PUB02-04 - SOCON Sonar Control Kavernenvermessung GmbH

PUB02-04 - SOCON Sonar Control Kavernenvermessung GmbH

PUB02-04 - SOCON Sonar Control Kavernenvermessung GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

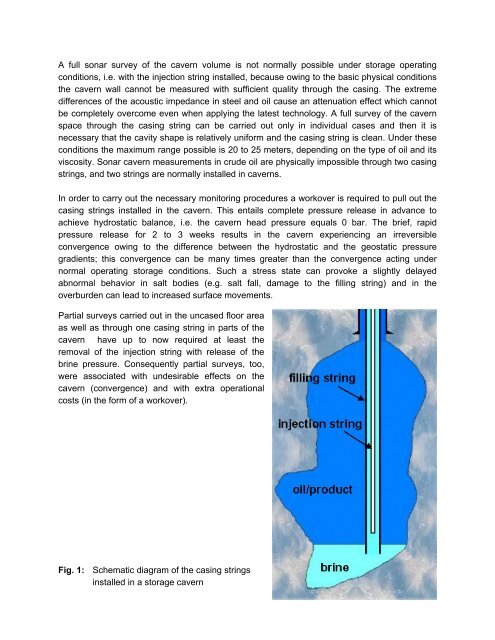

A full sonar survey of the cavern volume is not normally possible under storage operatingconditions, i.e. with the injection string installed, because owing to the basic physical conditionsthe cavern wall cannot be measured with sufficient quality through the casing. The extremedifferences of the acoustic impedance in steel and oil cause an attenuation effect which cannotbe completely overcome even when applying the latest technology. A full survey of the cavernspace through the casing string can be carried out only in individual cases and then it isnecessary that the cavity shape is relatively uniform and the casing string is clean. Under theseconditions the maximum range possible is 20 to 25 meters, depending on the type of oil and itsviscosity. <strong>Sonar</strong> cavern measurements in crude oil are physically impossible through two casingstrings, and two strings are normally installed in caverns.In order to carry out the necessary monitoring procedures a workover is required to pull out thecasing strings installed in the cavern. This entails complete pressure release in advance toachieve hydrostatic balance, i.e. the cavern head pressure equals 0 bar. The brief, rapidpressure release for 2 to 3 weeks results in the cavern experiencing an irreversibleconvergence owing to the difference between the hydrostatic and the geostatic pressuregradients; this convergence can be many times greater than the convergence acting undernormal operating storage conditions. Such a stress state can provoke a slightly delayedabnormal behavior in salt bodies (e.g. salt fall, damage to the filling string) and in theoverburden can lead to increased surface movements.Partial surveys carried out in the uncased floor areaas well as through one casing string in parts of thecavern have up to now required at least theremoval of the injection string with release of thebrine pressure. Consequently partial surveys, too,were associated with undesirable effects on thecavern (convergence) and with extra operationalcosts (in the form of a workover).Fig. 1: Schematic diagram of the casing stringsinstalled in a storage cavern