Seitz® IR Series Depth Filter Sheets - Pall Corporation (PLL)

Seitz® IR Series Depth Filter Sheets - Pall Corporation (PLL)

Seitz® IR Series Depth Filter Sheets - Pall Corporation (PLL)

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

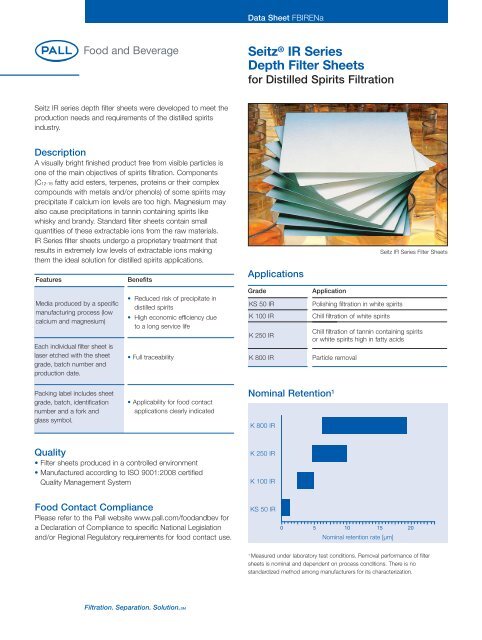

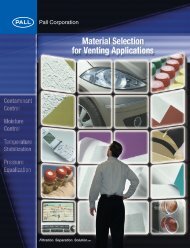

Data Sheet FB<strong>IR</strong>ENaSeitz ® <strong>IR</strong> <strong>Series</strong><strong>Depth</strong> <strong>Filter</strong> <strong>Sheets</strong>for Distilled Spirits FiltrationSeitz <strong>IR</strong> series depth filter sheets were developed to meet theproduction needs and requirements of the distilled spiritsindustry.DescriptionA visually bright finished product free from visible particles isone of the main objectives of spirits filtration. Components(C12-16 fatty acid esters, terpenes, proteins or their complexcompounds with metals and/or phenols) of some spirits mayprecipitate if calcium ion levels are too high. Magnesium mayalso cause precipitations in tannin containing spirits likewhisky and brandy. Standard filter sheets contain smallquantities of these extractable ions from the raw materials.<strong>IR</strong> <strong>Series</strong> filter sheets undergo a proprietary treatment thatresults in extremely low levels of extractable ions makingthem the ideal solution for distilled spirits applications.FeaturesMedia produced by a specificmanufacturing process (lowcalcium and magnesium)Each individual filter sheet islaser etched with the sheetgrade, batch number andproduction date.Benefits• Reduced risk of precipitate indistilled spirits• High economic efficiency dueto a long service life• Full traceabilityApplicationsGradeKS 50 <strong>IR</strong>K 100 <strong>IR</strong>K 250 <strong>IR</strong>K 800 <strong>IR</strong>ApplicationPolishing filtration in white spiritsChill filtration of white spiritsChill filtration of tannin containing spiritsor white spirits high in fatty acidsParticle removalSeitz <strong>IR</strong> <strong>Series</strong> <strong>Filter</strong> <strong>Sheets</strong>Packing label includes sheetgrade, batch, identificationnumber and a fork andglass symbol.• Applicability for food contactapplications clearly indicatedNominal Retention 1K 800 <strong>IR</strong>Quality• <strong>Filter</strong> sheets produced in a controlled environment• Manufactured according to ISO 9001:2008 certified• Quality Management SystemK 250 <strong>IR</strong>K 100 <strong>IR</strong>Food Contact CompliancePlease refer to the <strong>Pall</strong> website www.pall.com/foodandbev fora Declaration of Compliance to specific National Legislationand/or Regional Regulatory requirements for food contact use.KS 50 <strong>IR</strong>0 5 10 15 20Nominal retention rate [μm]1Measured under laboratory test conditions. Removal performance of filtersheets is nominal and dependent on process conditions. There is nostandardized method among manufacturers for its characterization.

CharacterizationGradeMass per UnitArea (g m-²)Thickness(mm)Ash (%)WaterPermeability 2(L/m²/min)KS 50 <strong>IR</strong> 1350 3.7 46 93K 100 <strong>IR</strong> 1400 4.2 51 204K 250 <strong>IR</strong> 1250 4.0 46 510K 800 <strong>IR</strong> 1250 4.1 46 1275These figures have been determined in accordance with in-house test methodsand the methods of the Technical / Analytical Work Group within the European<strong>Depth</strong> Filtration Association.2The permeability was measured under test conditions with clean water at 20°C(68°F) and a Δp of 1 bar (14.5 psi).General Instructions for UseThe use of ion-reduced water (deionized water) is highlyrecommended for the reconstitution of distillates to singlestrength.To prevent dilution upon installation, a water rinse is notrecommended for sheet filters used in the spirits industry.Product circulation for 10 to 15 minutes back to the feed tankhelps to distribute ions extracted at the beginning of filtrationto the entire batch reducing the overall risk of precipitation.As the filtrate quality can be impacted by the filtration flow rate,the following table provides guidelines for flux rate.The diagram below illustrates the release of calcium andmagnesium from the comparable standard filter sheet K100and K100 <strong>IR</strong> into whisky during filtration.Filtration Guidelines 4ApplicationFlow Velocity L/m²/h (gph/ft²)Calcium and Magnesium Release [mg/L]2015105Release of Ca and Mgduring Filtration of WhiskyCa - K 100Mg - K 100Ca - K 100 <strong>IR</strong>Mg - K 100 <strong>IR</strong>00 50 100 150 200Particle filtration of brown spirits 500 – 700 (12.3 – 17.2 gph/ft 2 )Particle filtration white spirits 700 – 900 (17.2 – 22.1 gph/ft 2 )Chill filtration of brown spirits andwhite spirits high in fatty acidsAvailable Sheet FormatsRectangular <strong>Sheets</strong>400 x 400 mm (15.8" x 15.8")600 x 612 mm (23.6" x 24")Other formats are available on request.250 – 400 (6.1 – 9.8 gph/ft 2 )Chill filtration of white spirits 400 – 600 (9.8 – 14.7 gph/ft 2 )4Please contact <strong>Pall</strong> for recommendations on your specific filtration process asresults may vary by product, pre-filtration and filtration conditions.Volume <strong>Filter</strong>ed [L/m 2 ]The following total calcium and magnesium release per m²filter sheet at a flow velocity of 500 L/m²/h (2.9 gpm/ft²) wascalculated during this filtration run:Seitz <strong>IR</strong> series depth filter sheets are also available inSUPRAdisc II module configurations.Sheet Calcium mg/m² (%) Magnesium mg/m² (%)K 100 3 667 (100) 192 (100)K 100 <strong>IR</strong> 146 (22) 68 (35)3The K 100 is the comparable standard sheet to the K 100 <strong>IR</strong> with regard toretention rate and throughput.<strong>Pall</strong> Food and Beverage25 Harbor Park DrivePort Washington, NY 11050+1 516 484 3600 telephone+1 866 905 7255 toll free USfoodandbeverage@pall.comVisit us on the Web at www.pall.com/foodandbev<strong>Pall</strong> <strong>Corporation</strong> has offices and plants throughout the world. For <strong>Pall</strong> representativesin your area, please go to www.pall.com/contactPlease contact <strong>Pall</strong> <strong>Corporation</strong> to verify that the product conforms to your nationallegislation and/or regional regulatory requirements for water and food contact use.Because of technological developments related to the products, systems, and/orservices described herein, the data and procedures are subject to change without notice.Please consult your <strong>Pall</strong> representative or visit www.pall.com to verify that thisinformation remains valid.© Copyright 2011, <strong>Pall</strong> <strong>Corporation</strong>. <strong>Pall</strong>, , Seitz and SUPRAdisc are trademarks of <strong>Pall</strong><strong>Corporation</strong>. ® Indicates a trademark registered in the USA. Filtration. Separation. Solution.SM isa service mark of <strong>Pall</strong> <strong>Corporation</strong>.FB<strong>IR</strong>ENa April 2011