined sealing system withpolymer <strong>and</strong> felt elements to removedirt <strong>and</strong> lubricate the slideway• Integrated grease nipples for guidelubricationApplications:• Opening <strong>and</strong> closing operations• Gripping of workpieces – outside• Gripping of hollow workpieces– inside• Gripping underneath larger objects• Clamping force adjustable viapressure regulatorCharacteristicsCharacteristics Symbol Unit DescriptionGeneral FeaturesType<strong>Rodless</strong> cylinder for synchronizedbi-parting movements<strong>Series</strong>SystemGuideSynchronizationMountingAmbient temperaturerange<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesBi-Parting <strong>Rodless</strong> <strong>Cylinders</strong><strong>OSP</strong>-PDouble acting with end cushioning.For contactless position sensingSlideline SL40Toothed beltSee drawingsT min°C -10T max °C +60Weight (Mass) kg see page 29MediumFiltered, unlubricated compressed air(other media on request)LubricationSpecial slow speed grease – additionaloil mist lubrication not requiredMaterialToothed BeltSteel-corded polyurethaneBelt wheelAluminiumOperating pressurerangep maxbar 6CushioningElastic buffermiddle positionMax. Speed v maxm/s 0.2Max. stroke of eachmm 500strokeMax. mass per guidekg 25carrierMax. moments onguide carrierlateral moment Mx maxNm 25axial moment My maxNm 46rotating moment Mz maxNm 46For more technical information see pages 32 <strong>and</strong> 35ApplicationsGripping – outsideGripping – insideThe right to introduce technicalmodifications is reservedGripping – underneathDoor opening <strong>and</strong> closing<strong>ORIGA</strong>28 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical Data<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesBi-Parting <strong>Rodless</strong> <strong>Cylinders</strong>Weight (mass) kgCylinder series(Basic cylinder)Weight (Mass) kgAt 0 mm stroke per 100 mm stroke<strong>OSP</strong>-P40-SL-BP 10.334 2.134Function:The <strong>OSP</strong>-P40-SL-BP bidirectionallinear drive is based on the <strong>OSP</strong>-P40rodless pneumatic cylinder <strong>and</strong>adapted SLIDELINE SL40 polymerplain-bearing guides.Two pistons in the cylinder bore areconnected via yokes <strong>and</strong> carriers tothe SLIDELINE guide carriers, whichh<strong>and</strong>le the forces <strong>and</strong> momentsgenerated.The bi-parting movements of the guidecarriers are accurately synchronizedby a recirculating toothed belt.The two pistons are driven from themiddle to the end positions via acommon G1/4 air connection in themiddle of the cylinder, <strong>and</strong> are drivenfrom the end positions to the middlevia an air connection in each end cap.End position cushioning is providedby adjustable air cushioning in the endcaps, <strong>and</strong> middle position cushioningby rubber buffers.Dimensions (mm)Middle position Port size G1/4Port size G1/4 Port size G1/4 End cap can be rotated 4x90° End cap can be rotated 4x90° stroke stroke590 + 2x strokeFor more dimensions see pages 19 <strong>and</strong> 34Air connections:To drive the guide carriers to the middle position:pressurize ports 1 <strong>and</strong> 3.To drive the guide carriers to the end positions:pressurize port 2.<strong>ORIGA</strong>29 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Notes<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> Guides<strong>ORIGA</strong>30 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

<strong>ORIGA</strong>Linear Guides<strong>Series</strong> <strong>OSP</strong>-PNEWContentsDescriptionPageOverview 31-32Plain bearing guide SLIDELINE 33-34Roller guide POWERSLIDE 35-38Aluminium roller guide PROLINE 39-40Recirculating ball bearing guide STARLINE 41-46Heavy duty guide HD 47-50<strong>ORIGA</strong>31 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951FeaturesLinear Guides<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesLinear GuidesSLIDELINEThe cost-effective plain bearing guide for medium loads.Active/ Passive Brake optional.Piston diameters 16 – 80 mmSee pages 33-34adaptive modular systemThe Origa system plus – <strong>OSP</strong> –provides a comprehensive range oflinear guides for the pneumatic <strong>and</strong>electric linear drives.advantages:• takes high loads <strong>and</strong> forces• high precision• smooth operation• can be retrofitted• can be installed in any positionPowerslideThe roller guide for heavy loads<strong>and</strong> hard application conditionsPiston diameters 16 – 50 mmSee pages 35-38PROlineThe compact aluminium roller guide for high loads<strong>and</strong> velocities.Active/ Passive Brake optional.Piston diameters 16 – 50 mmSee pages 39-40StarlineRecirculating ball bearing guide forvery high loads <strong>and</strong> precisionPiston diameters 16 – 50 mmSee pages 41-46HD Heavy duty guideThe ball bushing guide for the heavy loads<strong>and</strong> greatest accuracy.Piston diameters 25 – 50 mmSee pages 47-50The right to introduce technicalmodifications is reserved<strong>ORIGA</strong>32 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical Dataversionsfor pneumatic linear drive:<strong>Series</strong> <strong>OSP</strong>-POption – Integrated Brakespring returnbrakeair connectionbrake piston withfriction liningLoads, Forces <strong>and</strong> Momentsplasticwiperaluminiumguide railIntegrated Brake (optional)for series <strong>OSP</strong>-P25 to <strong>OSP</strong>-P50:• actuated by pressure• released by exhausting <strong>and</strong>spring returnFor further technical data see alsolinear drives <strong>OSP</strong>-P (page 15)oiledfelt wiper<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesPlain Bearing Guide SLIDELINEaluminium guide carriageslide adjustmentelementsgrease nipplepressure plate <strong>and</strong>adjustment screwsPlain BearingGuideSLIDELINE<strong>Series</strong> SL 16 to 80for Linear-drive• <strong>Series</strong> <strong>OSP</strong>-Pfeatures:• aTEX-version (without brake) is alsoavailable(see page 27)• anodized aluminium guide rail withprism-shaped slideway arrangement• adjustable plastic slide elements– optional with integral brake• composite sealing system withplastic <strong>and</strong> felt wiper elements toremove dirt <strong>and</strong> lubricate theslideways.• corrosion resistant version availableon request.• Any length of stroke up to 5500 mm(longer strokes on request)The right to introduce technicalmodifications is reservedTechnical DataThe table shows the maximum permissible values for smooth operation,which should not be exceeded evenunder dynamic conditions.The load <strong>and</strong> moment figures applyto speeds v < 0.2 m/s.* Please note:In the cushioning diagram, add themass of the guide carriage to themass to be cushioned.<strong>Series</strong> For Max. moments Max. Maximum Mass of linear drive Mass *linear [Nm] loads braking force with guide of guidedrive [N] at 6 bar [kg] carriage[N] 1)[kg]with increase perMx My Mz Fy, Fz 0 mm stroke 100 mm strokeSL16 <strong>OSP</strong>-P16 6 11 11 325 – 0.57 0.22 0.23SL 25 <strong>OSP</strong>-P25 14 34 34 675 325 1.55 0.39 0.61SL 32 <strong>OSP</strong>-P32 29 60 60 925 545 2.98 0.65 0.95SL 40 <strong>OSP</strong>-P40 50 110 110 1500 835 4.05 0.78 1.22SL50 <strong>OSP</strong>-P50 77 180 180 2000 1200 6.72 0.97 2.06SL63 <strong>OSP</strong>-P63 120 260 260 2500 – 11.66 1.47 3.32SL80 <strong>OSP</strong>-P80 120 260 260 2500 – 15.71 1.81 3.321)Only with integrated brake:Braking force on dry oil-free surfaceValues are decreased for lubricatedslideways2)Corrosion resistant fixtures availableon request<strong>ORIGA</strong>33 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Features<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesPlain Bearing Guide SLIDELINEDimensions<strong>Series</strong> <strong>OSP</strong>-PStroke + 2 x AStrokeAir connection for brake (Option)For further mounting elements<strong>and</strong> options see accessories.For further information <strong>and</strong>technical data see datasheets for linear drives<strong>OSP</strong>-P (page 15)Air connectionfor brake(Option)Type SL25 to SL80Type SL16Dimension Table (mm)<strong>Series</strong> A B J M Z AA BB DB DD CF EC ED EE EG EJ EK EL EW FF FT FS GG JJ ZZSL 16 65 14 69 31 M4 106 88 – 30 55 36 8 40 30 – – – 22 48 55 14 36 70 8SL 25 100 22 117 40.5 M6 162 142 M5 60 72.5 47 12 53 39 22 6 6 30 64 73.5 20 50 120 12SL 32 125 25.5 152 49 M6 205 185 M5 80 91 67 14 62 48 32 6 6 33 84 88 21 64 160 12SL 40 150 28 152 55 M6 240 220 M5 100 102 77 14 64 50 58 6 6 34 94 98.5 21.5 78 200 12SL 50 175 33 200 62 M6 284 264 M5 120 117 94 14 75 56 81 6 6 39 110 118.5 26 90 240 16SL 63 215 38 256 79 M8 312 292 – 130 152 116 18 86 66 – – – 46 152 139 29 120 260 14SL 80 260 47 348 96 M8 312 292 – 130 169 116 18 99 79 – – – 46 152 165 29 120 260 14Mid-SectionSupport(for versions see pages 71)Mid-section supports are requiredfrom a certain stroke length to preventexces sive deflection <strong>and</strong> vibrationof the line ar drive. The diagramsshow the maxi mum permissibleunsupported length in relation toloading. A distinc tion must be drawnbetween loading 1 <strong>and</strong> loading 2.Deflection of 0.5 mm max. betweensupports is permissible.Note:For speeds v > 0.5 m/s the distancebetween supports should not exceed1 m.Load FLoad Fpermissable unsupported length: SL 16, SL 25, SL 32SL 16 Loading 1SL 16 Loading 2SL 25 Loading 2SL 25 Loading 1SL 32 Loading 2SL 32 Loading 1distance between supports kpermissable unsupported length: SL40, SL50, SL63, SL80SL40 Loading 2SL40 Loading 1SL50 Loading 2SL50 Loading 1SL63 Loading 2SL63 Loading 1SL80 Loading 2SL80 Loading 1distance between supports kloading 1 loading 2<strong>ORIGA</strong>34 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical DataVersionsfor pneumatic linear drive:<strong>Series</strong> <strong>OSP</strong>-Paluminium guide carriagealuminiumclamping railhardenedsteel rail<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesRoller Guide POWERSLIDErollercover withwiper <strong>and</strong>grease nippleRoller GuidePowerslideLoads, Forces <strong>and</strong> Moments<strong>Series</strong> PS 16 to 50for Linear-drive• <strong>Series</strong> <strong>OSP</strong>-Pexample: PS 25/35width ofguide rail(35 mm)Technical DataThe Table shows the maximum permissible values for smooth operation,which should not be exceeded evenunder dynamic conditions.For further information <strong>and</strong> technicaldata see page 15 for linear drives<strong>OSP</strong>-Psize of drive<strong>OSP</strong>-P25* Please note:In the cushioning diagram, add themass of the guide carriage to themass to be cushioned.Features:• anodized aluminium guide carriagewith vee rollers having 2 rows of ballbearings• hardened steel guide rail• Several guide sizes can be used onthe same drive• corrosion resistance versionavailable on request• max. speed v = 3 m/s,• tough roller cover with wiper <strong>and</strong>grease nipple• any length of stroke up to 3500 mm,(longer strokes on request)The right to introduce technicalmodifications is reserved<strong>Series</strong> For linear Max. moments Max. load Mass of linear drive Mass *drive [Nm] [N] with guide of guide[kg]carriagewith increase per [kg]Mx My Mz Fy, Fz 0 mm stroke 100 mm strokePS 16/25 <strong>OSP</strong>-P16 14 45 45 1400 0.93 0.24 0.7PS 25/25 <strong>OSP</strong>-P25 14 63 63 1400 1.5 0.4 0.7PS 25/35 <strong>OSP</strong>-P25 20 70 70 1400 1.7 0.4 0.8PS 25/44 <strong>OSP</strong>-P25 65 175 175 3000 2.6 0.5 1.5PS 32/35 <strong>OSP</strong>-P32 20 70 70 1400 2.6 0.6 0.8PS 32/44 <strong>OSP</strong>-P32 65 175 175 3000 3.4 0.7 1.5PS 40/44 <strong>OSP</strong>-P40 65 175 175 3000 4.6 1.1 1.5PS 40/60 <strong>OSP</strong>-P40 90 250 250 3000 6 1.3 2.2PS 50/60 <strong>OSP</strong>-P50 90 250 250 3000 7.6 1.4 2.3PS 50/76 <strong>OSP</strong>-P50 140 350 350 4000 11.5 1.8 4.91)corrosion resistance version available on request (max. loads <strong>and</strong> moments are 25% lower)<strong>ORIGA</strong>35 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Dimensions<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesRoller Guide POWERSLIDEDimensions<strong>Series</strong> <strong>OSP</strong>-PStroke + 2 x AStrokeThreaded holes Z x EF deepDimension Table (mm)<strong>Series</strong> A B Z AA BB CC CF EE EF EG FF FS FT GG JJPS 16/25 65 14 4xM6 120 65 47 80 49 12 35 80 21 64 64 100PS 25/25 100 22 6xM6 145 90 47 79.5 53 11 39 80 20 73.5 64 125PS 25/35 100 22 6xM6 156 100 57 89.5 52.5 12.5 37.5 95 21.5 73 80 140PS 25/44 100 22 6xM8 190 118 73 100 58 15 39 116 26 78.5 96 164PS 32/35 125 25.5 6xM6 156 100 57 95.5 58.5 12.5 43.5 95 21.5 84.5 80 140PS 32/44 125 25.5 6xM8 190 118 73 107 64 15 45 116 26 90 96 164PS 40/44 150 28 6xM8 190 118 73 112.5 75 15 56 116 26 109.5 96 164PS 40/60 150 28 6xM8 240 167 89 122.5 74 17 54 135 28.5 108.5 115 216PS 50/60 175 33 6xM8 240 167 89 130.5 81 17 61 135 28.5 123.5 115 216PS 50/76 175 33 6xM10 280 178 119 155.5 93 20 64 185 39 135.5 160 250<strong>ORIGA</strong>36 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical Data<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesRoller Guide POWERSLIDELoad FLoad Fpermissable unsupported length: PS 16/25, PS 25/25, PS 25/35, PS 25/44PS 16/25 Loading 1PS 16/25 Loading 2PS 25/25 Loading 1PS 25/25 Loading 2PS 25/35 Loading 1PS 25/35 Loading 2PS 25/44 Loading 1PS 25/44 Loading 2PS 32/35 Loading 1PS 32/35 Loading 2PS 32/44 Loading 1PS 32/44 Loading 2distance between supports kpermissable unsupported length: PS 32/35, PS 32/44Mid-SectionSupport(for versions, see accessories)Mid section supports are requiredfrom a certain stroke length to preventexces sive deflection <strong>and</strong> vibration ofthe linear drive. The diagramsshow the maximum permissibleunsupported length in relation toloading.A distinction must be drawn betweenloading 1 <strong>and</strong> loading 2.Deflection of 0.5 mm max. betweensupports is permissible.NoteFor speeds v > 0.5 m/s the distancebetween supports should not exceed1m.distance between supports kloading 1 loading 2permissable unsupported length: PS 40/44, PS 40/60Load FPS 40/44 Loading 1PS 40/44 Loading 2PS 40/60 Loading 1PS 40/60 Loading 2distance between supports kLoad Fpermissable unsupported length: PS 50/60, PS 50/76PS 50/60 Loading 1PS 50/60 Loading 2PS 50/76 Loading 1PS 50/76 Loading 2distance between supports k<strong>ORIGA</strong>37 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical DataService lifeCalculation of service life is achievedin two stages:1. Calculation of load factor L F<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesRoller Guide POWERSLIDE• Determination of load factor L Ffrom the loads to be carried• Calculation of service life in kmMx My Mz FyL F= + + + +Mx maxMy maxMzmaxFy maxFzFz maxwith combined loads, L Fshould not exceed the value 1.LubricationFor maximum system life, lubricationof the rollers must be maintained atall times.Only high quality Lithium basedgreases should be used.Lubrication intervals are dependenton environmental conditions(temperature, running speed, greasequality etc.) therefore the installationshould be regularly inspected.2. Service life calculation• for PS 16/25, PS 25/25, PS 25/35, Service life [km] =<strong>and</strong> PS 32/35• for PS 25/44, PS 32/44, PS 40/44, Service life [km] =PS 40/60 <strong>and</strong> PS 50/60:• for PS 50/76: Service life [km] =106(L F+ 0,02) 3314(L F+ 0,015) 3680(L F+ 0,015) 3<strong>ORIGA</strong>38 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical DataVersionsfor pneumatic linear drive:<strong>Series</strong> <strong>OSP</strong>-Pwiper coverlateral felt scraperaluminiumguide railground <strong>and</strong>calibrated tracks<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesAluminum Roller Guide PROLINEaluminium carriagealuminiumroller shoecrosswise arrangedrollers on needle bearingsplastic wiperplastic cap plugsAluminiumRoller GuidePROLINE<strong>Series</strong> PL 16 to 50for Linear-drive• <strong>Series</strong> <strong>OSP</strong>-PTechnical DataThe table shows the maximal permissibleloads. If multiple moments <strong>and</strong>forces act upon the cylinder simultaneously,the following equation applies:Mx My Mz Fy+ + + +Mx maxMymaxMzmaxFy maxFzFz max≤ 1The sum of the loads should not exceed >1.With a load factor of less than 1, service lifeis 8000 kmThe table shows the maximum permissiblevalues for light, shock-freeoperation, which must not be exceededeven under dynamic conditions.Option – Integrated Brakereturn springcover plate for return springbrakeair connectionbrake liningbrake pistonFeatures:• High precision• High velocities (10 m/s)• Smooth operation - low noise• Integated wiper system• Long life lubrication• Compact dimensions - compatibleto Slideline plain bearing guide• Any length of stroke up to 3750 mmIntegrated Brake (optional)for <strong>Series</strong> <strong>OSP</strong>-P25 to <strong>OSP</strong>-P50:• Actuated by pressurization• Release by depressurization <strong>and</strong>spring actuationLoads, Forces <strong>and</strong> MomentsThe right to introduce technicalmodifications is reserved<strong>Series</strong> For Max. Max. Maximum Mass of linear drive Mass *linear moments loads braking force with guide [kg] guidedrive [Nm] [N] at 6 bar with increase per carriage[N] 1) 0 mm 100 mm [kg]Mx My Mz Fy, Fz stroke strokePL 16 <strong>OSP</strong>-P16 8 12 12 542 – 0.55 0.19 0.24PL 25 <strong>OSP</strong>-P25 16 39 39 857 on request 1.65 0.40 0.75PL 32 <strong>OSP</strong>-P32 29 73 73 1171 on request 3.24 0.62 1.18PL 40 <strong>OSP</strong>-P40 57 158 158 2074 on request 4.35 0.70 1.70PL 50 <strong>OSP</strong>-P50 111 249 249 3111 on request 7.03 0.95 2.501)Only for version with brake:Braking surface dry – oiled surface reduces the effective braking force.* Please note:The mass of the carriage has to beadded to the total moving masswhen using the cushioning diagram.<strong>ORIGA</strong>39 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Dimensions & Technical Data<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesAluminum Roller Guide PROLINEDimension Table (mm) <strong>Series</strong> <strong>OSP</strong>-P PL16, PL25, PL32, PL40, PL50Stroke + 2x AStrokeAir connection for brake(Option)Type PL25 to PL50Type PL16Dimension Table (mm) <strong>Series</strong> <strong>OSP</strong>-P PL16,PL25, PL32, PL40, PL50<strong>Series</strong> A B J M Z AA BB DB DD CF EC EE EG EJ EK EL FF FS FT GG JJ ZZPL16 65 14 69 31 M4 98 88 - 30 55 23 40 30 - - - 48 17 55 36 70 8PL25 100 22 117 40.5 M6 154 144 M5 60 72.5 32.5 53 39 22 6 6 64 23 73.5 50 120 12PL32 125 25.5 152 49 M6 197 187 M5 80 91 42 62 48 32 6 6 84 25 88 64 160 12PL40 150 28 152 55 M6 232 222 M5 100 102 47 64 50.5 58 6 6 94 23.5 98.5 78 200 12PL50 175 33 200 62 M6 276 266 M5 120 117 63 75 57 81 6 6 110 29 118.5 90 240 16Mid-Section Support(For versions, see page 71)Mid-section supports are requiredfrom a certain stroke length to preventexcessive deflection <strong>and</strong> vibrationof the linear drive. The diagramsshow the maximum permissibleunsupported length in relation toloading. A distinction must be drawnbetween loading 1 <strong>and</strong> loading 2.Deflection of 0.5 mm max. betweensupports is permissible. Loading 2Loading 1Note:For speeds v > 0.5 m/s the distancebetween supports should not exceed1 m.Permissible Unsupported Length PL16, PL25, PL32, PL40 und PL50Load F [N]PL50 Loading 1PL50 Loading 2PL40 Loading 1PL40 Loading 2PL32 Loading 1PL32 Loading 2PL25 Loading 1PL25 Loading 2PL16 Loading 1PL16 Loading 2 Distance between supports k [m]<strong>ORIGA</strong>40 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical DataVersionsfor pneumatic linear drive:<strong>Series</strong> <strong>OSP</strong>-Pintegratedwipergrease nipple<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesRecirculating Ball Bearing Guide STARLINEaluminium carriageRecirculatingBall BearingGuideSTARLINEpolished,hardened steelguide railguide carriage<strong>Series</strong> STL 16 to 50for Linear Drive <strong>Series</strong> <strong>OSP</strong>-PThe right to introduce technicalmodifications is reservedLoads, Forces <strong>and</strong> MomentsTechnical DataThe table shows the maximumpermissible loads. If multiple moments<strong>and</strong> forces act upon the cylindersimultaneously, the following equationapplies:Mx My Mz Fy Fz+ + + + ≤1Mx maxMymaxMzmaxFy 1maxFz maxThe sum of the loads should notexceed >1<strong>Series</strong> For Max. moments Max. loads Mass of linear drive Mass **linear drive [Nm] [N] with guide guide[kg]carriagewith increase per [kg]Mx My Mz Fy Fz 0 mm stroke 100 mm strokeSTL16 <strong>OSP</strong>-P16 15 30 30 1000 1000 0.598 0.210 0.268STL25 <strong>OSP</strong>-P25 50 110 110 3100 3100 1.733 0.369 0.835STL32 <strong>OSP</strong>-P32 62 160 160 3100 3100 2.934 0.526 1.181STL40 <strong>OSP</strong>-P40 150 400 400 4000 7500 4.452 0.701 1.901STL50 <strong>OSP</strong>-P50 210 580 580 4000 7500 7.361 0.936 2.880The table shows the maximumpermissible values for light, shock-freeoperation, which must not beexceeded even under dynamicconditions.Features:• Polished <strong>and</strong> hardened steel guiderail• For very high loads in all directions• High precision• Integrated wiper system• Integrated grease nipples• Any length of stroke up to 3700 mm• Anodized aluminium guide carriage– dimensions compatible with <strong>OSP</strong>guides SLIDELINE <strong>and</strong>PROLINE• Installation height (STL16 - 32)compatible with <strong>OSP</strong> guidesSLIDELINE <strong>and</strong> PROLINE• Maximum speedSTL16: v = 3 m/sSTL25 to 50: v = 5 m/s** Please note:The mass of the carriage has to beadded to the total moving masswhen using the cushioningdiagram.<strong>ORIGA</strong>41 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Dimensions<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesRecirculating Ball Bearing Guide STARLINEDimensions <strong>Series</strong> <strong>OSP</strong>-P STL16 to STL 50stroke + 2x AstrokeType STL25 to PL50Type STL16Dimension Table (mm) <strong>Series</strong> <strong>OSP</strong>-P STL16 to STL50<strong>Series</strong> A B J M Z AA BB CF DD EC EE EG FF FS FT GG JJ ZZSTL16 65 14 69 31 M4 93 90 55 30 15 40 24.6 48 18 55 36 70 8STL25 100 22 117 40.5 M6 146.6 144 72.5 60 15 53 36.2 64 23.2 73.5 50 120 12STL32 125 25.5 152 49 M6 186.6 184 91 80 15 62 42.2 84 26.2 88 64 160 12STL40 150 28 152 55 M6 231 226 102 100 20 72 51.6 94 28.5 106.5 78 200 12STL50 175 33 200 62 M6 270.9 266 117 120 23 85 62.3 110 32.5 128.5 90 240 16<strong>ORIGA</strong>42 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical Data<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesRecirculating Ball Bearing Guide STARLINEPermissible Unsupported Length STL16 to STL50Loading 1 – Top carrier1 = <strong>OSP</strong>-P STL 162 = <strong>OSP</strong>-P STL 253 = <strong>OSP</strong>-P STL 324 = <strong>OSP</strong>-P STL 405 = <strong>OSP</strong>-P STL 50Mid-Section Support(For versions, see pages 76-77)Mid-section supports are requiredfrom a certain stroke length to preventexcessive deflection <strong>and</strong> vibrationof the linear drive. The diagramsshow the maximum permissible unsupportedlength in relation to loading.A distinction must be drawn betweenloading 1 <strong>and</strong> loading 2. Deflectionof 0.5 mm max. between supports ispermissible.Load FLoading 1Top carrierLoading 2Side carrier Distance between supportsPermissible Unsupported Length STL16 to STL50Loading 2 – Side carrier1 = <strong>OSP</strong>-P STL 162 = <strong>OSP</strong>-P STL 253 = <strong>OSP</strong>-P STL 324 = <strong>OSP</strong>-P STL 405 = <strong>OSP</strong>-P STL 50Note:For speeds v > 0.5 m/s the distancebetween supports should not exceed1 m.Load F Distance between supports<strong>ORIGA</strong>43 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical DataVariable StopThe variable stop Type VS providessimple stroke limitation.It can be retrofitted <strong>and</strong> positionedanywhere along the stroke length.For every cylinder diameter two typesof shock absorber are available– see “Shock Absorber Selection”below.Mid-section supports <strong>and</strong> magneticswitches can still be fitted on the sameside as the variable stop.Depending on the application, twovariable stops can be fitted if required.Variable Stop Type VS16 to VS50Arrangement with two variable stops<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesRecirculating Ball Bearing Guide STARLINEShock absorber holderwith shock absorberStopShock absorberwith plastic capShock Absorber SelectionThe shock absorber is selected independence on the mass <strong>and</strong> speed.The mass of the carrier itself must betaken into account.Shock Absorber Selection in Dependence on Mass <strong>and</strong> Speedfor <strong>Series</strong> <strong>OSP</strong>-STL16Speed [m/s]Type SA10Type SA10SThe values relate to an effectivedriving force of 78 N (6 bar) Mass [kg]Shock Absorber Selection in Dependence on Mass <strong>and</strong> Speedfor <strong>Series</strong> <strong>OSP</strong>-STL25Speed [m/s]Type SA12Typ e SA12SThe values relate to an effectivedriving force of 250 N (6 bar) Mass [kg]<strong>ORIGA</strong>44 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical Data<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesRecirculating Ball Bearing Guide STARLINEShock Absorber Selection in Dependence on Mass <strong>and</strong> Speedfor <strong>Series</strong> <strong>OSP</strong>-STL32Speed [m/s]Type SA14Type SA14S Mass [kg]The values relate to an effectivedriving force of 420 N (6 bar)Shock Absorber Selection in Dependence on Mass <strong>and</strong> Speedfor <strong>Series</strong> <strong>OSP</strong>-STL40Speed [m/s]Type SA20Type SA20S Mass [kg]The values relate to an effectivedriving force of 640 N (6 bar)Shock Absorber Selection in Dependence on Mass <strong>and</strong> Speedfor <strong>Series</strong> <strong>OSP</strong>-STL50Speed [m/s]Type SAI25Type SAI25S Mass [kg]The values relate to an effectivedriving force of 1000 N (6 bar)<strong>ORIGA</strong>45 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Dimensions & Ordering Information<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesRecirculating Ball Bearing Guide STARLINEDimensions – Variable Stop Type VS16 to VS50Dimension Table (mm) – Variable Stop Type VS16 to VS50<strong>Series</strong> Type A B C D E G H K L M N P SW1 SW2<strong>OSP</strong>-STL16 VS16 30 14 25 33 30 28 38 16.2 25.5 20.5 30 M10x1 4 12.5<strong>OSP</strong>-STL25 VS25 40 30 50 41.5 37 33 43 18 31.5 23 39 M12x1 5 16<strong>OSP</strong>-STL32 VS32 60 40 50 45.5 42 35 45 19 35.5 25 48 M14x1.5 5 17<strong>OSP</strong>-STL40 VS40 84 52 60 64 59 48 63 25.6 50 34 58.6 M20x1.5 5 24<strong>OSP</strong>-STL50 VS50 84 - 60 75 69 55 70 26.9 57 38 66.9 M25x1.5 5 30Order Information – Variable Stop Type VS16 to VS50Item 2Shock absorber holdercomplete with fittings– without shock absorberItem 1Stop completewith fittingsItem 3Shock absorberwith plastic capOrder Instructions – Variable Stop Type VS16 to VS50Item DescriptionSizeVS16 VS25 VS32 VS40 VS50Type Order No. Type Order No. Type Order No. Type Order No. Type Order No.1 Stop, complete – 21196 – 21197 – 21198 – 21199 – 212002 Shock absorber – 21201 – 21202 – 21203 – 21204 – 21205holder, complete3 * Shock absorber, st<strong>and</strong>ard SA10 7718 SA12 7706 SA14 7708 SA20 7710 SAI25 7712Shock absorber, version S SA10S 7721 SA12S 7707 SA14S 7709 SA20S 7711 SAI25S 7835* Shock absorber with plastic cap<strong>ORIGA</strong>46 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Technical DataVersion with pneumatic linear drive series <strong>OSP</strong>-Pintegrated wiperaluminium carriage<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesHeavy Duty Guide HDHeavy Duty-GuideHDT-nut mountingguide carriagepolished. hardened steel guide railmagnet for electric sensingwith magnetic switches<strong>Series</strong> HD 25 to 50for Linear Drive <strong>Series</strong> <strong>OSP</strong>-PLoads. Forces <strong>and</strong> Moments Features:• Guide system:4-row recirculating ball bearing guide• Polished <strong>and</strong> hardened steel guiderail• For highest loads in all directions• Highest precision• Integrated wiper system• Integrated grease nipples• Any lengths of stroke up to3700 mm(longer strokes on request)• Anodized aluminium guide carriage- dimensions compatible with<strong>OSP</strong> guide GUIDELINE• Maximum speed v = 5 m/sTechnical DataThe table shows the maximumpermissible loads. If multiple moments<strong>and</strong> forces act upon the cylindersimultaneously, the following equationapplies:The table shows the maximumpermissible values for light, shockfreeoperation. which must notbe exeeded even under dynamicconditions.The right to introduce technicalmodifications is reservedMx My Mz Fy+ + + +Mx maxMy maxMzmaxFy maxThe sum of the loads should not >1FzFz max≤1* Please note:The mass of the carriage does nothave to be added to the total movingmass when using the cushioningdiagram.<strong>Series</strong> for Max. moments Max. loads Mass of the linear drive Mass *linear [Nm] [N] with guide guidedrive [kg] carriagewith increase per [kg]Mx My Mz Fy Fz 0 mm stroke 100 mm strokeHD 25 <strong>OSP</strong>-P25 260 320 320 6000 6000 3.065 0.924 1.289HD 32 <strong>OSP</strong>-P32 285 475 475 6000 6000 4.308 1.112 1.367HD 40 <strong>OSP</strong>-P40 800 1100 1100 15000 15000 7.901 1.748 2.712HD 50 <strong>OSP</strong>-P50 1100 1400 1400 18000 18000 11.648 2.180 3.551<strong>ORIGA</strong>47 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com

Catalog 0951Dimensions<strong>OSP</strong>-P <strong>Pneumatic</strong> <strong>Rodless</strong> <strong>Cylinders</strong> <strong>and</strong> GuidesHeavy Duty Guide HDDimensions<strong>Series</strong> <strong>OSP</strong>-Pstroke + 2 x Astroke Note:The HD heavy duty guide must bemounted on a flat surface for its entirelength.If T-grooves or T-bolts are used, thedistance between them should notexeed 100 mm.Variable StopType VS25 to VS50The variable stop provides simplestroke limitation <strong>and</strong> can be suppliedmounted on the right or left, asrequired.For further information see followingdata sheets:For dimensions <strong>and</strong> order instructionssee page 50For shock absorber selection seepages 44-45Incremental displacementmeasuring system<strong>ORIGA</strong>-Sensoflex<strong>Series</strong> SFI-pluscan be supplied mounted on the rightor left, as required.For further information see page 97Arrangement of magnetic switches:Magnetic switches can be fittedanywhere on either side.For further information see followingdata sheets:Magnetic Switches see pages 84, 86<strong>and</strong> 88-94Cable Cover see page 87Shock absorberStopShock absorber holderMeasuring scaleSensingheadOption: Cable coverMagnetic switch<strong>ORIGA</strong>48 <strong>Parker</strong> Hannifin Corporation<strong>Parker</strong>-OrigaGlendale Heights, Illinoiswww.parkeroriga.com