Semi-dry Absorption System for Flue Gas Cleaning

Semi-dry Absorption System for Flue Gas Cleaning

Semi-dry Absorption System for Flue Gas Cleaning

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

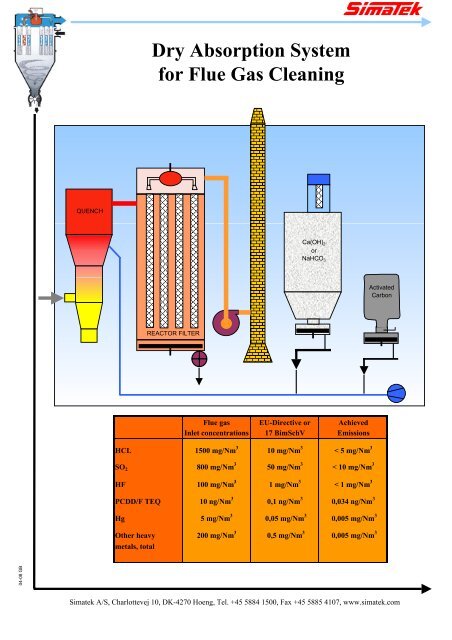

Dry <strong>Absorption</strong> <strong>System</strong><strong>for</strong> <strong>Flue</strong> <strong>Gas</strong> <strong>Cleaning</strong>MQUENCHCa(OH) 2orNaHCO 3ActivatedCarbonREACTOR FILTERMM MM M MM<strong>Flue</strong> gasInlet concentrationsEU-Directive or17 BimSchVAchievedEmissionsHCLSO 2HFPCDD/F TEQHgOther heavymetals, total1500 mg/Nm 3 10 mg/Nm 3 < 5 mg/Nm 3200 mg/Nm 3 0,5 mg/Nm 3 0,005 mg/Nm 3800 mg/Nm 3 50 mg/Nm 3 < 10 mg/Nm 3100 mg/Nm 310 ng/Nm 31 mg/Nm 30,1 ng/Nm 3< 1 mg/Nm 30,034 ng/Nm 35 mg/Nm 3 0,05 mg/Nm 3 0,005 mg/Nm 304-08 GBSimatek A/S, Charlottevej 10, DK-4270 Hoeng, Tel. +45 5884 1500, Fax +45 5885 4107, www.simatek.com

<strong>Semi</strong>-<strong>dry</strong> <strong>Absorption</strong> <strong>System</strong><strong>for</strong> <strong>Flue</strong> <strong>Gas</strong> <strong>Cleaning</strong>Ca(OH) 2Spray AbsorberFILTERActivatedCarbon04-08 GBSimatek A/S, Charlottevej 10, DK-4270 Hoeng, Tel. +45 5884 1500, Fax +45 5885 4107, www.simatek.com

Simatek 3C FilterExperience in <strong>Flue</strong> <strong>Gas</strong> <strong>Cleaning</strong> Bio Fuel- Straw- Chemically Treated Wood- Wood Chips Municipal Waste Hazardous Waste Clinical Waste Crematorium Incinerators Oil Waste Sludge Coal Metal Furnaces04-08.GB

Operating Opportunities with the mostAdvanced FilterSimatek 3C• Filter Resistance Control:- The dP set point will fluctuate with the <strong>Gas</strong> Flow, higher dP set point with higher gas flowand a decreased set point with a reduced gas flow.- The pulse pressure will be controlled by the dP, lower dP gives automatically lower pulsepressure and higher dP gives a higher pulse pressure , but still within 0.4-0.9 bar.- Only one (1) bag being pulsed and the <strong>Gas</strong> Flow between the bags is down flow to supportthe transport of particles, mainly the sub micron particles, down to the filter bottom and out.• Constant Thickness of Ab-/Adsorbing Filter Cake:- With the above-mentioned control of the Filter Resistance the filter cake with Chemicals <strong>for</strong>Ab-/Adsorption is controlled to a constant thickness which gives a controlled Emission ofAcid <strong>Gas</strong>es and Toxic Elements and with an optimized utilization of the injectedchemicals.• Injection of Chemicals depends on the <strong>Flue</strong> <strong>Gas</strong>:- The amount of injected Chemicals is regulated from the Emission of HCl and SO X if theconcentration is fairly stable. If the inlet concentration of SO X is suddenly heavilyincreased both the set point <strong>for</strong> dP and the amount of Chemicals injected is also increasedto <strong>for</strong>m a thicker and more reactive filter cake as well as the Recycling of unreactedChemicals is also initiated.- This way of operating the filter is only used with very high SO X inlet concentrationswhile still receiving low SO X emission and it is due to its slower reaction compared withHCl and HF.- The Injection of Activated Carbon is kept constant because the PCDD/F Emission is notconstantly measured.04-08.GB

Intelligent Filter Control <strong>for</strong> constant thickness ofAb-/ Adsorption Filter Cake<strong>Flue</strong> <strong>Gas</strong> <strong>Cleaning</strong> <strong>System</strong>Application: Aluminium Melting FurnaceCapacity: 80.000 m³/hTemperature: < 200 ºCDust: Aluminium OxideAcid <strong>Gas</strong>: Hydrogen Fluoride (HF)04-08.GB

AITOS NorwayIndustrial Waste incineratorSimatek scope of supply:Item 7,8 and 9Complete <strong>Flue</strong> <strong>Gas</strong><strong>Cleaning</strong> <strong>System</strong><strong>for</strong> removal of: HCl, SOx,Dioxins,heavy metals and fly ashÅrdal NorwayMunicipal WasteIncineratorSimatek scope of supply:Complete <strong>Flue</strong> <strong>Gas</strong> <strong>Cleaning</strong> <strong>System</strong>Including boiler, reactor, filter,stack, silos, quench and dosingsystems.04-08.GB

AITOS NORWAYRemoval of: SOx, HCL, Dioxins and Heavy Metals04-08.GB

Diagram <strong>for</strong> SO 210.90.80.70.60.50.40.30.20.1008/11/1998 00:09,5008/11/1998 01:19,5008/11/1998 02:29,50Measuring period: 08-11-98 at 00,09,5009-11-98 at 00,09,5008/11/1998 03:39,5008/11/1998 04:49,5008/11/1998 05:59,5008/11/1998 07:09,5008/11/1998 08:19,5008/11/1998 09:29,5008/11/1998 10:39,5008/11/1998 11:49,5008/11/1998 12:59,5008/11/1998 14:09,5008/11/1998 15:19,5008/11/1998 16:29,5008/11/1998 17:39,5008/11/1998 18:49,5008/11/1998 19:59,5008/11/1998 21:09,5008/11/1998 22:19,5008/11/1998 23:29,501676.9 SO2rågass55.6 Ut SO246.6 Snitt kalk 3timer#I/T #I/TValues: SO 2 Raw gas (rågass): mg/Nm 3Out (Ut) SO 2 : mg/Nm 3Lime average (Snitt kalk) 3 hours: kg/hThe values placed in the box to the right of the data area represent the maximum values of thedata in question. The ordinate to the left in the data area shows the multiplication factor <strong>for</strong>calculation of the actual value.Example: Raw gas SO 2 on 08-11-98 at 00,09,50 shows the ordinate of app. 0.6, and themaximum value <strong>for</strong> raw gas SO 2 is 1676.9. Multiply the factors and you have 0.6 x 1676.9 =1006 mg/Nm 3 .The diagram situation shows that the plant is operating with a SO 2 inlet concentration of app.1200 mg/Nm 3 during the first half of the period. Then the concentration falls to 1000 mg/Nm 3 inthe latter part of the diagram. The emission requirement is

Test Results of Aitos A/S Ranheim energi10.90.80.70.60.50.40.30.20.1008/11/1998 00:09,5008/11/1998 01:19,5008/11/1998 02:29,50Measuring period: 08-11-98 at 00,09,5009-11-98 at 00,09,5008/11/1998 03:39,5008/11/1998 04:49,5008/11/1998 05:59,5008/11/1998 07:09,5008/11/1998 08:19,5008/11/1998 09:29,5008/11/1998 10:39,5008/11/1998 11:49,5008/11/1998 12:59,5008/11/1998 14:09,5008/11/1998 15:19,5008/11/1998 16:29,5008/11/1998 17:39,5008/11/1998 18:49,5008/11/1998 19:59,5008/11/1998 21:09,5008/11/1998 22:19,5008/11/1998 23:29,501762.8 RågassHCL4.1 Ut HCL46.6 Snitt kalk 3timer#I/T #I/TValues: Raw gas (Rågass) HCl: mg/Nm 3Out (Ut) HCl: mg/Nm 3Lime average (Snit kalk) 3 hours: kg/hThe values placed in the box to the right of the data area represent the maximum values of thedata in question. The ordinate to the left in the data area shows the multiplication factor <strong>for</strong>calculation of the actual value.Example: Raw gas HCl on 08-11-98 at 00,09,50 shows the ordinate of app. 0.65, and themaximum value <strong>for</strong> raw gas HCl is 1762.8. Multiply the factors and you have 0.65 x 1762.8 =1145 mg/Nm 3The diagram situation shows that the plant is operating with a stable inlet concentration of HClof app. 1100 mg/Nm 3 during the first half of the period. Then the concentration rises to 1762.8mg/Nm 3 in the latter part of the diagram. The figures show clearly that there is no difficulty incomplying with the emission requirement of

THIS DIAGRAM SHOWS A NORMAL OPERATING SITUATIONAT THE INCINERATION PLANT OF AITOS A/S RANHEIMENERGI10.90.80.70.60.50.40.30.20.1025/11/1998 00:09,5025/11/1998 01:19,5025/11/1998 02:29,50Measuring period: 25-11-98 at 00,09,5026-11-98 at 00,09,50Values: Raw gas (Rågass) HCl: mg/Nm 3Out (Ut) HCl: mg/Nm 3Raw gas (Rågass) SO2: mg/Nm 3Out (Ut) SO 2 : mg/Nm 325/11/1998 03:39,5025/11/1998 04:49,5025/11/1998 05:59,5025/11/1998 07:09,5025/11/1998 08:19,5025/11/1998 09:29,5025/11/1998 10:39,5025/11/1998 11:49,5025/11/1998 12:59,5025/11/1998 14:09,5025/11/1998 15:19,5025/11/1998 16:29,5025/11/1998 17:39,5025/11/1998 18:49,5025/11/1998 19:59,5025/11/1998 21:09,5025/11/1998 22:19,5025/11/1998 23:29,501424.1 RågassHCL8.0 Ut HCL363.5 SO2 rågass22.0 Ut SO2Emissions of Acid gases and Toxic elements:Parameter Req. mg/Nm 3 MeasuredWet chemestryHCL 10,0 0,3 mg/Nm 3HF 1,0 < 1 mg/Nm 3SOx 50,0 9,0 mg/Nm 3PCDD/F 0,1 0,034 ng/Nm 3Hg 0,03 < 0,01 mg/Nm 304-08.GB

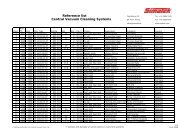

Filter No.: 4241<strong>Flue</strong> <strong>Gas</strong> Ref. No.: 72Dry <strong>Absorption</strong>(Sodium Bicarbonate)Application: Fluid-bed Incinerator <strong>for</strong> Municipal Sludge<strong>Flue</strong> gas flow:8,300 Am³/hTemperature: 230ºCCountry: Denmark (Krüger / Lundtofte Renholdningsværk, Lyngby)Measured by:MILJØ-KEMI, Dansk Miljø Center A/SFilter type: JM 80/50-05, Series 3CFilter area: 176 m²Bag length: 5.0 mAbsorbent: Bicarbonate - NaHCO 3Adsorbent: Activated carbonParameters <strong>Flue</strong> <strong>Gas</strong> (dk-Teknik)Inlet Concentration<strong>Flue</strong> <strong>Gas</strong>Emission (Measured)Official RequirementEmission (Permissible)Dust 21840 mg/Nm³

Filters No.: 4258+4259<strong>Flue</strong> <strong>Gas</strong> Ref. No.: 79<strong>Semi</strong>-Dry <strong>Absorption</strong>(Hydrated Lime)Ca(OH) 2Spray AbsorberFILTERActivatedCarbonApplication: Waste Incineration (Foster Wheeler Circulating Fluid-Bed Boiler)<strong>Flue</strong> gas flow:Temperature: 140-170ºCCountry: NorwayMeasured by:95,000 Am³/hMETLAB KontrolFilter type: 2 modules JM 280/80-05, Series 3CFilter area: 1970 m²Bag length: 8.0 mAbsorbent: Hydrated lime – Ca(OH) 2Adsorbent: Activated carbon04-08.GBParameters<strong>Flue</strong> <strong>Gas</strong>Inlet Concentration<strong>Flue</strong> <strong>Gas</strong>Emission (Measured)Official RequirementEmission (Permissible)Dust 20 g/Nm³ 1-2 mg/Nm³ 10 mg/Nm³HCl 1000-2500 mg/Nm³ 0-3mg/Nm³ 10 mg/Nm³SO 2 300-1500 10-50 mg/Nm³ 50 mg/Nm³HF 5-20

Filter No.: 4402<strong>Flue</strong> <strong>Gas</strong> Ref. No. 80Dry <strong>Absorption</strong>(Hydrated Lime)Application: Waste Incineration<strong>Flue</strong> <strong>Gas</strong> Flow: 72,000 Am³/h (Energos incineration plant)Temperature: 140-170ºCCountry: NorwayMeasured by: Jebens MiljøteknikkFilter type: JM 280/100-05, Series 3CFilter area: 1232 m²Bag length: 10.0 mAbsorbent: Hydrated lime – Ca(OH) 2Adsorbent: Activated carbon04-08.GBParameters <strong>Flue</strong> <strong>Gas</strong> (Expected)Inlet Concentration<strong>Flue</strong> <strong>Gas</strong>Emission (Measured)Official RequirementEmission (Permissible)Dust 3.2 mg/Nm³ 10 mg/Nm³HCl 300-1200 mg/Nm³ 1.9 mg/Nm³ 10 mg/Nm³SO 2 200-800 mg/Nm³ 0.9 mg/Nm³ 50 mg/Nm³HF