Chapter 19 Thermal Properties

Chapter 19 Thermal Properties

Chapter 19 Thermal Properties

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

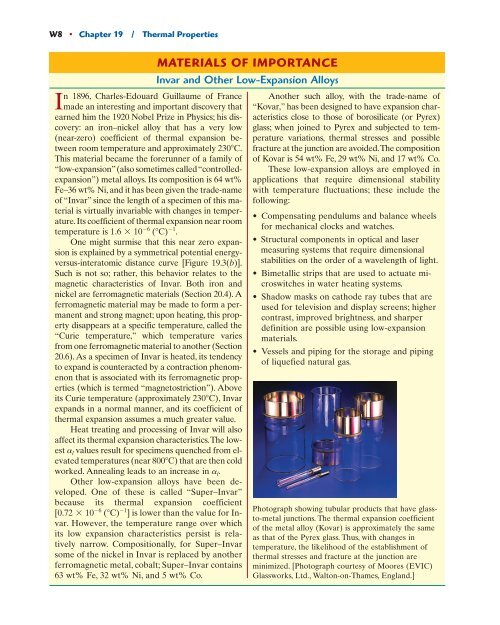

W8 • <strong>Chapter</strong> <strong>19</strong> / <strong>Thermal</strong> <strong>Properties</strong>MATERIALS OF IMPORTANCEInvar and Other Low-Expansion AlloysIn 1896, Charles-Edouard Guillaume of Francemade an interesting and important discovery thatearned him the <strong>19</strong>20 Nobel Prize in Physics; his discovery:an iron–nickel alloy that has a very low(near-zero) coefficient of thermal expansion betweenroom temperature and approximately 230C.This material became the forerunner of a family of“low-expansion”(also sometimes called “controlledexpansion”)metal alloys. Its composition is 64 wt%Fe–36 wt% Ni, and it has been given the trade-nameof “Invar” since the length of a specimen of this materialis virtually invariable with changes in temperature.Its coefficient of thermal expansion near roomtemperature is 1.6 10 6 (C) 1 .One might surmise that this near zero expansionis explained by a symmetrical potential energyversus-interatomicdistance curve [Figure <strong>19</strong>.3(b)].Such is not so; rather, this behavior relates to themagnetic characteristics of Invar. Both iron andnickel are ferromagnetic materials (Section 20.4). Aferromagnetic material may be made to form a permanentand strong magnet; upon heating, this propertydisappears at a specific temperature, called the“Curie temperature,” which temperature variesfrom one ferromagnetic material to another (Section20.6). As a specimen of Invar is heated, its tendencyto expand is counteracted by a contraction phenomenonthat is associated with its ferromagnetic properties(which is termed “magnetostriction”). Abovea lits Curie temperature (approximately 230C), Invarexpands in a normal manner, and its coefficient ofthermal expansion assumes a much greater value.Heat treating and processing of Invar will alsoaffect its thermal expansion characteristics.The lowestvalues result for specimens quenched from elevatedtemperatures (near 800C) that are then coldworked. Annealing leads to an increase in a l .Other low-expansion alloys have been developed.One of these is called “Super–Invar”because its thermal expansion coefficient[0.72 10 6 (C) 1 ] is lower than the value for Invar.However, the temperature range over whichits low expansion characteristics persist is relativelynarrow. Compositionally, for Super–Invarsome of the nickel in Invar is replaced by anotherferromagnetic metal, cobalt; Super–Invar contains63 wt% Fe, 32 wt% Ni, and 5 wt% Co.Another such alloy, with the trade-name of“Kovar,” has been designed to have expansion characteristicsclose to those of borosilicate (or Pyrex)glass; when joined to Pyrex and subjected to temperaturevariations, thermal stresses and possiblefracture at the junction are avoided.The compositionof Kovar is 54 wt% Fe, 29 wt% Ni, and 17 wt% Co.These low-expansion alloys are employed inapplications that require dimensional stabilitywith temperature fluctuations; these include thefollowing:• Compensating pendulums and balance wheelsfor mechanical clocks and watches.• Structural components in optical and lasermeasuring systems that require dimensionalstabilities on the order of a wavelength of light.• Bimetallic strips that are used to actuate microswitchesin water heating systems.• Shadow masks on cathode ray tubes that areused for television and display screens; highercontrast, improved brightness, and sharperdefinition are possible using low-expansionmaterials.• Vessels and piping for the storage and pipingof liquefied natural gas.Photograph showing tubular products that have glassto-metaljunctions. The thermal expansion coefficientof the metal alloy (Kovar) is approximately the sameas that of the Pyrex glass. Thus, with changes intemperature, the likelihood of the establishment ofthermal stresses and fracture at the junction areminimized. [Photograph courtesy of Moores (EVIC)Glassworks, Ltd., Walton-on-Thames, England.]

![Data Structures and Algorithms in Java[1].pdf - Fulvio Frisone](https://img.yumpu.com/30982515/1/190x245/data-structures-and-algorithms-in-java1pdf-fulvio-frisone.jpg?quality=85)

![(Microsoft PowerPoint - Topic 4.ppt [Mode de compatibilit\351])](https://img.yumpu.com/30966934/1/190x245/microsoft-powerpoint-topic-4ppt-mode-de-compatibilit351.jpg?quality=85)