Collapsible Core & Collapsible Minicore - Roehr Tool Corporation

Collapsible Core & Collapsible Minicore - Roehr Tool Corporation

Collapsible Core & Collapsible Minicore - Roehr Tool Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

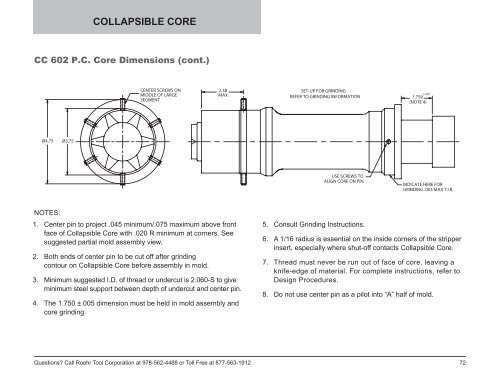

COLLAPSIBLE CORECC 602 P.C. <strong>Core</strong> Dimensions (cont.)CENTER SCREWS ONMIDDLE OF LARGESEGMENT2.38MAXSET-UP FOR GRINDINGREFER TO GRINDING INFORMATION 1.750(NOTE 4)±.005Ø4.75 Ø3.75USE SCREWS TOALIGN CORE ON PININDICATE HERE FORGRINDING .003 MAX T.I.R.NOTES:1. Center pin to project .045 minimum/.075 maximum above frontface of <strong>Collapsible</strong> <strong>Core</strong> with .020 R minimum at corners. Seesuggested partial mold assembly view.2. Both ends of center pin to be cut off after grindingcontour on <strong>Collapsible</strong> <strong>Core</strong> before assembly in mold.3. Minimum suggested I.D. of thread or undercut is 2.060-S to giveminimum steel support between depth of undercut and center pin.4. The 1.750 ±.005 dimension must be held in mold assembly andcore grinding.5. Consult Grinding Instructions.6. A 1/16 radius is essential on the inside corners of the stripperinsert, especially where shut-off contacts <strong>Collapsible</strong> <strong>Core</strong>.7. Thread must never be run out of face of core, leaving aknife-edge of material. For complete instructions, refer toDesign Procedures.8. Do not use center pin as a pilot into “A” half of mold.Questions? Call <strong>Roehr</strong> <strong>Tool</strong> <strong>Corporation</strong> at 978-562-4488 or Toll Free at 877-563-1912.72