Linear grille fixed blades - Mp3

Linear grille fixed blades - Mp3

Linear grille fixed blades - Mp3

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

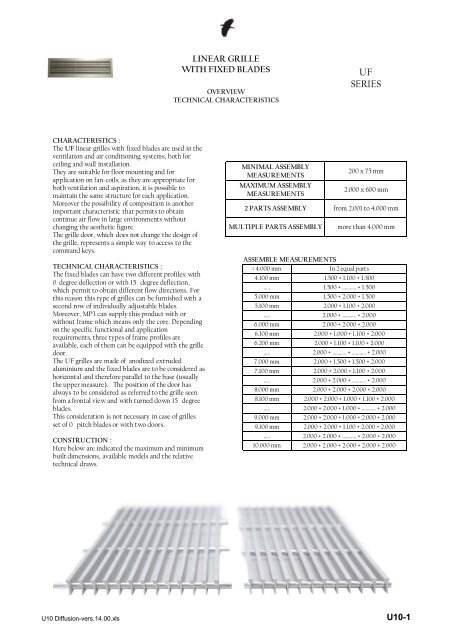

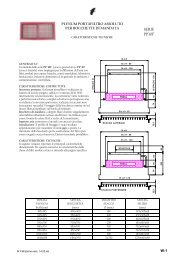

LINEAR GRILLEWITH FIXED BLADESOVERVIEWTECHNICAL CHARACTERISTICSUFSERIESCHARACTERISTICS :The UF linear <strong>grille</strong>s with <strong>fixed</strong> <strong>blades</strong> are used in theventilation and air conditioning systems, both forceiling and wall installation.They are suitable for floor mounting and forapplication on fan-coils; as they are appropriate forboth ventilation and aspiration, it is possible tomaintain the same structure for each application.Moreover the possibility of composition is anotherimportant characteristic that permits to obtaincontinue air flow in large environments withoutchanging the aesthetic figure.The <strong>grille</strong> door, which does not change the design ofthe <strong>grille</strong>, represents a simple way to access to thecommand keys.TECHNICAL CHARACTERISTICS :The <strong>fixed</strong> <strong>blades</strong> can have two different profiles: with0 degree deflection or with 15 degree deflection,which permit to obtain different flow directions. Forthis reason this type of <strong>grille</strong>s can be furnished with asecond row of individually adjustable <strong>blades</strong>.Moreover, MP3 can supply this product with orwithout frame which means only the core. Dependingon the specific functional and applicationrequirements, three types of frame profiles areavailable, each of them can be equipped with the <strong>grille</strong>door.The UF <strong>grille</strong>s are made of anodized extrudedaluminium and the <strong>fixed</strong> <strong>blades</strong> are to be considered ashorizontal and therefore parallel to the base (usuallythe upper measure). The position of the door hasalways to be considered as referred to the <strong>grille</strong> seenfrom a frontal view and with turned down 15 degree<strong>blades</strong>.This consideration is not necessary in case of <strong>grille</strong>sset of 0 pitch <strong>blades</strong> or with two doors.CONSTRUCTION :Here below are indicated the maximum and minimumbuilt dimensions, available models and the relativetechnical draws.MINIMAL ASSEMBLYMEASUREMENTSMAXIMUM ASSEMBLYMEASUREMENTS200 x 75 mm2.000 x 600 mm2 PARTS ASSEMBLY from 2.001 to 4.000 mmMULTIPLE PARTS ASSEMBLYmore than 4.000 mmASSEMBLE MEASUREMENTS< 4.000 mm In 2 equal parts4.100 mm 1.500 + 1.100 + 1.500….. 1.500 + ……….. + 1.5005.000 mm 1.500 + 2.000 + 1.5005.100 mm 2.000 + 1.100 + 2.000….. 2.000 + ……….. + 2.0006.000 mm 2.000 + 2.000 + 2.0006.100 mm 2.000 + 1.000 + 1.100 + 2.0006.200 mm 2.000 + 1.100 + 1.100 + 2.000….. 2.000 + ……….. + ……….. + 2.0007.000 mm 2.000 + 1.500 + 1.500 + 2.0007.100 mm 2.000 + 2.000 + 1.100 + 2.000….. 2.000 + 2.000 + ……….. + 2.0008.000 mm 2.000 + 2.000 + 2.000 + 2.0008.100 mm 2.000 + 2.000 + 1.000 + 1.100 + 2.000….. 2.000 + 2.000 + 1.000 + ……….. + 2.0009.000 mm 2.000 + 2.000 + 1.000 + 2.000 + 2.0009.100 mm 2.000 + 2.000 + 1.100 + 2.000 + 2.000….. 2.000 + 2.000 + ……….. + 2.000 + 2.00010.000 mm 2.000 + 2.000 + 2.000 + 2.000 + 2.000U10 Diffusion-vers.14.00.xls U10-1

LINEAR GRILLEWITH FIXED BLADESCONSTRUCTIONUFSERIESUF 0Grille with horizontal <strong>fixed</strong> <strong>blades</strong> with deflection angle 0°with low frame.UF 1Grille with horizontal <strong>fixed</strong> <strong>blades</strong> with deflection angle 15°with low frameUF 0 AHGrille with horizontal <strong>fixed</strong> <strong>blades</strong> with deflection angle 0°with high frame and back adjustable vertical <strong>blades</strong>.UF 1 AHGrille with horizontal <strong>fixed</strong> <strong>blades</strong> with deflection angle 15°with high frame and back adjustable vertical <strong>blades</strong>.UF 0 AGrille with horizontal <strong>fixed</strong> <strong>blades</strong> with deflection angle 0 with high frame.UF 1 AGrille with horizontal <strong>fixed</strong> <strong>blades</strong> with deflection angle 15 with high frame.U10 Diffusion-vers.14.00.xls U10-2

LINEAR GRILLEWITH FIXED BLADESCONSTRUCTIONUFSERIESUF 0 AHGrille with horizontal <strong>fixed</strong> <strong>blades</strong> with deflection angle 0° with high frame and backadjustable vertical <strong>blades</strong>.UF 1 AHGrille with <strong>fixed</strong> horizontal <strong>blades</strong>, deflection angle 15° with high frame and internalgroup of adjustable vertical <strong>blades</strong>.UF 0 A P1UF 1 A PDUF 1 A PSGrille with horizontal <strong>fixed</strong> <strong>blades</strong> and deflection angle0°/15° , with high frame and <strong>grille</strong> door. In case of <strong>fixed</strong><strong>blades</strong> with deflection angle 15° the position of the dooron the left or right side is to be considered as seen from afrontal point of view with turned down deflection.UF 0 B P1UF 1 B PDUF 1 B PSGrille with horizontal <strong>fixed</strong> <strong>blades</strong> and deflection angle0°/15° , with low frame and <strong>grille</strong> door. In case of <strong>fixed</strong><strong>blades</strong> with deflection angle 15° the position of the dooron the left or right side is to be considered as seen from afrontal point of view with turned down deflection.UF 0 A P2UF 1 A P2Grille with <strong>fixed</strong> horizontal <strong>blades</strong> with deflection angleof 0° / 15°, with high frame and double <strong>grille</strong>d gate.UF 0 B P2UF 1 B P2Grille with <strong>fixed</strong> horizontal bars, with deflection angle0°/ 15°, with flat frame and double <strong>grille</strong>d gate .U10 Diffusion-vers.14.00.xls U10-3

LINEAR GRILLEWITH FIXED BLADESWITHOUT FRAMEPERFORMANCEUF0SERIESQ = 100 [m 3 /h] Q = 200 [m 3 /h] Q = 300 [m 3 /h] Q = 400 [m 3 /h] Q = 500 [m 3 /h] Q = 600 [m 3 /h]L x H T Δpt Lw T Δpt Lw T Δpt Lw T Δpt Lw T Δpt Lw T Δpt Lw[m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa300 2,9 1,9

LINEAR GRILLEWITH FIXED BLADESWITHOUT FRAMEPERFORMANCEUF1SERIESQ = 100 [m 3 /h] Q = 200 [m 3 /h] Q = 300 [m 3 /h] Q = 400 [m 3 /h] Q = 500 [m 3 /h] Q = 600 [m 3 /h]L x H T Δpt Lw T Δpt Lw T Δpt Lw T Δpt Lw T Δpt Lw T Δpt Lw[m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa300 2,8 1,9

LINEAR GRILLEWITH FIXED BLADESWITH FRAMEPERFORMANCEUF0SERIESQ = 100 [m 3 /h] Q = 200 [m 3 /h] Q = 300 [m 3 /h] Q = 400 [m 3 /h] Q = 500 [m 3 /h] Q = 600 [m 3 /h]L x H T Δpt Lw T Δpt Lw T Δpt Lw T Δpt Lw T Δpt Lw T Δpt Lw[m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa300 4,1 7,7 30400 3,5 4,1 22 7,0 16,2 42500 3,1 2,5

LINEAR GRILLEWITH FIXED BLADESWITH FRAMEPERFORMANCEUF1SERIESQ = 100 [m 3 /h] Q = 200 [m 3 /h] Q = 300 [m 3 /h] Q = 400 [m 3 /h] Q = 500 [m 3 /h] Q = 600 [m 3 /h]L x H T Δpt Lw T Δpt Lw T Δpt Lw T Δpt Lw T Δpt Lw T Δpt Lw[m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa [m] [Pa] dBa300 4,0 7,7 30400 3,4 4,1 22 6,8 16,2 42500 3,0 2,5

LINEAR GRILLEWITH FIXED BLADESHOW TO ORDERUFSERIESUF01--R--ABAH<strong>Linear</strong> <strong>grille</strong> <strong>fixed</strong> <strong>blades</strong>0° deflection15° deflectionanodizedpainted RAL 9010without framestandard frameflat framefrontal fix <strong>blades</strong>deflection <strong>blades</strong> behind-- without <strong>grille</strong> doorP with <strong>grille</strong> door-- without <strong>grille</strong> door1 one <strong>grille</strong> doorD right <strong>grille</strong> door (UF1)S left <strong>grille</strong> door (UF1)2 two <strong>grille</strong> doorsbaseheightUF0RBP 2 800 200U10 Diffusion-vers.14.00.xls U10-8

VENTILATION GRILLESACCESSORIESUMSERIESPP30Plenum with rear connectioninsulated and non insulated versionPP30Plenum with lateral connectioninsulated and non insulated versionSCControl damperUTCCounterframeU-FIXQuick installingU10 Diffusion-vers.14.00.xls U10-9

PLENUM FORVENTILATION GRILLES PP 30SERIESTECHNICAL CHARACTERISTICSL H A N° SPP 30200 100 140 1 80300 100 140 1 80400 100 140 1 80500 100 140 2 80600 100 140 2 80700 100 140 2 80800 100 140 2 80200 150 180 1 127300 150 180 1 127400 150 180 1 127500 150 180 2 127600 150 180 2 127700 150 180 2 127800 150 180 2 127900 150 180 2 1271000 150 180 2 127200 200 220 1 150300 200 220 1 150400 200 220 1 180500 200 220 1 180600 200 220 2 150700 200 220 2 150800 200 220 2 150900 200 220 2 1801000 200 220 2 180200 250 220 1 200300 250 220 1 200400 250 220 1 200500 250 220 1 200600 250 220 2 150700 250 220 2 150800 250 220 2 150900 250 220 2 1801000 300 220 2 180300 300 260 1 250400 300 260 1 250500 300 260 1 250Plenum for ventilation <strong>grille</strong>s600 300 260 2 160rear connection700 300 260 2 160800 300 260 2 160 -- not insulated900 300 260 2 200 I insulated1000 300 260 2 200400 400 260 1 350 base500 400 260 1 350600 400 260 2 160height700 400 260 2 160800 400 260 2 160900 400 260 2 200 PP30 I 200 1001000 400 260 2 200 For S = 125 - 160 - 200 - 250 connection in ABS - steel on request515 515 150 1 250 For other diameters connection in steel563 563 270 1 350U10 Diffusion-vers.14.00.xls U10-10

PLENUM FORVENTILATION GRILLES PP 40SERIESTECHNICAL CHARACTERISTICSL H A B C N° SPP 40200 100 200 70 80 1 100300 100 250 95 80 1 150400 100 250 95 80 1 150500 100 300 120 80 1 200600 100 300 120 80 1 200700 100 350 145 80 1 250800 100 350 145 80 1 250200 150 250 95 80 1 150300 150 300 120 80 1 200400 150 300 120 80 1 200500 150 350 145 80 1 250600 150 350 145 80 1 250700 150 350 145 80 1 250800 150 415 178 80 1 315900 150 415 178 80 1 3151000 150 415 178 80 1 315200 200 250 95 80 1 150300 200 250 95 80 1 150400 200 350 145 80 1 250500 200 350 145 80 1 250600 200 415 178 80 1 315700 200 415 178 80 1 315800 200 415 178 80 1 315900 200 450 195 80 1 3501000 200 450 195 80 1 350200 250 300 120 80 1 200300 250 300 120 80 1 200400 250 350 145 80 1 250500 250 350 145 80 1 250600 250 415 178 80 1 315700 250 415 178 80 1 315800 250 415 178 80 1 315900 250 450 195 80 1 3501000 250 450 195 80 1 350300 300 350 145 80 1 250400 300 415 178 80 1 315500 300 450 195 80 1 350Plenum for ventilation <strong>grille</strong>s600 300 450 195 80 1 350lateral connection700 300 450 195 80 1 350800 300 450 195 80 1 350 -- not insulated900 300 500 220 80 1 400 I insulated1000 300 500 220 80 1 400400 400 450 195 80 1 350base500 400 450 195 80 1 350600 400 450 195 80 1 350 height700 400 450 195 80 1 350800 400 450 195 80 1 350900 400 500 220 80 1 400 PP40 I 200 1001000 400 500 220 80 1 400 For S = 125 - 160 - 200 - 250 connection in ABS - steel on request515 515 320 145 50 1 250 For other diameters connection in steel563 563 450 195 80 1 350U10 Diffusion-vers.14.00.xls U10-11

CONTROL DAMPERSOVERVIEWTECHNICAL CHARACTERISTICSSCSERIESOVERVIEW AND CHARACTERISTICS :The contrast control dampers of SC series can be fitted to UF KG UM UR GI KN e CR-KN series . They are held in place byspecial patented clips, designed both for fitting the damper to the grill and for fitting it on a false frame.The SC series dampers are made entirely of galvanised steel and have a mechanism for moving and closing all the <strong>blades</strong>simultaneously.This mechanism is a simple longitudinal plate that links all the <strong>blades</strong>, and can be removed by unscrewing a nut using ascrewdriver. The careful design, precise assembly, and the quality of the materials used, make this an economical, practical, andefficient component.Contrast control damper- dimensions that can becreated in a single solutionContrast control damper - overall dimensions1row2 rowsHEIGHTContrast control damper -detail of patented fixing clipsContrast control damperbaseheightSC 400 200U10 Diffusion-vers.14.00.xls U10-12

COUNTERFRAMES FOR SUPPLYAND RETURN GRILLESOVERVIEWUTCSERIESOVERVIEWThe UTC series counterframes used for supply and return<strong>grille</strong>s are a strong frame on which the fixing clips can rest.They are required if the <strong>grille</strong>s need to be frequently removedfor cleaning, inspection, filter changing and other similar jobs.The UTC counterframes can be installed both next to steelducts and on masonry walls.Bendable parts are placed inside the fixing agent of the walland a frame that will be completely hidden from the frame ofthe <strong>grille</strong> itself, for fixing by means of screws or rivets to theduct wall.The use of the counterframe on the side of the steel ductallows the use of <strong>grille</strong>s with fixing clips rather than withscrews, therefore allowing to undertake jobs that requireremoving and reinstalling the <strong>grille</strong> with the up mostsimplicity without the need of tools.The use of the counterframe on masonry walls allows for analmost unlimited number of removals and replacements of the<strong>grille</strong> without ever damaging or wearing-out the border of thehole made in the wall. The position of the <strong>grille</strong> can thereforebe maintained, precise and secure.AVAILABLE SIZESThe available sizes for each part range from 100mm up to amaximum of 1400mm, in multiples of 50mm.Special sizes are also available on request.By composing the various sizes, all the necessary sizes areachievable.TECHNICAL CHARACTERISTICSThe UTC Series counterframes are made of four separateparts, of galvanized carbon steel sheet,fixable to each other without the need of tools. The parts arecompletely interchangeable as the particular system ofconnection eliminated the need to distinguish betweenhorizontal and vertical parts and with between left and rightparts.As shown in the illustration, the necessary space for thecounterframe needs to be 5mm more than the nominal size ofthe <strong>grille</strong>.The parts are supplied unassembled, the complete interchangeabilityhelps to easily manage the parts kept in stock.Mounting with single deflection <strong>grille</strong>Mounting with double deflection <strong>grille</strong>U10 Diffusion-vers.14.00.xls U10-13

COUNTERFRAMES FOR SUPPLYAND RETURN GRILLESOVERVIEWUTCSERIESLinguetta da sollevare per fissaggioin Lip parete to lift to in fixing muratura to masonry wallsLamelle <strong>blades</strong> to bend da piegare at 90° and a 90° insert e inserire the attachingpart nei riscontri to assemblethe dell'elemento counterframe adiacenteDetail of the fixing method between partsThis system allows to quickly assemble the counterframe, even during the construction fase.UTC 400Element of counterframelengthExample:To order a counterframe for a 400x200mm <strong>grille</strong>,request:UTC-400 - 2 piecesUTC-200 - 2 piecesTo order a counterframe for a 300x300 <strong>grille</strong>, request:UTC-300 - 4 piecesCOUNTERFRAME SIZES WITH AVAILABLE PARTS KEPT IN STOCKHEIGHT H10009008007006005635004504003503002502001501001001502002503003504004505005636007008009001000BASE BThe 563x563 size is for <strong>grille</strong>s with a 595x595mm outside frame measurement, used for modular counterceilings.U10 Diffusion-vers.14.00.xls U10-14

QUICK INSTALLINGU-FIXSERIESOVERVIEWGrille with Grille with Grille withvisible screw fixing hidden screw fixing friction springsAll the fixing metods are avaiable for all the models of <strong>grille</strong>, with one or two rows of finsUMURUFUQUHNew fixing with hidden screwThe new U-FIX kit allows a quick fixing of the shown grids tothe counterframe simply rotating a hidden screw behind thefront fins.The kit is suitable for <strong>grille</strong>s with two rows or a single row offins.This solution allows you to quickly disassemble andreassemble the grid for any cleaning or maintenance.The kit consists of two or four hardware, depending on thesize of the grid.The kit comes already assembled on the grid.For the sizes up to 1000x300 and 600x600 it is possible toprovide an SC damper mounted during manifacturing on thegrid frame.1000GRKG600300U-FIX2compatible withthe damperU-FIX4not compatible withthe damper0600 10001200U10 Diffusion-vers.14.00.xls U10-15

QUICK INSTALLINGU-FIXSERIESOVERVIEWCounterframeCounterframe + damperHOW TO ORDERThe code of the grid must be with "clips configuration" (not with "holes configuration").Standard clips will not be provided in presence of U-FIX kit mounted.The counterframe must be ordered according to standard counterframe dimension.In case of SC regulation damper request, please use the special code SCUFIXORDER EXAMPLESGrid UM 400x200mm with U-FIX and counterframe1) UM1HC400200 q.ty 12) U-FIX2 q.ty 13) UTCC0400200 q.ty 1Grid UM 700x400mm with U-FIX and counterframe1) UM1HC700400 q.ty 12) U-FIX4 q.ty 13) UTCC0700400 q.ty 1Grid UM 400x200mm with U-FIX , counterframe and regulation damper1) UM1HC400200 q.ty 12) U-FIX2 q.ty 13) UTCC0400200 q.ty 14) SCUFIX400200 q.ty 1U10 Diffusion-vers.14.00.xls U10-16

SUPPLY DIFFUSERSWITH CURVED BLADESOVERVIEWTECHNICAL CHARACTERISTICSKGSERIESOVERVIEW AND CHARACTERISTICS :The KG series is made up of a range of fully adjustable inlets, with curved <strong>blades</strong> that can be oriented individually, arranged inone or two ranks. The first horizontal rank of curved <strong>blades</strong> is used to control the way the air is emitted, and controls the anglethe airflow is deflected. The second horizontal rank with straight <strong>blades</strong>, when fitted, is used to correct the lateral direction inwhich the air moves.Frame : In extruded aluminium, 25 mm in width, with rounded edges and made up in four parts, which are connected to oneanother invisibly using a mechanical assembly system. Blades : In extruded aluminium at 20 mm centres, hinged on a selflockingnylon track, which is inserted into the frame. Transverse reinforcing : Included for all the diffusers which are longer than600 mm. Damper : Made entirely of steel, with multiple fins that move in opposite directions. Counterframe: Rigid structure insteel sheet suitable for installing using exposed screws and hidden clips. Installing the diffuser on a wall or ceiling: Done using asystem without screws and with clips and a counterframe, with the screw system traditionally used directly on the ducting orwall, or using clips or screws directly into the plenum chamber. Finish : The KG series is made in natural anodised aluminium orwith an epoxy powder coating finish - colour RAL 9010.20,55736.5 20,5( H x B )( H - 16 ) x ( B - 16 )( H - 30 ) x ( B - 30 )( H + 32 ) x ( B + 32 )( H x B )KG 1 L KG 2 L KG 1 C KG 2 Cmin 200x100 min 200x100 min 200x150 min 200x150U10 Diffusion-vers.14.00.xls U10-17

SUPPLY DIFFUSERSWITH CURVED BLADESTECNICAL DATAKGSERIESEFFECTIVE SECTION Akhaight100150200250300350400450500550600base200 250 300 350 400 450 500 550 6000,006096 0,007806 0,009516 0,011226 0,012936 0,014646 0,016356 0,018066 0,0197760,009846 0,012556 0,015266 0,017976 0,020686 0,023396 0,026106 0,028816 0,0315260,013596 0,017306 0,021016 0,024726 0,028436 0,032146 0,035856 0,039566 0,0432760,017346 0,022056 0,026766 0,031476 0,036186 0,040896 0,045606 0,050316 0,0550260,021096 0,026806 0,032516 0,038226 0,043936 0,049646 0,055356 0,061066 0,0667760,024846 0,031556 0,038266 0,044976 0,051686 0,058396 0,065106 0,071816 0,0785260,028596 0,036306 0,044016 0,051726 0,059436 0,067146 0,074856 0,082566 0,0902760,032346 0,041056 0,049766 0,058476 0,067186 0,075896 0,084606 0,093316 0,1020260,036096 0,045806 0,055516 0,065226 0,074936 0,084646 0,094356 0,104066 0,1137760,039846 0,050556 0,061266 0,071976 0,082686 0,093396 0,104106 0,114816 0,1255260,043596 0,055306 0,067016 0,078726 0,090436 0,102146 0,113856 0,125566 0,137276Vk (m/s) = Q (m³/h)/3600/Ak (m²)U10 Diffusion-vers.14.00.xls U10-18

SUPPLY DIFFUSERSWITH CURVED BLADESTECNICAL DATAKGSERIESVk (m/s) = Q (m³/h)/3600/Ak (m²)U10 Diffusion-vers.14.00.xls U10-19

SUPPLY DIFFUSERSWITH CURVED BLADESTECNICAL DATAKGSERIESU10 Diffusion-vers.14.00.xls U10-20

SUPPLY DIFFUSERSWITH CURVED BLADESHOW TO ORDERKGSERIES12KGLCSuppy diffusers with curved <strong>blades</strong>one direction throwtwo direction throwhorizontal <strong>blades</strong>vertical <strong>blades</strong>baseheightKG 1 L 200 100U10 Diffusion-vers.14.00.xls U10-21

U10 Diffusion-vers.14.00.xls U10-22

VENTILATION GRILLESACCESSORIESUMSERIESPP30Plenum with rear connectioninsulated and non insulated versionPP30Plenum with lateral connectioninsulated and non insulated versionSCControl damperUTCCounterframeU-FIXQuick installingU10 Diffusion-vers.14.00.xls U10-23

PLENUM FORVENTILATION GRILLES PP 30SERIESTECHNICAL CHARACTERISTICSL H A N° SPP 30200 100 140 1 80300 100 140 1 80400 100 140 1 80500 100 140 2 80600 100 140 2 80700 100 140 2 80800 100 140 2 80200 150 180 1 127300 150 180 1 127400 150 180 1 127500 150 180 2 127600 150 180 2 127700 150 180 2 127800 150 180 2 127900 150 180 2 1271000 150 180 2 127200 200 220 1 150300 200 220 1 150400 200 220 1 180500 200 220 1 180600 200 220 2 150700 200 220 2 150800 200 220 2 150900 200 220 2 1801000 200 220 2 180200 250 220 1 200300 250 220 1 200400 250 220 1 200500 250 220 1 200600 250 220 2 150700 250 220 2 150800 250 220 2 150900 250 220 2 1801000 300 220 2 180300 300 260 1 250400 300 260 1 250500 300 260 1 250Plenum for ventilation <strong>grille</strong>s600 300 260 2 160rear connection700 300 260 2 160800 300 260 2 160 -- not insulated900 300 260 2 200 I insulated1000 300 260 2 200400 400 260 1 350 base500 400 260 1 350600 400 260 2 160height700 400 260 2 160800 400 260 2 160900 400 260 2 200 PP30 I 200 1001000 400 260 2 200 For S = 125 - 160 - 200 - 250 connection in ABS - steel on request515 515 150 1 250 For other diameters connection in steel563 563 270 1 350U10 Diffusion-vers.14.00.xls U10-24

PLENUM FORVENTILATION GRILLES PP 40SERIESTECHNICAL CHARACTERISTICSL H A B C N° SPP 40200 100 200 70 80 1 100300 100 250 95 80 1 150400 100 250 95 80 1 150500 100 300 120 80 1 200600 100 300 120 80 1 200700 100 350 145 80 1 250800 100 350 145 80 1 250200 150 250 95 80 1 150300 150 300 120 80 1 200400 150 300 120 80 1 200500 150 350 145 80 1 250600 150 350 145 80 1 250700 150 350 145 80 1 250800 150 415 178 80 1 315900 150 415 178 80 1 3151000 150 415 178 80 1 315200 200 250 95 80 1 150300 200 250 95 80 1 150400 200 350 145 80 1 250500 200 350 145 80 1 250600 200 415 178 80 1 315700 200 415 178 80 1 315800 200 415 178 80 1 315900 200 450 195 80 1 3501000 200 450 195 80 1 350200 250 300 120 80 1 200300 250 300 120 80 1 200400 250 350 145 80 1 250500 250 350 145 80 1 250600 250 415 178 80 1 315700 250 415 178 80 1 315800 250 415 178 80 1 315900 250 450 195 80 1 3501000 250 450 195 80 1 350300 300 350 145 80 1 250400 300 415 178 80 1 315500 300 450 195 80 1 350Plenum for ventilation <strong>grille</strong>s600 300 450 195 80 1 350lateral connection700 300 450 195 80 1 350800 300 450 195 80 1 350 -- not insulated900 300 500 220 80 1 400 I insulated1000 300 500 220 80 1 400400 400 450 195 80 1 350base500 400 450 195 80 1 350600 400 450 195 80 1 350 height700 400 450 195 80 1 350800 400 450 195 80 1 350900 400 500 220 80 1 400 PP40 I 200 1001000 400 500 220 80 1 400 For S = 125 - 160 - 200 - 250 connection in ABS - steel on request515 515 320 145 50 1 250 For other diameters connection in steel563 563 450 195 80 1 350U10 Diffusion-vers.14.00.xls U10-25

CONTROL DAMPERSOVERVIEWTECHNICAL CHARACTERISTICSSCSERIESOVERVIEW AND CHARACTERISTICS :The contrast control dampers of SC series can be fitted to UF KG UM UR GI KN e CR-KN series . They are held in place byspecial patented clips, designed both for fitting the damper to the grill and for fitting it on a false frame.The SC series dampers are made entirely of galvanised steel and have a mechanism for moving and closing all the <strong>blades</strong>simultaneously.This mechanism is a simple longitudinal plate that links all the <strong>blades</strong>, and can be removed by unscrewing a nut using ascrewdriver. The careful design, precise assembly, and the quality of the materials used, make this an economical, practical, andefficient component.Contrast control damper- dimensions that can becreated in a single solutionContrast control damper - overall dimensions1row2 rowsHEIGHTContrast control damper -detail of patented fixing clipsContrast control damperbaseheightSC 400 200U10 Diffusion-vers.14.00.xls U10-26

COUNTERFRAMES FOR SUPPLYAND RETURN GRILLESOVERVIEWUTCSERIESOVERVIEWThe UTC series counterframes used for supply and return<strong>grille</strong>s are a strong frame on which the fixing clips can rest.They are required if the <strong>grille</strong>s need to be frequently removedfor cleaning, inspection, filter changing and other similar jobs.The UTC counterframes can be installed both next to steelducts and on masonry walls.Bendable parts are placed inside the fixing agent of the walland a frame that will be completely hidden from the frame ofthe <strong>grille</strong> itself, for fixing by means of screws or rivets to theduct wall.The use of the counterframe on the side of the steel ductallows the use of <strong>grille</strong>s with fixing clips rather than withscrews, therefore allowing to undertake jobs that requireremoving and reinstalling the <strong>grille</strong> with the up mostsimplicity without the need of tools.The use of the counterframe on masonry walls allows for analmost unlimited number of removals and replacements of the<strong>grille</strong> without ever damaging or wearing-out the border of thehole made in the wall. The position of the <strong>grille</strong> can thereforebe maintained, precise and secure.AVAILABLE SIZESThe available sizes for each part range from 100mm up to amaximum of 1400mm, in multiples of 50mm.Special sizes are also available on request.By composing the various sizes, all the necessary sizes areachievable.TECHNICAL CHARACTERISTICSThe UTC Series counterframes are made of four separateparts, of galvanized carbon steel sheet,fixable to each other without the need of tools. The parts arecompletely interchangeable as the particular system ofconnection eliminated the need to distinguish betweenhorizontal and vertical parts and with between left and rightparts.As shown in the illustration, the necessary space for thecounterframe needs to be 5mm more than the nominal size ofthe <strong>grille</strong>.The parts are supplied unassembled, the complete interchangeabilityhelps to easily manage the parts kept in stock.Mounting with single deflection <strong>grille</strong>Mounting with double deflection <strong>grille</strong>U10 Diffusion-vers.14.00.xls U10-27

COUNTERFRAMES FOR SUPPLYAND RETURN GRILLESOVERVIEWUTCSERIESLinguetta da sollevare per fissaggioin Lip parete to lift to in fixing muratura to masonry wallsLamelle <strong>blades</strong> to bend da piegare at 90° and a 90° insert e inserire the attachingpart nei riscontri to assemblethe dell'elemento counterframe adiacenteDetail of the fixing method between partsThis system allows to quickly assemble the counterframe, even during the construction fase.UTC 400Element of counterframelengthExample:To order a counterframe for a 400x200mm <strong>grille</strong>,request:UTC-400 - 2 piecesUTC-200 - 2 piecesTo order a counterframe for a 300x300 <strong>grille</strong>, request:UTC-300 - 4 piecesCOUNTERFRAME SIZES WITH AVAILABLE PARTS KEPT IN STOCKHEIGHT H10009008007006005635004504003503002502001501001001502002503003504004505005636007008009001000BASE BThe 563x563 size is for <strong>grille</strong>s with a 595x595mm outside frame measurement, used for modular counterceilings.U10 Diffusion-vers.14.00.xls U10-28

QUICK INSTALLINGU-FIXSERIESOVERVIEWGrille with Grille with Grille withvisible screw fixing hidden screw fixing friction springsAll the fixing metods are avaiable for all the models of <strong>grille</strong>, with one or two rows of finsUMURUFUQUHNew fixing with hidden screwThe new U-FIX kit allows a quick fixing of the shown grids tothe counterframe simply rotating a hidden screw behind thefront fins.The kit is suitable for <strong>grille</strong>s with two rows or a single row offins.This solution allows you to quickly disassemble andreassemble the grid for any cleaning or maintenance.The kit consists of two or four hardware, depending on thesize of the grid.The kit comes already assembled on the grid.For the sizes up to 1000x300 and 600x600 it is possible toprovide an SC damper mounted during manifacturing on thegrid frame.1000GRKG600300U-FIX2compatible withthe damperU-FIX4not compatible withthe damper0600 10001200U10 Diffusion-vers.14.00.xls U10-29

QUICK INSTALLINGU-FIXSERIESOVERVIEWCounterframeCounterframe + damperHOW TO ORDERThe code of the grid must be with "clips configuration" (not with "holes configuration").Standard clips will not be provided in presence of U-FIX kit mounted.The counterframe must be ordered according to standard counterframe dimension.In case of SC regulation damper request, please use the special code SCUFIXORDER EXAMPLESGrid UM 400x200mm with U-FIX and counterframe1) UM1HC400200 q.ty 12) U-FIX2 q.ty 13) UTCC0400200 q.ty 1Grid UM 700x400mm with U-FIX and counterframe1) UM1HC700400 q.ty 12) U-FIX4 q.ty 13) UTCC0700400 q.ty 1Grid UM 400x200mm with U-FIX , counterframe and regulation damper1) UM1HC400200 q.ty 12) U-FIX2 q.ty 13) UTCC0400200 q.ty 14) SCUFIX400200 q.ty 1U10 Diffusion-vers.14.00.xls U10-30

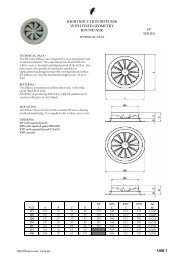

SUPPLY GRILLEFOR CIRCULAR DUCTOVERVIEWUDCSERIESCHARACTERISTICS :The UDC <strong>grille</strong>, purposely studied for the installation on circularducts, is different due to the realization of the profile in a singleAnodized extruded natural aluminium body, with moulded frontalprofile, horizontal and vertical <strong>blades</strong> to adjustable shape of dropsingularly, in Anodized extruded aluminium natural, with mouldedfront, horizontal and vertical adjustable drop shaped <strong>blades</strong>, eachone adjustable independently, all in anodized extruded naturalaluminium.The particular geometry and the interchangeable ends (made inABS, class 1, antistatic) purposely designed ( allow it to adapt tothe different diameters (Ø200 ÷Ø800) of the ducts. In this way,there is the possibility of using one single item for the differentdiameters, with the advantage of not having to order differentmodels but simply of changing the <strong>grille</strong> ends, resulting in a quickinstallation and a complete adaptability to the duct.The original design of the <strong>grille</strong>, also allows the installation on acalibration sliding damper or a collection damper, without the needto vary the space used.ACCESSORIES :Sliding calibrating damper, collection damper and Ends.INSTALLATION :Fast mounting interlocking on ductUDC 100UDC 150UDC 200U10 Diffusion-vers.14.00.xls U10-31

SUPPLY GRILLEFOR CIRCULAR DUCTPERFORMANCEUDCSERIESMODEL UDC 100L H Q T ∆ps LpfrontalsectionL H Q T ∆ps Lpfrontalsectionmm mm m 3 /h m Pa dBa m 2 mm mm m 3 /h m Pa dBa m 2200 100 4,2 3

SUPPLY GRILLEFOR CIRCULAR DUCTPERFORMANCEUDCSERIESMODEL UDC 200L H Q T ∆ps LpfrontalsectionL H Q T ∆ps Lpfrontalsectionmm mm m 3 /h m Pa dBa m 2 mm mm m 3 /h m Pa dBa m 2200 200 6,6 4

SUPPLY GRILLEFOR CIRCULAR DUCTAVAILABLE SIZESHOW TO ORDERUDCSERIESAs a result of the adjustable ends, the UDC circular duct <strong>grille</strong>s can be fitted without beingmodified or adapted to a wide range of diameters, as shown below.L X HDmmmm200 100 160300 100400 100500 100600 100800 1001000 1001200 100 2400L X HDmmmm200 150 250300 150400 150500 150600 150800 1501000 1501200 150 2400L X HDmmmm200 200 315300 200400 200500 200600 200800 2001000 2001200 200 2400The 100mm high <strong>grille</strong> can be used on circular ductswith diameters ranging from 160 to 2400mm.The length of the <strong>grille</strong> does not influence the choice in this respect.The 150mm high <strong>grille</strong> can be used on circular ductswith diameters ranging from 250 to 2400mm.The length of the <strong>grille</strong> does not influence the choice in this respect.The 200mm high <strong>grille</strong> can be used on circular ductswith diameters ranging from 315 to 2400mm.The length of the <strong>grille</strong> does not influence the choice in this respect.UDCSupply <strong>grille</strong> for cicular duct--Sdouble deflectionsingle deflectionheightlengthUDC S 150 800U10 Diffusion-vers.14.00.xls U10-34

SUPPLY GRILLEFOR CIRCULAR DUCTINSTALLATIONUDCSERIESThe UDC circular duct <strong>grille</strong>s are an innovative product with a high aesthetic quality. All models have a gasket whichguarantees contact with the air duct in complete on all the diameter. It is installed following three simple steps, asshown here below :1) GRILLE HOUSING IN THE DUCTProceed with cutting the hole in the duct.The dimensions of the hole are equal to the nominaldimensionsi of the <strong>grille</strong>, as indicated d in ourcatalogues andbrochures.Fig. 1Example : Grille 500x150 = Hole 500x150Fig. 22) GASKET CUTTING AND POSITIONINGOnce the hole has been made, proceed with preparing andinstalling the air tight gasket on the edge of the hole mad alreadymade.Cut four pieces of the gasket to size, two for length L and two forlength H + 10mm.Individually fix each piece so as to make a perfect continuousframe, as shown in Fig. 2 to ensure a better air tight seal.3) DUCT DIAMETER REGULATIONBefore inserting the <strong>grille</strong> in its housing, it is necessary toadjust the ends to fit duct's diameter (Fig. 3).Theendpieceisequippedwithagraduatedscaleshowingthe various positions for the possible dimensions. Chosethe position as necessary.Fig. 34) POSITIONING THE GRILLE IN THE HOUSINGFig. 4Once the end pieces have been adjusted as necessary, the <strong>grille</strong> can nowbeen placed in its housing (Fig. 4).Fig. 5Hold the grill at 30°, taking care to insert first the end with the longer<strong>blades</strong> (as per Fig. 7) making sure to correctly align the end piece withthe duct and the gasket (as per Fig. 5).Proceed carefully by resting the other part of the <strong>grille</strong> on the duct, applya gentle force to press the gasket and in a lateral movement proceed withfixing the <strong>grille</strong> in place (Fig. 6).Fig. 6During this process it is necessary to be sure that the gasket remainscorrectly in place between the duct and the <strong>grille</strong>.insert first theend with thelonger <strong>blades</strong>ALETTE LUNGHE1° POSIZIONAMENTOFig. 7U10 Diffusion-vers.14.00.xls U10-35

U10 Diffusion-vers.14.00.xls U10-36