You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

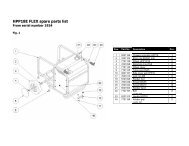

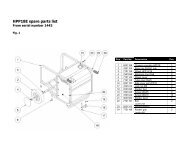

HPP18E FLEX<strong>Hydraulic</strong> PowerpackFrom serialnumber 1924RevisedMarch 2006Prior to OperationWe thank you for choosing a<strong>HYCON</strong> powerpack.Please note that the powerpackis delivered without hydraulicoil, and therefore it must befilled up with hydraulic oil priorto operation.To ensure smooth operationand long-lasting performance ofyour new powerpack, werecommend that you study thisoperating manual carefully andpay special attention to theSafety and ServicePrecautionsWe hope you will be satisfiedwith your new <strong>HYCON</strong> powerpack.<strong>HYCON</strong> A/SJuelstrupparken 11DK-9530 StøvringDenmarkTel: +45 9647 5200Fax: +45 9647 5201Mail hycon@hycon.dkwww.hycon.dkBest regards<strong>HYCON</strong> A/S

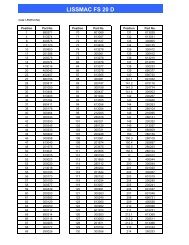

ContentsPageSafety precautions............................................................................................ 2Filling up hydraulic oil ....................................................................................... 2Technical data.................................................................................................. 3Electrical Circuit Diagram .................................................................................. 4Starting instructions ......................................................................................... 5Service, maintenance and hydraulic settings ...................................................... 6Oil types .......................................................................................................... 6EC-Declaration of Conformity ............................................................................ 7Warranty conditions ......................................................................................... 8Spare parts list................................................................................................. 91

Safety Precautions1. Always use protective earplugs even though the powerpack has a low noiselevel.2. Always connect hoses before starting.3. Always keep electric box, cables and sockets clean.4. In case of non-operation or performance of service, always turn off the motor.5. Never start the motor without side covers.6. Operation of the powerpack without tool connected and with lever at “ON” maycause overheating of the system and damage to the powerpack.7. When lifting the powerpack from a vehicle, we recommend the use of a crane.8. The pressure relief valve is set at 160 bar from our plant. Never set it higher.9. Always use filters with by-pass. The use of filters without by-pass may blow thehydraulic hoses and the filter cover.10. Never perform service on the powerpack without disconnecting the powersupply.Filling Up <strong>Hydraulic</strong> Oil••ToForfillpåfyldningup with hydraulicaf hydraulikolieoil, loosenløsnesthefilterfilterlågetcover onøversttop ofpåthedrivstationenpowerpack.••RemoveHerefterthetagesfilterfilterindsatsenelement (seeudphoto),(seandfoto)fillogupderwithkanoil.nuWhenfyldesoilolieis showingpå.atNårthederbottomkan sesof theoliefilteri bundenunit, thereaf filterenheden,isenough oil onerthederpowerpack.olie nok på.••InsertFilterindsatsenthe filter elementsættes iagain,igen, lågetmountthemonteres,cover andogthedrivstationenpowerpackerisnureadyklarfortiluse.brug.Please Vær note: opmærksom When connecting på, at ved new tilkobling extension af nyehoses, forlængerslanger, it is necessary to vil fill der up skulle with extra påfyldes 2 litres 2 ofoil. liter Therefore olie mere. always Derfor top up skal the drivstationenpowerpack whenconnecting efterfyldes, new hvis extension der tilkobles hoses. nye slanger.2

Technical dataThe <strong>HYCON</strong> HPP18E FLEX open centre powerpack is an advanced hydraulic powersource, which regulates the revolutions of the motor and thereby the oil flowsupplied by means of a built in frequency converter. The powerpack therefore coversas much as three EHTMA-categories (C, D and E) with an output of 20, 30 and 40l.p.m. respectively at 138 bar. The <strong>HYCON</strong> powerpack is fully compatible with andsufficient for the common European tools.The powerpack is mounted with a pressure relief valve to avoid a too high pressure.Furthermore, the very efficient air cooling protects the powerpack againstoverheating.The frequency converter incorporates a phase inverter, which always ensures correctmotor rotation direction.Oil flowWorking pressure nominalPressure relief valvePumpOil temperatureTank capacity hydraulic oil<strong>Hydraulic</strong> system completeFilter system (filter element)MotorFuse min.Protection classGuaranteed sound power level L WASound pressure level 1 m L PADimensions (LxWxH)Weight, without hydraulic oil20, 30 or 40 l.p.m.120 barSet at 160 barGear pumpMax. 70° CMin. 8 litres/max. 11 litresMax. 12 litres25 Micron with by-passElectric motor11 kW, 3x400 V35 Amp.IP5598 dB86 dB805x625x695 mm128 kg3

Electrical Circuit DiagramHPP18E FLEX (11 kW) Control Circuit Frequency Converter4

Starting InstructionsPlease observe the starting instructions on the electric box.Start:Stop:• Check hydraulic oil level at sight glass• Connect hoses and tool• Press the green button• Move the lever to ”ON”• Move the lever to “OFF“• Press the ”STOP” buttonOil FlowAlways set the oil flow correctly in accordance with the tool connected. Choose the oilflow on the step cam switch:1: 20 l.p.m.2: 30 l.p.m.3: 40 l.p.m.5

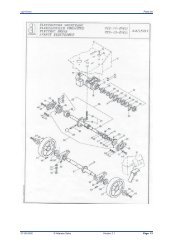

Service, Maintenance and <strong>Hydraulic</strong> SettingsService/Maintenance Daily Weekly Yearly<strong>Hydraulic</strong> oil Check 1 x replacement<strong>Hydraulic</strong> oil filter *)Check hoses*) use only filters with by-pass<strong>Hydraulic</strong> Settings(tighten up if needed)1 x replacementCheck the working pressure by means of test equipment. The test equipment mustcomprise a pressure gauge, a flow meter and a valve for adjustment of pressure.The pressure relief valve is placed on the valve block on the right side.1. Connect the test equipment, start the powerpack and move the lever to “ON”. Thenclose the valve on the test equipment - the pressure gauge must show 160 bar.Adjust the pressure relief valve by loosening the lock nut and turning theadjustment screw in or out. “In” increases the pressure, and “out” decreases thepressure.Retighten the lock nut after adjustment.2. When the pressure relief valve has been adjusted correctly, the working pressuremust be set at 100 bar by means of the valve on the test equipment. At 100 barcheck that the oil flow is correct according to the technical data.If correct pressure/oil flow cannot be achieved by following the aboveinstructions, the powerpack must be re-adjusted. Is the pressure/oilflow then still incorrect, the pump is defect and must be replaced.Oil TypesThe <strong>HYCON</strong> powerpacks use standard hydraulic oil, i.e. all types of mineral oil andbiodegradable oil, which comply with the following values:Recommended viscosity 20-40 cStPermitted viscosity15-1000 cStViscosity index Min. 100Temperature area-20° to +70° C6

EC-Declaration of Conformity<strong>HYCON</strong> A/SJuelstrupparken . 11DK-9530 StøvringDenmarkTel: +45 9647 5200Fax: +45 9647 5201Mail hycon@hycon.dkwww.hycon.dkWe hereby declare thatHPP18E FLEX hydraulic powerpack – from serial No. 1924(with 11 kW electric motor)is manufactured in conformity with the EC directives:98/37/EC2000/14/EC2006/95/ECNotified body 1585:AkustikNet A/SFrederikssundsvej 179 BDK-2700 BrønshøjDenmarkGuaranteed sound power level: 98 dB<strong>HYCON</strong> A/SJuelstrupparken 11DK-9530 StøvringDenmarkHenrik SteenGeneral Manager08.03.20067

Warranty ConditionsWe grant 12 months warranty from the first date of operation – however, not morethan 18 months from the date of delivery.The warranty applies to faults that can be related to construction and production errors.Faults caused by incorrect operation, incorrect handling, lack of maintenance or the likewill not be accepted as warranty.The warranty covers the parts necessary for repair and the suggested average timeneeded for repair.For further warranty details, please contact your local dealer.8